Stamping die side punching waste discharging structure

A stamping die and side punching technology, which is applied in the field of waste discharge structure of stamping die side punching, can solve the problem of low failure probability and achieve the effects of low failure probability, simple structure, and high work safety and reliability

Inactive Publication Date: 2013-04-10

江苏振世达汽车模具有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The invention has simple structure, convenient processing and installation, low probability of failure in the working process, high working safety and reliability, convenient observation of waste discharge, and solves the shortcomings of traditional processing methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

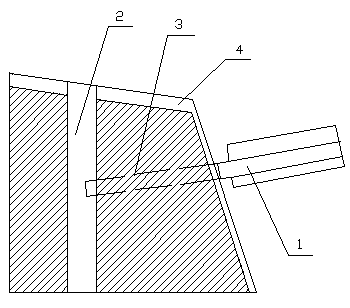

[0008] A punching die side punching waste discharge structure, including a die, a punch 1 and a forced discharger 2, the die includes a die insert 3 and a die sleeve 4, the die sleeve 4 is set Outside the die insert 3, the forced ejector 2 is arranged in the die insert 3, and the punch 1 is oblique to the die.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a stamping die side punching waste discharging structure. The stamping die side punching waste discharging structure comprises a concave die, a plunger chip and a compelling material discharger. The concave die comprises a concave die plate insert and a concave die case, wherein the concave die case is arranged outside the concave die plate insert. The compelling material discharger is arranged inside the concave die plate insert. The plunger chip faces sideling towards the concave die. The stamping die side punching waste discharging structure is simple in structure, convenient to machine and install, low in failure probability in working process, high in working safe reliability, and capable of bringing convenience to the observation of the waste discharging condition and overcoming defects of a traditional treatment method.

Description

technical field [0001] The invention relates to a discharge device for punching waste in mechanical engineering, in particular to a discharge structure for punching waste on the side of a stamping die. Background technique [0002] Side punching molds must ensure that the waste can be discharged smoothly, especially in the production process of the automatic line, once the waste cannot be discharged smoothly, it will affect the production efficiency and may damage the mold. During the use of the mold, due to the blunt cutting edge and other reasons, there are burrs in the waste material, and the waste material forms a columnar shape, making it difficult to discharge. The traditional processing method installs a forced discharger in the mold structure, through which the discharge direction of the waste is changed, and the columnar waste is separated into a single piece or several pieces of waste, which can be discharged smoothly. However, this structure is difficult to proce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D37/10B21D28/34B21D45/02

Inventor 焦惠泉

Owner 江苏振世达汽车模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com