Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve contact accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

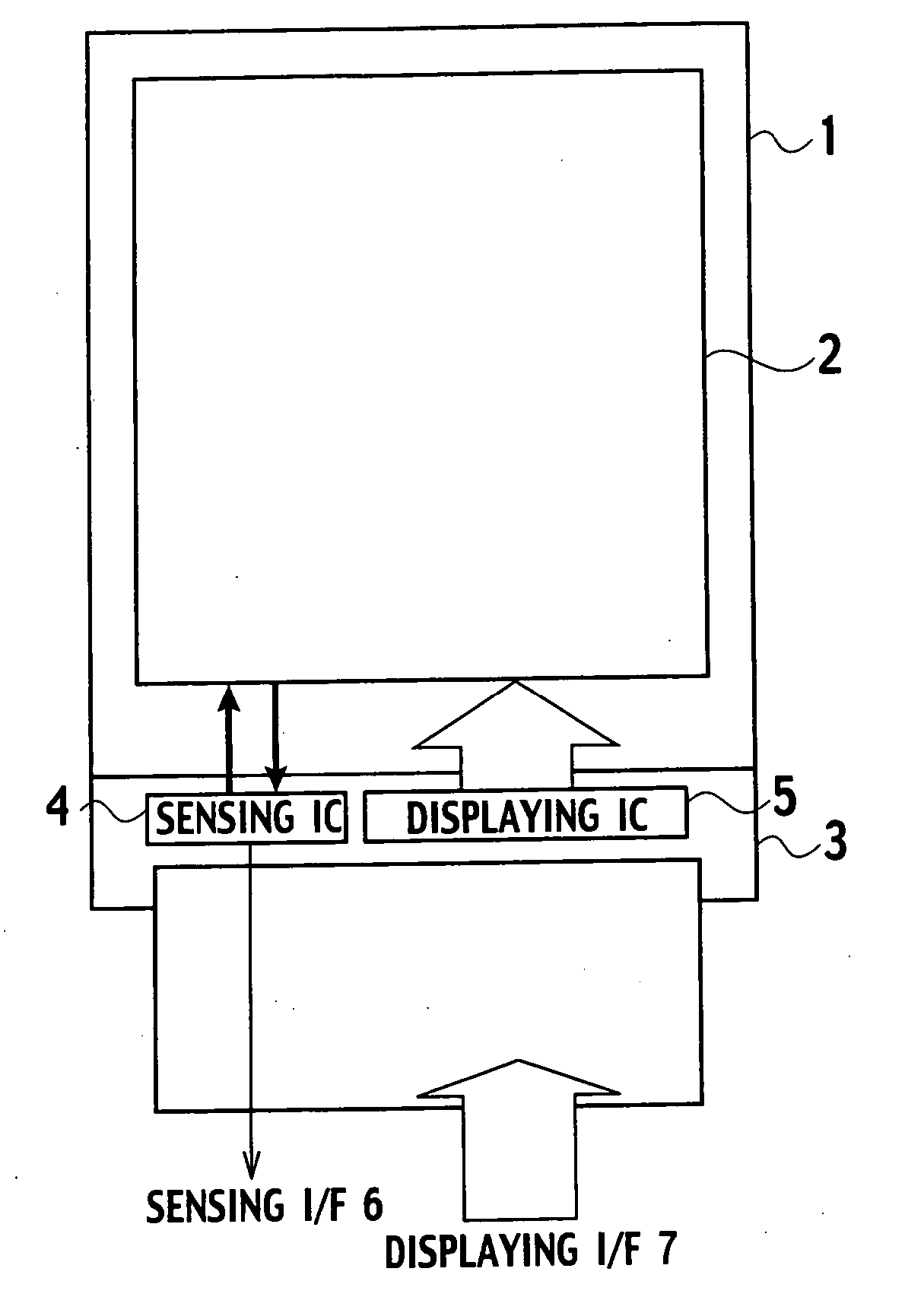

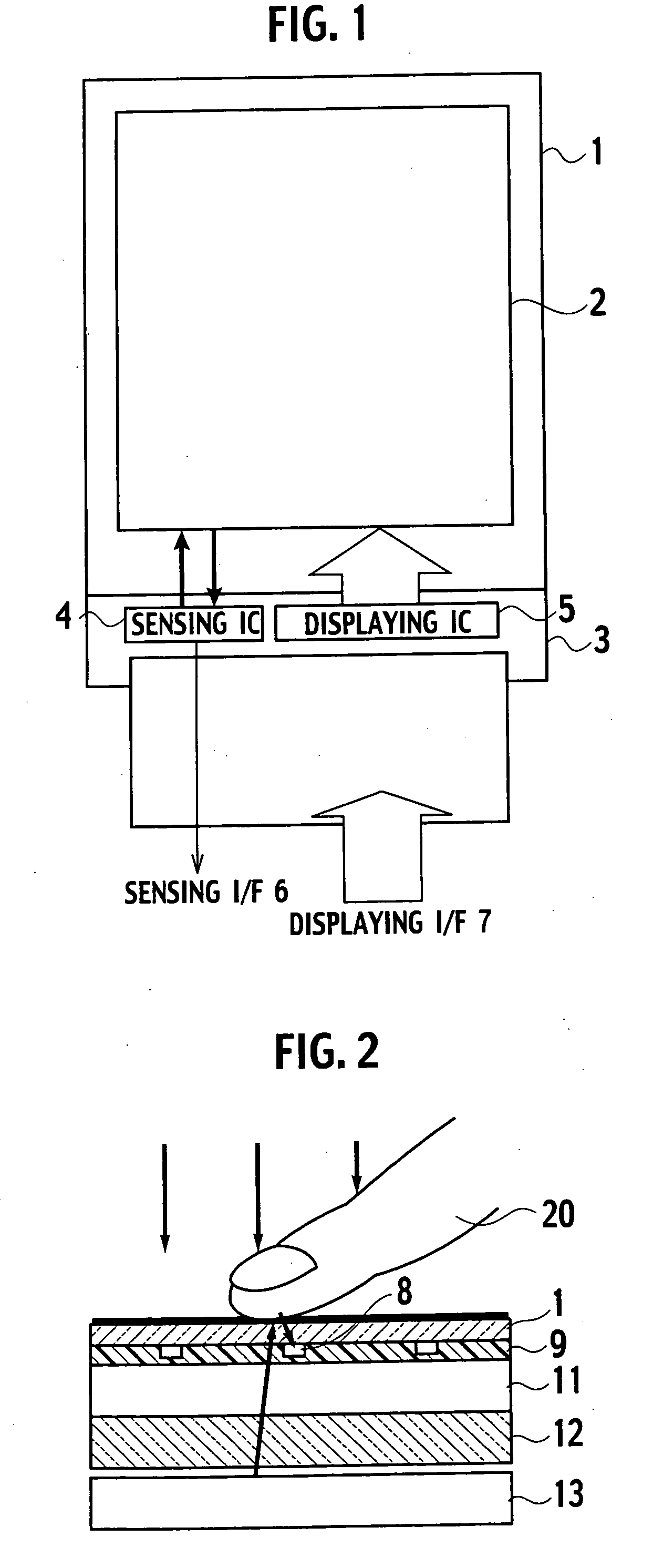

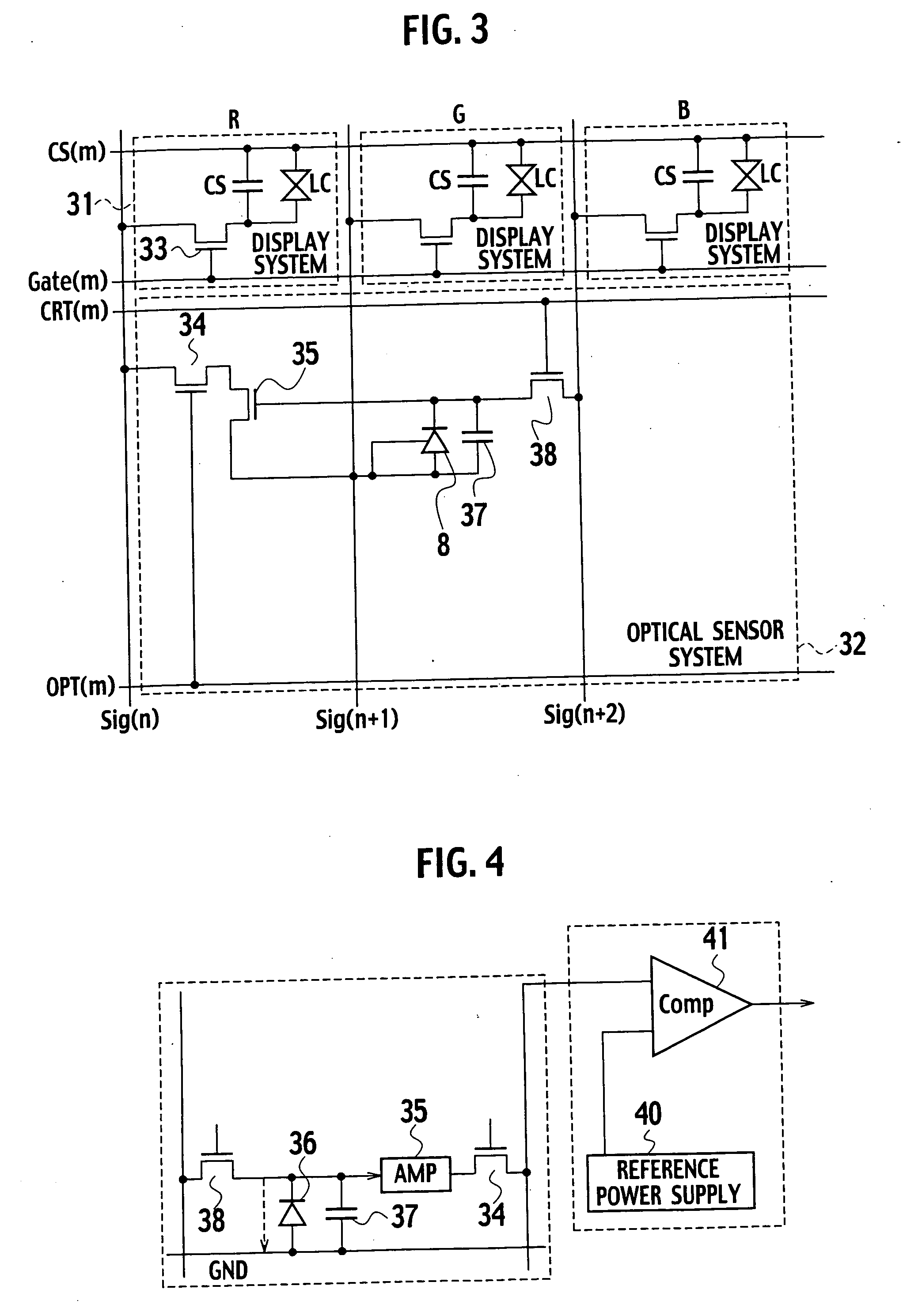

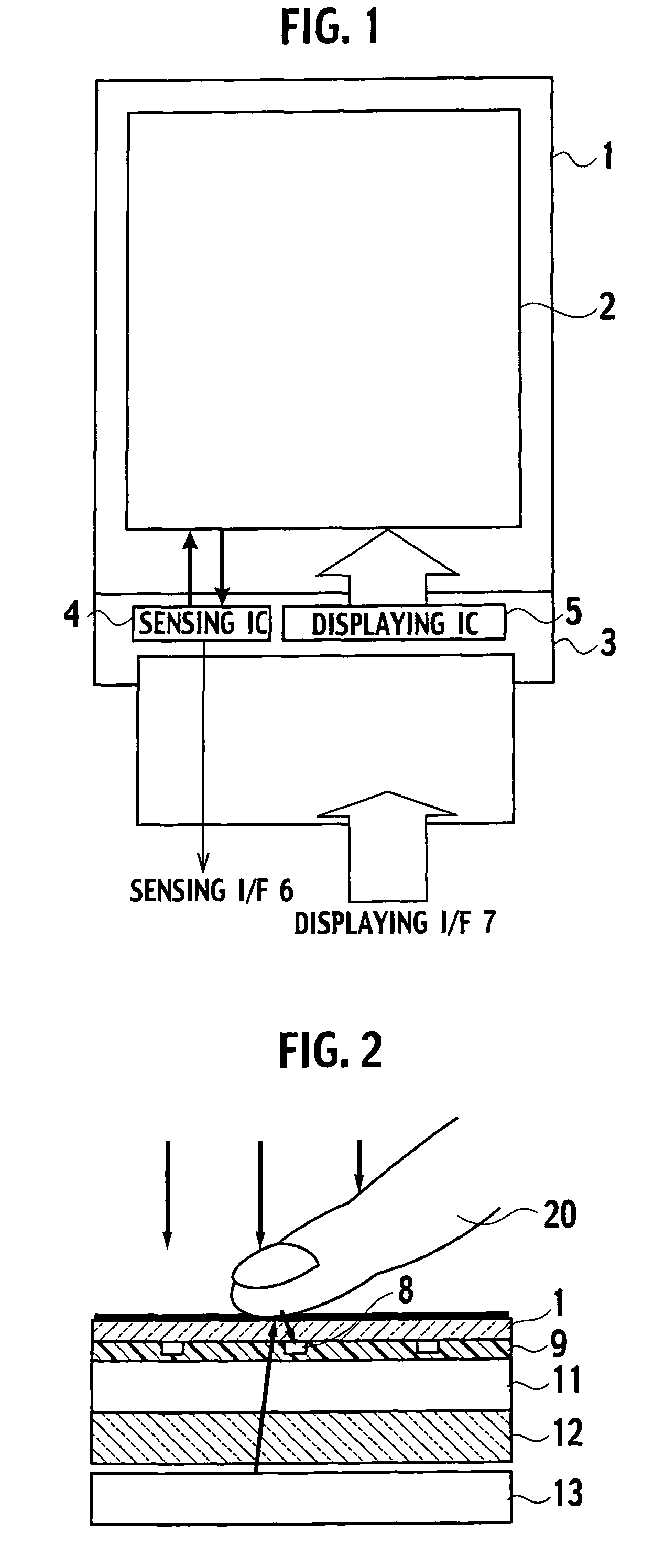

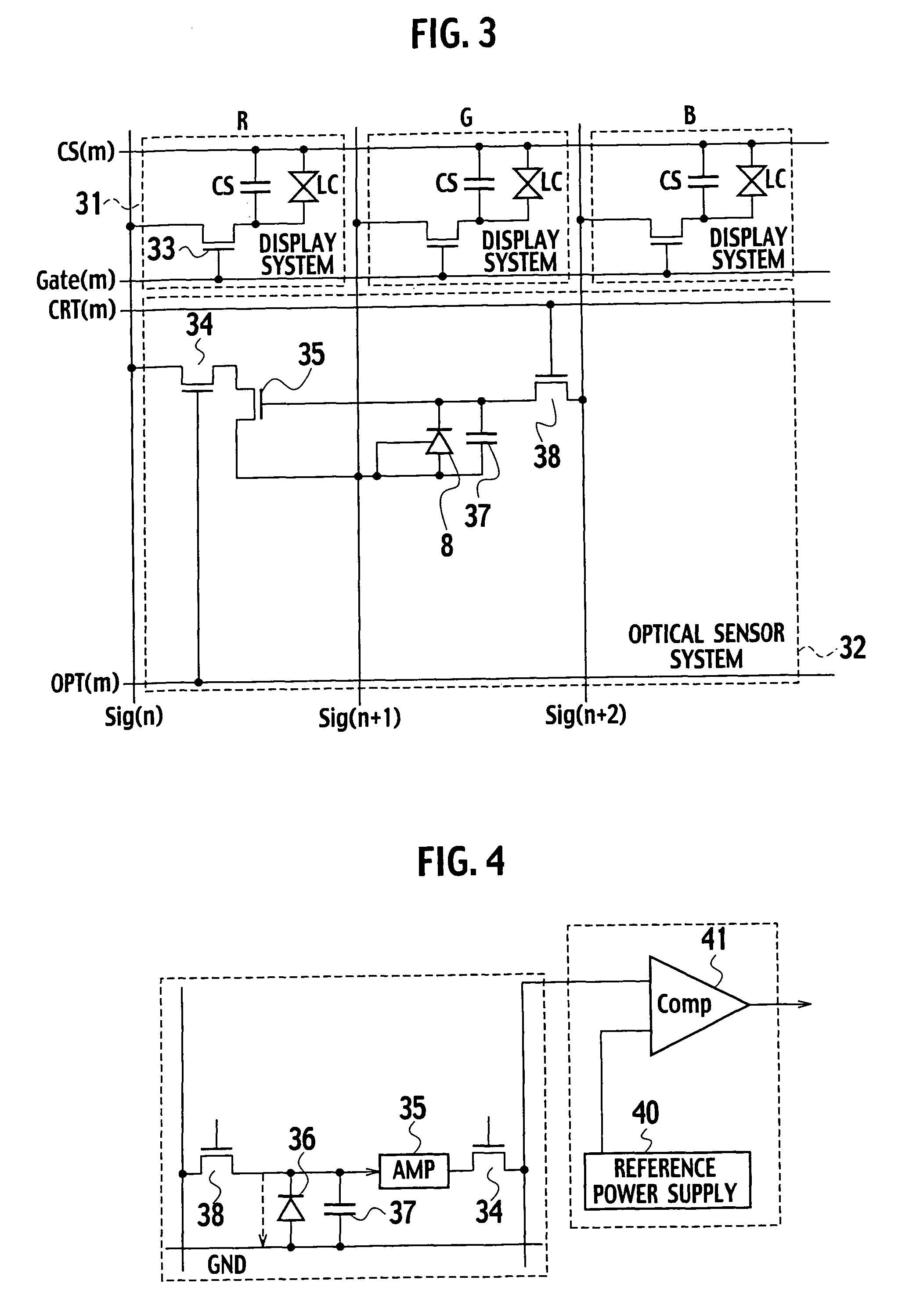

Display device including function to input information from screen by light

ActiveUS20060170658A1Ensure correct executionHigh measurement accuracyInput/output for user-computer interactionCathode-ray tube indicatorsDisplay deviceComputer science

In order to enhance accuracy of determination as to whether an object has contacted a screen and to enhance accuracy of calculation of a coordinate position of the object, edges of an imaged image are detected by an edge detection circuit 76, and by using the edges, it is determined by a contact determination circuit 77 whether or not the object has contacted the screen. Moreover, in order to appropriately control sensitivity of optical sensors in response to external light, by a calibration circuit 93, a drive condition of the optical sensors is changed based on output values of the optical sensors, which are varied in response to the external light.

Owner:JAPAN DISPLAY CENT INC

Display device including function to input information from screen by light

ActiveUS7800594B2Improve contact accuracyEasy to calculateInput/output for user-computer interactionCathode-ray tube indicatorsDisplay deviceComputer science

In order to enhance accuracy of determination as to whether an object has contacted a screen and to enhance accuracy of calculation of a coordinate position of the object, edges of an imaged image are detected by an edge detection circuit 76, and by using the edges, it is determined by a contact determination circuit 77 whether or not the object has contacted the screen. Moreover, in order to appropriately control sensitivity of optical sensors in response to external light, by a calibration circuit 93, a drive condition of the optical sensors is changed based on output values of the optical sensors, which are varied in response to the external light.

Owner:JAPAN DISPLAY CENTRAL CO LTD

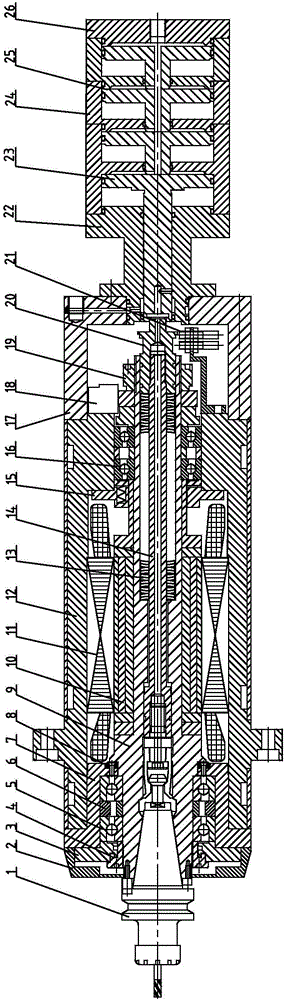

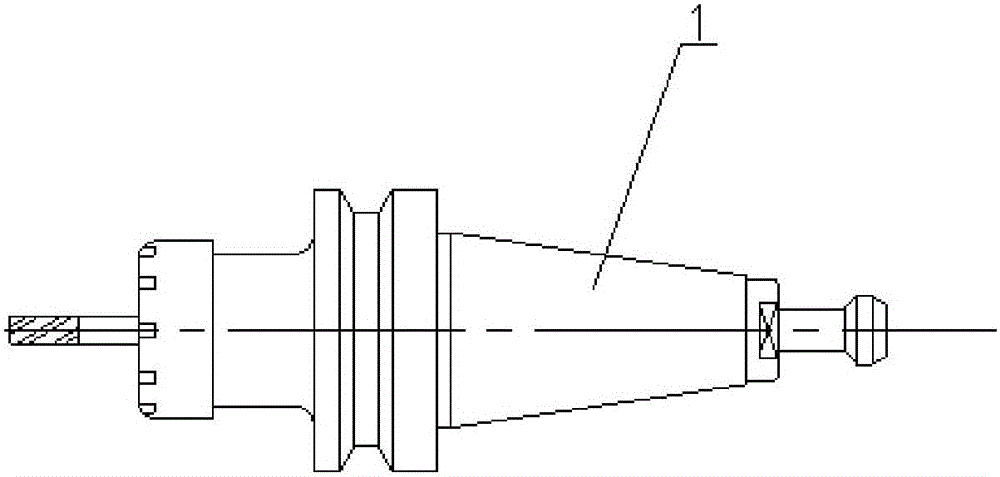

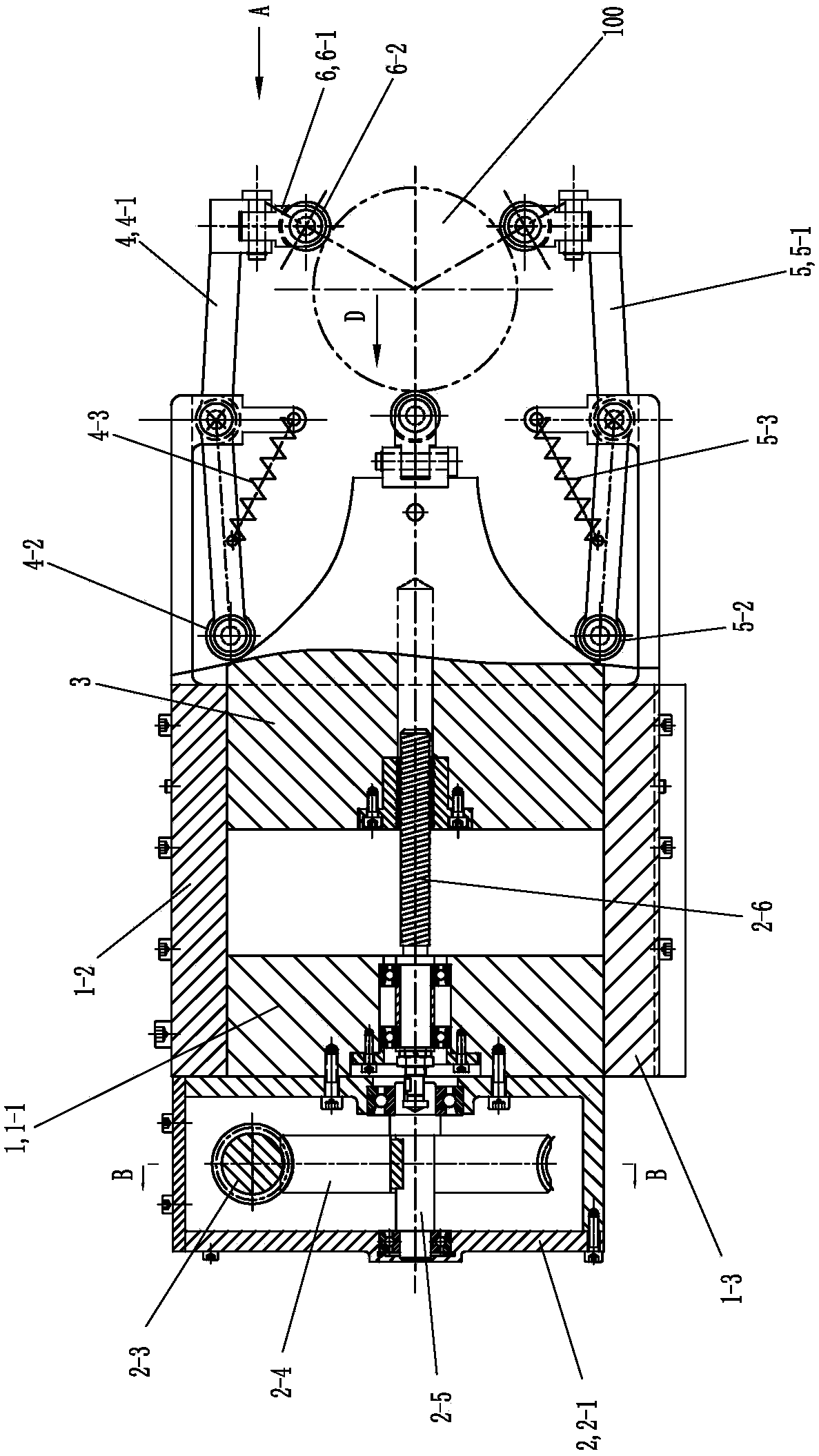

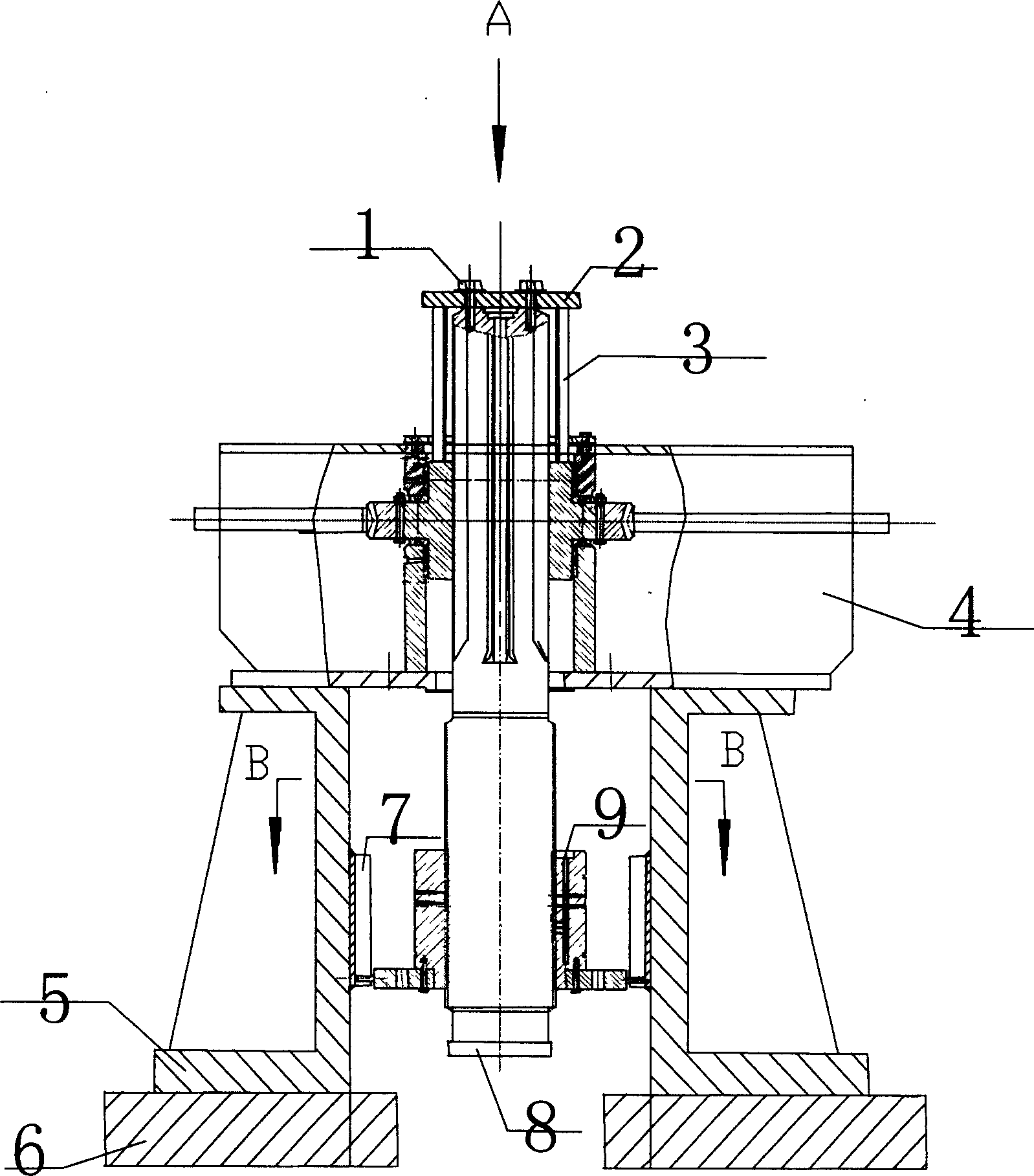

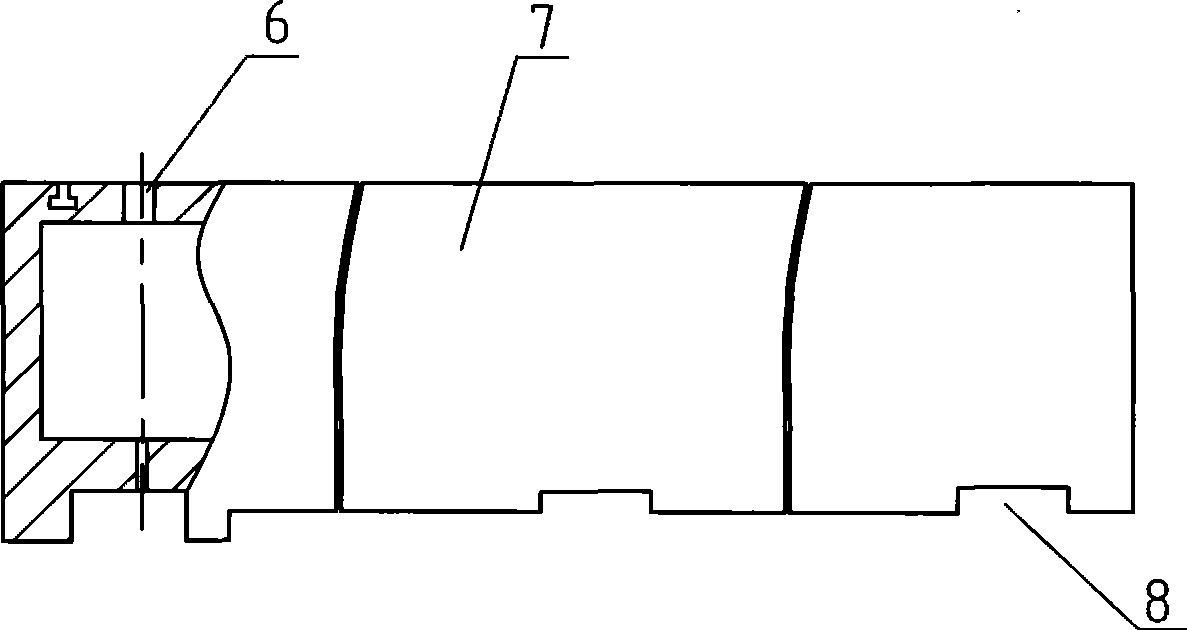

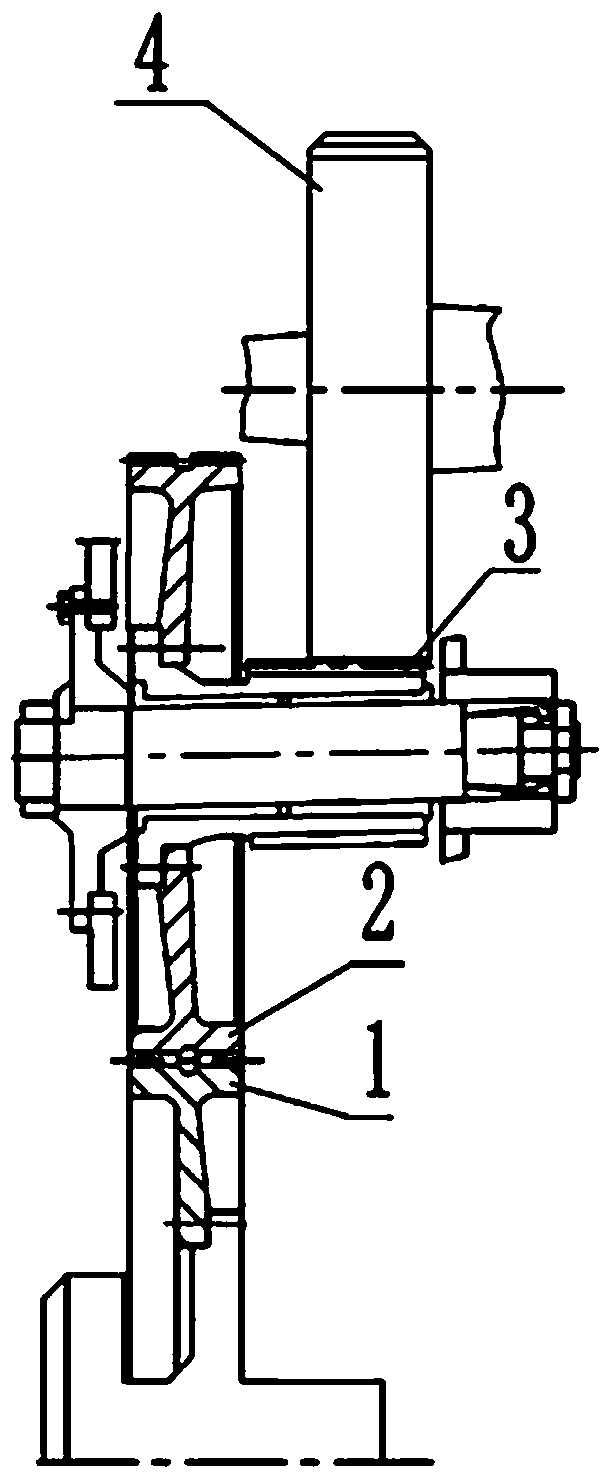

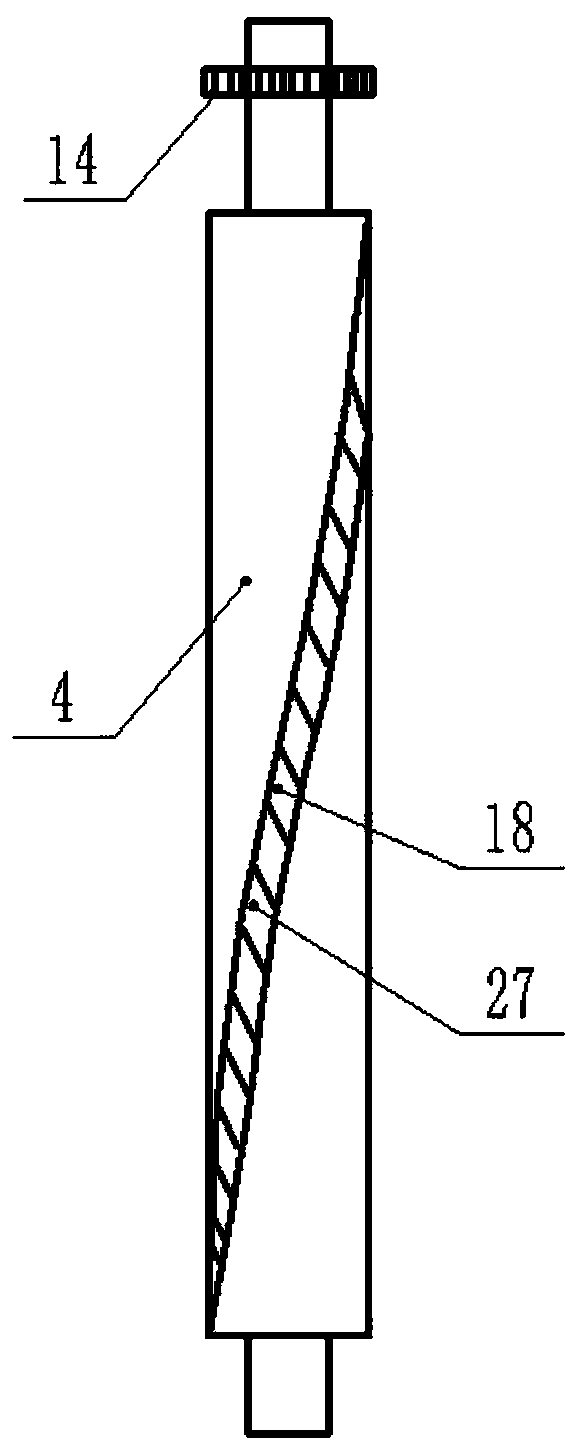

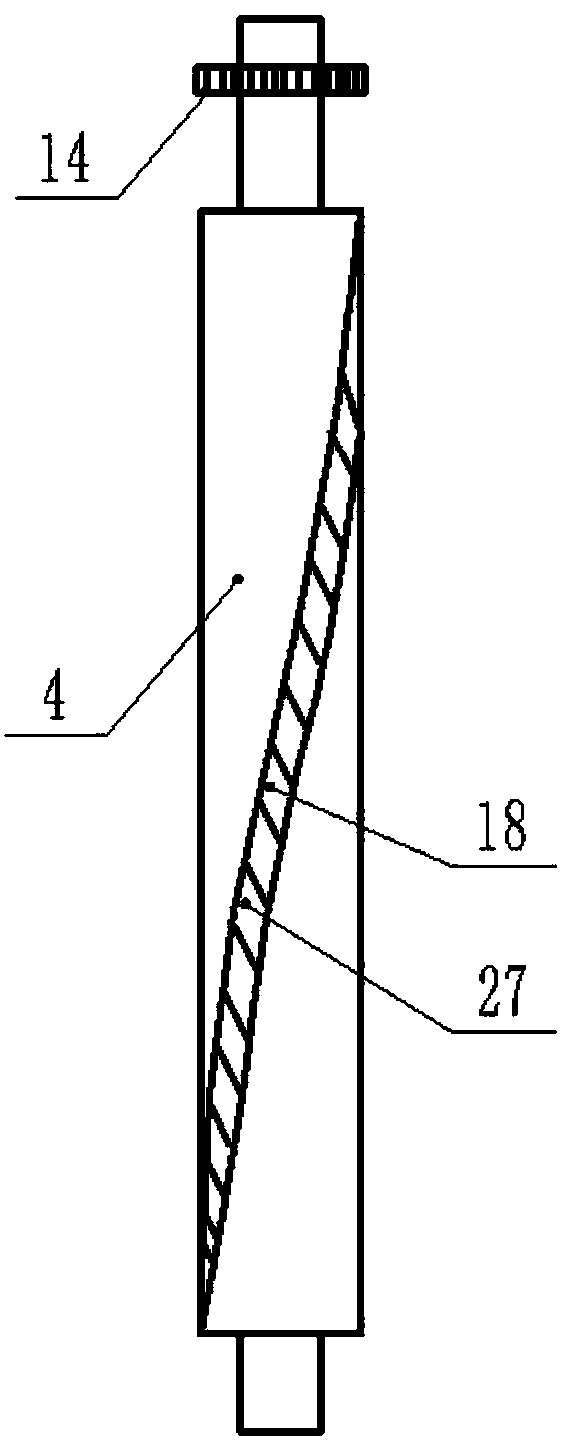

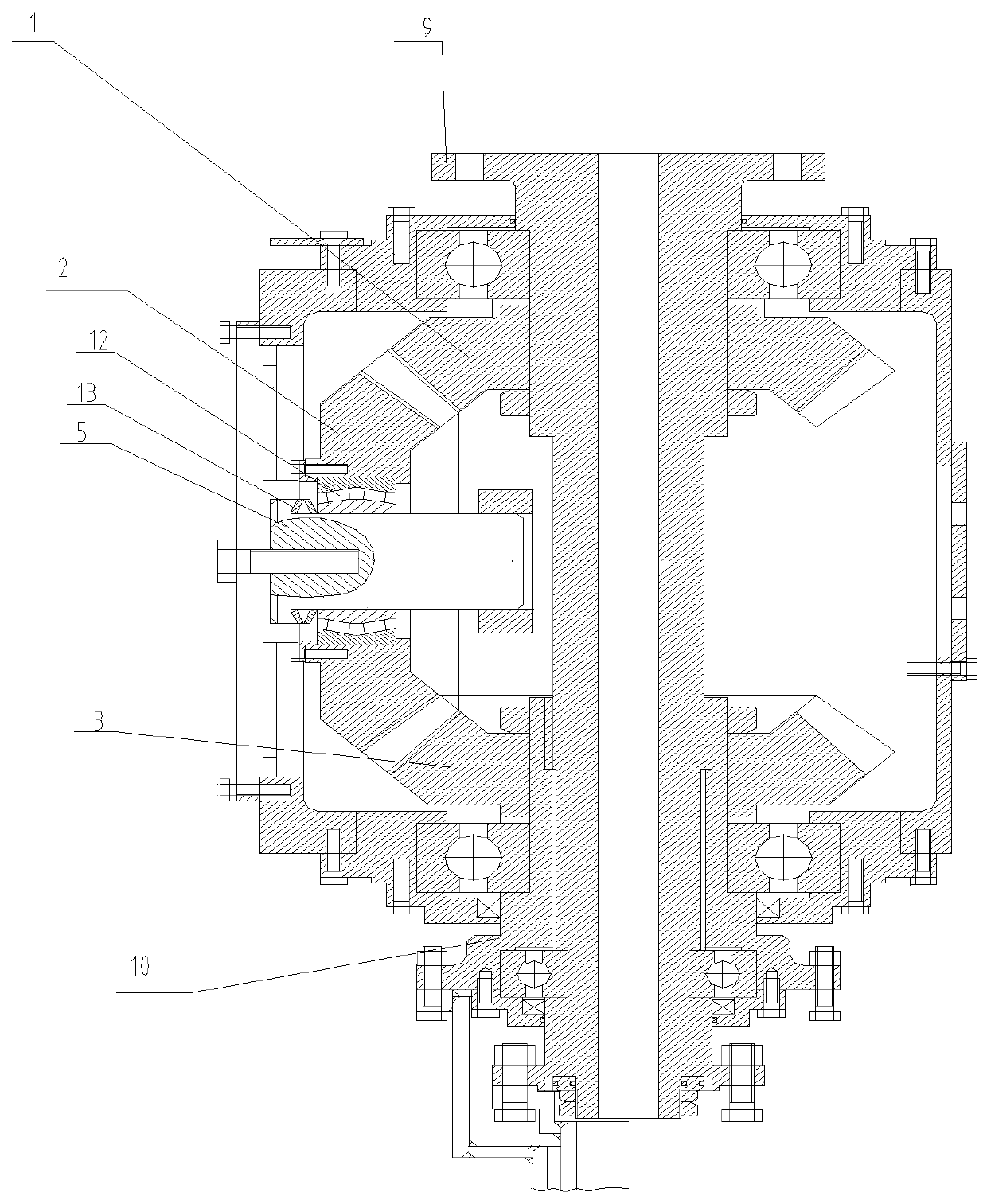

Low-speed high-torque and permanent-magnet synchronous high-speed automatic tool-changing electric spindle

ActiveCN106041130ARealize automatic replacementEasy tool changePositioning apparatusMaintainance and safety accessoriesElectricityLow speed

The invention discloses a low-speed high-torque and permanent-magnet synchronous high-speed automatic tool-changing electric spindle. The electric spindle comprises a motor body, and a stator, a rotor, a rotor shaft, a spring pre-tightening mechanism, a front bearing and a rear bearing are arranged inside the motor body. The electric spindle further comprises a connection base fixed to the rear end of the motor body, a connector fixedly connected to the connection base, a steam cylinder assembly fixedly connected to the connector, a rear cover arranged at the end of the steam cylinder assembly and a front end cover connected to the front end of the motor body. A tool loosening and pulling mechanism is arranged in the center of the rotor shaft, a pulling claw is arranged at the front end of the tool loosening and pulling mechanism, a disc spring assembly is installed in the middle of the tool loosening and pulling mechanism, a high-performance sensor is adopted together, and therefore automatic tool changing is more convenient and accurate and rapider. A magneto-electric coder is adopted at the rear end, so that low-speed torque output is more balanced. Compressed air is adopted for non-contact air sealing so that higher rotation speed can be obtained. The electric spindle is simple and compact in structure and powerful in function, is smaller than common electric spindles with the same power in size, has the advantages that the speed is low and the torque is high and can be widely applied to high-speed and low-speed precision machining of various materials.

Owner:江苏华雕机械有限公司

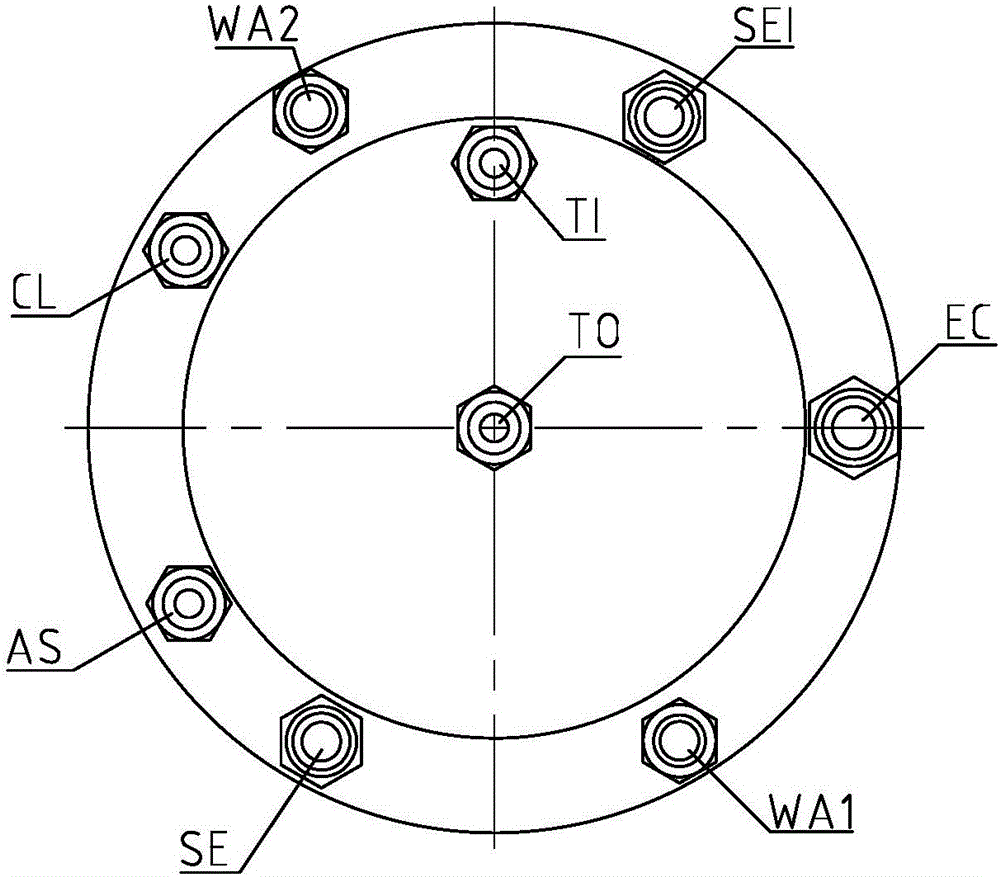

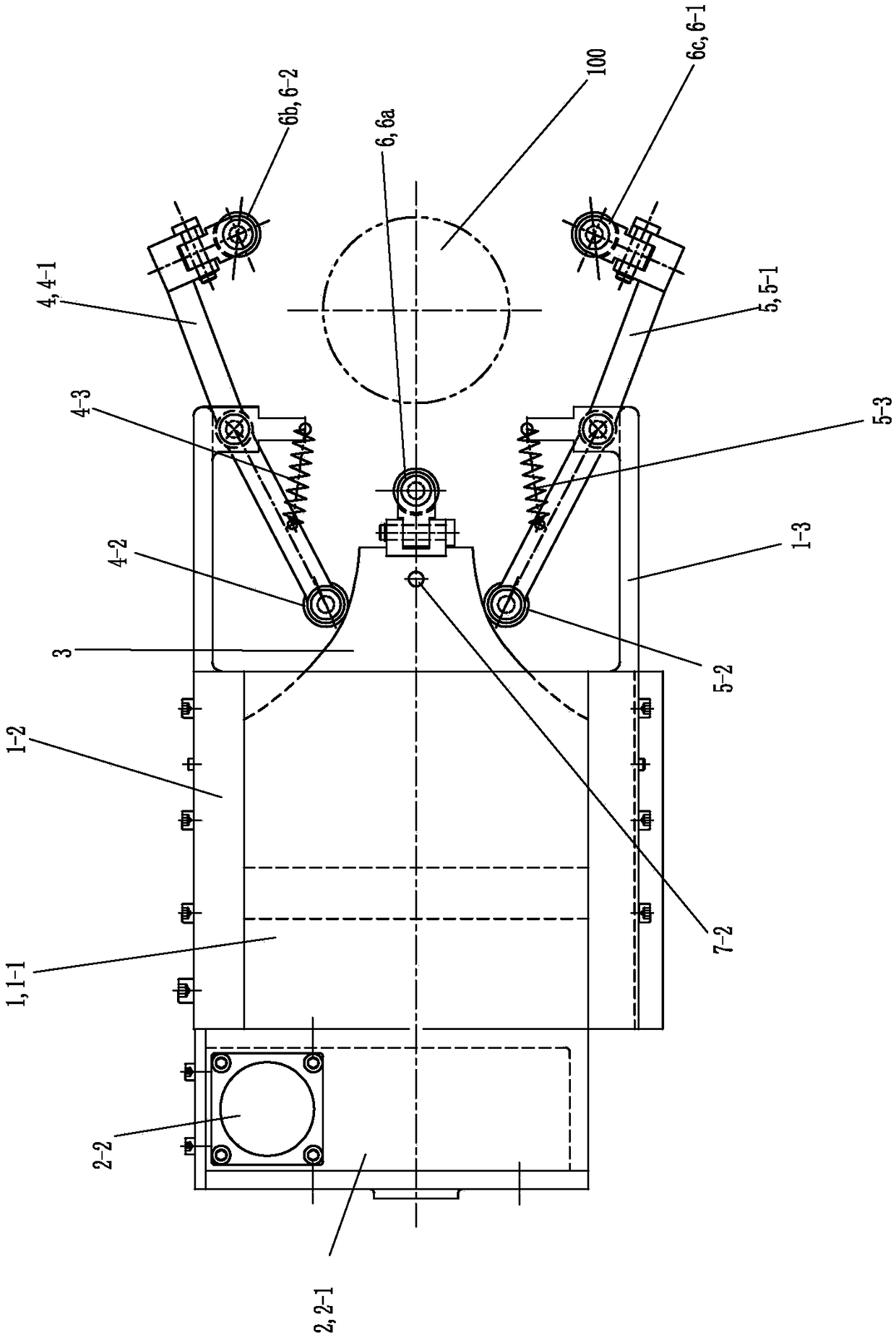

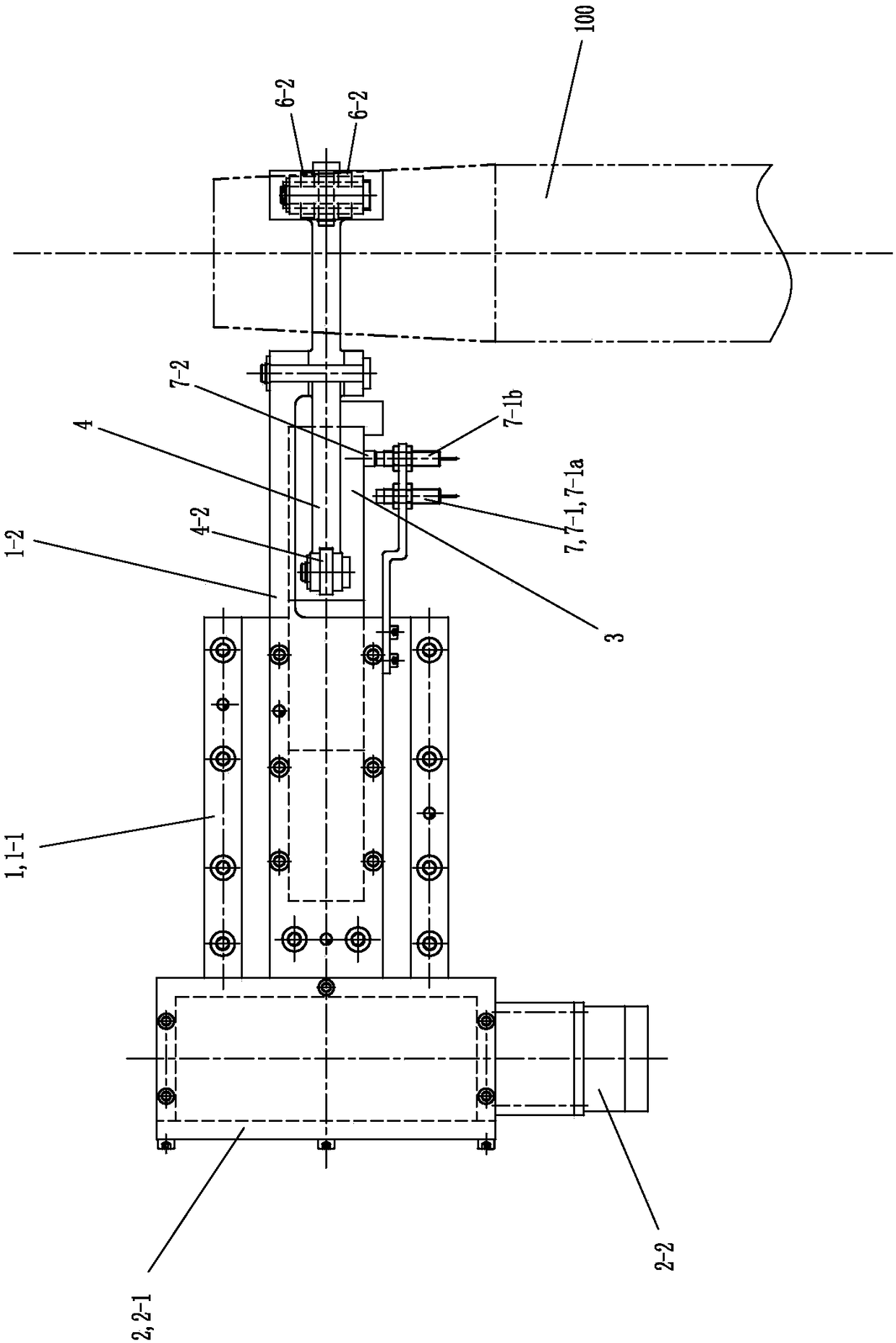

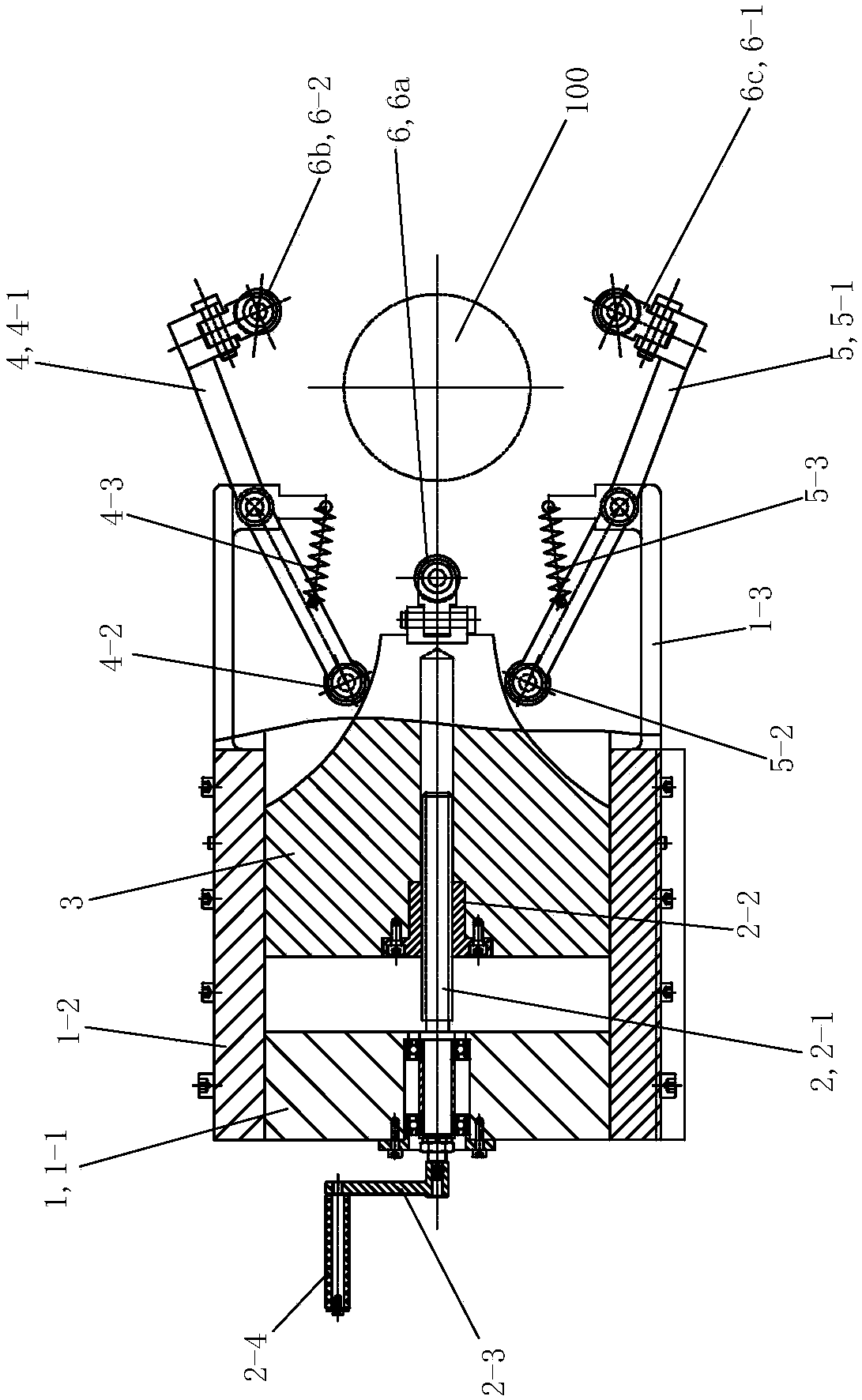

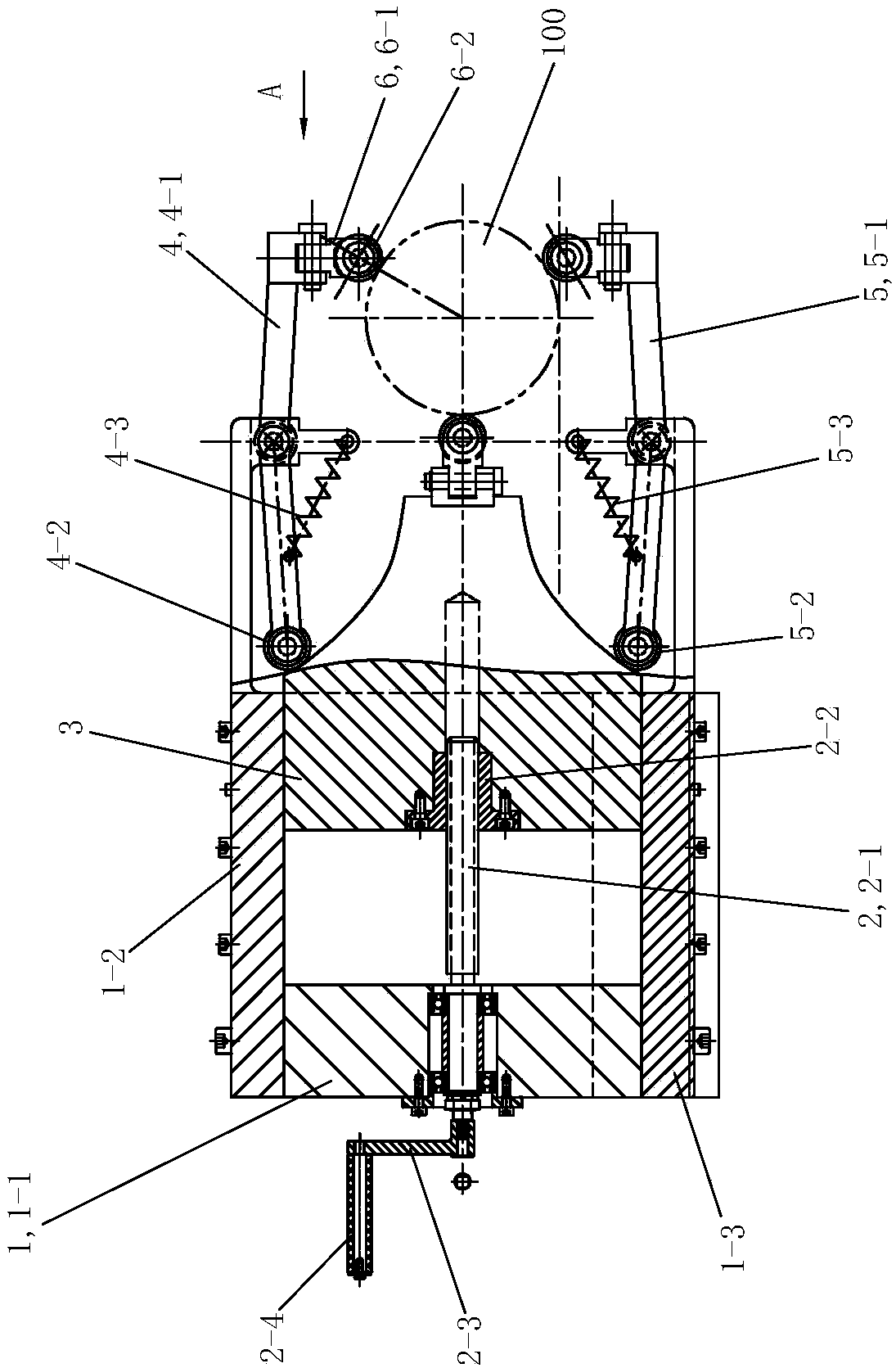

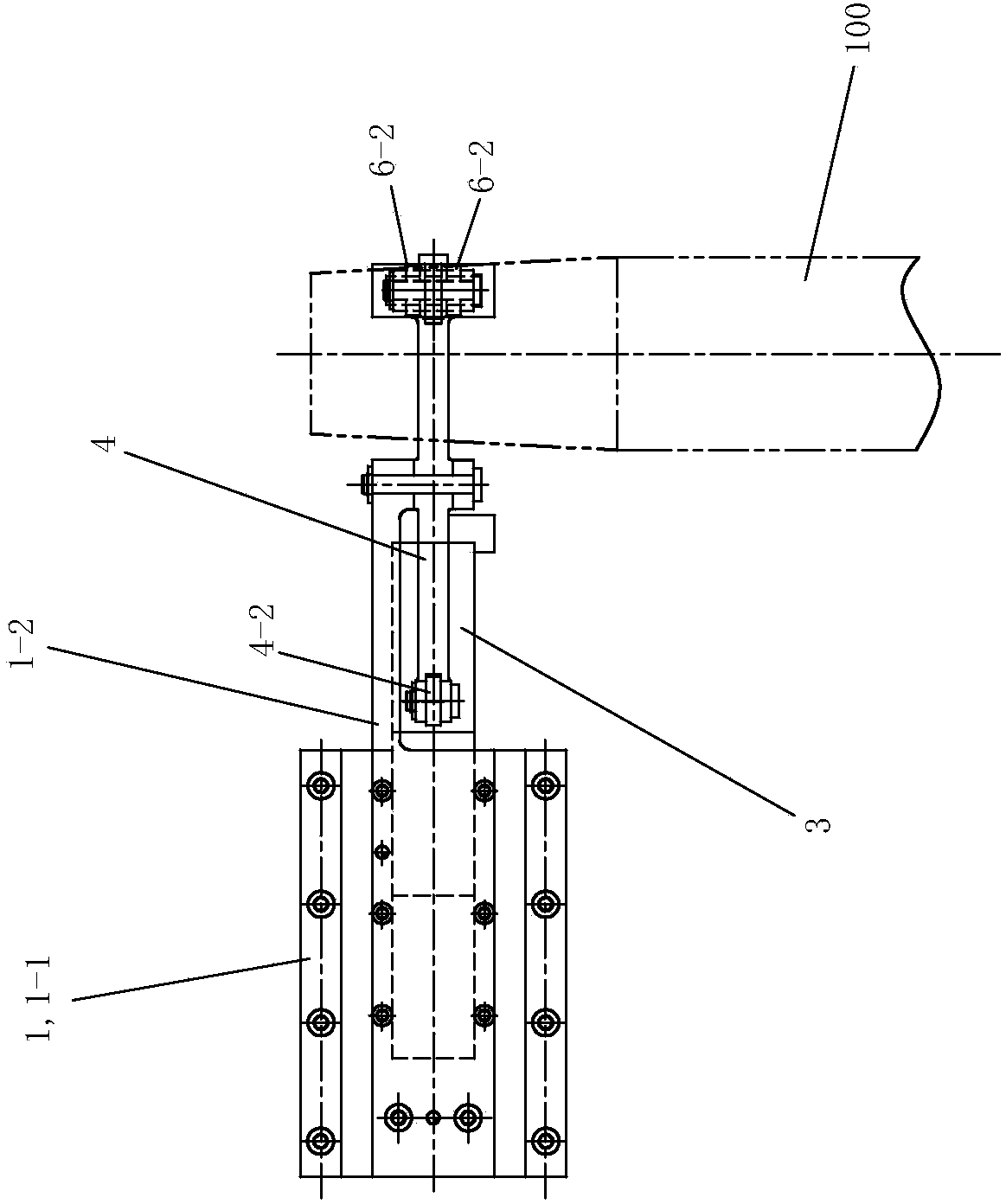

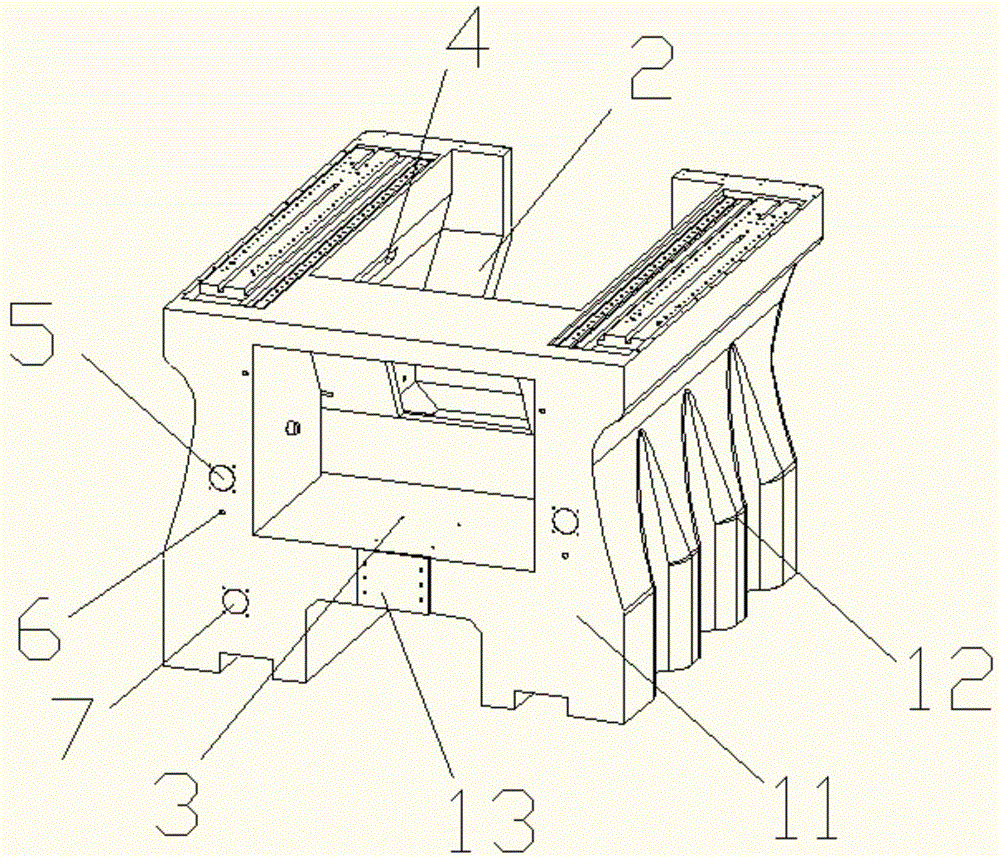

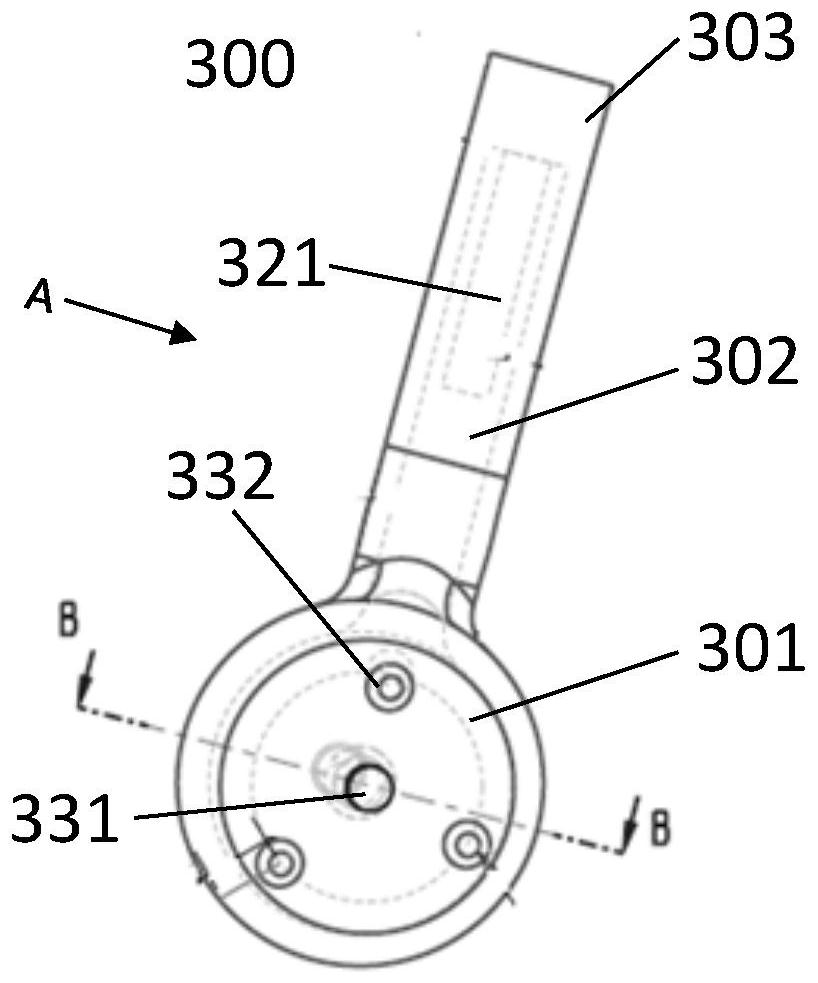

Automatic alignment center rack

InactiveCN108481018ASimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEdge surfaceEngineering

The invention discloses an automatic alignment center rack. The automatic alignment center rack is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rodcomponent, a lower pressing rod component and pressing head components, the translation cam is arranged inside the machine box in a left and right sliding manner and is driven by the driving device to move left and right, an upper pressing rod on the upper pressing rod component and a lower pressing rod are made to swing by the translation cam to make the pressing head components located on the upper pressing rod and the lower pressing rod and the pressing head component on the translation cam be simultaneously closed to the axis of a workpiece to be machined, so that the workpiece to be machined is supported, wheel support racks of the pressing head components automatically rotate according to the shape of the outer edge surface of the workpiece to be machined, and two support wheels ofeach wheel support rack are guaranteed to be pressed tightly against the workpiece to be machined simultaneously.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

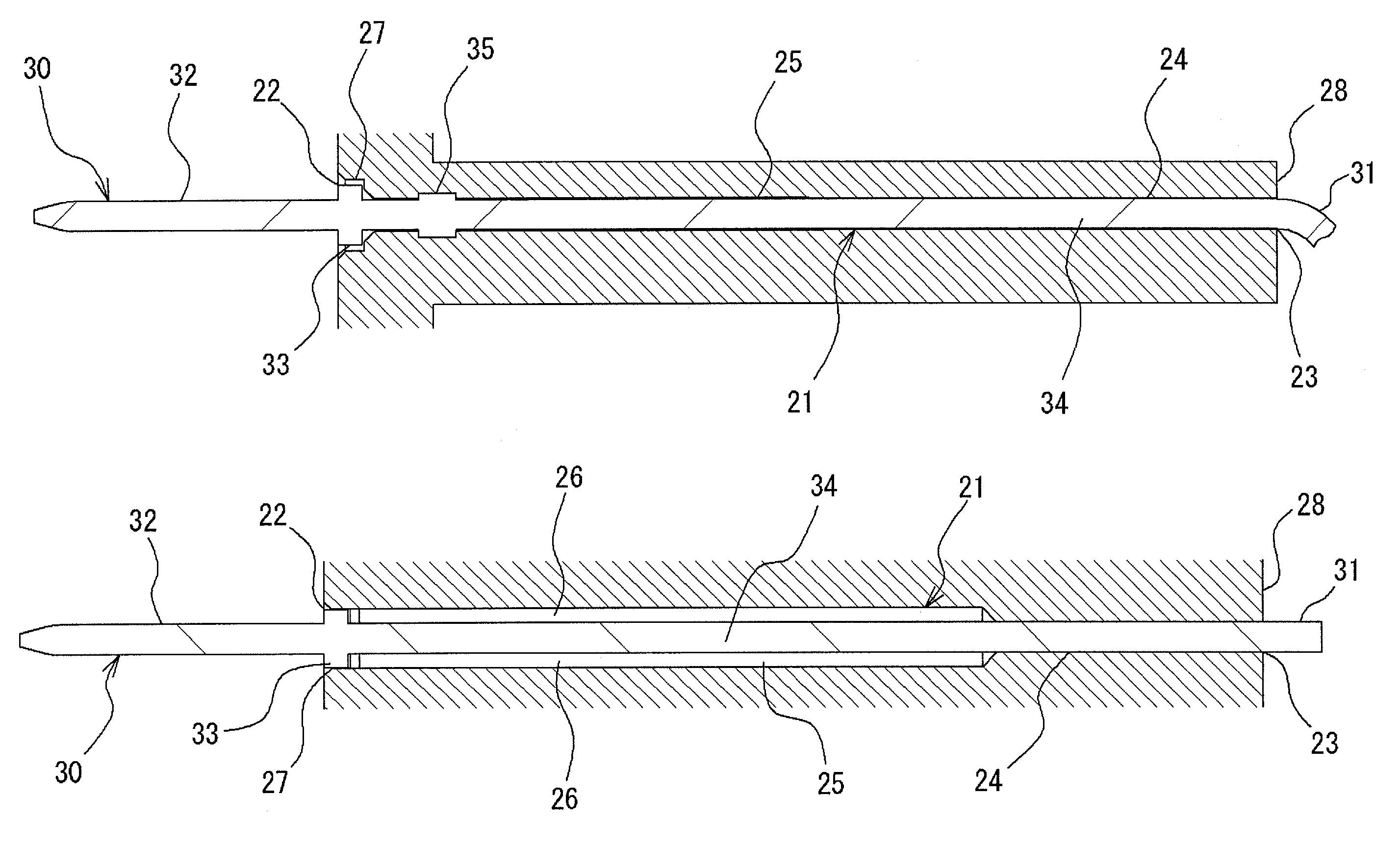

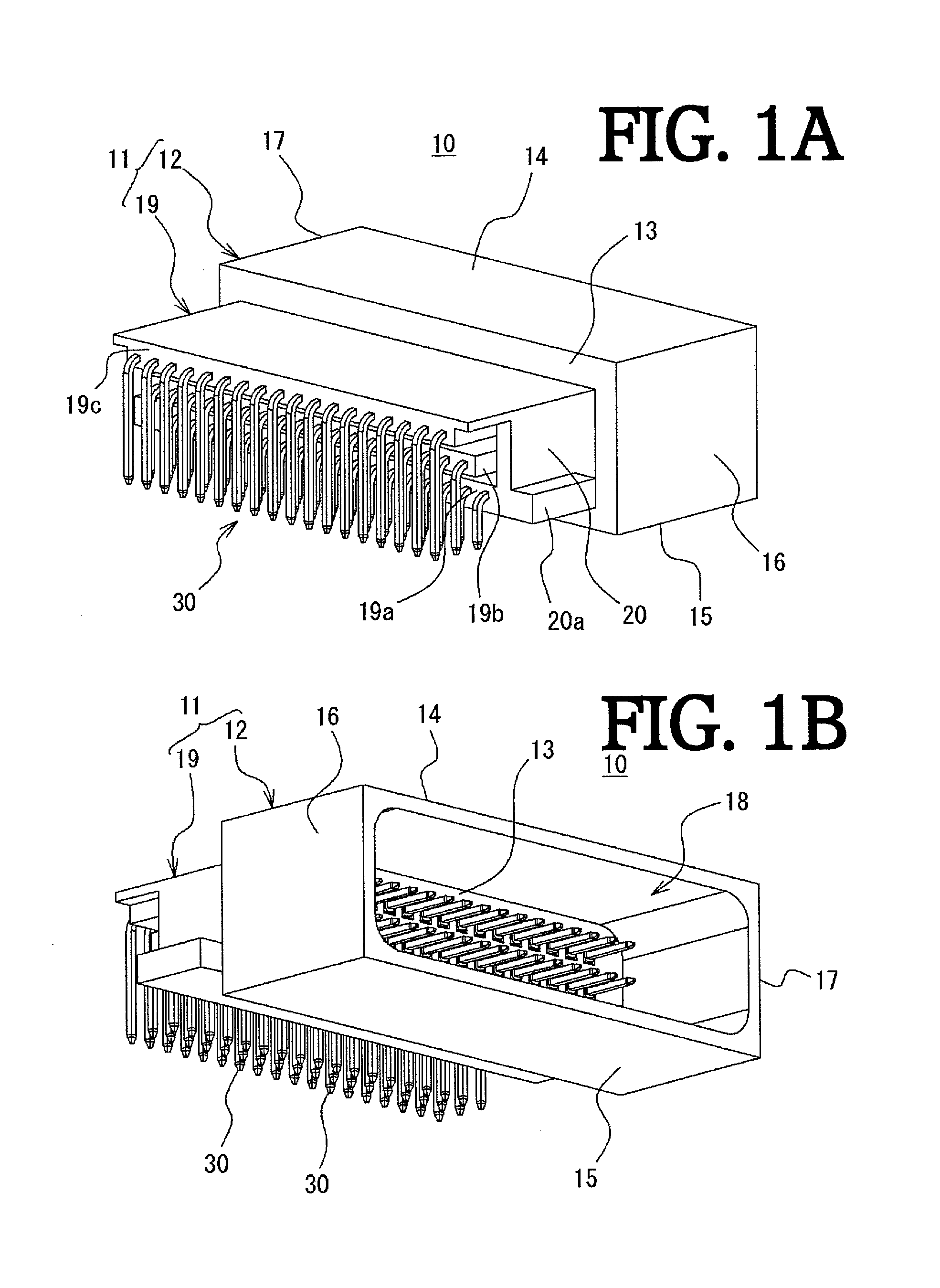

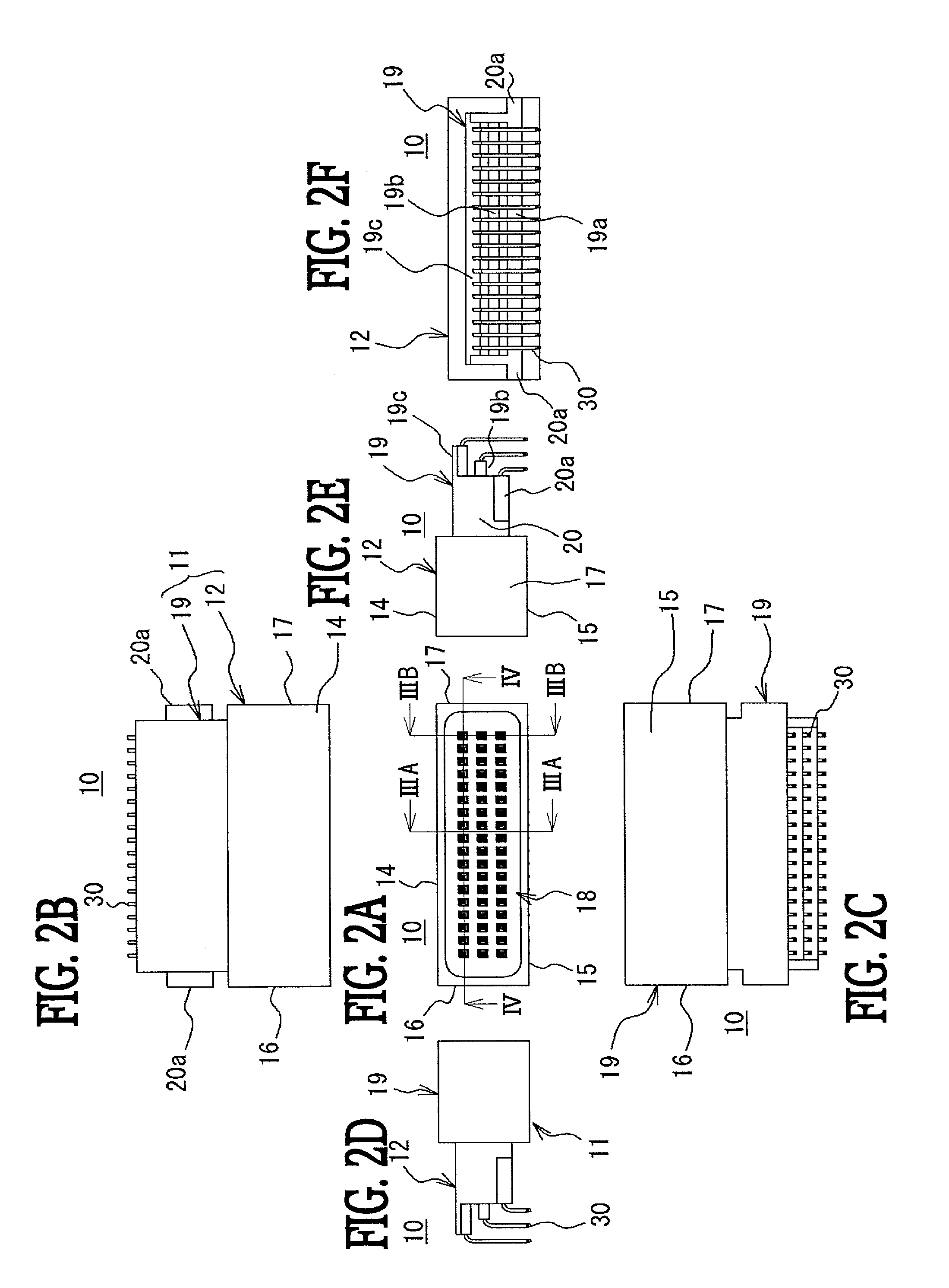

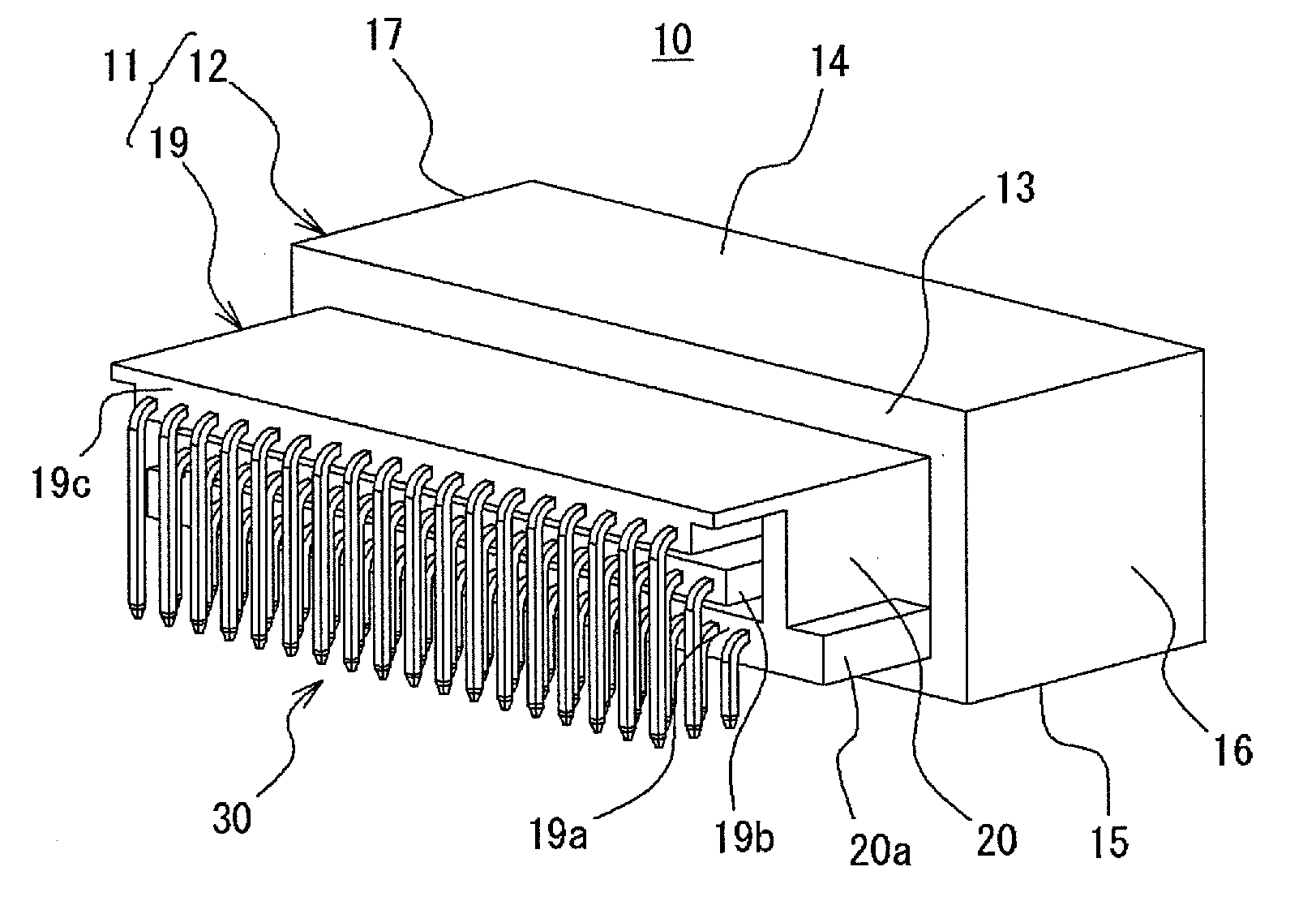

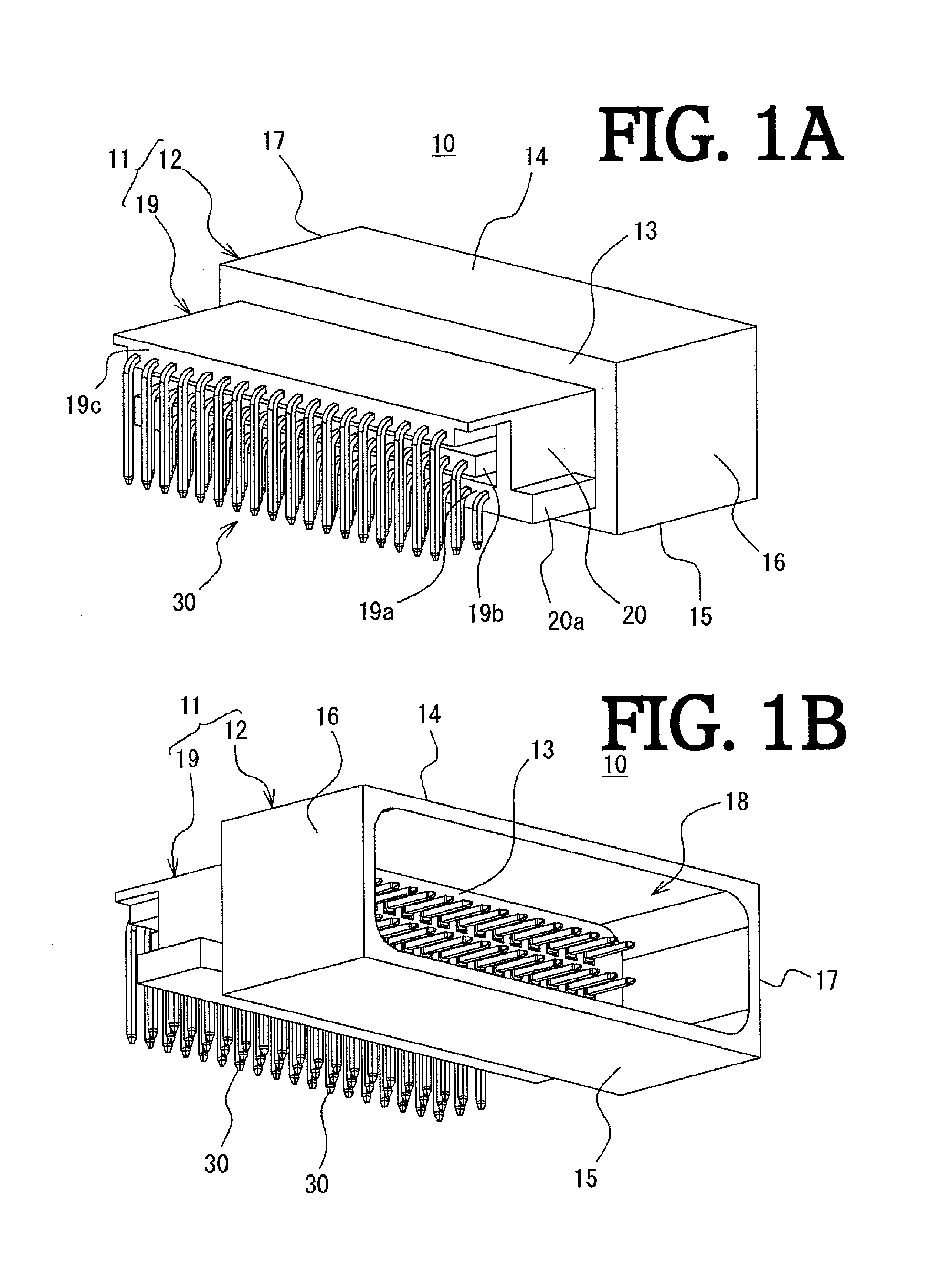

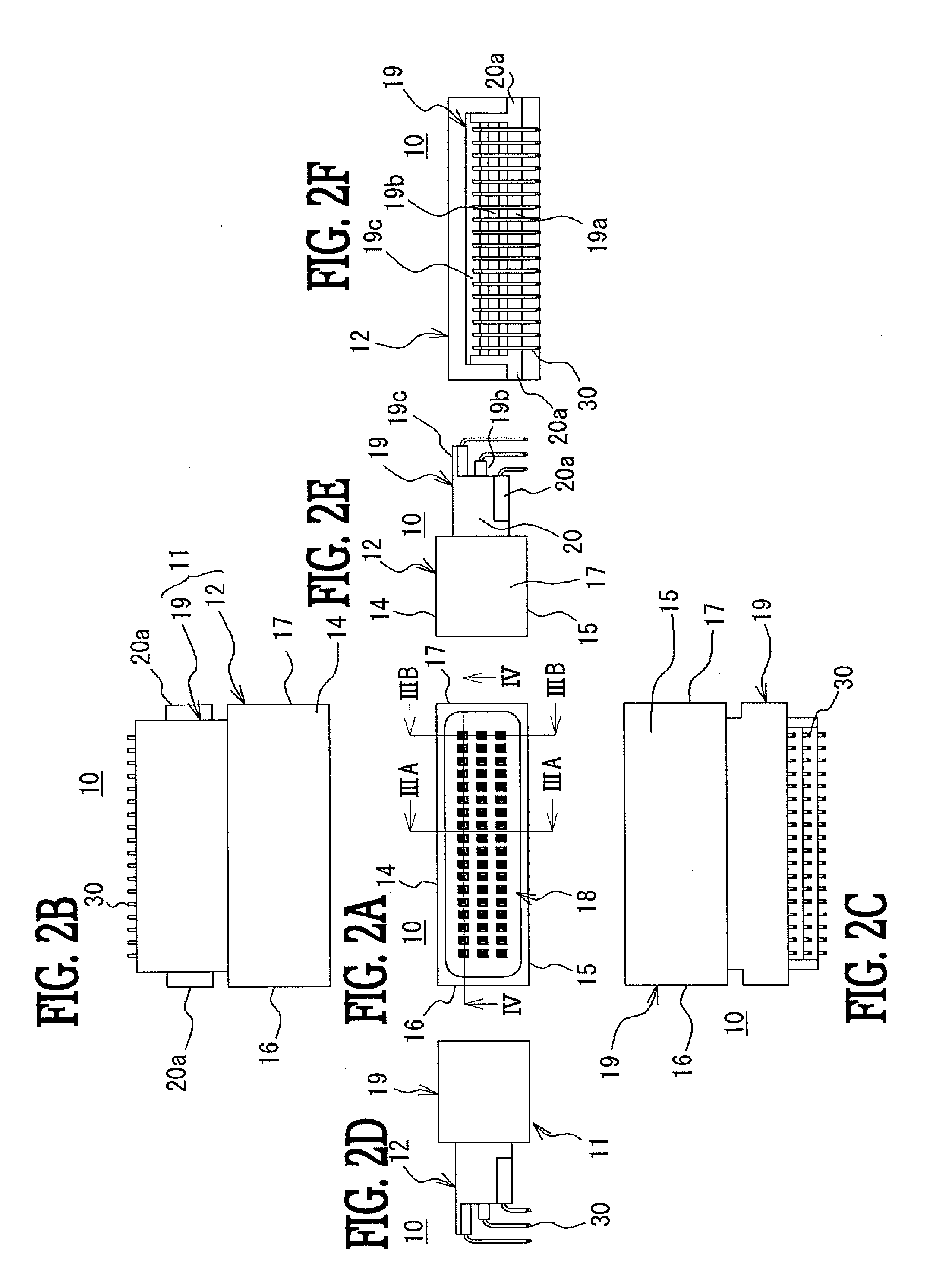

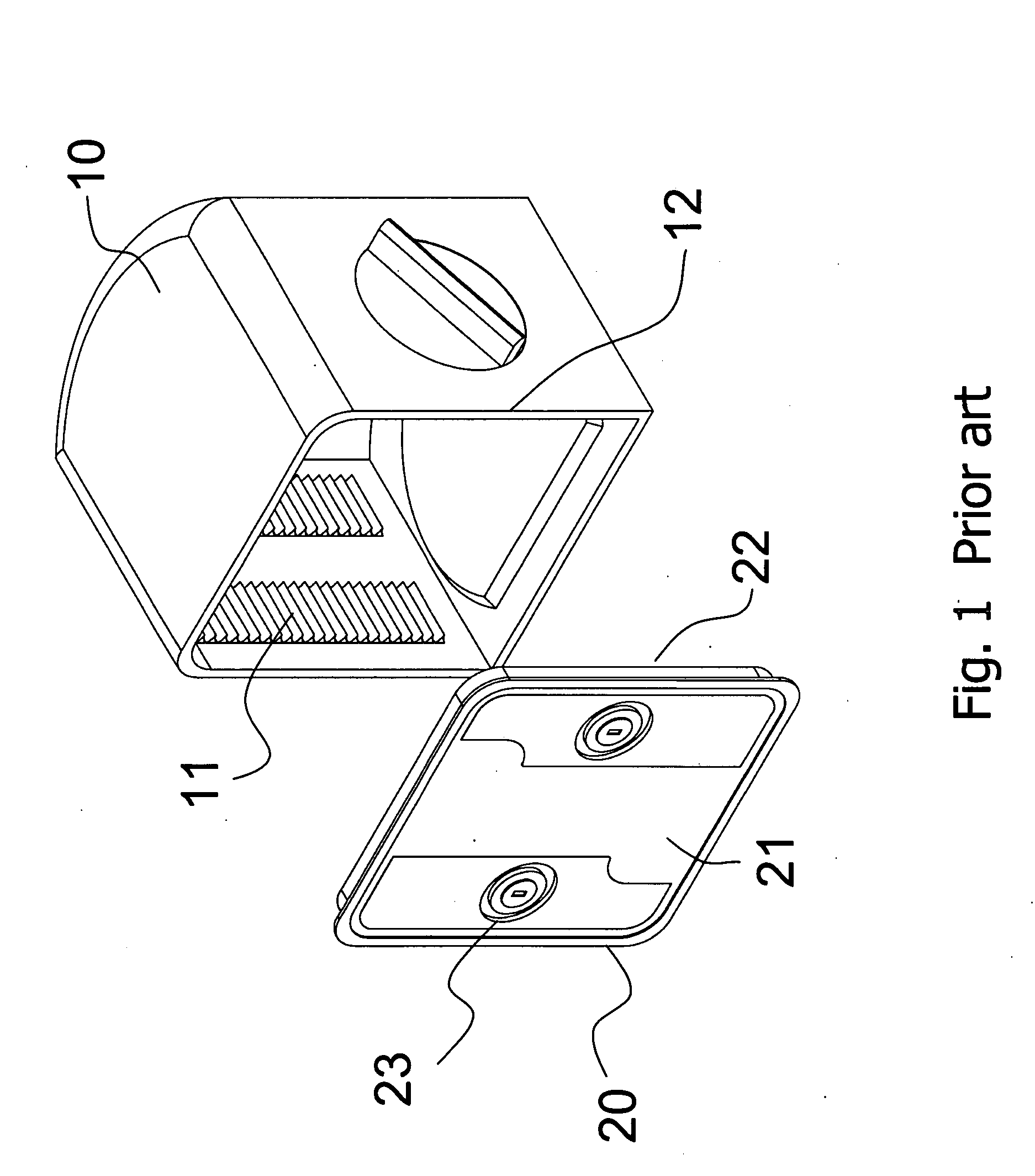

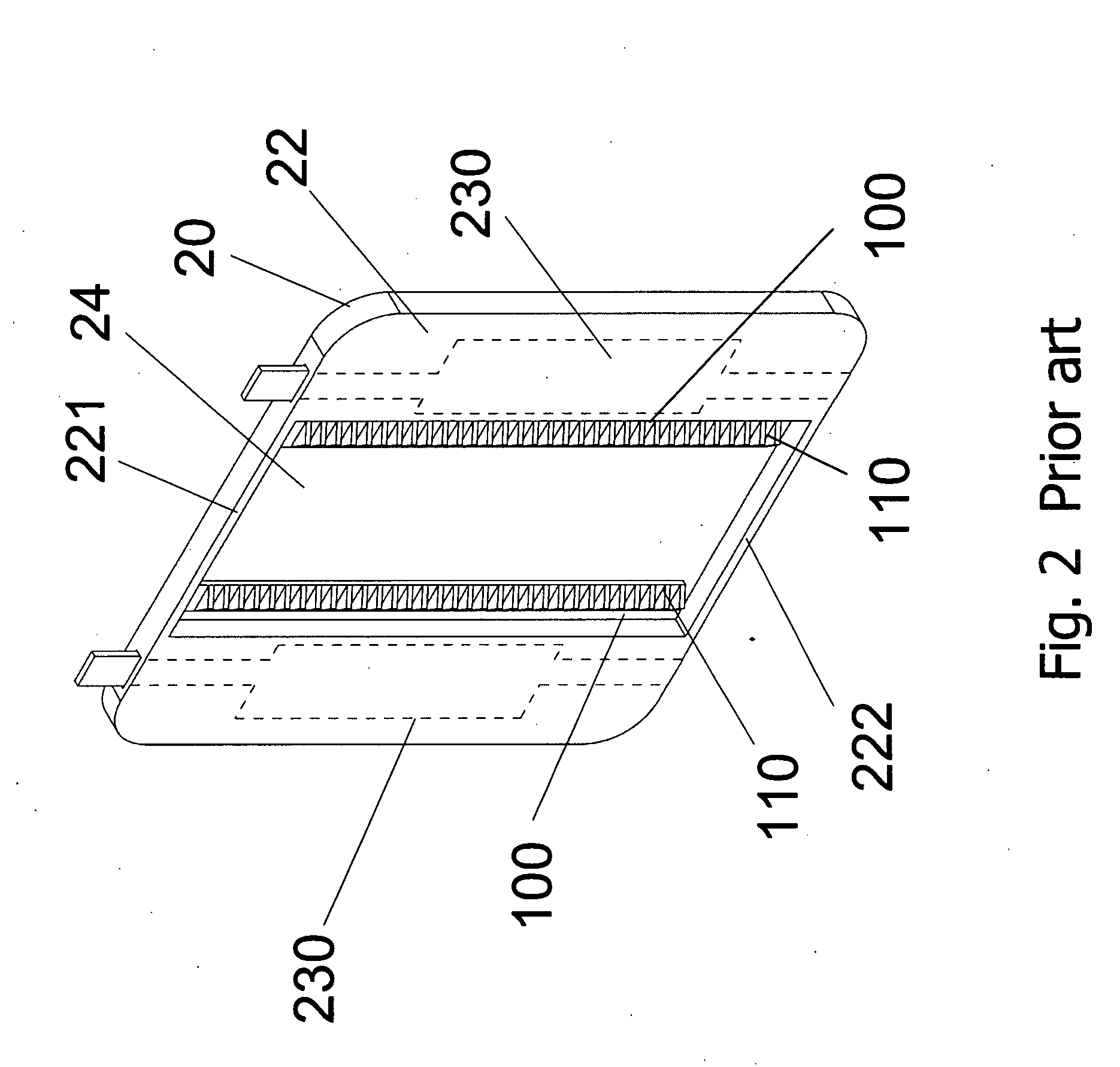

Connector

ActiveUS8876538B2Shorten the lengthImprove contact accuracySecuring/insulating coupling contact membersPrinted circuitsEngineeringFlange

A connector includes a housing and contacts. Each of the contacts includes a leading end, a connecting part, a held part, and a flange part. The housing has a holding part having a contact insertion hole into which the held part is inserted. The contact insertion hole includes: a first insertion hole in which a side surface of the held part of the contact is held; a second insertion hole formed in a size that holds one opposite side surface of the held part of the contact, and having a space on the other opposite side surface side, the second insertion hole being formed to be longer than the first insertion hole; and a flange holding part. The held part of the contact is made longer than the leading end of the contact. This configuration can improve alignment accuracy of the contacts without using a compensation plate.

Owner:JST MFG CO LTD

Connector

ActiveUS20130217278A1Improve gripEasy to manufactureSecuring/insulating coupling contact membersEngineeringFirst insertion

A connector includes a housing and contacts. Each of the contacts includes a leading end, a connecting part, a held part, and a flange part. The housing has a holding part having a contact insertion hole into which the held part is inserted. The contact insertion hole includes: a first insertion hole in which a side surface of the held part of the contact is held; a second insertion hole formed in a size that holds one opposite side surface of the held part of the contact, and having a space on the other opposite side surface side, the second insertion hole being formed to be longer than the first insertion hole; and a flange holding part. The held part of the contact is made longer than the leading end of the contact. This configuration can improve alignment accuracy of the contacts without using a compensation plate.

Owner:JST MFG CO LTD

Machining method for worm gear tooth part

The invention relates to a machining method for a worm gear tooth part. The machining method comprises the steps that S1, arc machining is conducted on the worm gear tooth part; S2, the half angles of hobs and the center distance between the center of each hob and the center of a worm gear are calculated; S3, rough hobbing is conducted on the worm gear tooth part; S4, semi-finish hobbing is conducted on the worm gear tooth part; S5, finish hobbing is conducted on the worm gear tooth part; S6, grinding is conducted on the worm gear tooth part. The step S3, the step S4, the step S5 and the step S6 are all performed on a gear hobbing machine, and the same datum plane is utilized; the worm gear hubs used for gear hobbing conducted on the worm gear tooth part in the step S3, the step S4 and the step S5 are large-diameter worm gear hobs. The machining method has the advantages that a machined worm gear is high in accuracy and stable in transmission, contacting surfaces are easy to match, gear teeth are good in abrasion resistance, and bending strength is high.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Technology for improving mesh accuracy between screwdown nut and screwdown screw of strip steel rough mill and plate mill

InactiveCN1701885AImprove contact accuracySolve the long-standing problem of low contact accuracyStrip millSurface roughness

The invention discloses technique to improve the engagement accuracy of housing screw and nut of hoop rolling mill roughing mill and plate mill and particular fit to prepare screw and nut for multi-start screw thread of heavy mill. The invention needs equipment with simple structure, low cost, easy to operate and with perfect effect. The product (B520x48 P=24) with two pieces of screw thread 100% contact and Ra0.8 of surface roughness, and achieves international first-class standard.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

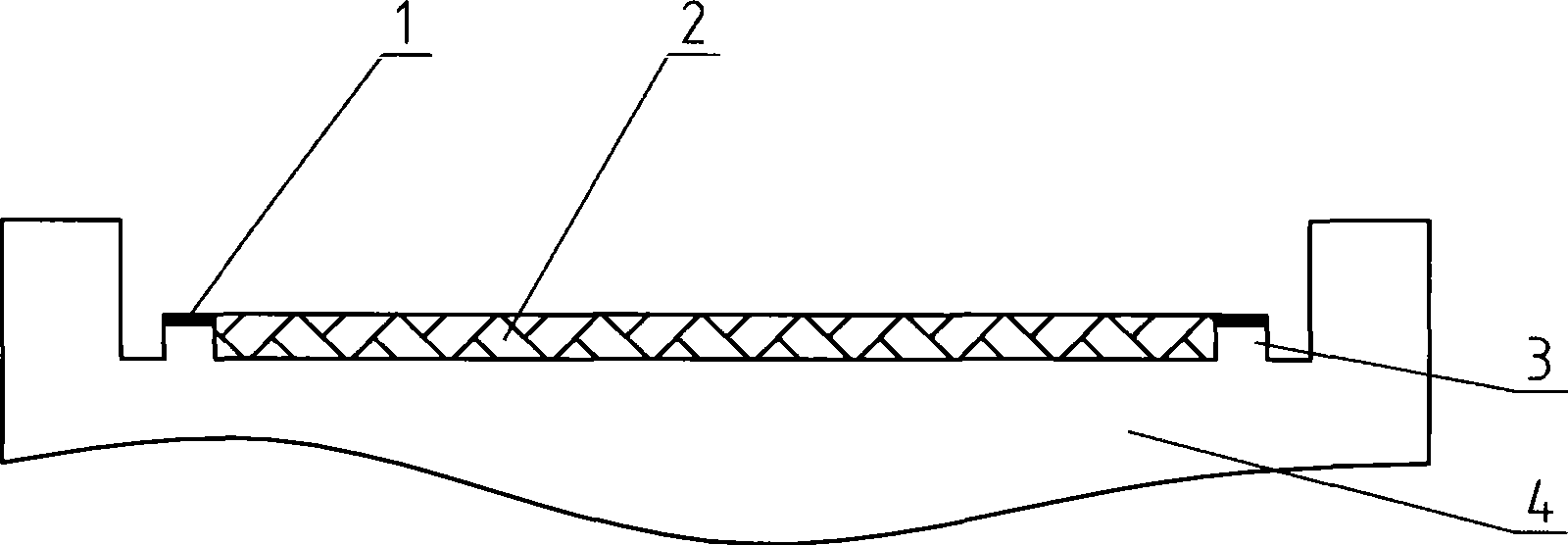

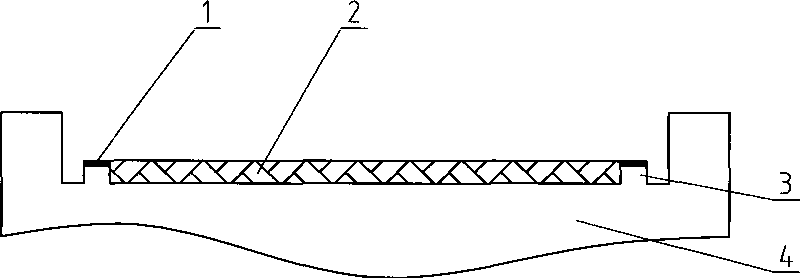

Guide-rail injection molding technique of heavy numerically controlled machine

ActiveCN101380799AReduce labor intensityImprove contact accuracyLarge fixed membersFastening meansNumerical controlEngineering

The present invention discloses a guide way injection molding technology of a heavy numerical control machine tool working table. After the assembly precision of a lathe bed guide way meets the requirements, and a working table is processed, a static press oil cavity is manufactured on the surface of the lathe bed guide way; two sides of the lathe bed guide way corresponding to a face to be injected with glue are respectively provided with a support edge used for supporting the working table; and the working table is provided with a plurality of holes used for injecting the glue and exhausting. The core of the technology lies on constructing a glue-injecting cavity and evenly spraying demoulding agents on the contacted surface of the lathe bed guide way and adhesive when injecting the glue to ensure that a molded guide way is molded at one time. The present invention provides a guide way injection molding technology of the heavy numerical control machine tool working table, which has strong combination affinity and good adhesive bonding performance between a coating layer and metal and the high molding precision and good quality of the guide way and has the characteristic of the high molding efficiency and the long service life of the guide way.

Owner:JIER MACHINE TOOL GROUP

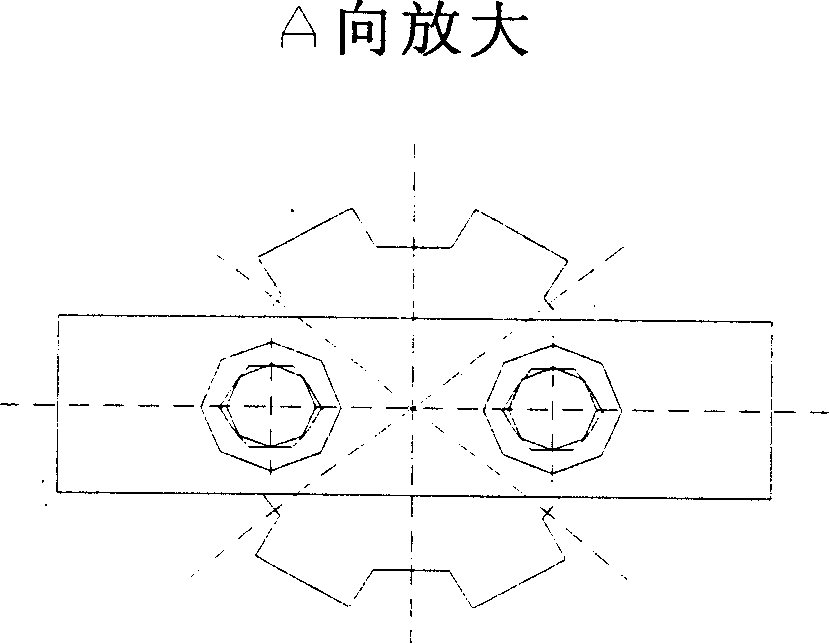

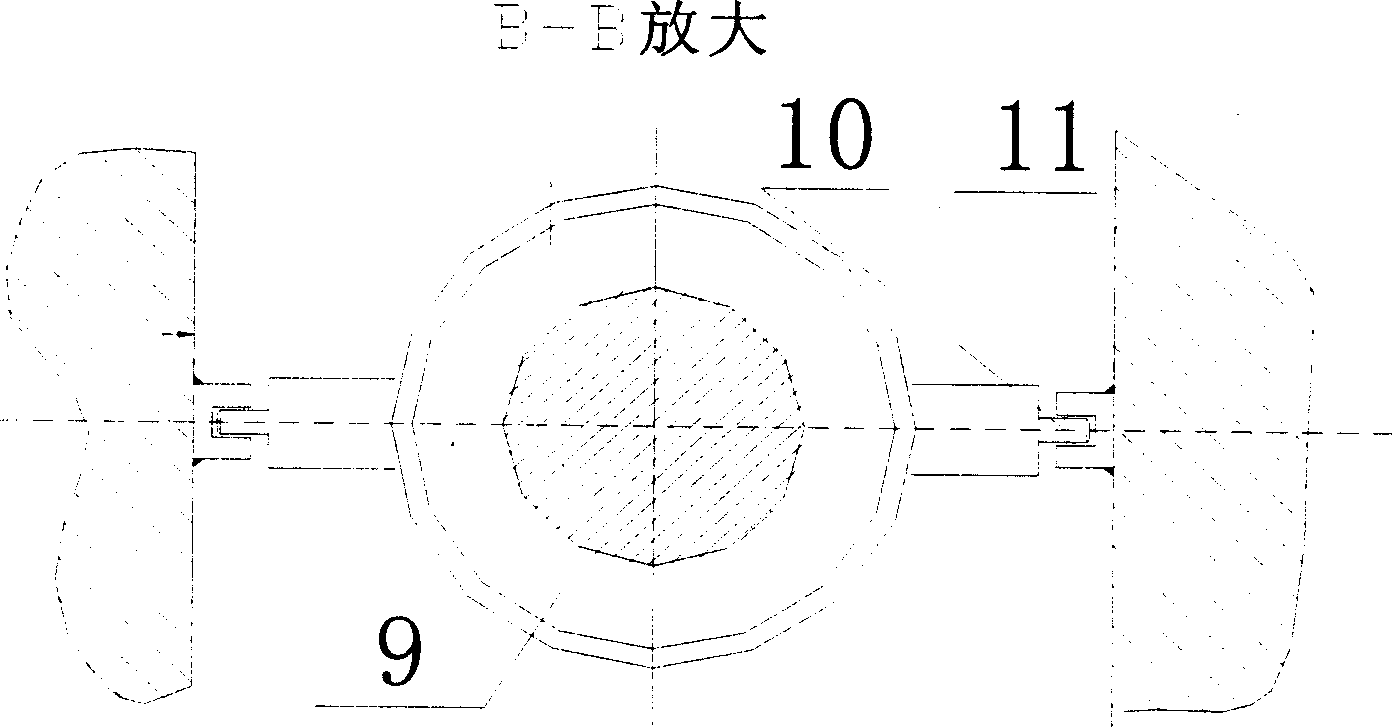

Herringbone gear assembly positioning method and device, assembling method and high-power diesel engine

The invention belongs to the technical field of diesel engine manufacturing, and discloses a herringbone gear assembly positioning method and device, an assembling method and a high-power diesel engine. The herringbone gear assembly positioning method includes the steps that datum tooth scale lines of a right-rotation gear tooth ring and datum tooth scale lines of a left-rotation gear tooth ring are aligned for visual inspection coarse tuning; and datum teeth of the left-rotation gear tooth ring are used as a datum for fixation with fixed positioning teeth of a positioning device, automatic alignment is conducted through movement of movable positioning teeth to obtain the correct positions of datum teeth of the right-rotation gear tooth ring based on the positional accuracy between the movable positioning teeth and the fixed positioning teeth of the positioning device as well as the body dimensional accuracy of the two positioning teeth, and positional assembling between the datum teeth of the right-rotation gear tooth ring and the datum teeth of the left-rotation gear tooth ring is carried out. According to the herringbone gear assembly positioning method and device, the assembling method and the high-power diesel engine, by using the intermediate-speed high-power diesel engine combined-type herringbone gear assembly, assembly accuracy is improved, assembly technology stability is ensured, the economic cost of herringbone tooth gears is reduced, and operational reliability of diesel engine gears is guaranteed; and the application field is broad and the popularization valueis good.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

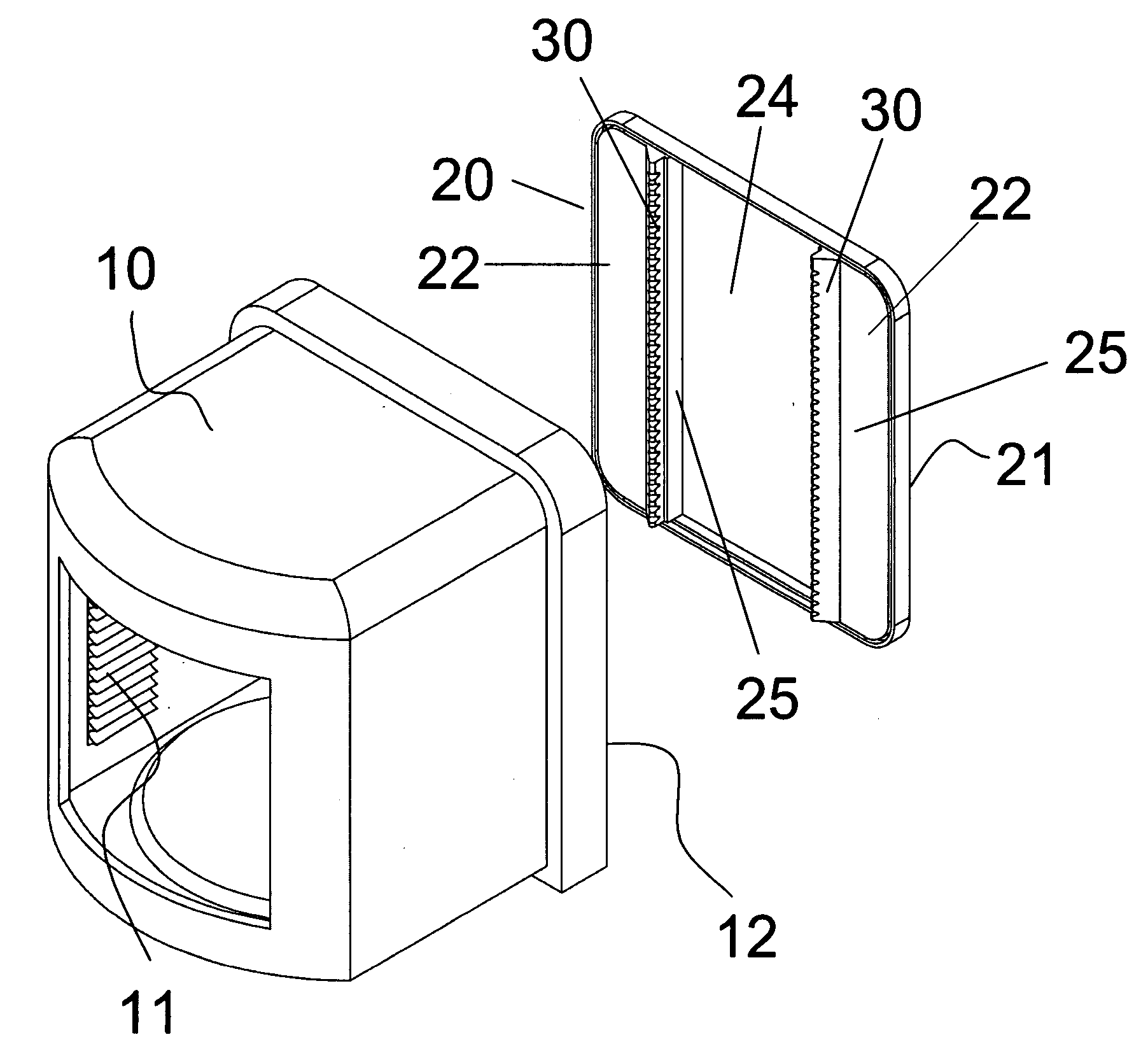

Wafer Container with Integrated Wafer Restraint Module

InactiveUS20100051504A1Improve contact accuracySize of wafer can not be decreasedSemiconductor/solid-state device manufacturingOther accessoriesEngineeringMechanical engineering

A wafer container includes a container body, the internal of which is disposed with a plurality of slots for supporting a plurality of wafers and an opening is formed on one sidewall of which for importing and exporting said plurality of wafers, and a door with an outer surface and an inner surface, which is joined with opening of the container body with its inner surface for protecting the plurality of wafers in the container body, the characteristic in that: a recess is integrated with the inner surface of the door for separating the inner surface into two platforms, a restraint module is formed respectively on each of two platforms, and each restraint module includes a base which is disposed with a plurality of notches arranged at interval for contacting said plurality of wafers.

Owner:GUDENG PRECISION IND CO LTD

Center frame

InactiveCN108500652ASimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEngineeringCam

The invention discloses an automatic-centering center frame. The automatic-centering center frame is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rod assembly, a lower pressing rod assembly and pressing head assemblies. The translation cam is arranged in the machine box in a left-right sliding mode and driven by the driving device to move left and right. An upper pressing rod of the upper pressing rod assembly and a lower pressing rod are made to swing through the translation cam, so that the pressing head assemblies located on the upper pressing rod and the lower pressing rod and the pressing head assembly on the translation cam are gathered towards the axis of a workpiece to be machined at the same time, the workpiece to be machined issupported, a supporting wheel frame of each pressing head assembly can be automatically rotated according to the shape of the outer edge face of the workpiece to be machined, and it is ensured that two supporting wheels located on each supporting wheel frame are pressed on the workpiece to be machined at the same time.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Integral gear quenching equipment and process thereof

InactiveCN108774680ASimple methodEasy to operateFurnace typesHeat treatment process controlMonitoring systemGear tooth

The invention discloses integral gear quenching equipment and a process thereof. The integral gear quenching equipment comprises a base and a gear positioning device, wherein the gear positioning device is located on the base and is used for fixing a gear, gear quenching equipment is arranged above the gear positioning device, the gear quenching equipment comprises a longitudinal adjustment fixedseat, a heating device and an oil spraying and cooling device which are arranged on the longitudinal adjustment fixed seat and are matched with a tooth groove of the gear, the heating device and the oil spraying and cooling device are connected with a gear monitoring system which is used for monitoring the gear processing state in real time by virtue of a controller, the gear is fixed to a platform on the base by the gear positioning device, and the position and the precision of the heating device and the oil spraying and cooling device are controlled by the controller according to quenching depth requirements so as to integrally quench the load surface of the gear. The gear quenching equipment has the advantages of integrality in quenching and simple method, the product quality and yieldare obviously increased, and processed gear teeth have the advantages of high strength, good wear resistance, long service life and high bearing capacity.

Owner:苏州远征魂车船技术有限公司

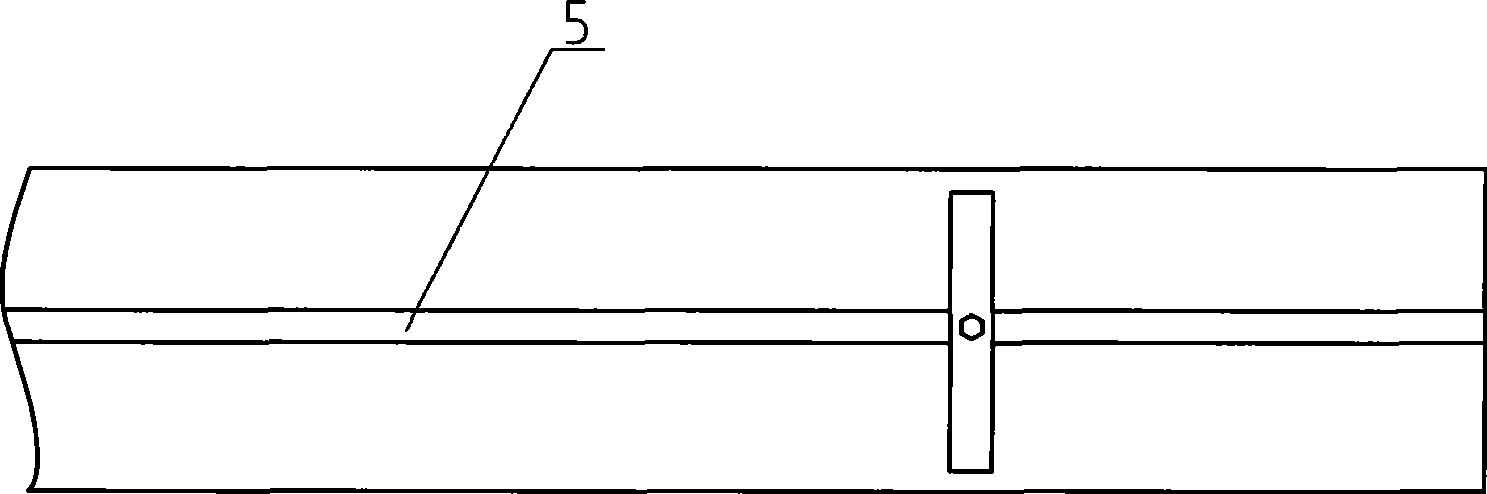

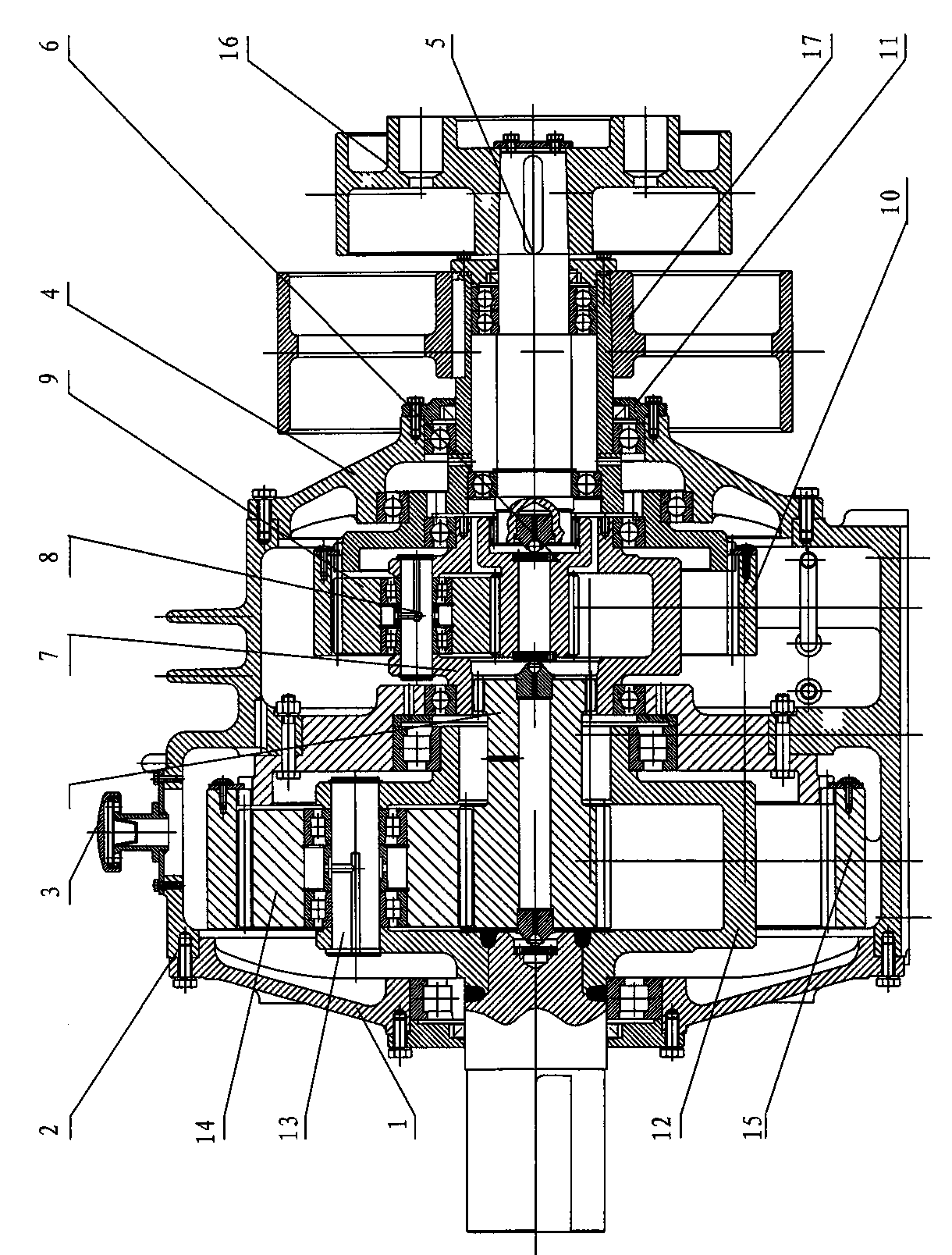

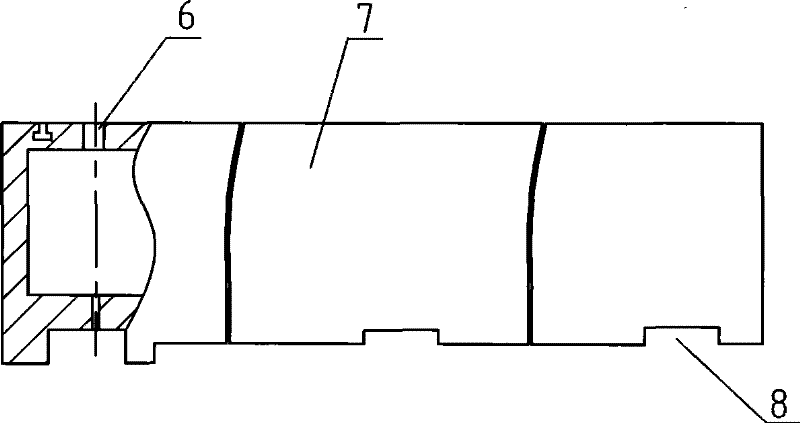

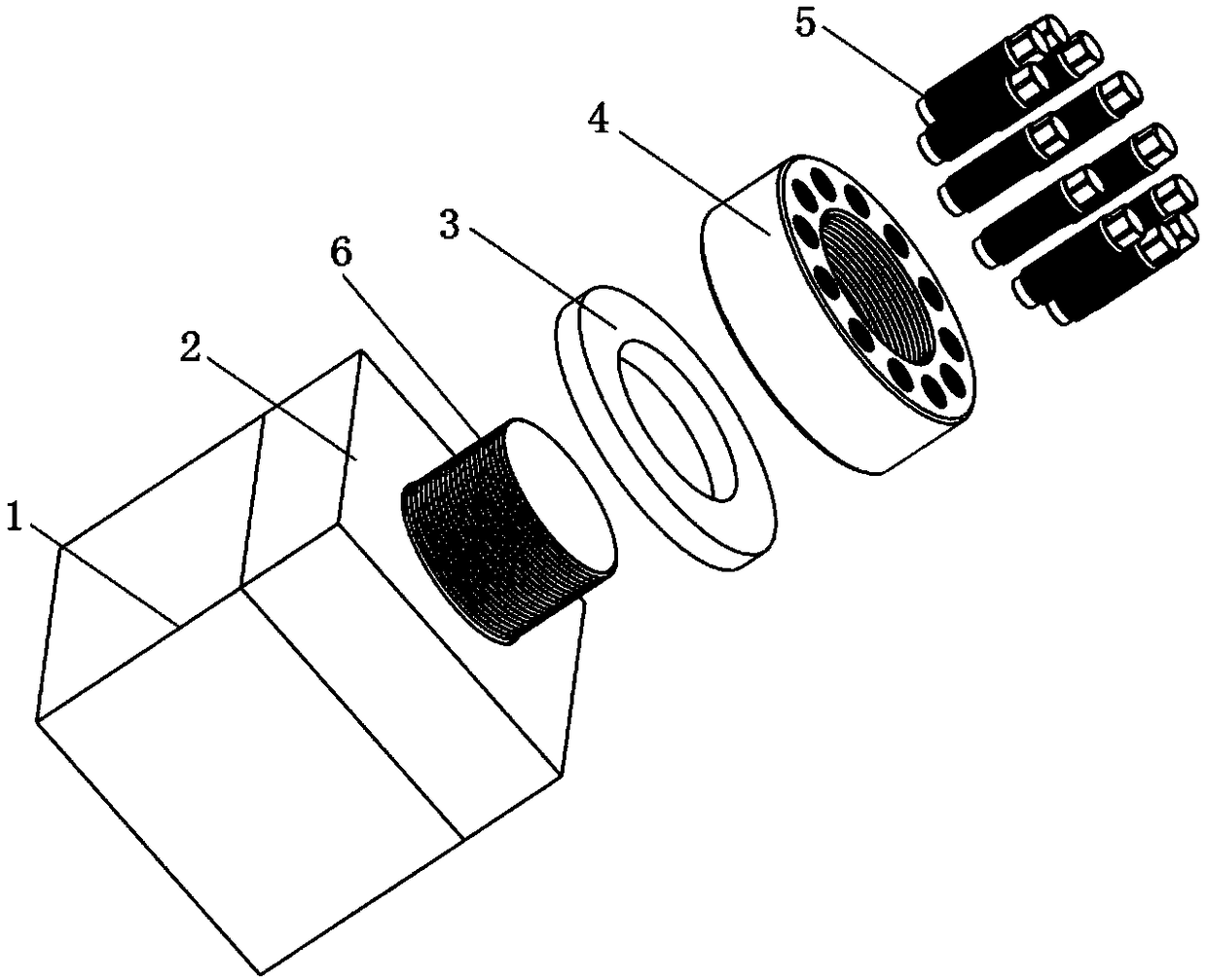

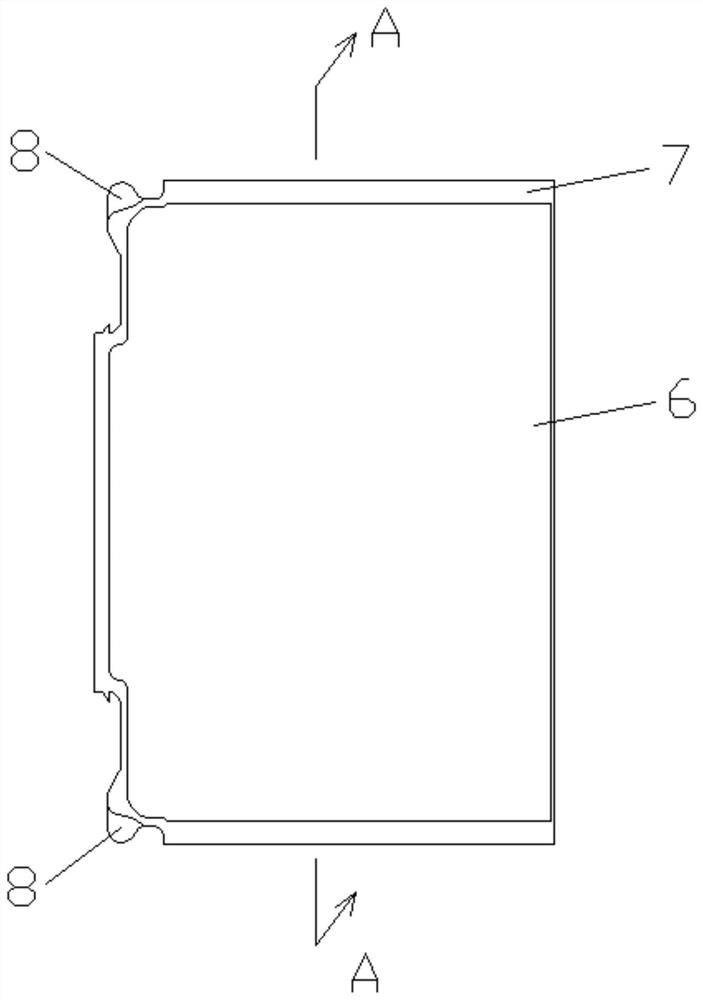

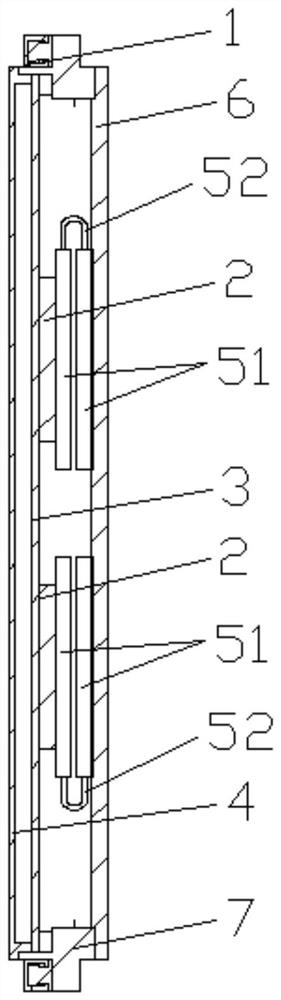

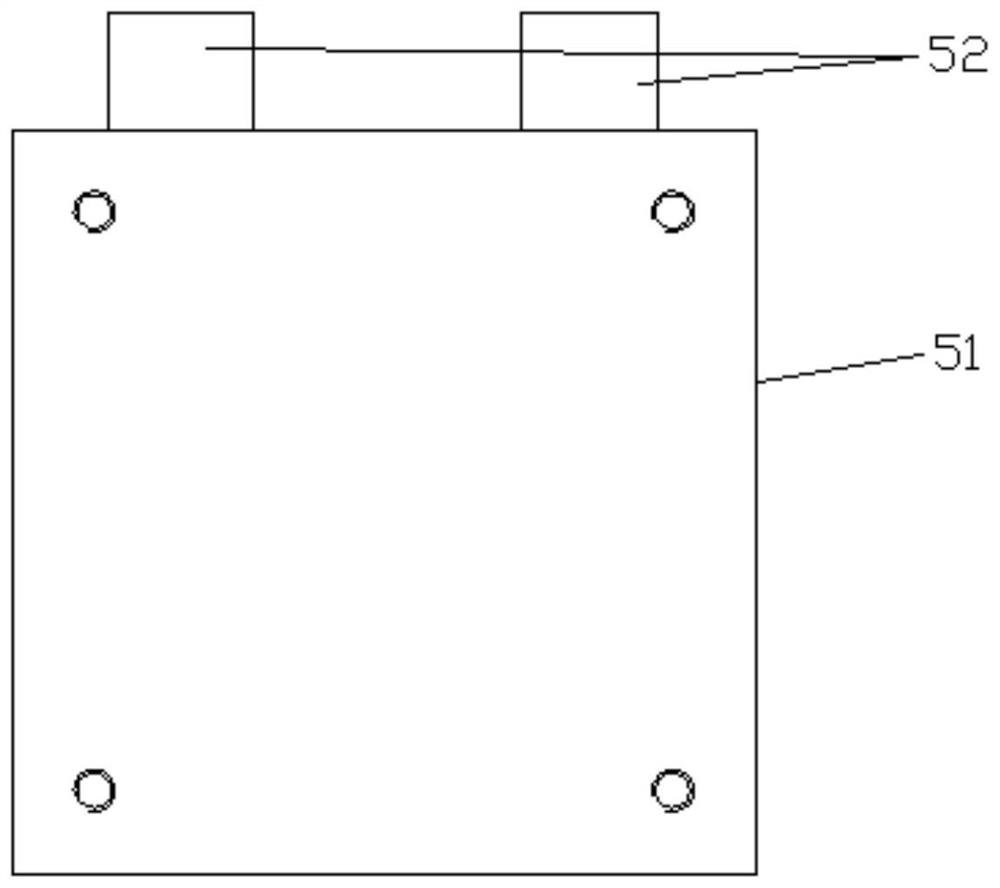

Speed reducer for planetary differential motion mechanical speed regulation

InactiveCN103708369AImprove contact accuracyExtended service lifeGear lubrication/coolingWinding mechanismsLow speedReduction drive

A speed reducer for planetary differential motion mechanical speed regulation comprises a front end cover 1, a box body, a ventilation cover 3, a rear end cover 4, a high-speed planetary portion and a low-speed planetary portion. The high-speed planetary portion comprises a high-speed gear shaft 5, a high-speed sun wheel 6, a high-speed planetary carrier 7, a high-speed planetary wheel shaft 8, a high-speed planetary wheel 9 and a high-speed inner gear 10. The high-speed gear shaft 5 penetrates out of the center of a bearing cover 11. The high-speed sun wheel 6 is installed on the high-speed gear shaft 5 through inner teeth. The high-speed planetary carrier 7 is installed on an umbrella handle gear. The low-speed planetary portion comprises a low-speed planetary frame 12, a low-speed planetary wheel shaft 13, a low-speed planetary wheel 14 and a low-speed inner gear 15. The low-speed planetary frame 12 is arranged inside the box body 2. The low-speed planetary wheel shaft 13 and the low-speed planetary wheel 14 are both distributed on the low-speed planetary frame 12. The low-speed inner gear 15 is meshed with the low-speed planetary wheel 14. Compared with the prior art, the speed reducer has the advantages of being high in transmission efficiency, long in service life, small in working noise, low in production cost, convenient to maintain and the like.

Owner:耒阳市湘发环保机械制造有限公司

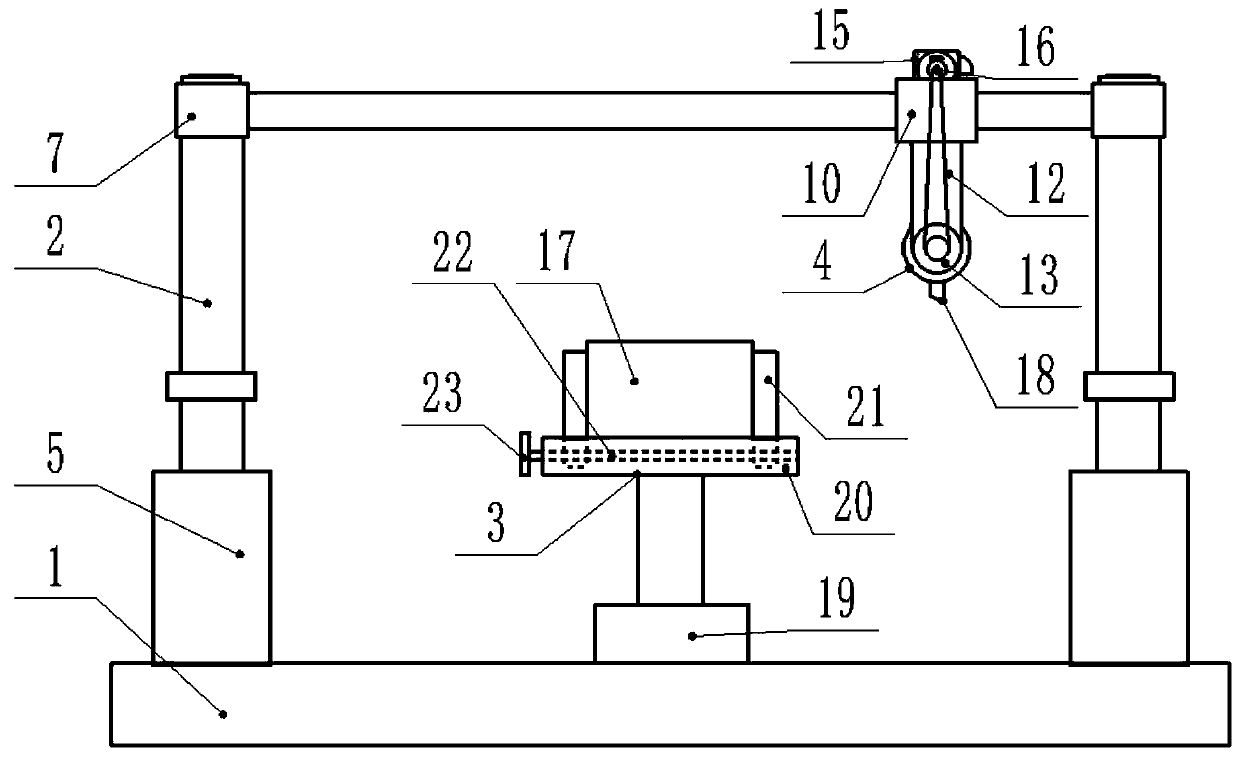

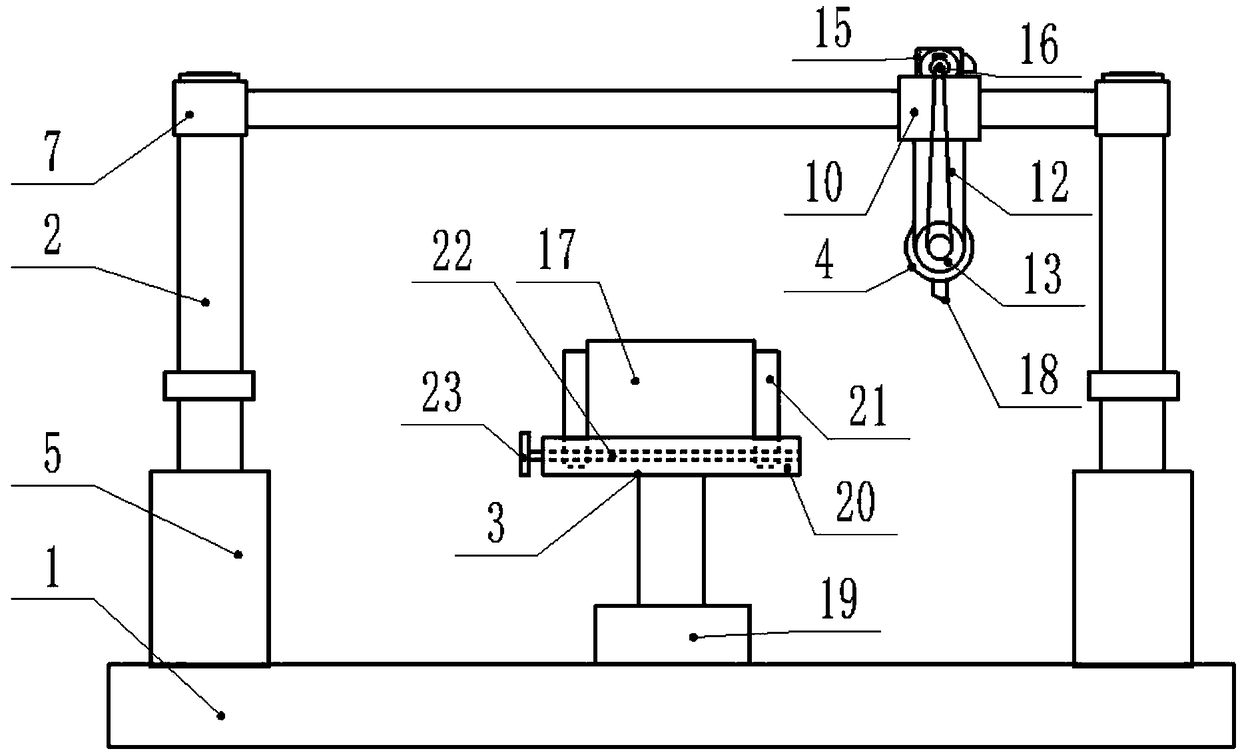

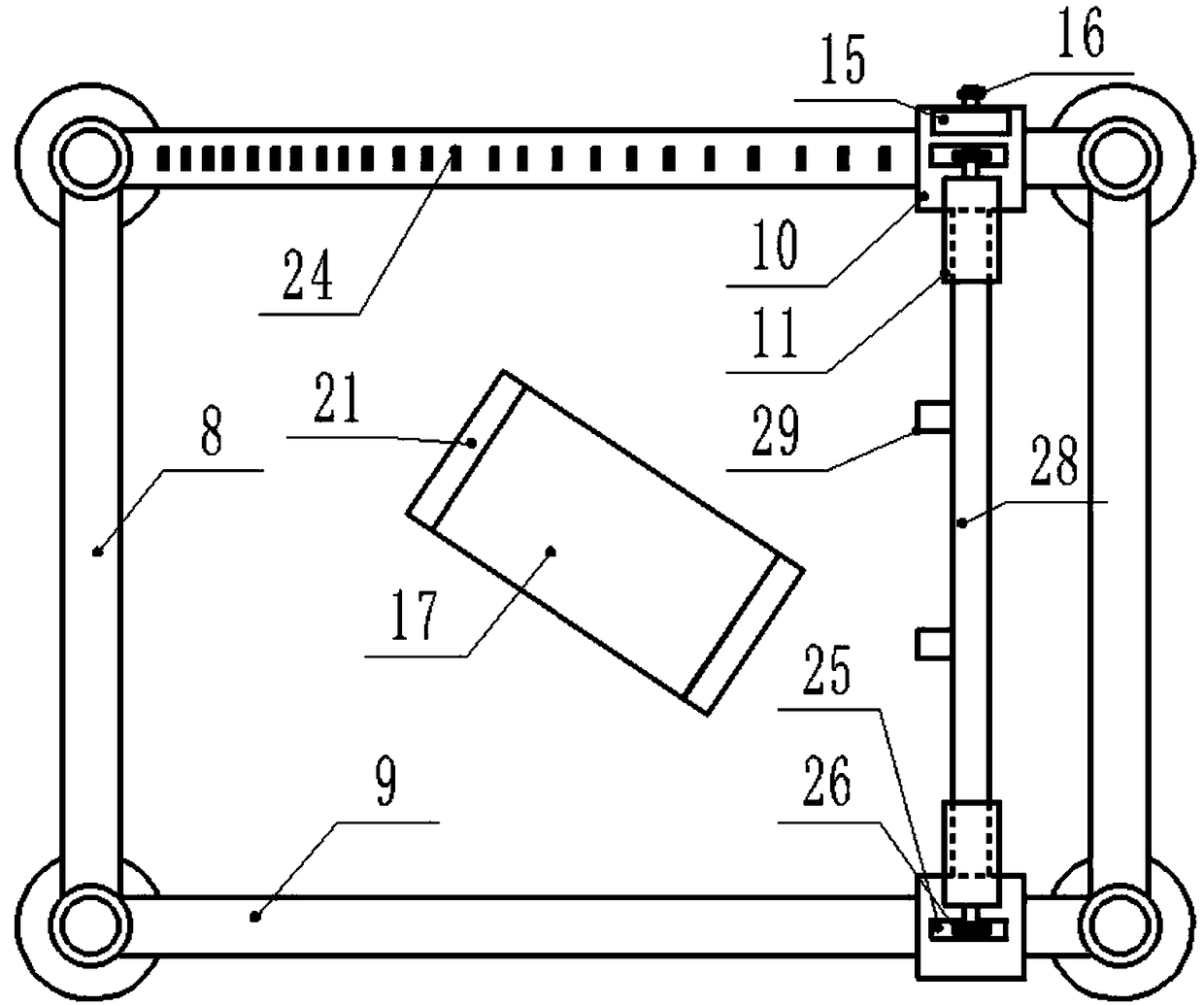

An electromechanical tile scraping device and tile scraping method

The invention discloses an electric mechanical bearing bush grinding device and a bearing bush grinding method. According to the electric mechanical bearing bush grinding device, the four corners of abearing bush grinding base are correspondingly provided with lifting motors, each lifting motor is connected with a lifting supporting column, and lifting sleeves are arranged at the upper ends of the lifting supporting columns; the four lifting sleeves are connected end to end through two transverse rods and two longitudinal rods to form a square frame structure, longitudinal moving blocks are correspondingly arranged on the two longitudinal rods in a sleeving mode, the two longitudinal moving blocks are correspondingly provided with moving motors, and the two moving motors synchronously drive the two longitudinal moving blocks to move left and right on the longitudinal rods; the lower portions of the longitudinal moving blocks are correspondingly connected with lifting rods, a hobbing cutter shaft is installed at one ends of the two lifting rods through a rotating seat, and a hobbing cutter shaft gear is arranged at one end of the hobbing cutter shaft; a hobbing cutter shaft motor is arranged on one of the longitudinal moving blocks, a rotating shaft gear is arranged on a rotating shaft of the hobbing cutter shaft motor, and the rotating shaft gear is in transmission connectionwith the hobbing cutter shaft gear through a chain; and a bearing bush clamping table is arranged in the middle of the bearing bush grinding base and is used for clamping a bearing bush, and the hobbing shaft is provided with a hobbing cutter for performing grinding on the bearing bush.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

Guide-rail injection molding technique of heavy numerically controlled machine

ActiveCN101380799BReduce labor intensityImprove contact accuracyLarge fixed membersFastening meansNumerical controlEngineering

The present invention discloses a guide way injection molding technology of a heavy numerical control machine tool working table. After the assembly precision of a lathe bed guide way meets the requirements, and a working table is processed, a static press oil cavity is manufactured on the surface of the lathe bed guide way; two sides of the lathe bed guide way corresponding to a face to be injected with glue are respectively provided with a support edge used for supporting the working table; and the working table is provided with a plurality of holes used for injecting the glue and exhausting. The core of the technology lies on constructing a glue-injecting cavity and evenly spraying demoulding agents on the contacted surface of the lathe bed guide way and adhesive when injecting the glue to ensure that a molded guide way is molded at one time. The present invention provides a guide way injection molding technology of the heavy numerical control machine tool working table, which has strong combination affinity and good adhesive bonding performance between a coating layer and metal and the high molding precision and good quality of the guide way and has the characteristic of the high molding efficiency and the long service life of the guide way.

Owner:JIER MACHINE TOOL GROUP

Processor base

InactiveCN107433457AImprove vibration resistanceImprove thermal stabilityLarge fixed membersHeat stabilityEngineering

The invention relates to a processor base applied to the field of equipment processing of numerically controlled machine tool industry. The processor base comprises a base body. A worktable placing tank and a magazine tool placing tank are arranged on the base body. The base body comprises two end surfaces and two side surfaces. A chip removal port communicating with the worktable placing tank is formed below the base body. Each of the side surfaces comprises a vertical portion located on the lower end and an inclined portion located on the upper end. The upper end of the inclined portion inclines toward the inner part of the base body and the side surface is wavy. The two side surfaces of the base body are arranged in a structure, one ends of which are closed. At the moment, the trapezoidal structure of the base is arranged, and the side surface is of the wavy shape, so that force dispersion in machine tool operation can be realized, the axial force and the radial force are reduced greatly, the internal stress and the extruding stress are reduced, and the unloading force is extremely enhanced. Meanwhile, the rigidity, the strength and the precision of the machine tool are improved by the processor base, the vibration resistance and the heat stability of the base are enhanced, and the stress of the base is relatively balanced.

Owner:张功煜

Electric mechanical bearing bush grinding device and bearing bush grinding method

The invention discloses an electric mechanical bearing bush grinding device and a bearing bush grinding method. According to the electric mechanical bearing bush grinding device, the four corners of abearing bush grinding base are correspondingly provided with lifting motors, each lifting motor is connected with a lifting supporting column, and lifting sleeves are arranged at the upper ends of the lifting supporting columns; the four lifting sleeves are connected end to end through two transverse rods and two longitudinal rods to form a square frame structure, longitudinal moving blocks are correspondingly arranged on the two longitudinal rods in a sleeving mode, the two longitudinal moving blocks are correspondingly provided with moving motors, and the two moving motors synchronously drive the two longitudinal moving blocks to move left and right on the longitudinal rods; the lower portions of the longitudinal moving blocks are correspondingly connected with lifting rods, a hobbing cutter shaft is installed at one ends of the two lifting rods through a rotating seat, and a hobbing cutter shaft gear is arranged at one end of the hobbing cutter shaft; a hobbing cutter shaft motor is arranged on one of the longitudinal moving blocks, a rotating shaft gear is arranged on a rotating shaft of the hobbing cutter shaft motor, and the rotating shaft gear is in transmission connectionwith the hobbing cutter shaft gear through a chain; and a bearing bush clamping table is arranged in the middle of the bearing bush grinding base and is used for clamping a bearing bush, and the hobbing shaft is provided with a hobbing cutter for performing grinding on the bearing bush.

Owner:STATE GRID SICHUAN ELECTRIC POWER

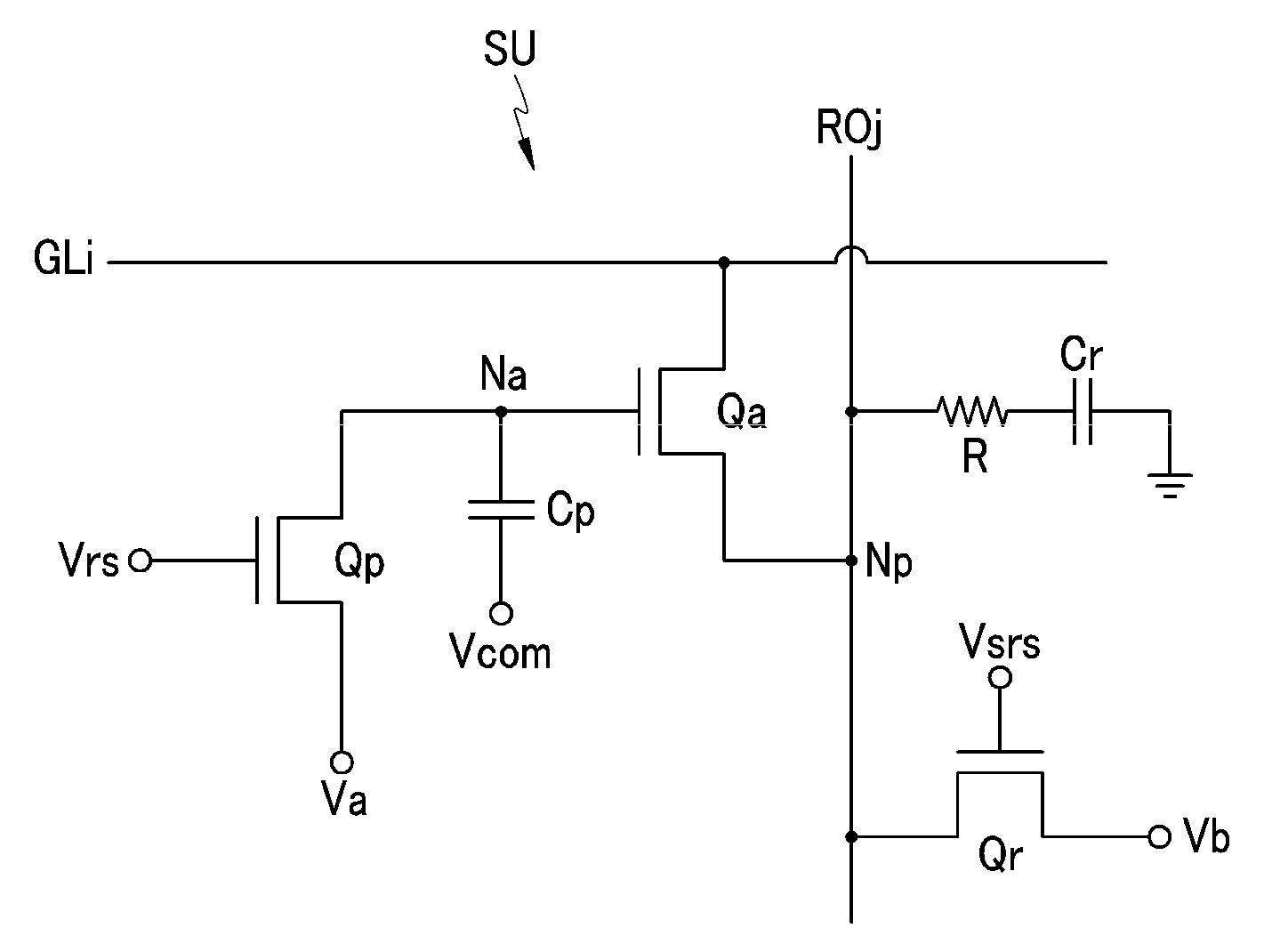

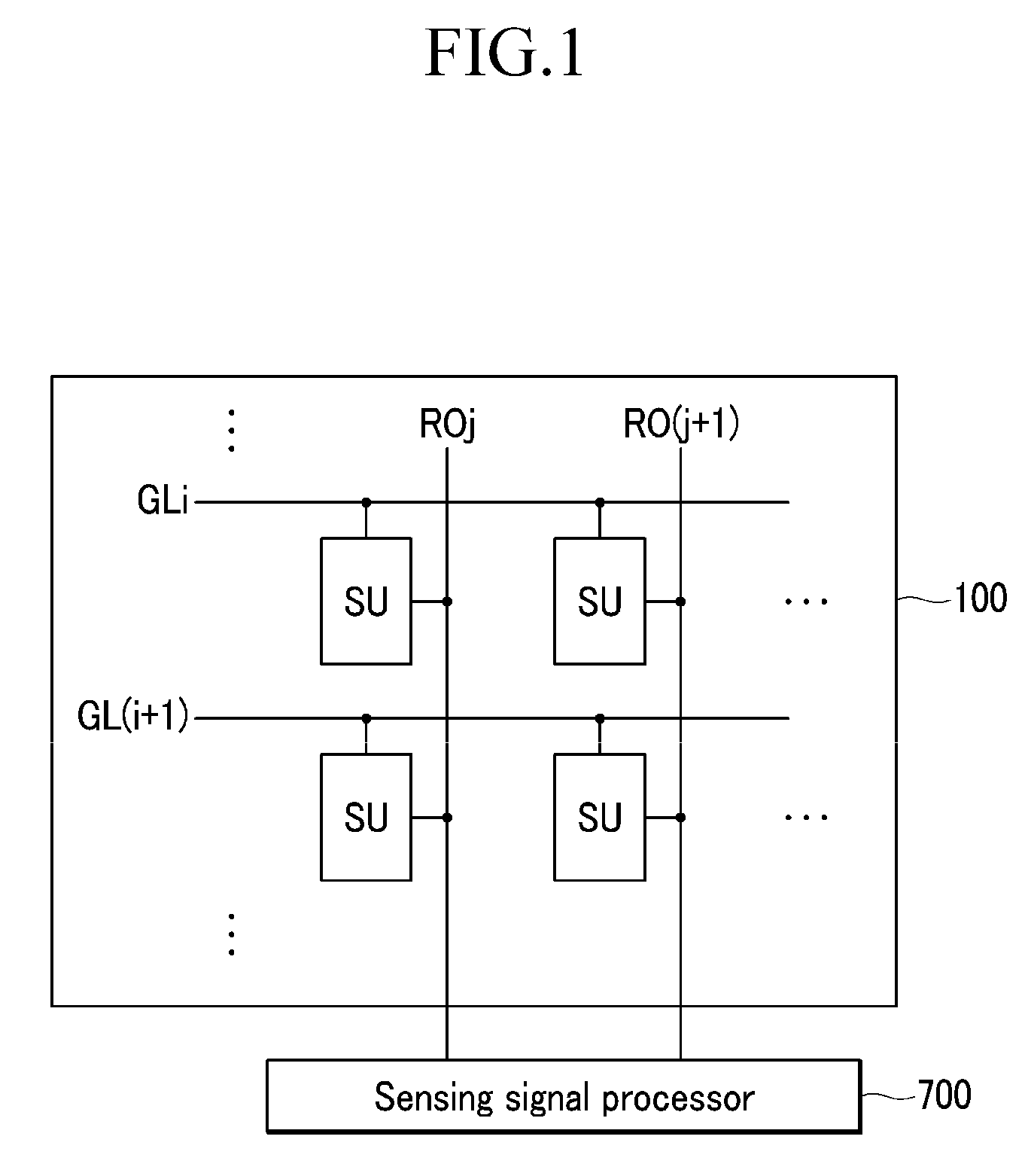

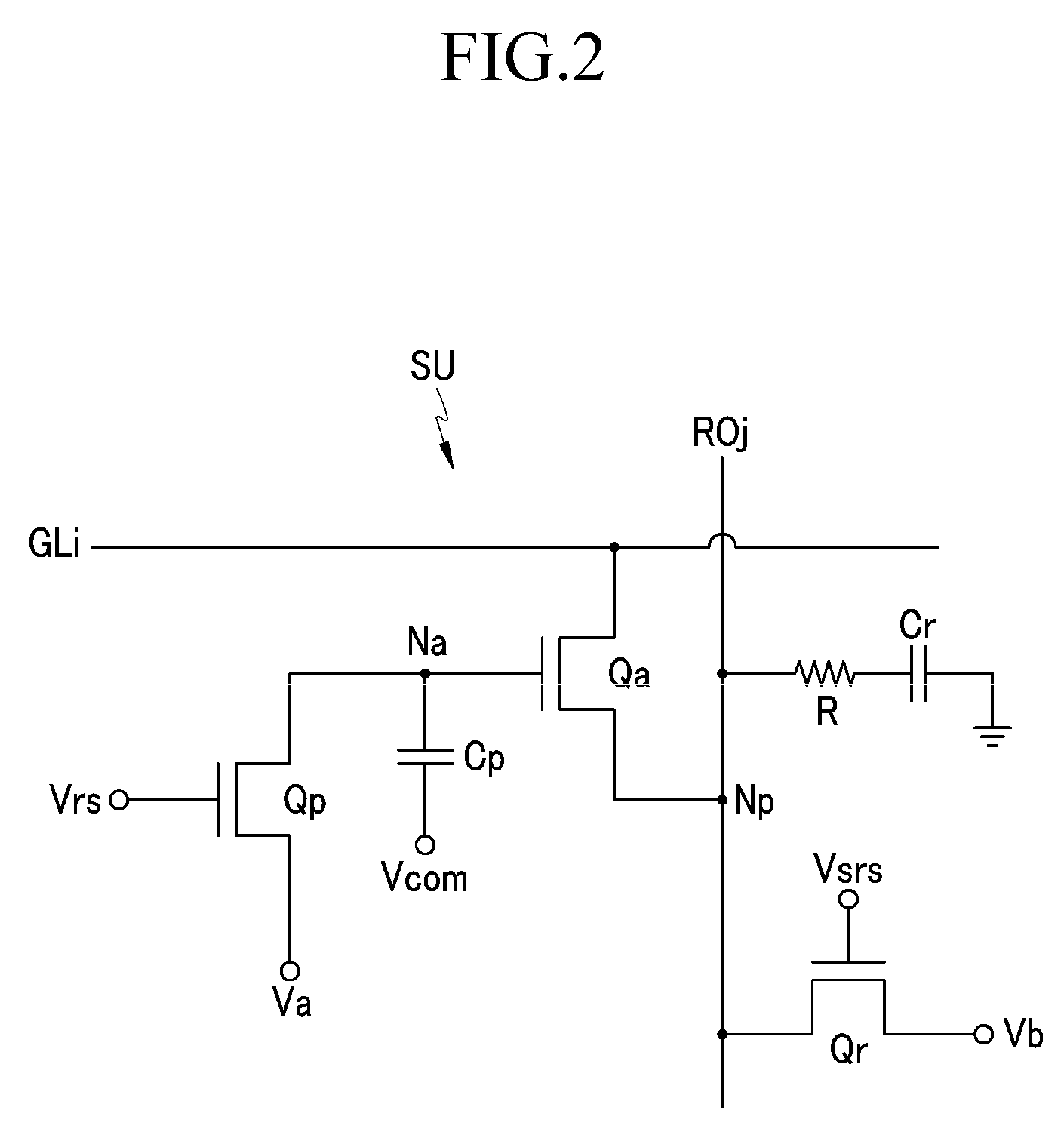

Photo sensor, display device including the same and driving method thereof

ActiveUS9214106B2Increase the aperture ratioImprove touch accuracyRadiation pyrometryStatic indicating devicesScan lineControl signal

Owner:SAMSUNG DISPLAY CO LTD +1

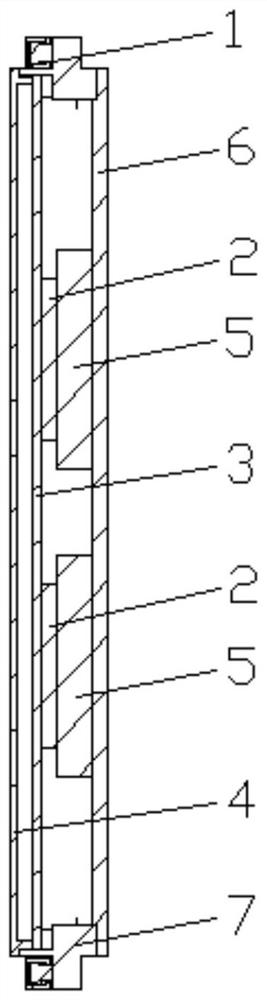

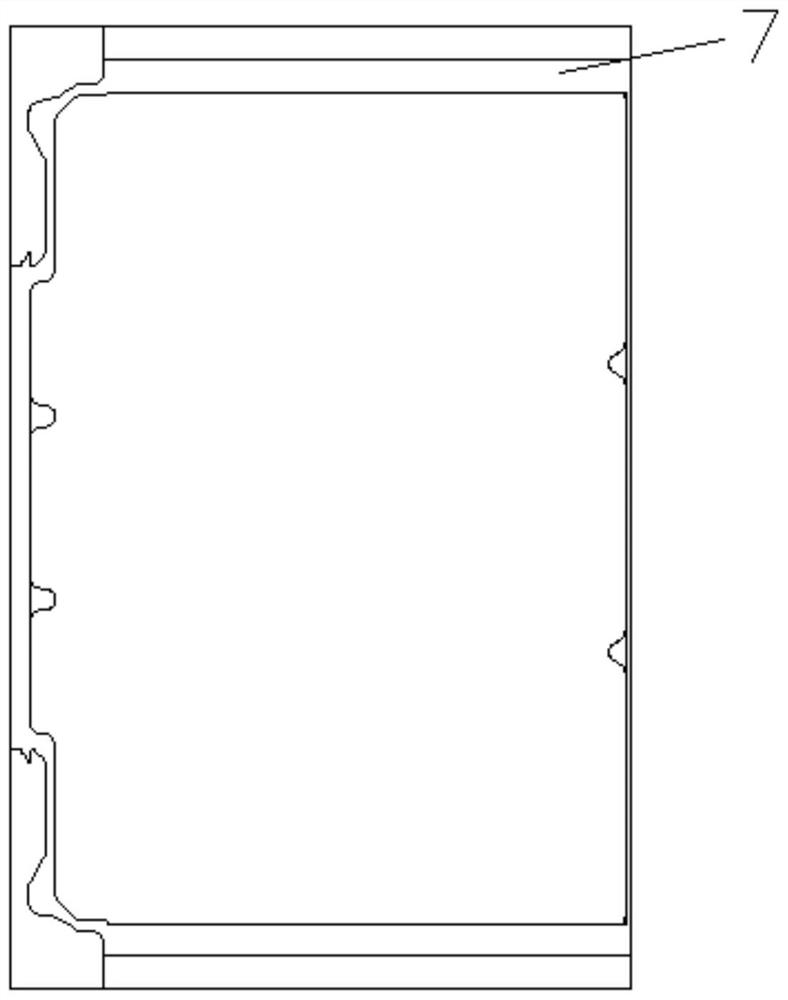

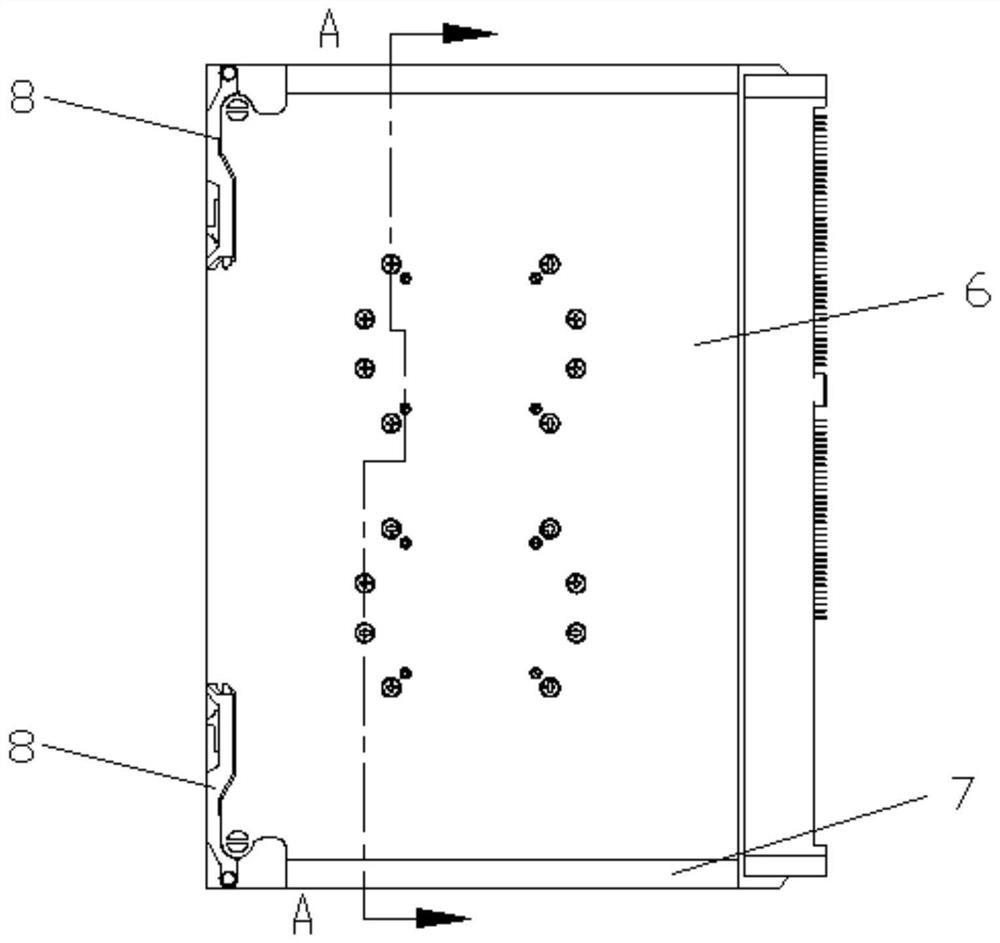

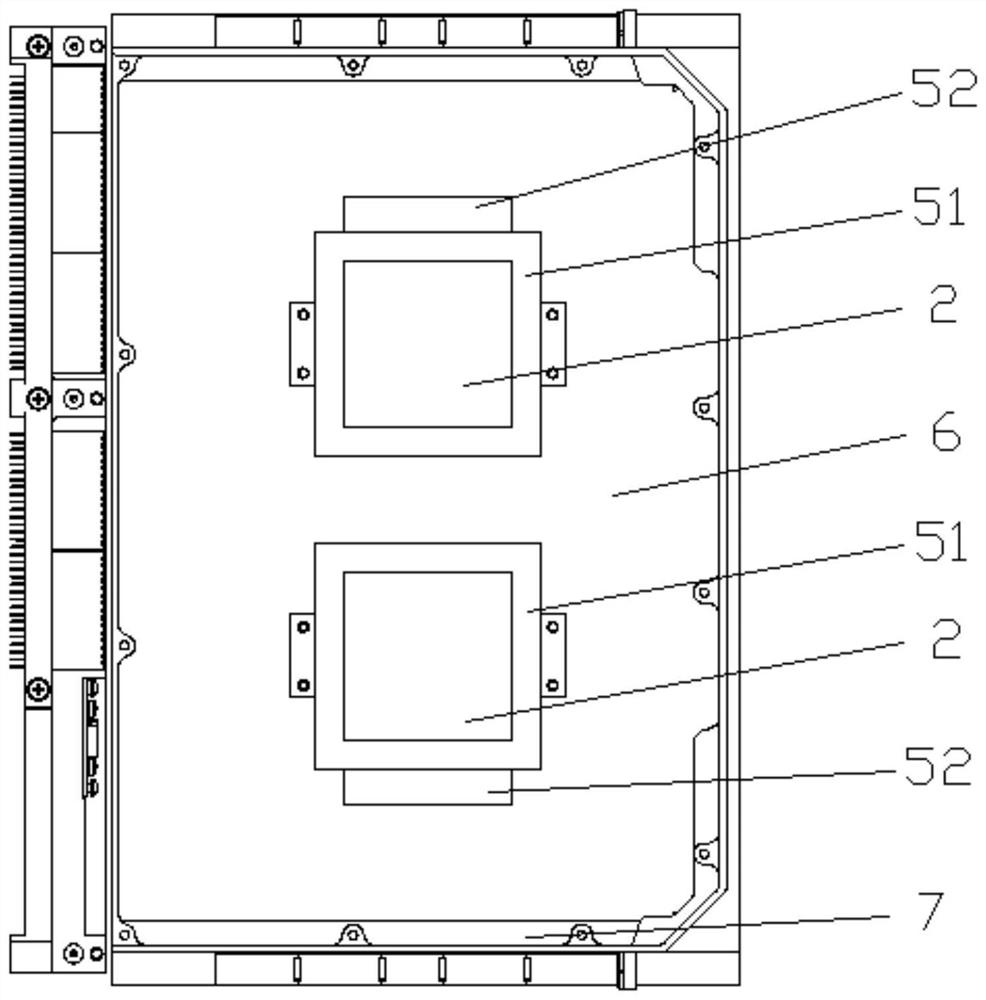

Heat dissipation shell, processing method thereof and conduction heat dissipation module

InactiveCN114040642AImprove processing efficiencyLow costSupport structure mountingModifications by conduction heat transferThermodynamicsMechanical engineering

The invention relates to a heat dissipation shell and a processing method thereof and a conduction heat dissipation module. The heat dissipation shell comprises a frame and a heat transfer bottom plate, wherein the heat transfer bottom plate is detachably installed on one side of the frame; the other side of the frame is fixedly connected with an extension part, and the extension part is used for fixing the PCB; at least one heat transfer boss is detachably mounted on one side, close to the frame, of the heat transfer bottom plate; and a PCB (Printed Circuit Board) and a chip are further included. The processing method of the heat dissipation shell comprises the steps that the frame, the heat transfer bottom plate and the cover plate are sequentially machined and formed, and the other side of the frame extends outwards to form the extension part; and the heat transfer bottom plate is detachably installed on one side of the frame, and a heat transfer boss is detachably installed on the side, close to the frame, of the heat transfer bottom plate, so that the heat dissipation shell is formed. The heat dissipation shell has the beneficial effects that the structure is simple, and the heat dissipation shell adopts a split design, so that the contact precision of the heat transfer boss and the chip is improved, the standardized processing production of a single component is realized, the processing efficiency is greatly improved, and the disassembly and assembly are convenient.

Owner:GUILIN CHANGHAI DEV

Heat dissipation shell, processing method thereof and conduction heat dissipation module

InactiveCN114040641AImprove heat transfer performanceDissipate quicklySupport structure mountingModifications by conduction heat transferEngineeringMachining

The invention relates to a heat dissipation shell and a processing method thereof and a conduction heat dissipation module. The heat dissipation shell comprises a frame and a heat transfer bottom plate, wherein the heat transfer bottom plate is detachably installed on one side of the frame; the other side of the frame is fixedly connected with an extension part, and the extension part is used for fixing the PCB; and at least one thickness-adjustable flexible heat transfer device is detachably mounted on one side, close to the frame, of the heat transfer bottom plate. The heat dissipation shell also comprises a PCB and a chip. The processing method of the heat dissipation shell comprises the steps that the frame, the heat transfer bottom plate and the cover plate are sequentially machined and formed, and the other side of the frame extends outwards to form the extension part; and the heat transfer bottom plate is detachably installed on one side of the frame, and the flexible heat transfer device is detachably installed on the side, close to the frame, of the heat transfer bottom plate, so that the heat dissipation shell is formed. The heat dissipation shell is simple in structure, and the heat dissipation shell is designed in a split mode, so that the contact precision of the flexible heat transfer device and the chip is improved, standardized machining and production of a single component are achieved, the machining efficiency is greatly improved, and disassembly and assembly are convenient.

Owner:GUILIN CHANGHAI DEV

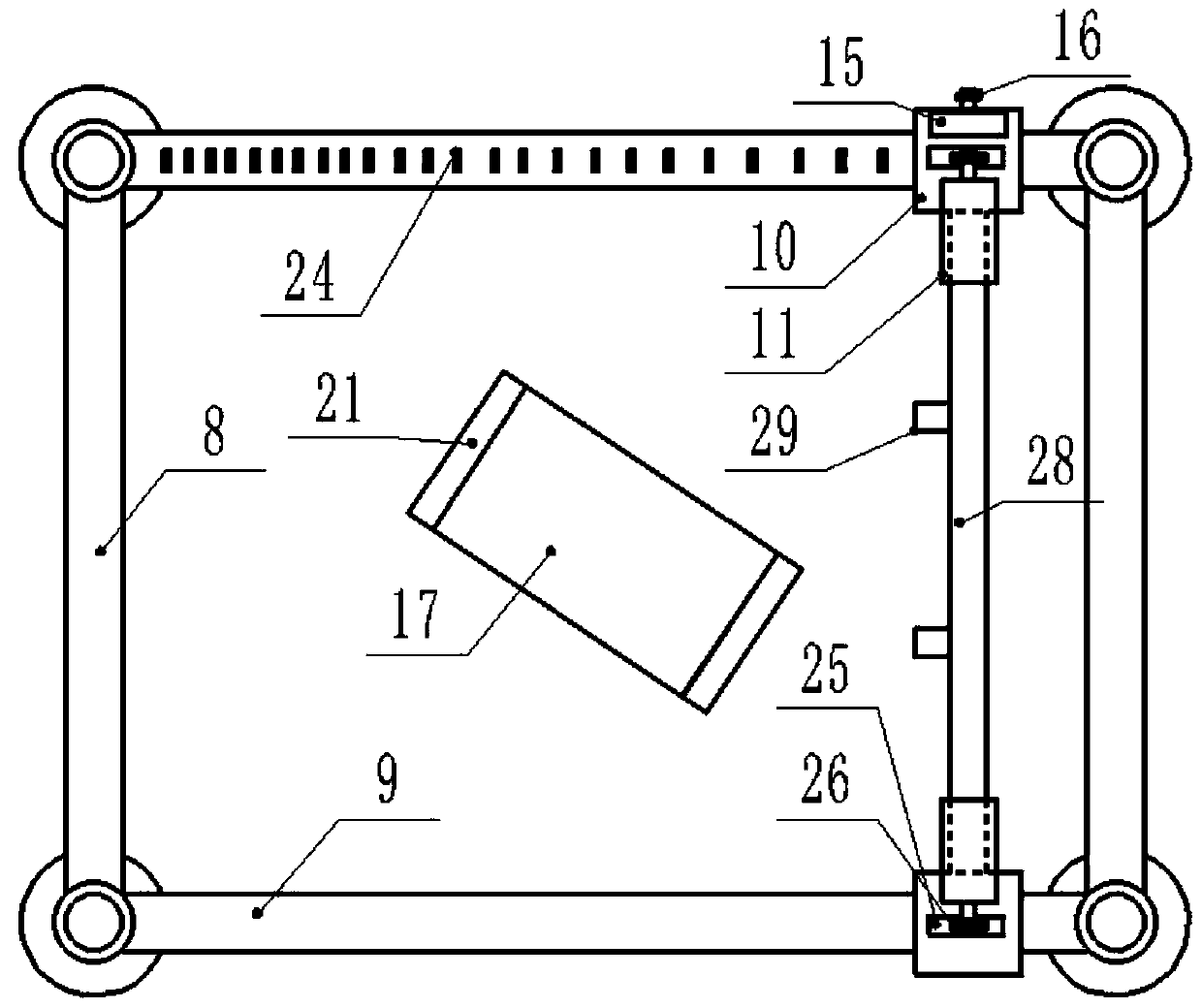

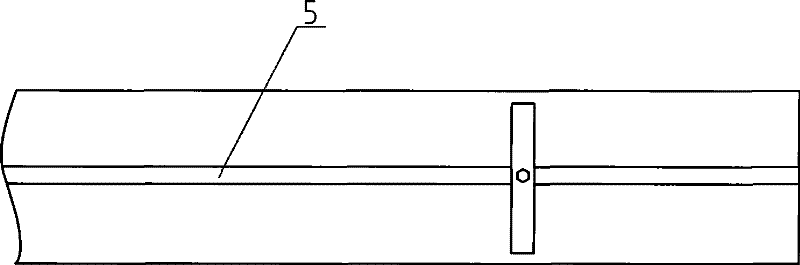

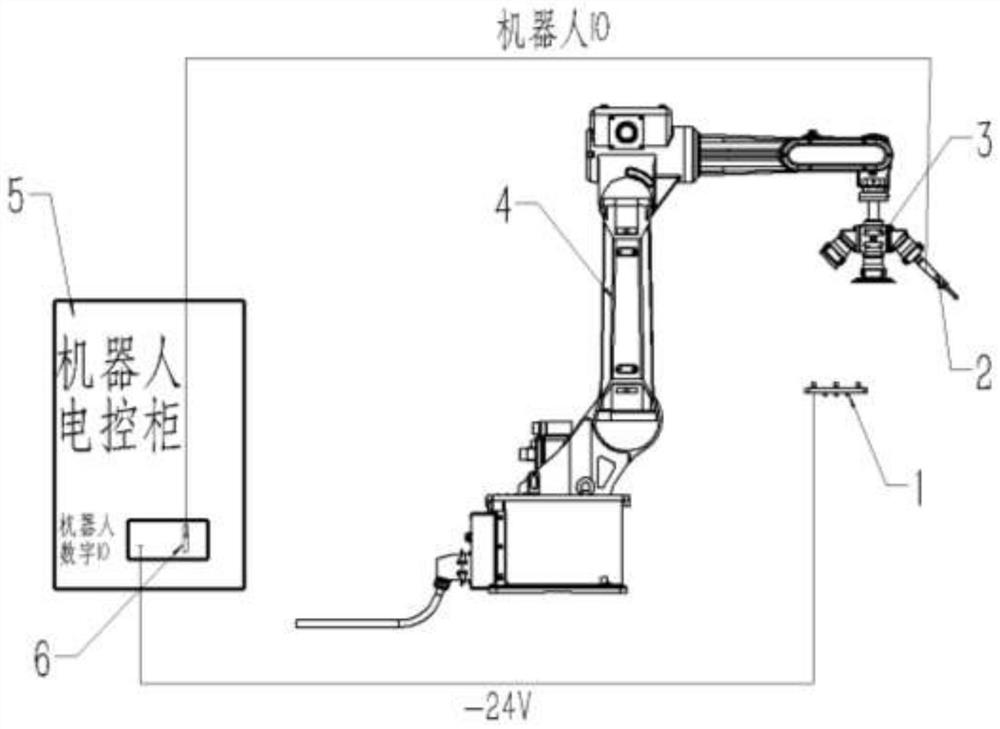

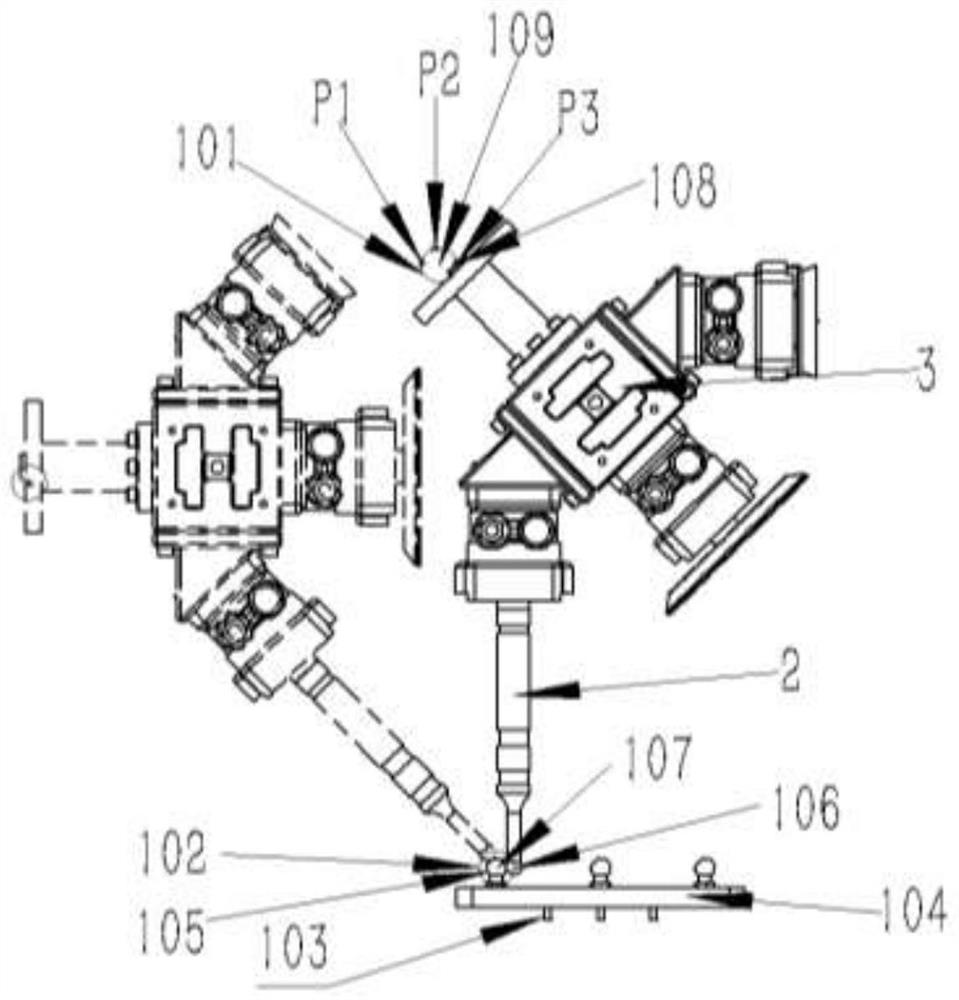

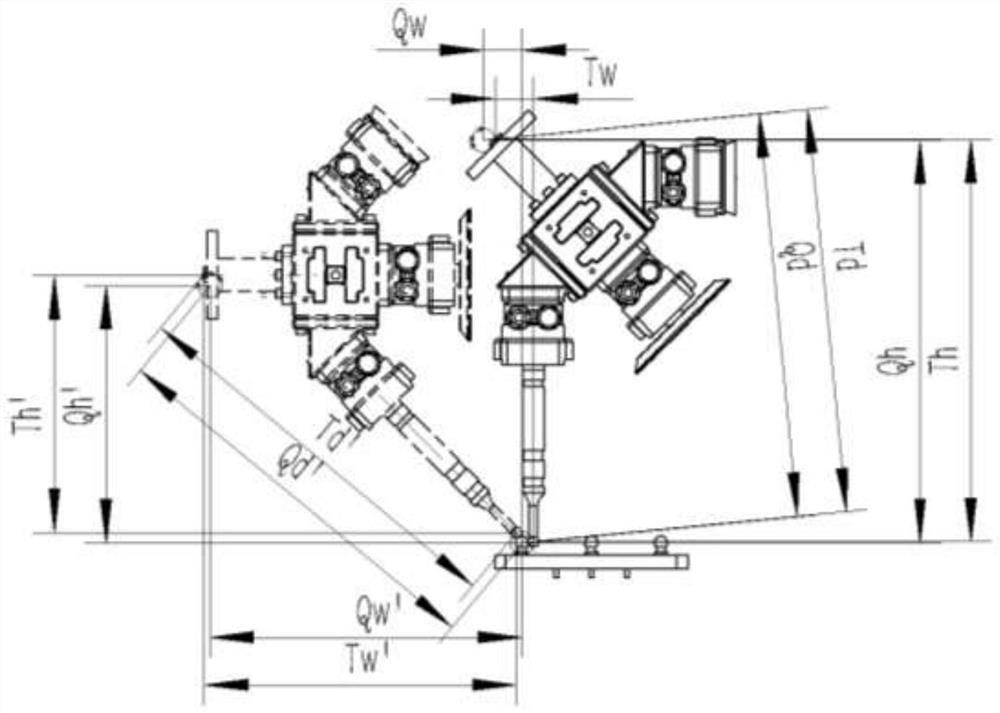

Industrial robot automatic tool workpiece calibration method

PendingCN114536324AImprove contact accuracyProgramme-controlled manipulatorControl engineeringProcess engineering

The invention discloses an industrial robot automatic tool workpiece calibration method. The industrial robot automatic tool workpiece calibration method comprises the following working steps that firstly, all hardware parts are connected according to structures and connection relations; 2, operating an industrial robot 4 to enable an edge finder 2 to be at a point position in front of the reference ball 105, wherein the edge finder 2 is not in contact with the reference ball 105 at the moment; and step 3, running an automatic calibration program of the robot, and enabling the robot to automatically search the 105-reference ball in a fixed posture, so that the 2-edge finder is in contact with the 105-reference ball. Fourthly, the robot (4) automatically runs in a fixed posture and makes contact with the reference ball (105) for three times, and the points P1, P2 and P3 are recorded respectively. And 5, according to the three points P1, P2 and P3, the circle center is solved, and 109-robot moving trajectory center coordinates are calculated. And 6, the posture of the robot 4 is changed. The positions of the centers of circles of the two balls are solved by utilizing multiple tangency of the two balls, point contact during contact can be ensured by ball contact, and the contact precision is improved to the maximum extent.

Owner:重庆智能机器人研究院

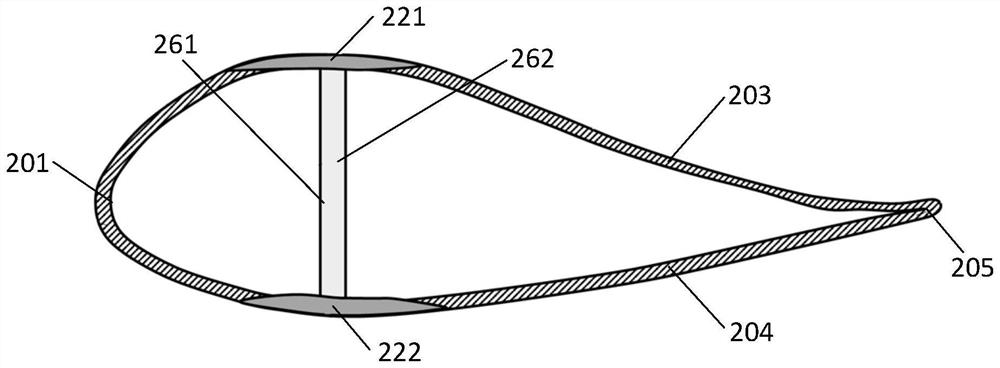

Lightning protection device for fan blade and installation method of lightning protection device

PendingCN114466972AReduce lightning damageReduce contact areaFinal product manufactureWind motor assemblyFan bladeScrew thread

The invention discloses a lightning protection device for a fan blade. The lightning protection device comprises a lightning arrester and a lightning arrester base. Wherein the lightning arrester comprises a connecting part, a lightning arresting part and a positioning part, the lightning arresting part is used for leading lightning, the surface of the connecting part is provided with external threads and used for being connected with the lightning arrester base, and the positioning part is arranged between the connecting part and the lightning arresting part, so that the positioning part can be matched with the shape of the concave part in the threaded hole after the connecting part is screwed into the threaded hole. The lightning arrester base is used for being connected with a lightning arrester and leading out lightning current received by the lightning arrester during lightning leading and comprises an insulating layer and at least one threaded hole, the insulating layer is arranged on the surface of the lightning arrester base, and the at least one threaded hole is formed in the base surface, facing a fan blade, of the lightning arrester base. The length direction of the threaded hole is perpendicular to the surface of the base, the threaded hole is matched with the external threads, and the end, close to the surface of the base, of the threaded hole is provided with a concave part matched with the positioning part in shape.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

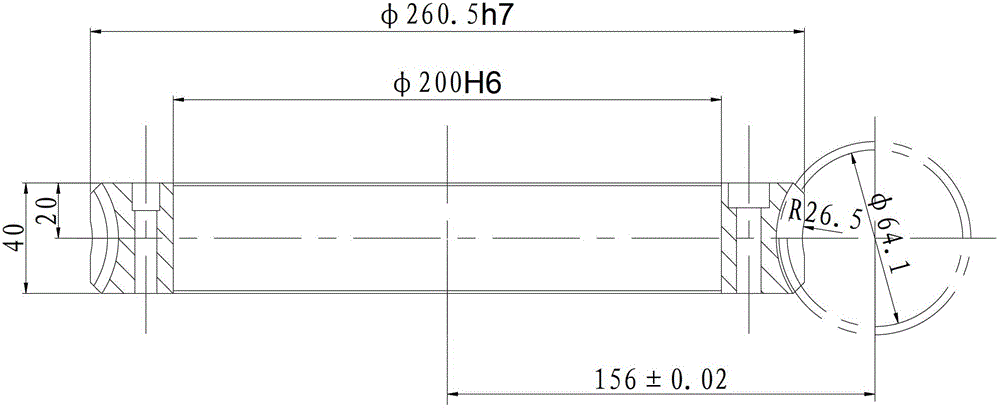

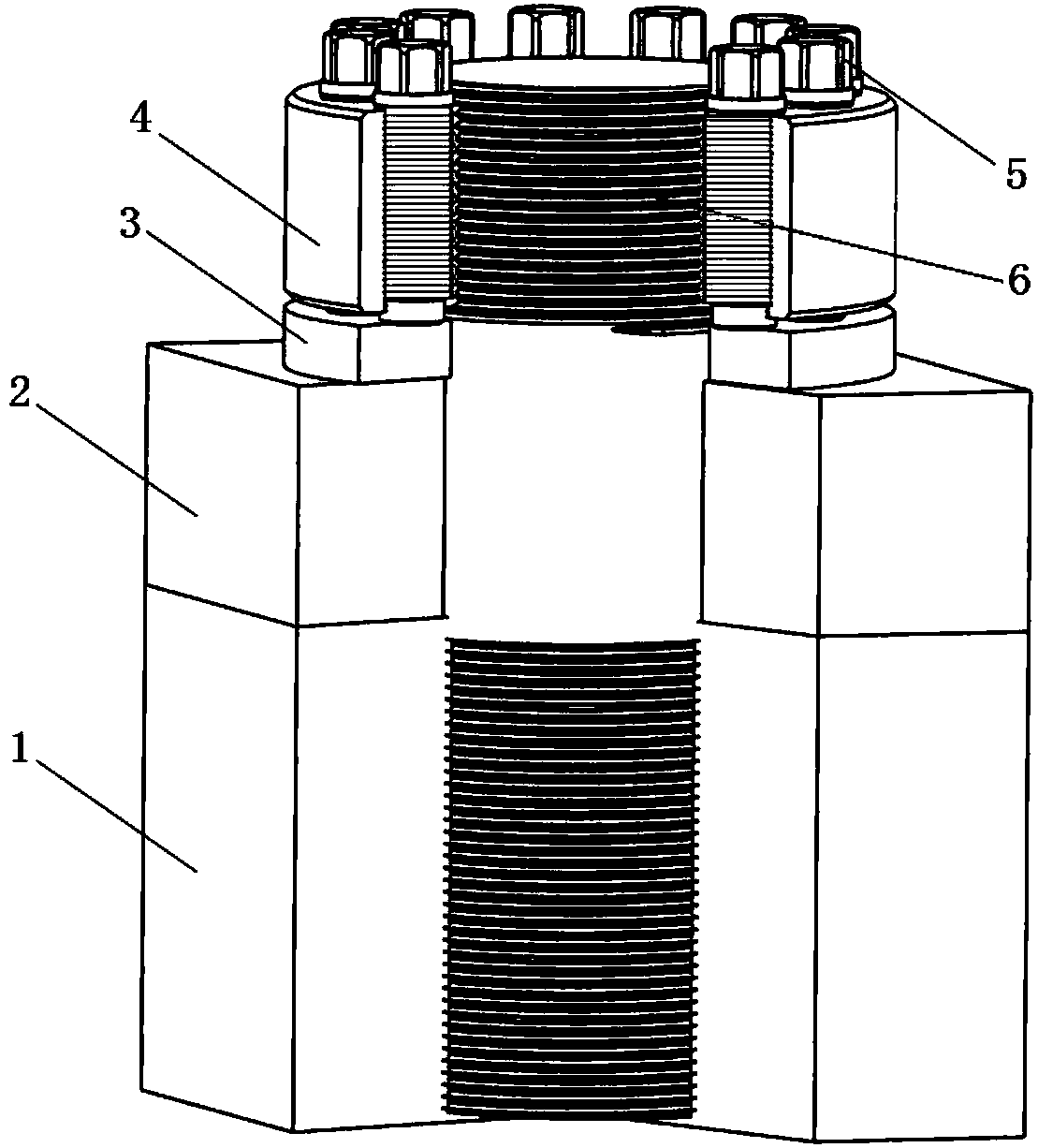

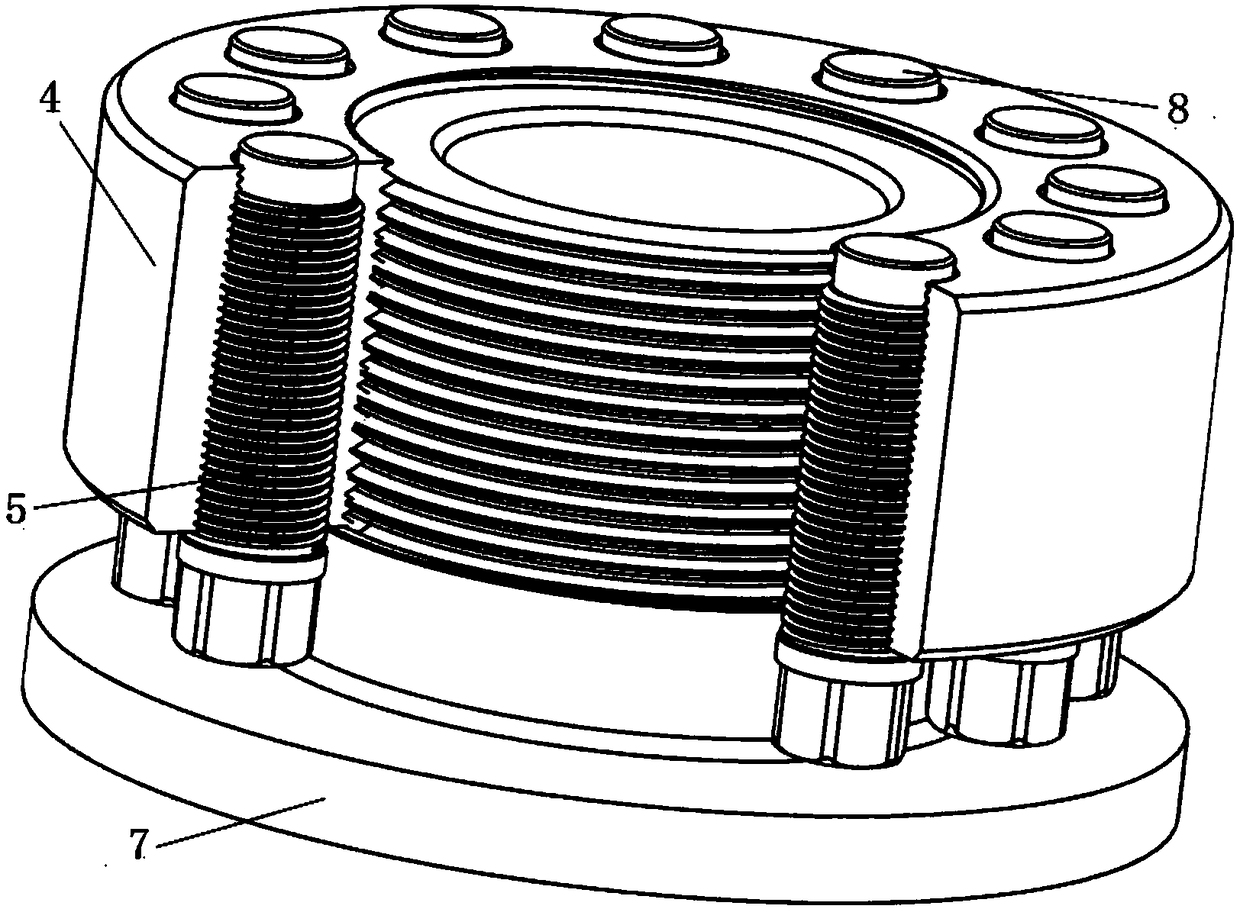

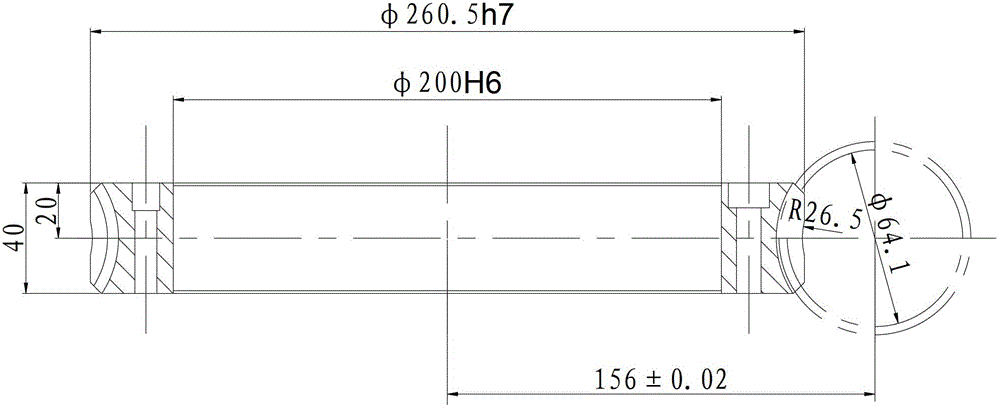

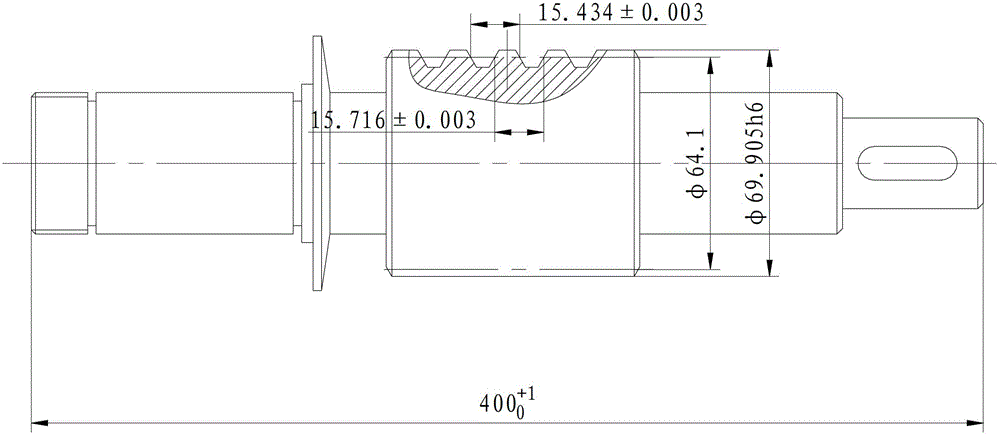

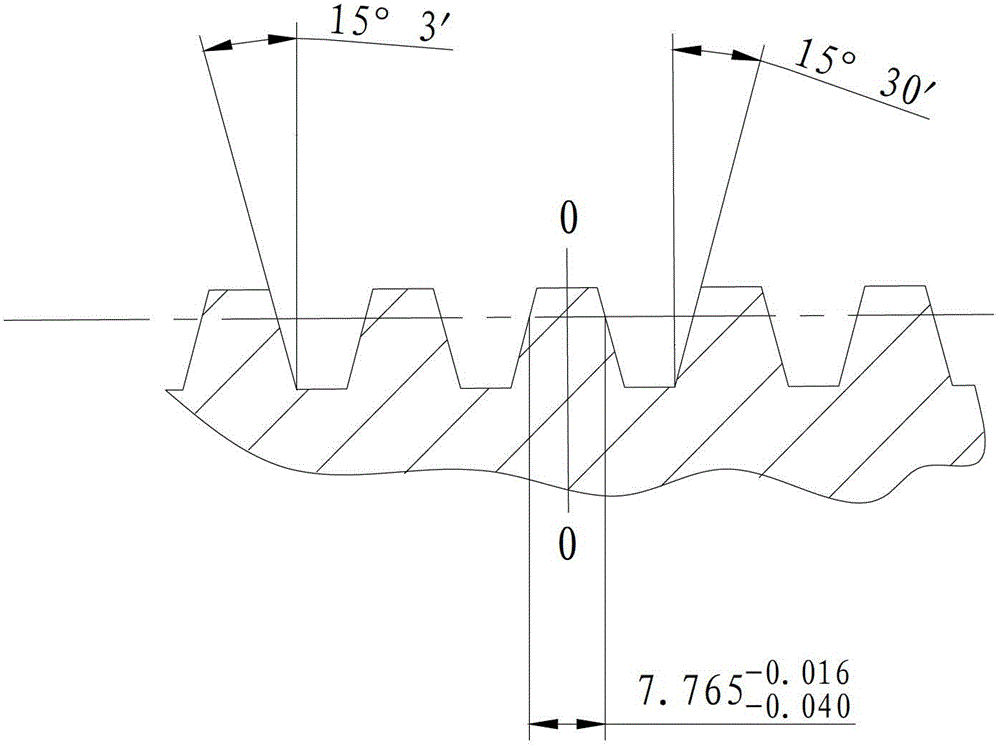

Method for improving contact precision of pushing screws small end surfaces in super nut and gasket

ActiveCN108481103AAvoid uneven forceImprove contact accuracyGrinding work supportsPlane surface grinding machinesScrew threadGrinding wheel

The invention discloses a method for improving the contact precision of pushing screws small end surfaces in a super nut and a gasket. The method specifically comprises the following steps of 1, a setof pushing screws to be machined are uniformly arranged in threaded holes in the periphery of a super nut before grinding, and a certain pre-tightening force is exerted on the pushing screws so as toprevent the pushing screws from loosening during grinding; 2, an external thread of a grinding tool is installed in the internal large threaded hole in the middle of the super nut with the pushing screws in the step 1 and is pre-tightened, enabling a small step surface of the grinding tool to be tightly attached to the bottom end surface of the super nut; and 3, a whole set of grinding tool to beground after being installed in the step 2 is placed on a workbench, so that the tool positioning surface of the grinding tool is sucked on a grinding machine sucking disc, a grinding machine wheel is used for carrying out unified grinding and machining on the small end surfaces of all the pushing screws, and until all the small end surfaces of the pushing screws are ground.

Owner:成都国科检测技术有限公司

Machining method of worm gear tooth

The invention relates to a machining method for a worm gear tooth part. The machining method comprises the steps that S1, arc machining is conducted on the worm gear tooth part; S2, the half angles of hobs and the center distance between the center of each hob and the center of a worm gear are calculated; S3, rough hobbing is conducted on the worm gear tooth part; S4, semi-finish hobbing is conducted on the worm gear tooth part; S5, finish hobbing is conducted on the worm gear tooth part; S6, grinding is conducted on the worm gear tooth part. The step S3, the step S4, the step S5 and the step S6 are all performed on a gear hobbing machine, and the same datum plane is utilized; the worm gear hubs used for gear hobbing conducted on the worm gear tooth part in the step S3, the step S4 and the step S5 are large-diameter worm gear hobs. The machining method has the advantages that a machined worm gear is high in accuracy and stable in transmission, contacting surfaces are easy to match, gear teeth are good in abrasion resistance, and bending strength is high.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Processing technology based on green silicon carbide grinding wheel

The invention relates to the technical field of grinding wheel machining application, in particular to a green silicon carbide grinding wheel-based machining process, which comprises the following steps of: (1) establishing a green silicon carbide grinding wheel finish machining database; (2) green silicon carbide grinding wheel machining parameters are selected from the database, and then a machining scheme is made; (3) processing the material according to the processing scheme; a green silicon carbide grinding wheel finish machining database is established, optimal green silicon carbide grinding wheel machining parameters are designed and selected, and the prepared polishing solution is added in the tough material machining process, so that the defects of technicians due to working experience, personal skills and detection equipment can be effectively reduced, and the machining efficiency is improved. The quality of the flatness and glossiness of the surface of the material cannot be guaranteed, the waste of raw materials is serious, and the polishing efficiency is low.

Owner:江苏砺彩砂品新材料有限公司

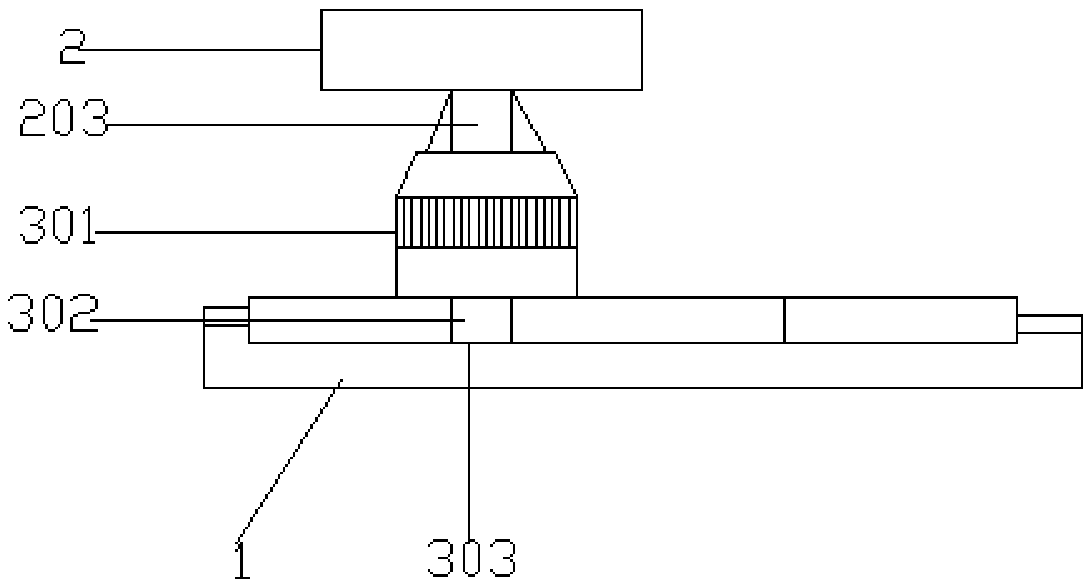

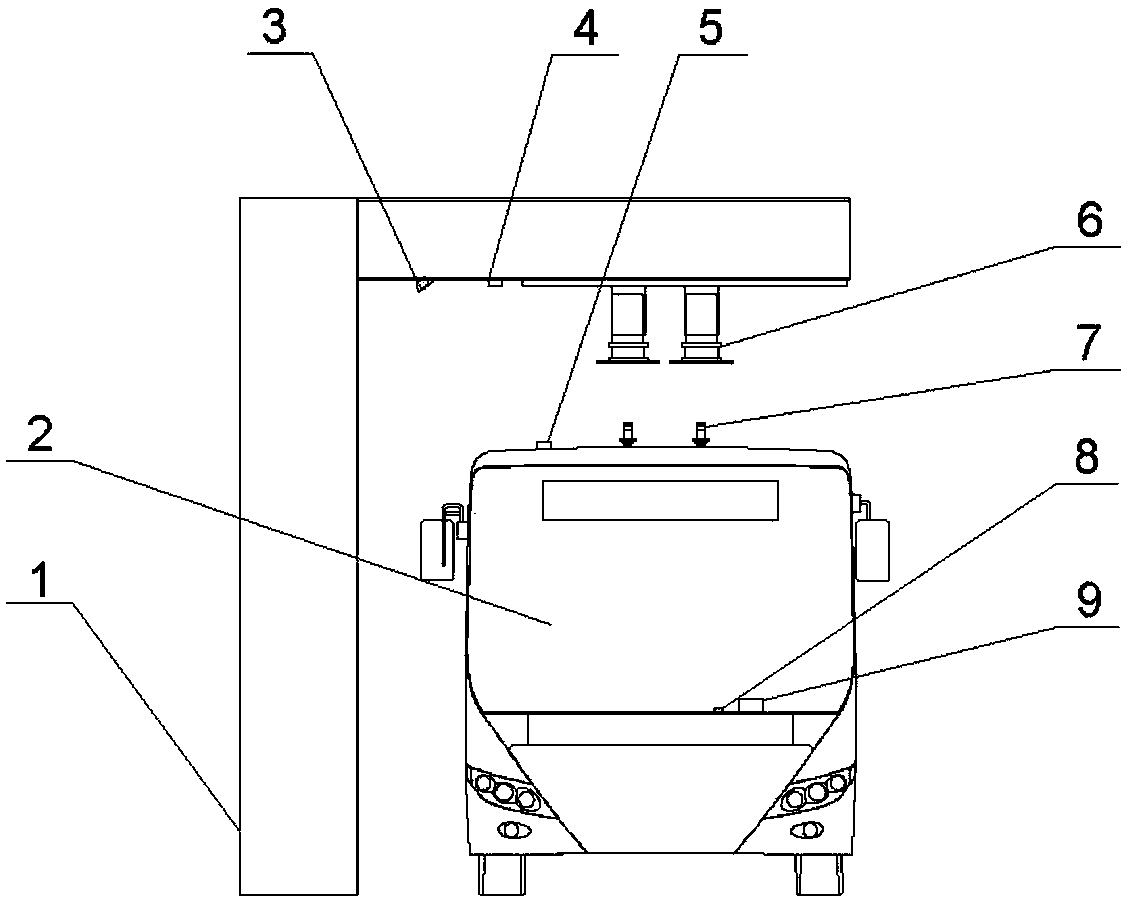

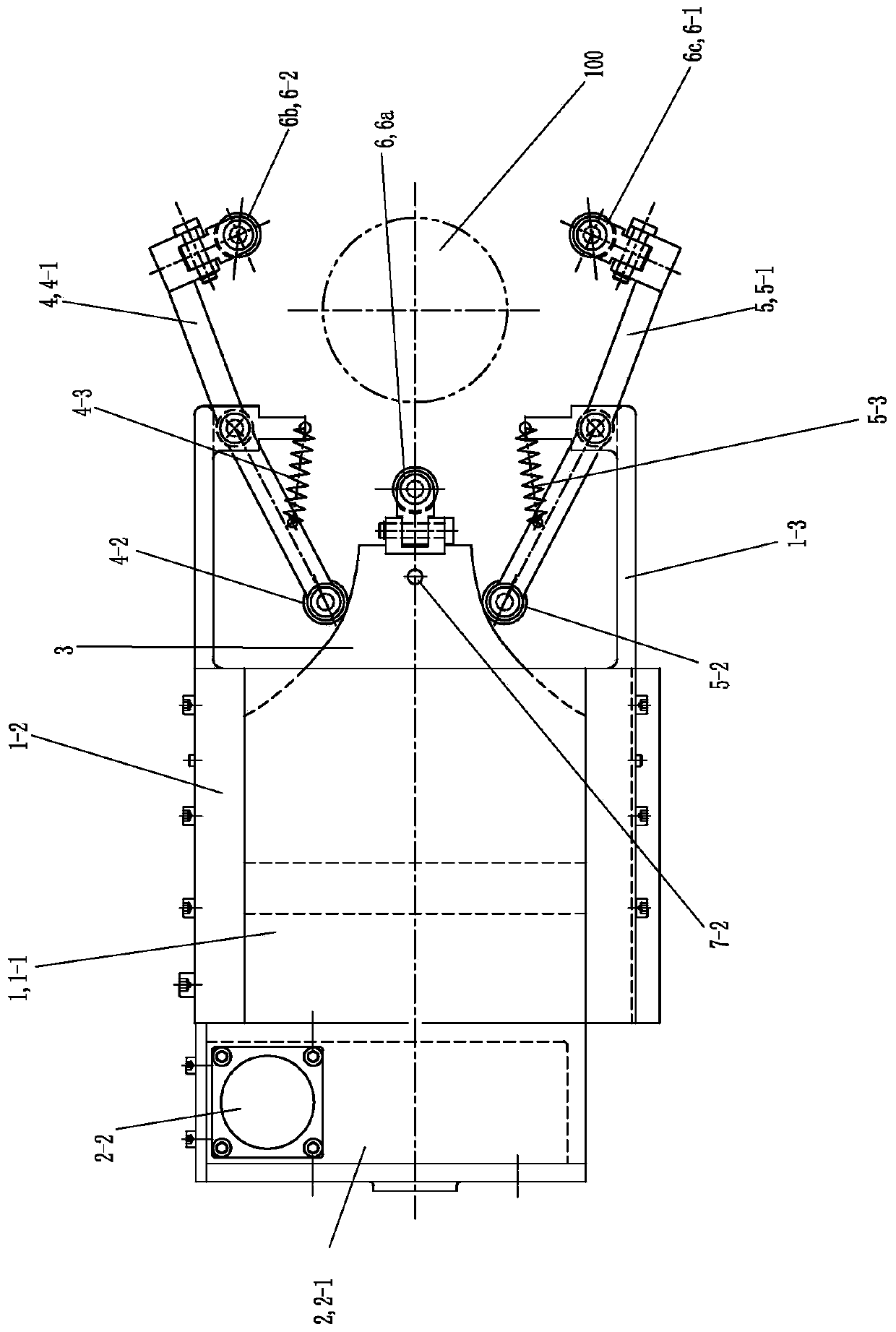

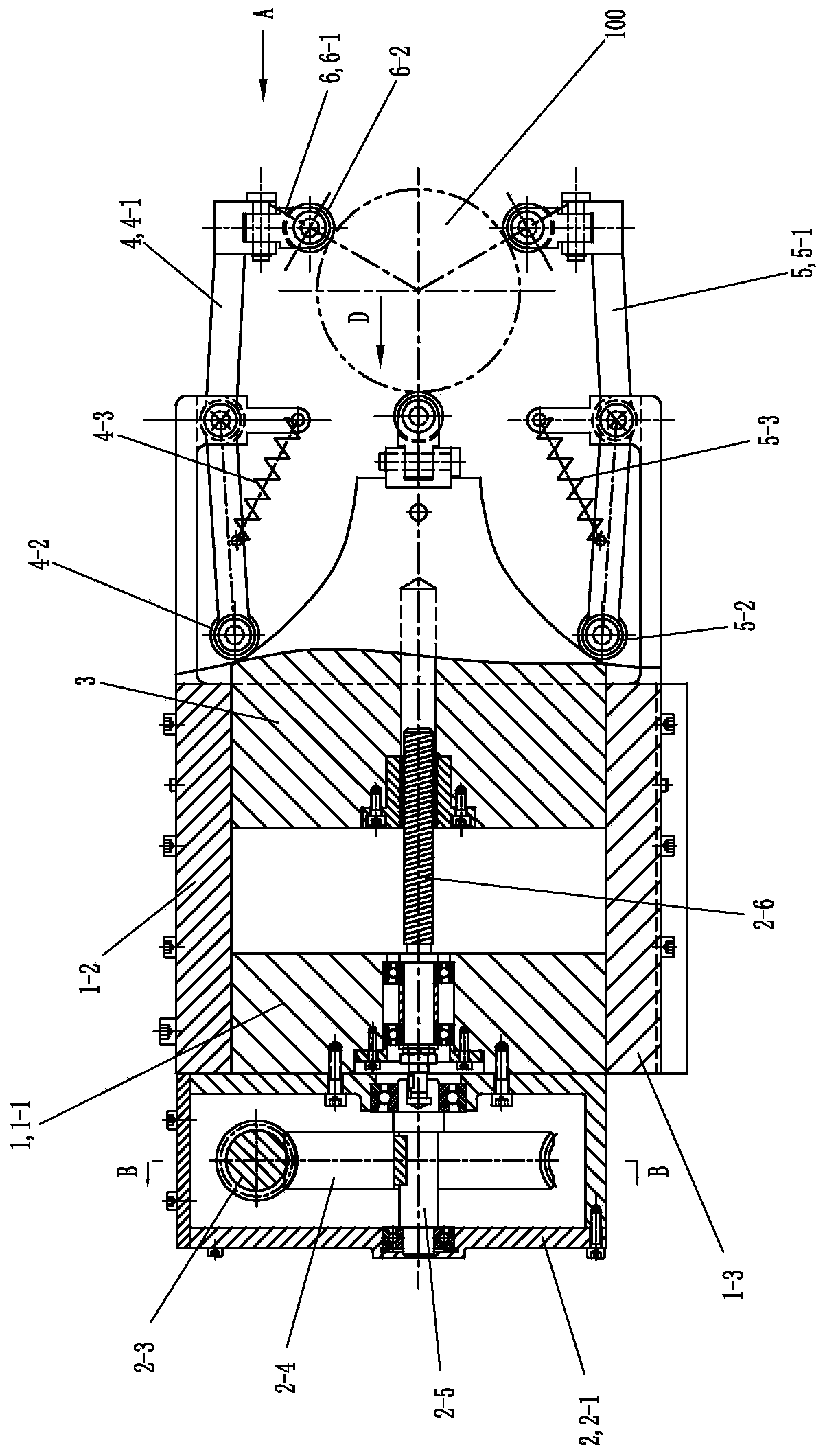

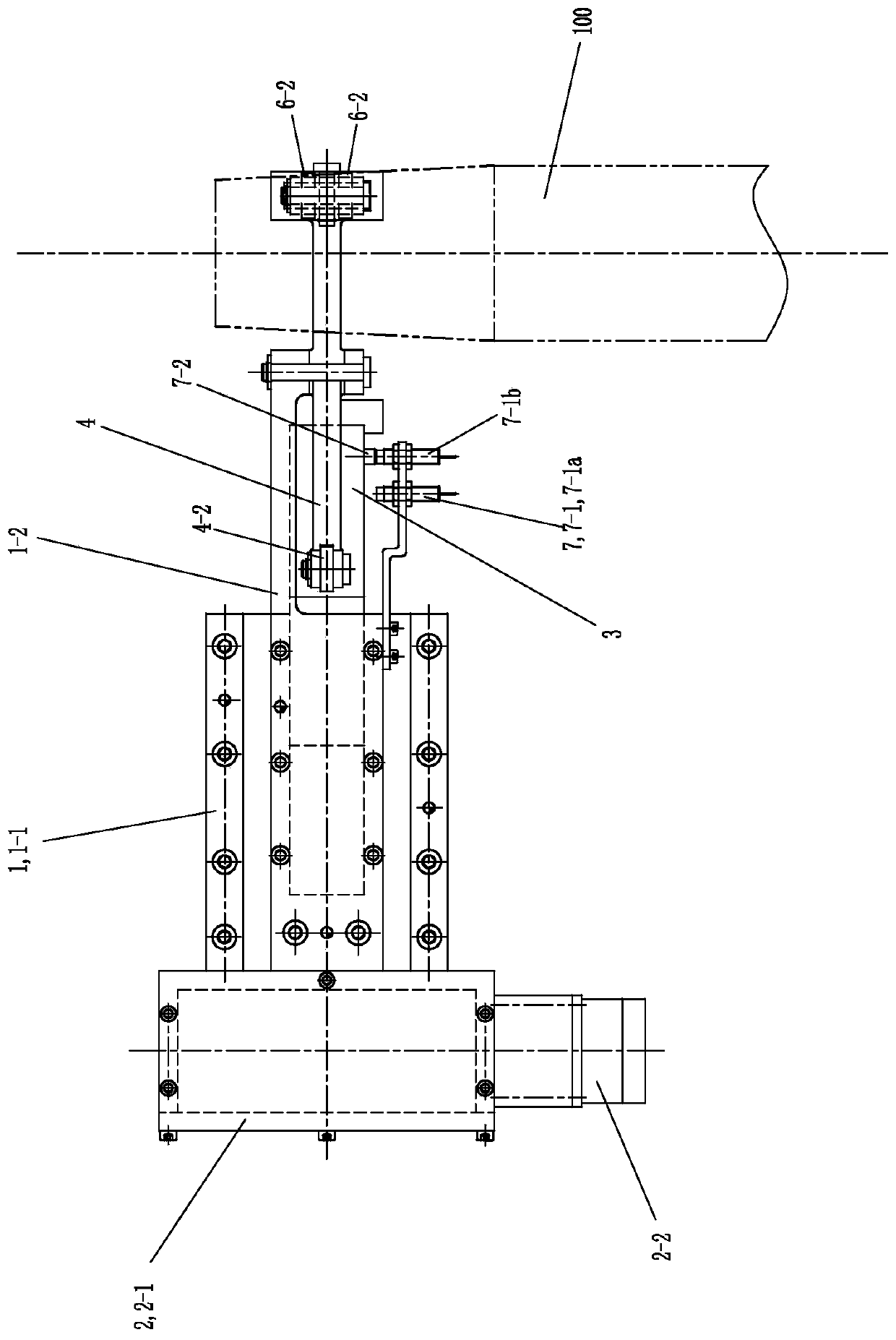

Vehicle charging system, charging pile and vehicle

PendingCN110014964AImprove contact accuracyReduce downtimeCharging stationsDriver interactionsDisplay deviceOperation time

The invention provides a vehicle charging system, a charging pile and a vehicle. The vehicle charging system comprises a charging device, a positioning module and a displayer which are arranged on thevehicle, the positioning module is used for positioning a charging interface in the charging pile, the charging device is used for being in butt connection with the charging interface in the chargingpile, and the displayer is connected with the positioning module. According to the vehicle charging system, the relative position between the vehicle and the charging pile can be obtained in real time and is sent to a display screen, thus a driver controls and adjusts the position of the vehicle according to the relative position displayed on the display screen, the contact precision of butt connection between the charging pile and the vehicle is improved, single-person parking operation by the driver is achieved, the parking operation time is effectively shortened, and the butt connection efficiency of the vehicle and the charging pile is greatly improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Automatic centering center frame

InactiveCN108481018BSimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEdge surfaceCam

The invention discloses an automatic alignment center rack. The automatic alignment center rack is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rodcomponent, a lower pressing rod component and pressing head components, the translation cam is arranged inside the machine box in a left and right sliding manner and is driven by the driving device to move left and right, an upper pressing rod on the upper pressing rod component and a lower pressing rod are made to swing by the translation cam to make the pressing head components located on the upper pressing rod and the lower pressing rod and the pressing head component on the translation cam be simultaneously closed to the axis of a workpiece to be machined, so that the workpiece to be machined is supported, wheel support racks of the pressing head components automatically rotate according to the shape of the outer edge surface of the workpiece to be machined, and two support wheels ofeach wheel support rack are guaranteed to be pressed tightly against the workpiece to be machined simultaneously.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Heat dissipation shell and processing method thereof and conduction heat dissipation module

InactiveCN114040640AImprove heat transfer performanceGuaranteed work performanceSupport structure mountingModifications by conduction heat transferEngineeringMechanical engineering

The invention relates to a heat dissipation shell and a processing method thereof and a conduction heat dissipation module. The heat dissipation shell comprises a frame and a heat transfer bottom plate, wherein the heat transfer bottom plate is detachably installed on one side of the frame; the other side of the frame is fixedly connected with an extension part, and the extension part is used for fixing the PCB; and at least one flexible heat transfer device is detachably mounted on one side, close to the frame, of the heat transfer bottom plate. The heat dissipation shell also comprises a PCB and a chip. The processing method of the heat dissipation shell comprises the steps that the frame, the heat transfer bottom plate and the cover plate are sequentially machined and formed, and the other side of the frame extends outwards to form the extension part; and the heat transfer bottom plate is detachably installed on one side of the frame, and the flexible heat transfer device is detachably installed on the side, close to the frame, of the heat transfer bottom plate, so that the heat dissipation shell is formed. The heat dissipation shell is simple in structure; and the heat dissipation shell is designed in a split mode, so that the contact precision of the flexible heat transfer device and the chip is improved, standardized machining and production of a single component are achieved, the machining efficiency is greatly improved, and disassembly and assembly are convenient.

Owner:GUILIN CHANGHAI DEV

Gear box redirection mechanism with floating intermediate wheel

PendingCN111022584AExtended service lifeIncrease contact areaToothed gearingsGearing detailsGear wheelEngineering

The invention provides a gear box redirection mechanism with a floating intermediate wheel. A set of self-aligning bearings is used for replacing two sets of tapered roller bearings in the prior art,inner rings of the self-aligning bearings sleeve an intermediate shaft in a movably matched mode, and outer rings are fixed to a center hole of the intermediate wheel. A plurality of elastic elementsare installed at the left end of the intermediate shaft to push the inner rings of the self-aligning bearings. The inner rings of the self-aligning bearings push rolling bodies of the self-aligning bearings, the rolling bodies push the outer rings of the self-aligning bearings, the intermediate wheel driven by the outer rings slides axially along the intermediate shaft, tooth surface of the intermediate wheel is always close to tooth surfaces of a first bevel gear and a second bevel gear, so that the intermediate wheel has a self-aligning floating function. According to the gear box redirection mechanism with the floating intermediate wheel, the contact area of the tooth surface of a transmission gear is increased, the contact accuracy is improved, and the service life of a gear is prolonged; the mechanism is novel and simple, the manufacturing cost is low, and the installation is convenient; the overall structure of an original gear box is not changed.

Owner:国营第一二三厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com