Intelligent airless open gear spray lubrication device

A spray lubrication and airless open technology, which is applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve problems such as blockage, local solidification point of the distributor, medium solidification, etc., to reduce nozzles, real-time intuitive spray effect, reduce The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

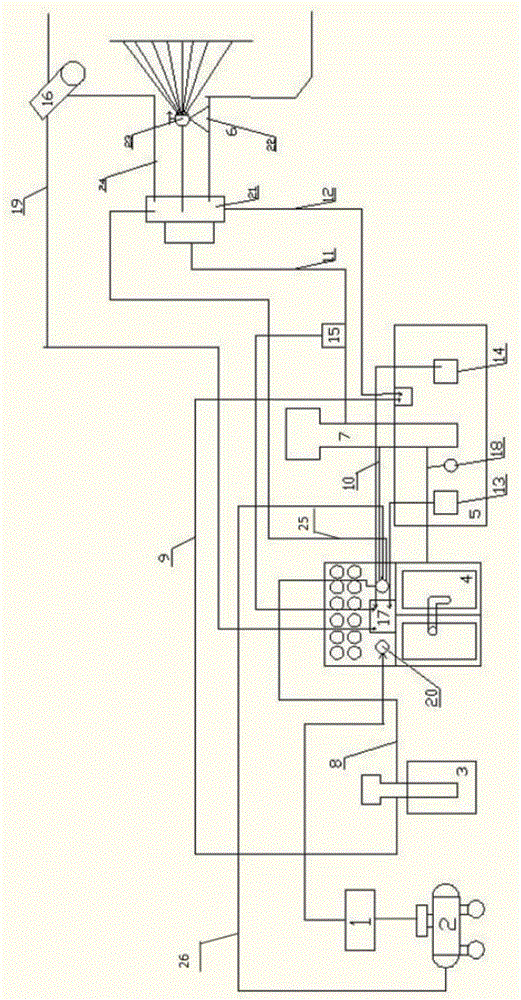

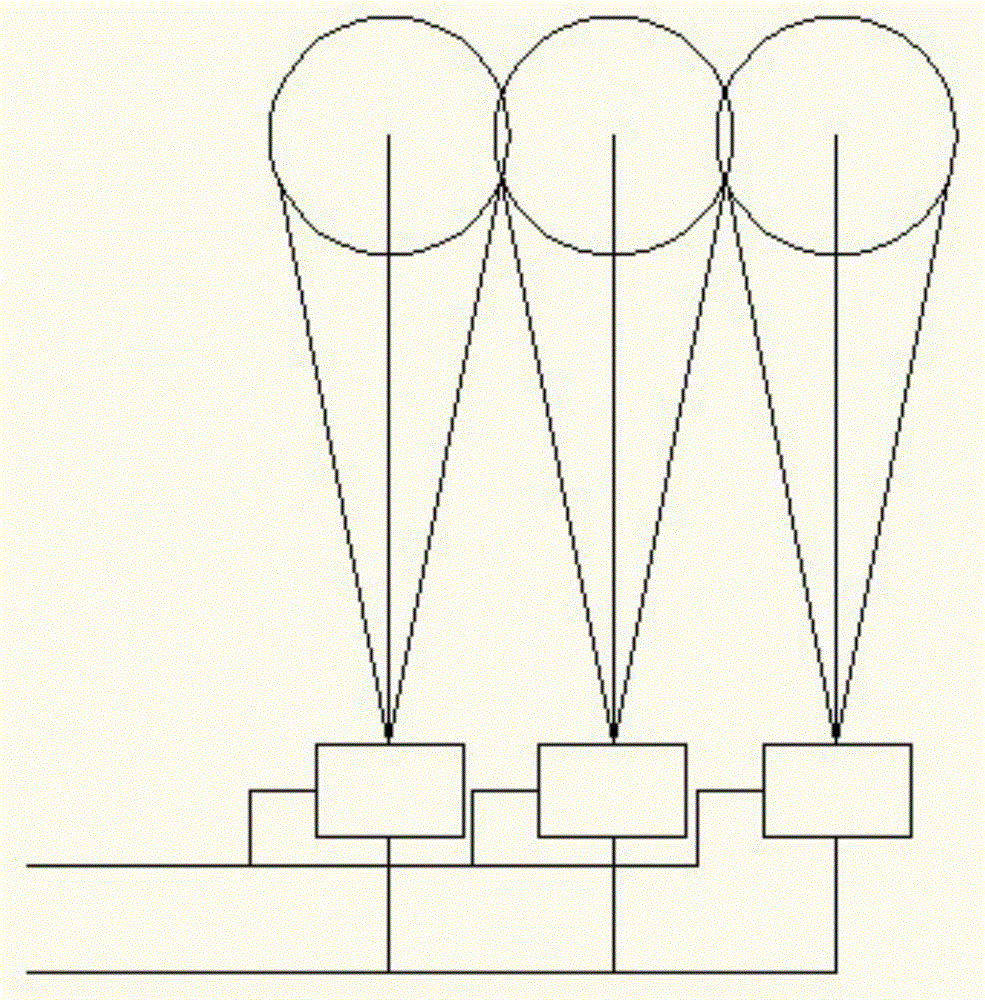

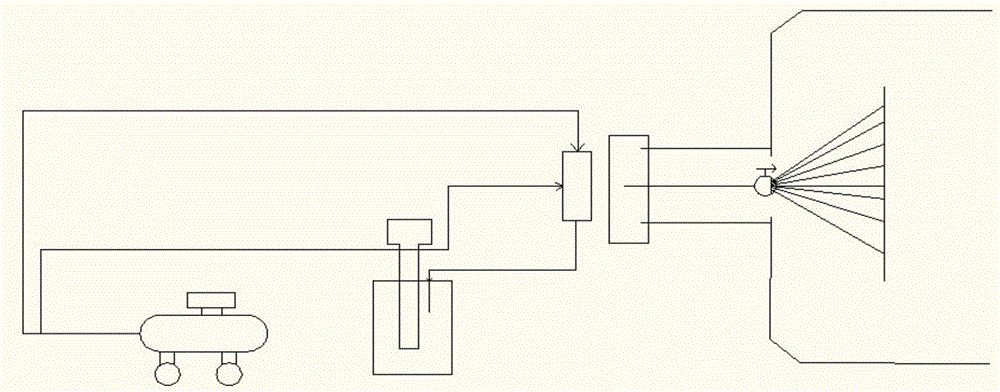

[0019] The air pump, oil inlet pipe, oil outlet pipe, jet pump, nozzle, video head and industrial computer etc. among the present invention can all be purchased from outside, and get final product with reference to the assembling connection of accompanying drawing. The present invention comprises a power switch 1, an air pump 2, a fuel tank 5, an oil outlet pipe 11, a refueling pump oil pipe 9, a jet pump 7, a control box 4, a pressure sensor 15, a multifunctional electromagnetic valve 21 and a nozzle 23, composed of a multifunctional electromagnetic valve 21, The nozzle bracket 24 and the nozzle 23 form the injection plate 6, the air pump 2 is connected to the multi-position multi-way electromagnetic valve 20 through the pipeline, and the multi-position multi-way electromagnetic valve 20 is connected to the injection pump 7 communicated with the fuel tank 5 through the pipeline 10, The oil outlet pipe 11 of the jet pump 7 is respectively connected to the jet pump 7 and the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com