Vertical shaft construction stepping-type template based on hydraulic drive and working method thereof

A stepping and formwork technology, which is applied in shaft equipment, earthwork drilling, shaft lining, etc., can solve the problems of high labor intensity, restriction of shaft excavation speed, and low integration, so as to improve shaft excavation efficiency and enhance work safety reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be further described below in conjunction with the embodiments in the drawings.

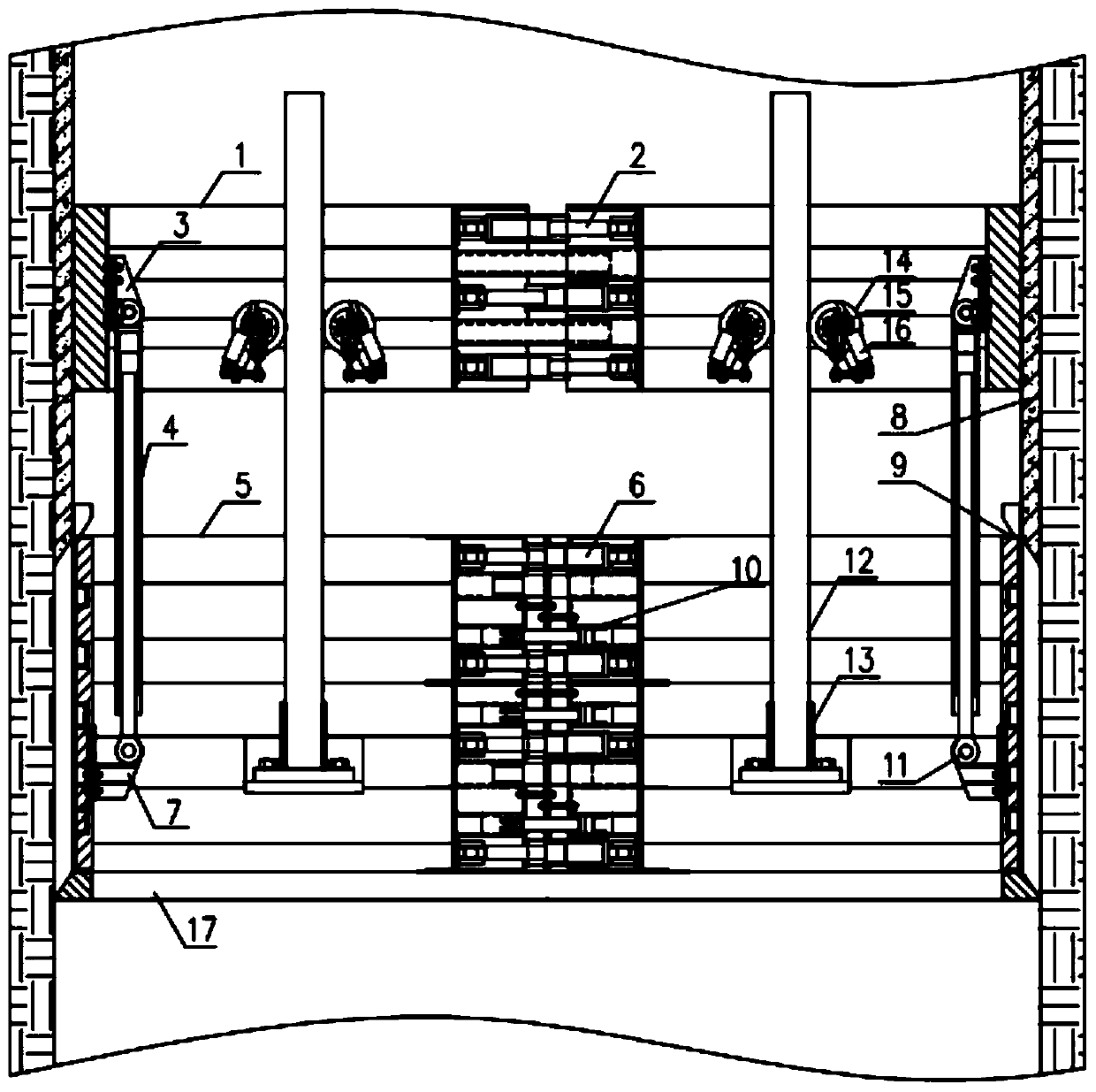

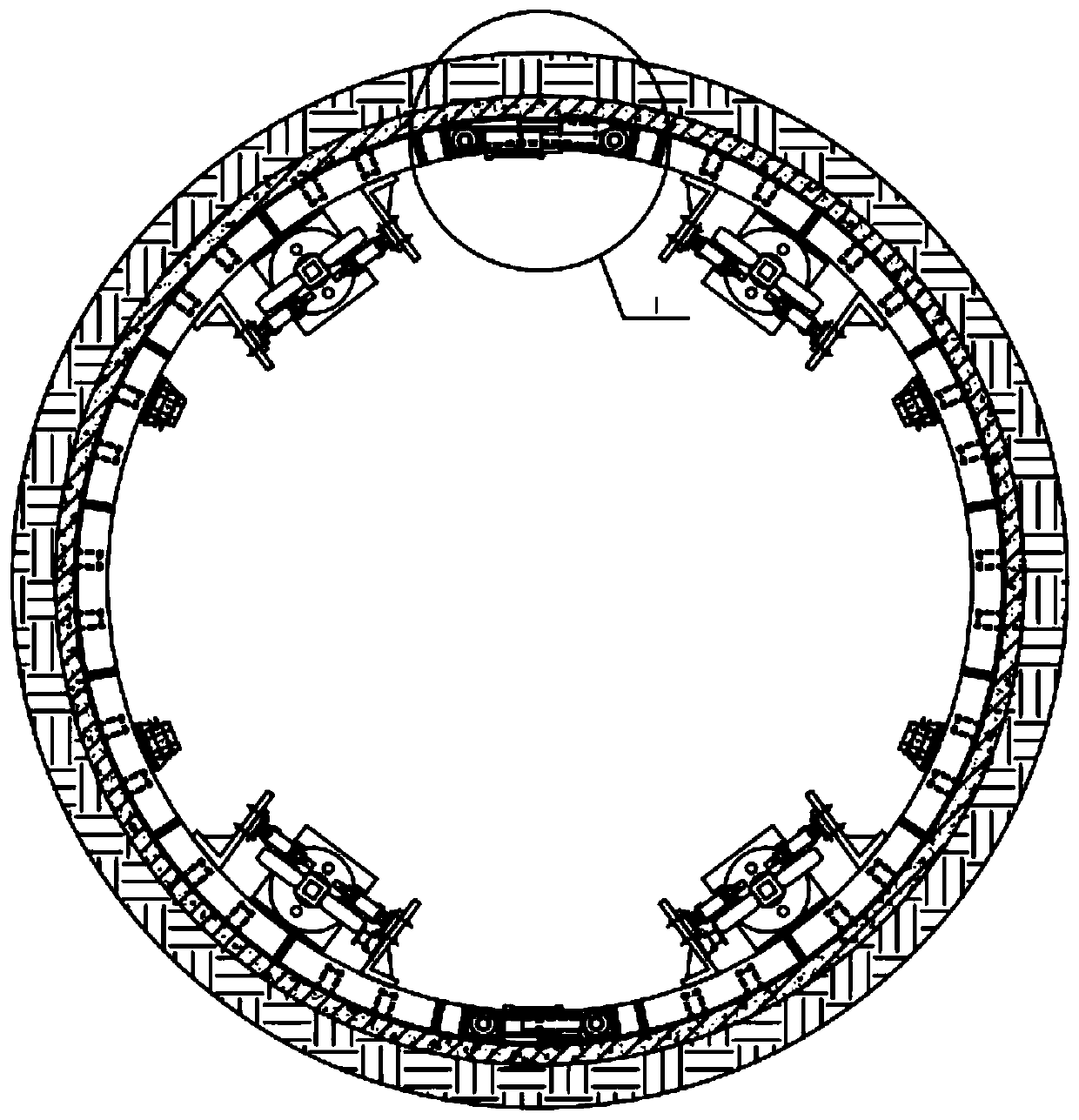

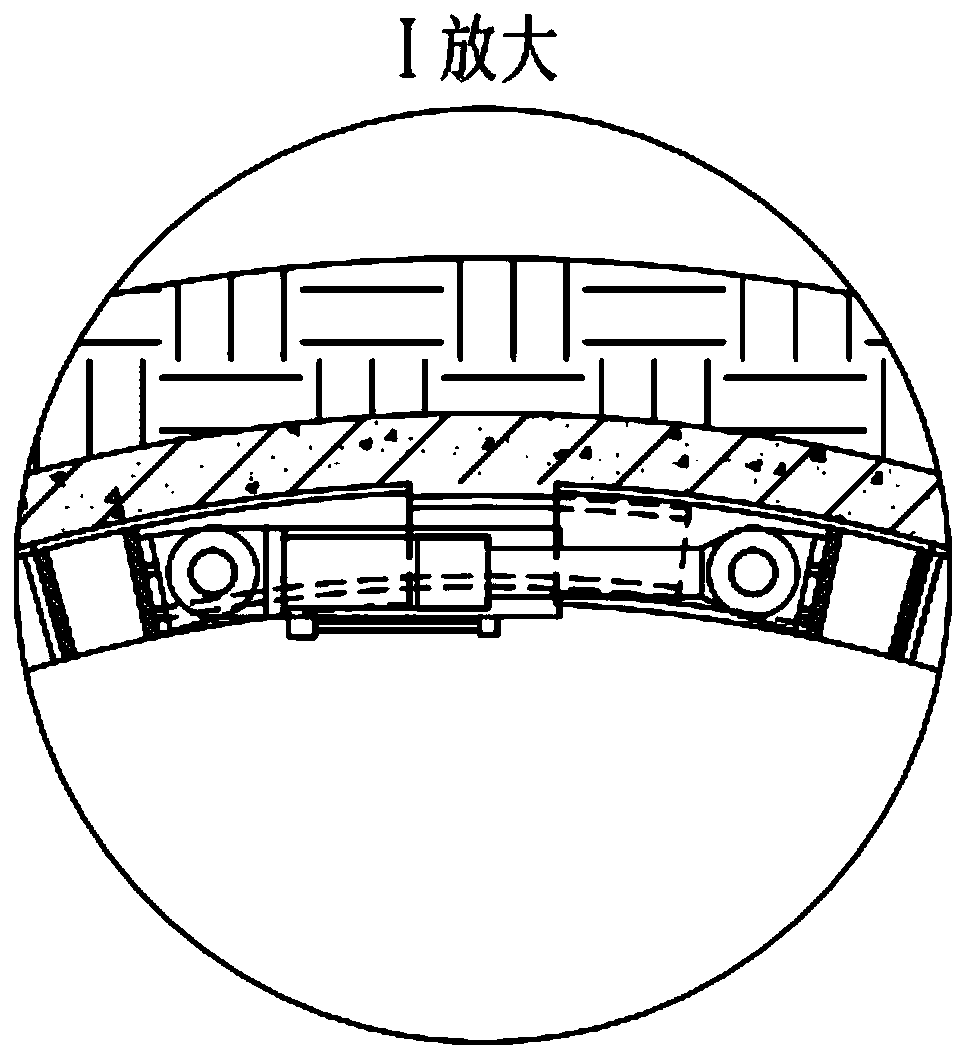

[0034] Such as figure 1 As shown, a stepping template for vertical shaft construction based on hydraulic drive of the present invention includes two parts in structure: one is the upper support shoe part, which is realized by extending or retracting the piston rod of the support shoe cylinder 2 1. Move away or move towards each other to realize the tightening of the concrete shaft wall 8 or the separation of the concrete shaft wall 8; the second is the stepping template part, the stepping cylinder 4 piston rod is extended or retracted to drive the template 5 to move downward; at the same time the template 5 is inside The expansion and contraction of the template support cylinder 2 can be used for compression and demoulding during the concrete pouring of the well wall; the alternate action combination of the support shoe cylinder, the stepping cylinder and the support cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com