Method for improving contact precision of pushing screws small end surfaces in super nut and gasket

A technology of pushing screw and super nut, which is applied to machine tools suitable for grinding workpiece plane, grinding workpiece support, grinding machine, etc. Convenience, easy tooling, and improved contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

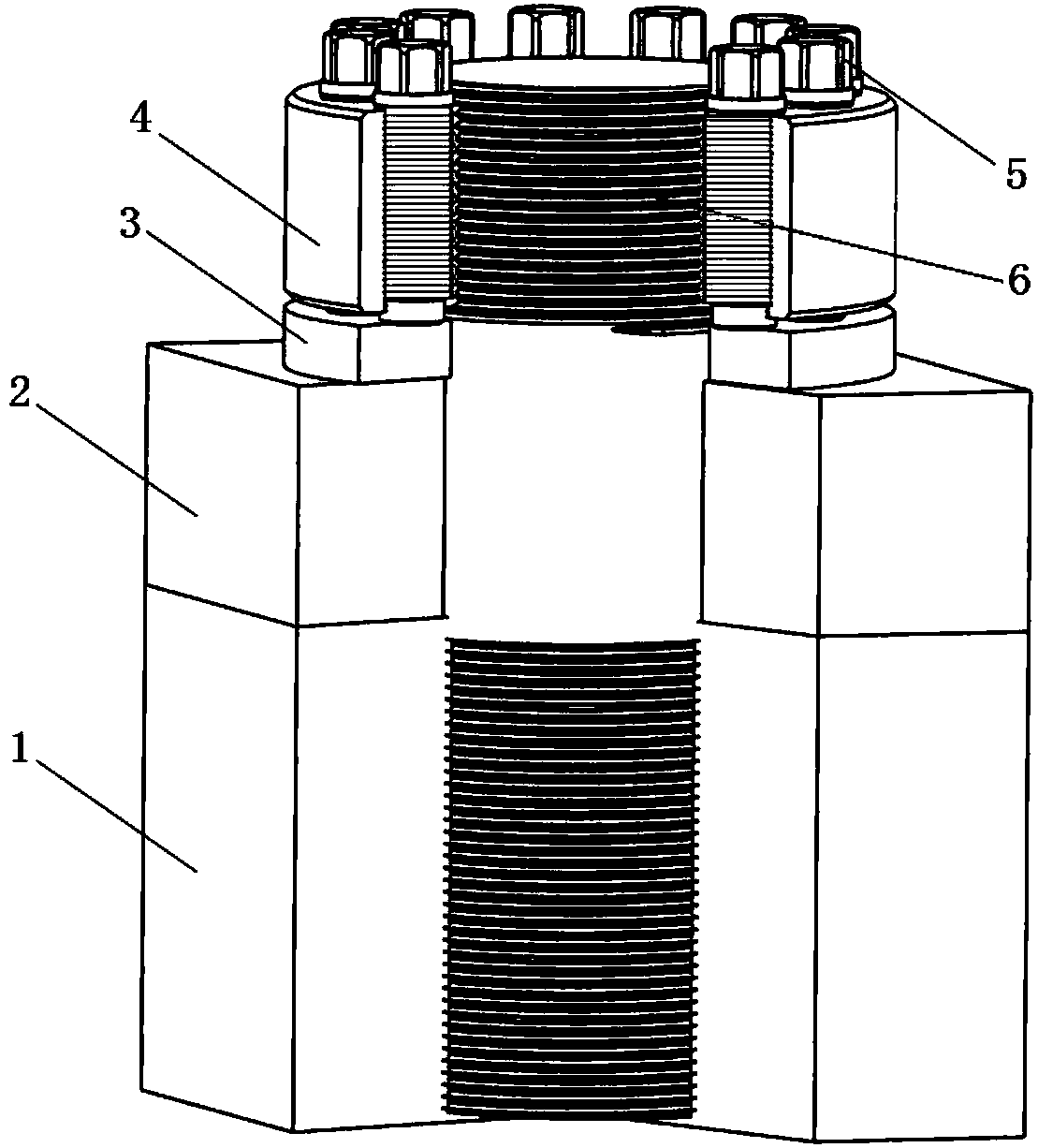

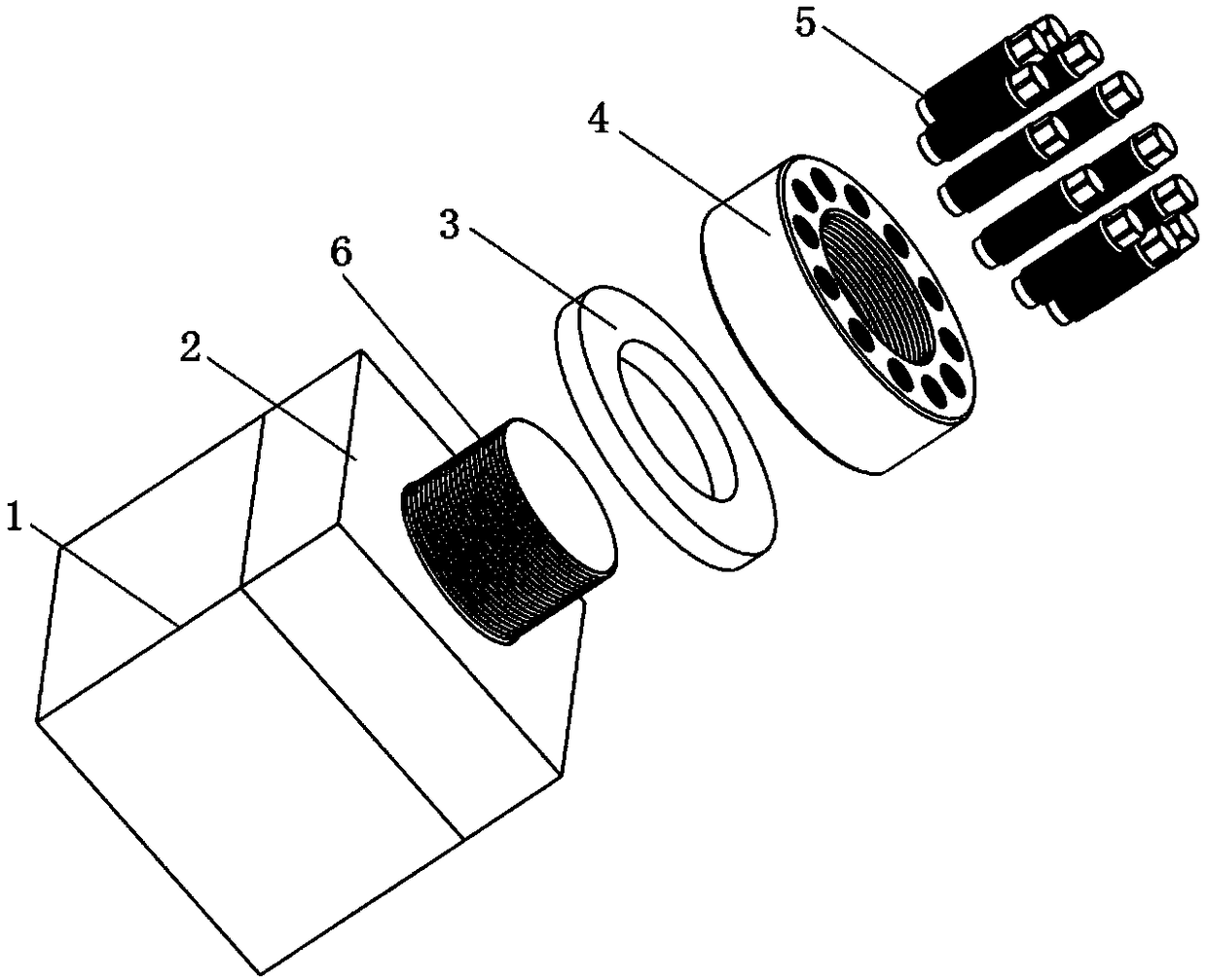

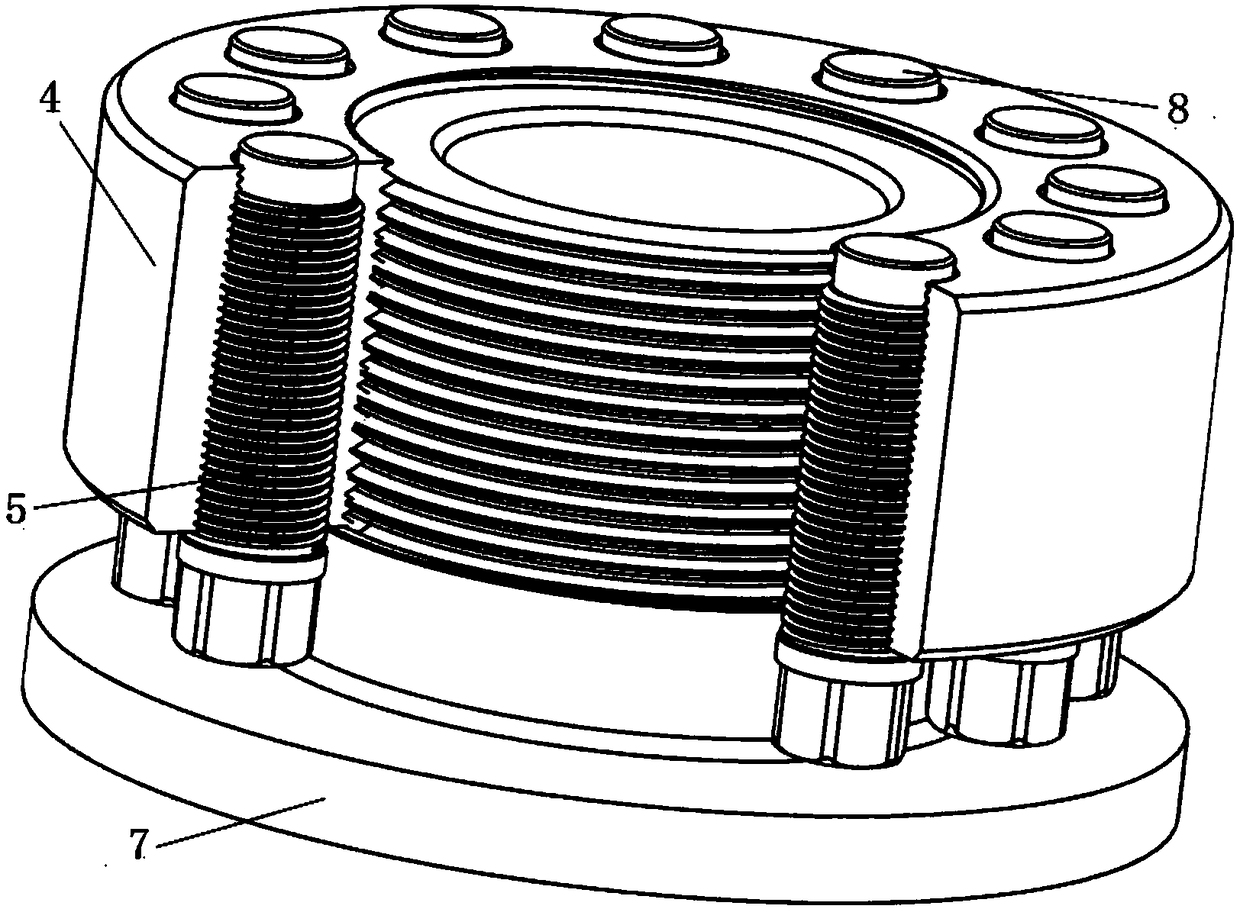

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The method for improving the contact accuracy between the small end surface of the jack screw in the super nut and the gasket in the present invention specifically includes the following steps:

[0028] Step 1, before grinding, put a set of jack screws 5 to be processed into the threaded holes 9 around the super nut 4, and apply a certain pre-tightening force to the jack screws 5 to prevent the jack screws 5 from being ground during grinding. loose;

[0029] Step 2, put the external thread 702 of the grinding tool 7 into the large inner threaded hole in the middle of the super nut 4 with the jack screw 5 installed in step 1 and pre-tighten it, so that the small step surface of the grinding tool 7 is aligned with the super nut 4 The bottom end face of the

[0030] Step 3, place a whole set of grinding tooling 7 to be ground after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com