Apparatus of water draining for gas pipeline

A technology for drainage devices and gas pipelines, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of uncoordinated beautiful environment, large investment, short working life, etc., and improve work safety and reliability. , to ensure the effect of work safety, work safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

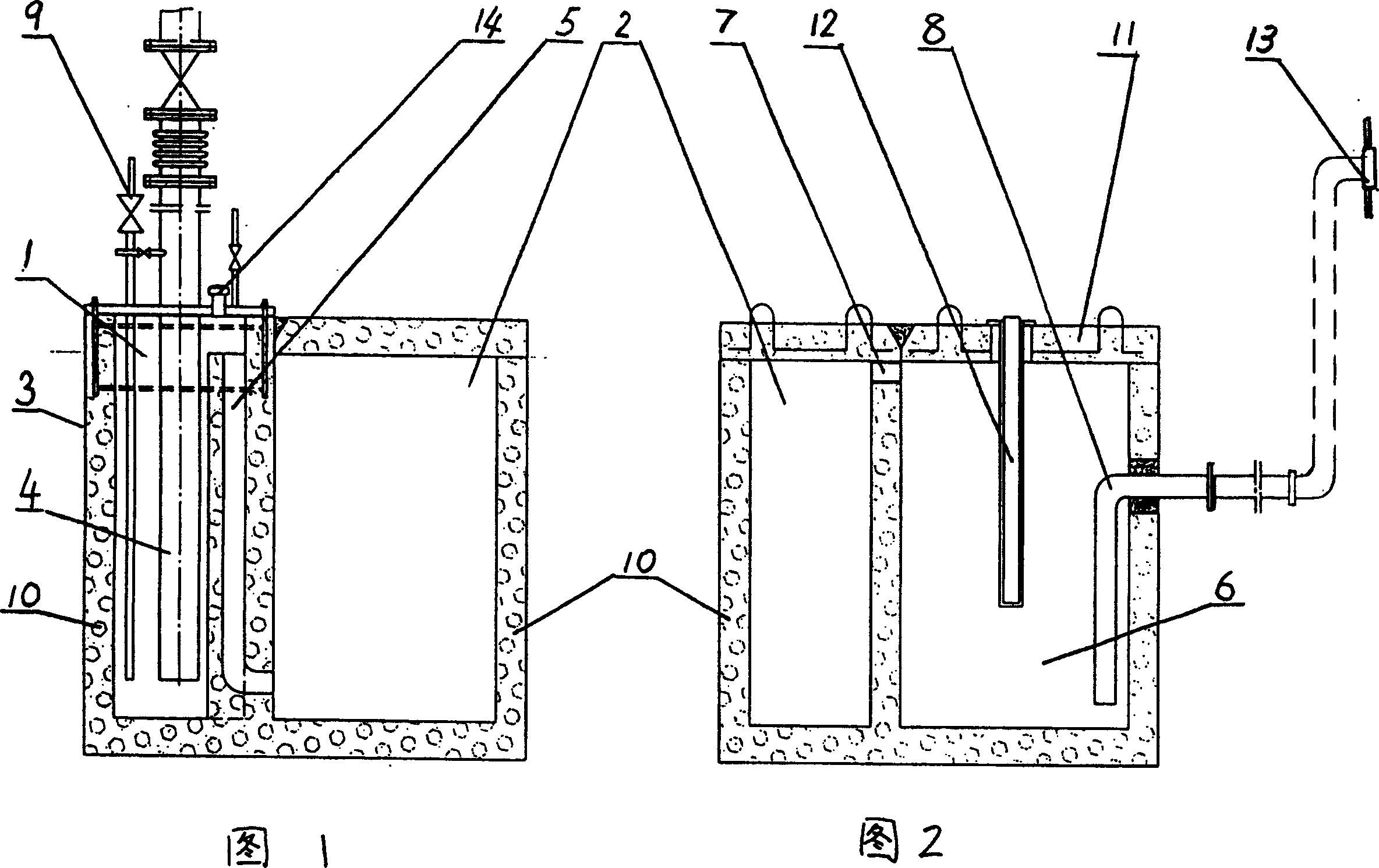

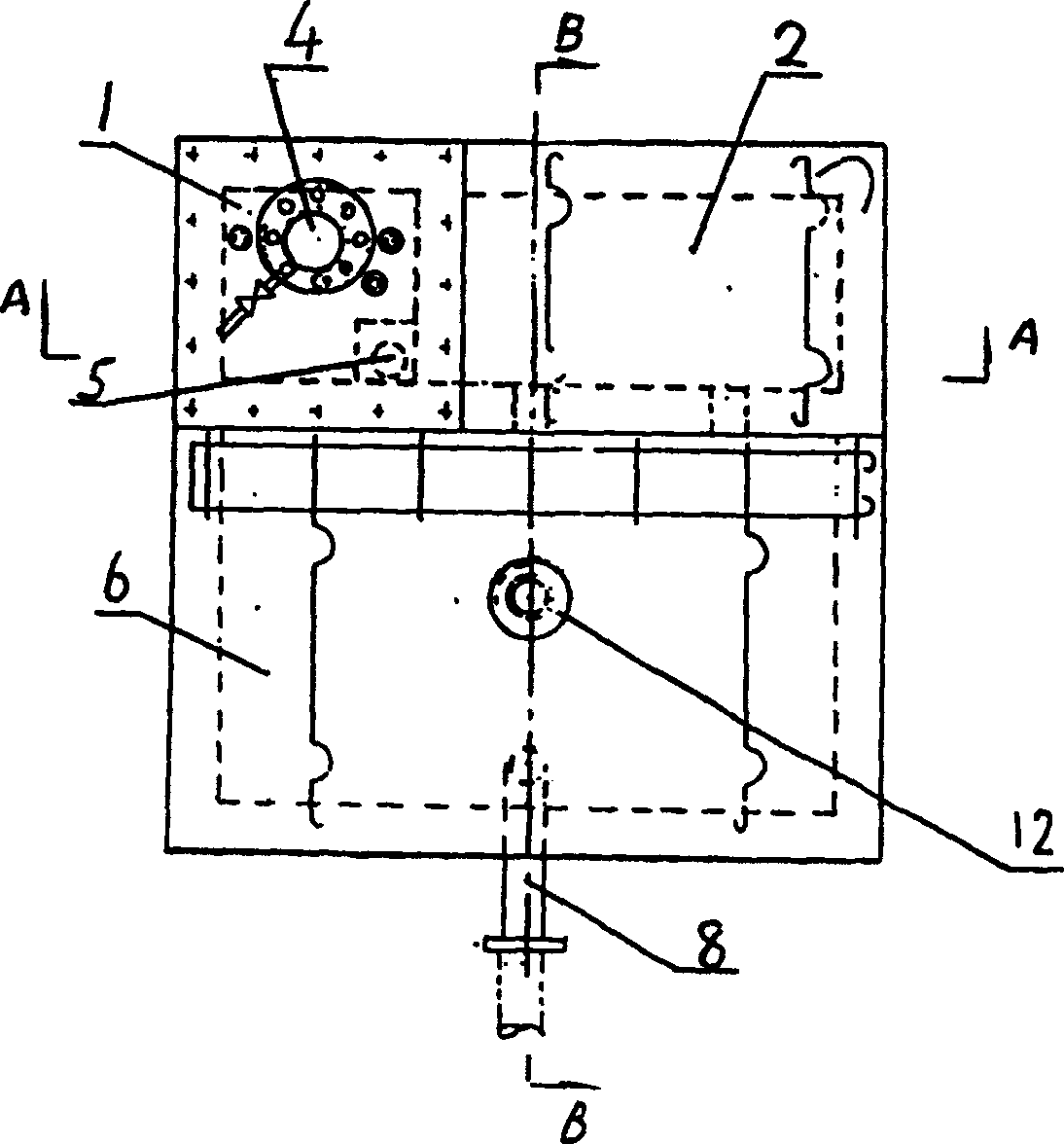

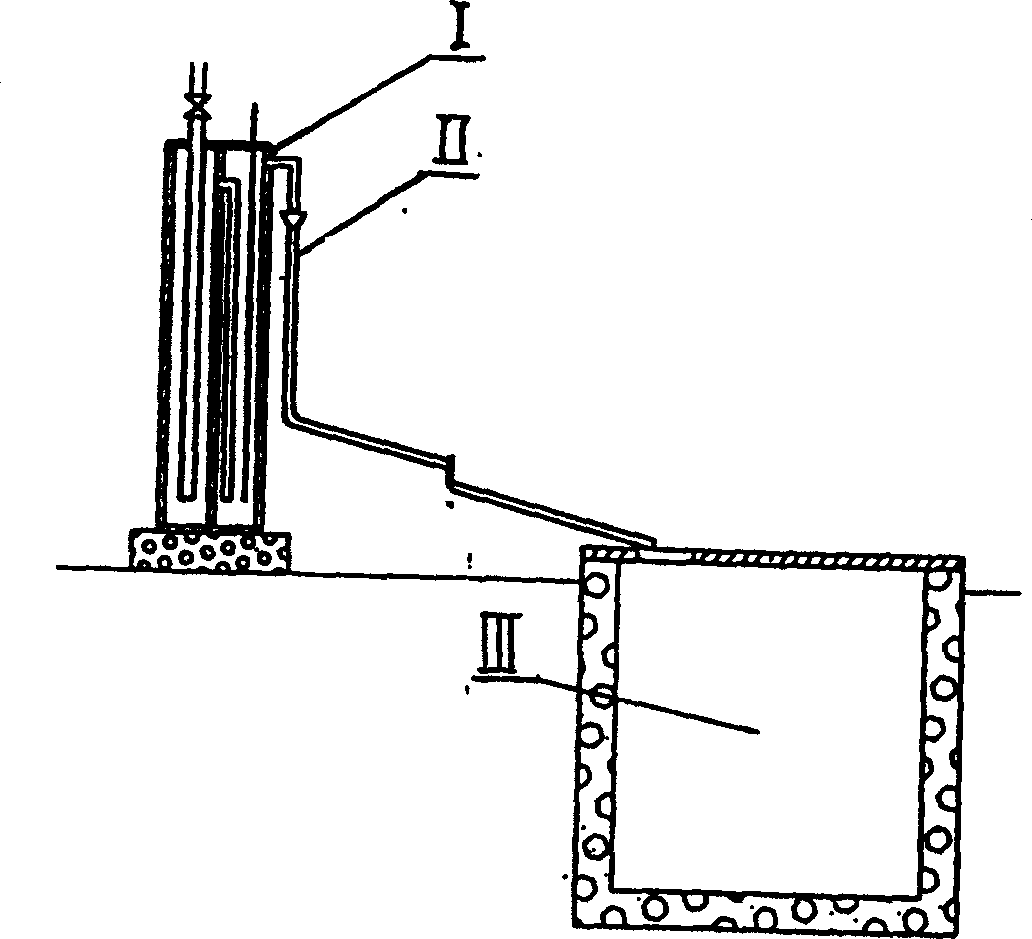

[0025] As shown in Figures 1, 2, and 3, a drainage device for a gas pipeline includes: a vertical drain and a sump. The vertical drain is divided into a high-pressure water seal chamber 1, a low-pressure water seal chamber 2, and a high-pressure water seal A high-pressure water-seal pipe 4 connected with the gas pipe network is inserted into the chamber 1, the low-pressure water-seal chamber 2 is connected to the low-pressure water-seal pipe 5, and the upper part of the low-pressure water-seal chamber 2 is connected to the sump through a drain pipe. The drain 3 and the sump 6 composed of the high-pressure water-sealing chamber 1 and the low-pressure water-sealing chamber 2 are designed as an integral structure and placed below the ground. The bottom of the high-pressure water-sealing chamber 1 is sealed by a low-pressure water-sealing pipe 5 It is connected with the low-pressure water-sealed chamber 2, and the upper part of the low-pressure water-sealed chamber 2 is in communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com