Propeller speed regulator

A technology for propellers and governors, applied in propellers, aircraft parts, transportation and packaging, etc., can solve problems such as waste, easy damage to the engine, and difficulty in ensuring oil circuit sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

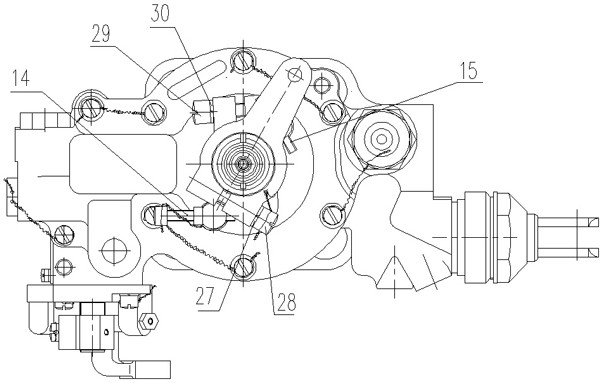

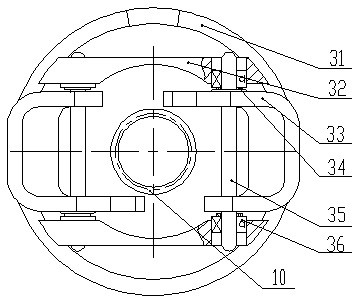

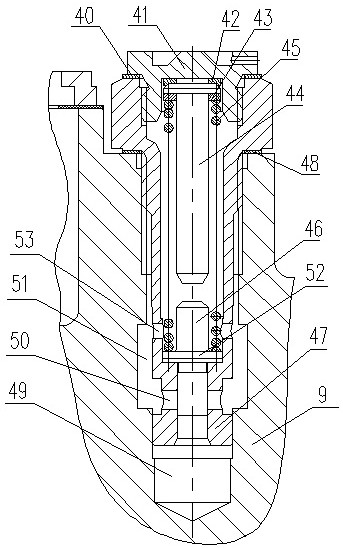

[0050] Such as Figure 1 to Figure 16 As shown, this embodiment includes an upper housing assembly 1, a lower housing assembly 9, a base plate 16, an oil filter assembly, and a speed selection device installed in the upper and lower housing assemblies 1, 9, the base plate 16, and the inner hole of the oil filter assembly. Mechanism, the power turbine adjustment assembly installed in the upper casing assembly 1, the gear pump 97 installed in the lower casing assembly 9, the pressure regulating valve assembly 96, the beta valve assembly 69 and the reset handle assembly 70 connected to the power push-pull rod. The upper housing assembly 1 is sealed and fixed on the upper end surface of the lower housing assembly 9 by a sealing pad. The lower housing assembly 9 is sealed and fixed on the upper end surface of the bottom plate 16 by a sealing ring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com