An elastic adjustable double glass component protection device

A technology of double-glass modules and protection devices, applied in electrical components, semiconductor devices, photovoltaic modules, etc., can solve the problems of increasing packaging costs, inconvenient operation, affecting the appearance of modules, and reducing production and packaging costs and shortening production time. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

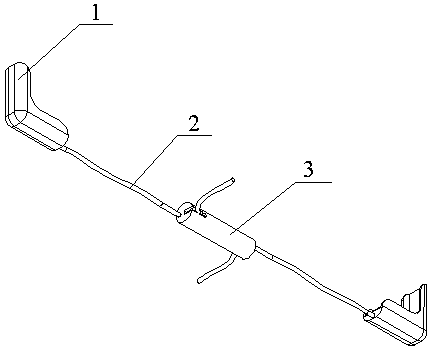

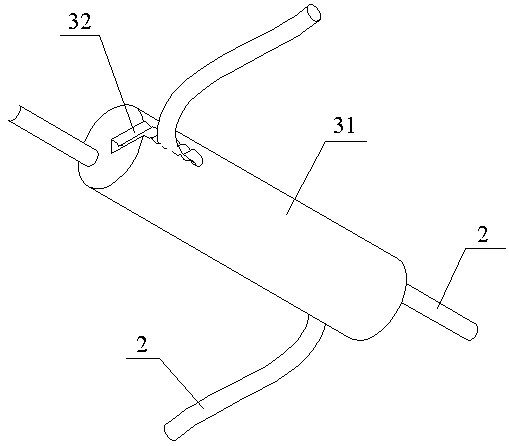

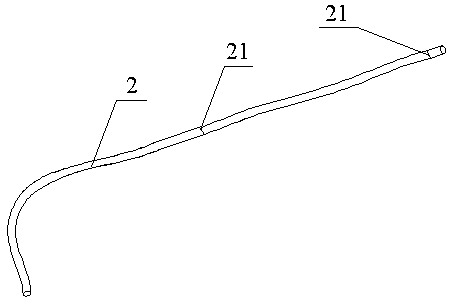

[0024] An elastic adjustable double glass component protection device, its structure is as follows figure 1 As shown, it includes two corner guards 1, two telescopic lines 2 and an adjustment buckle 3; one end of the telescopic line 2 and one side end surface of the two corner guards are tightly connected together by an integral compression molding process, and the stretchable line 2 The free end is positioned by an adjustment buckle 3 .

[0025] Corner protector 1 is used to clamp the corner of the double glass module. In the present invention, the corner protector is a right-angled U-shaped groove structure, and the groove depth of the corner protector 1 is 8-10mm, which is used to protect the front and back of the double glass component from the impact of external force; the groove width of the corner protector 1 Smaller than the thickness of the double-glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com