Electric mechanical bearing bush grinding device and bearing bush grinding method

A mechanical and electric technology, which is applied in the field of sliding bearing grinding and scraping in hydropower stations, can solve the problems of large temperature difference of bearings, low efficiency, long time for manual scraping and maintenance, etc., and achieve the effect of improving maintenance efficiency and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

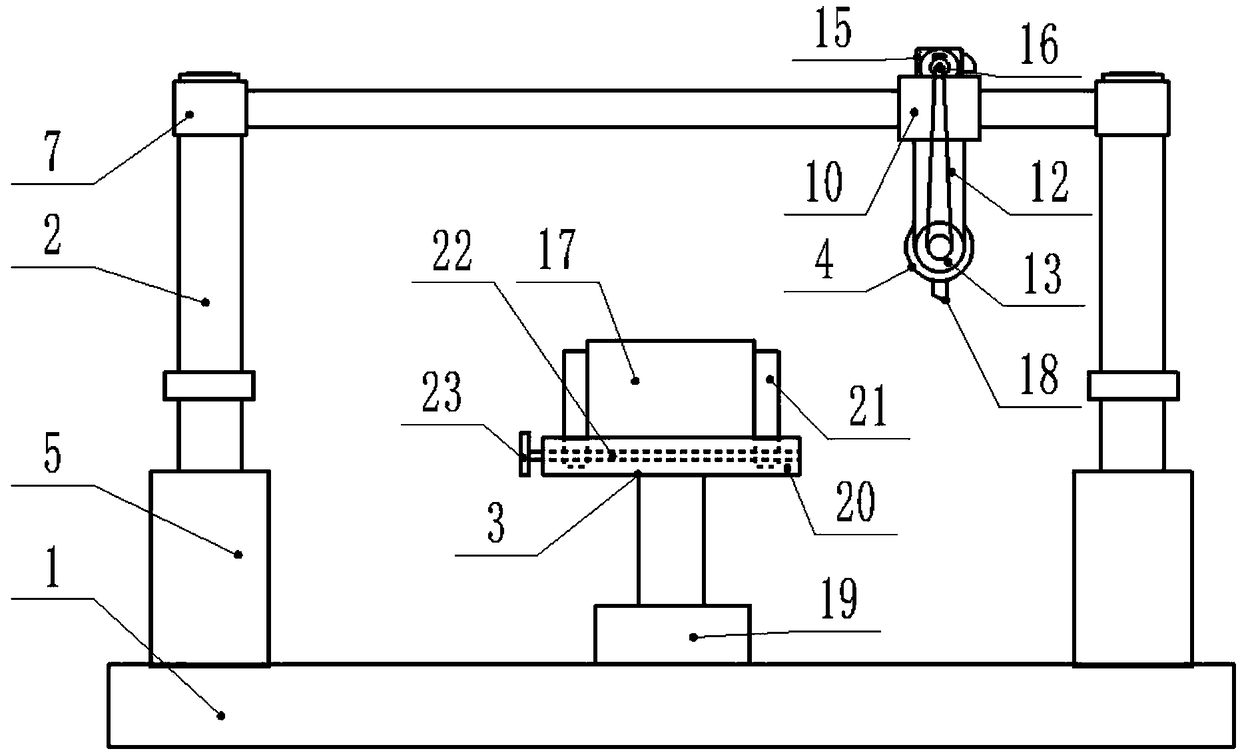

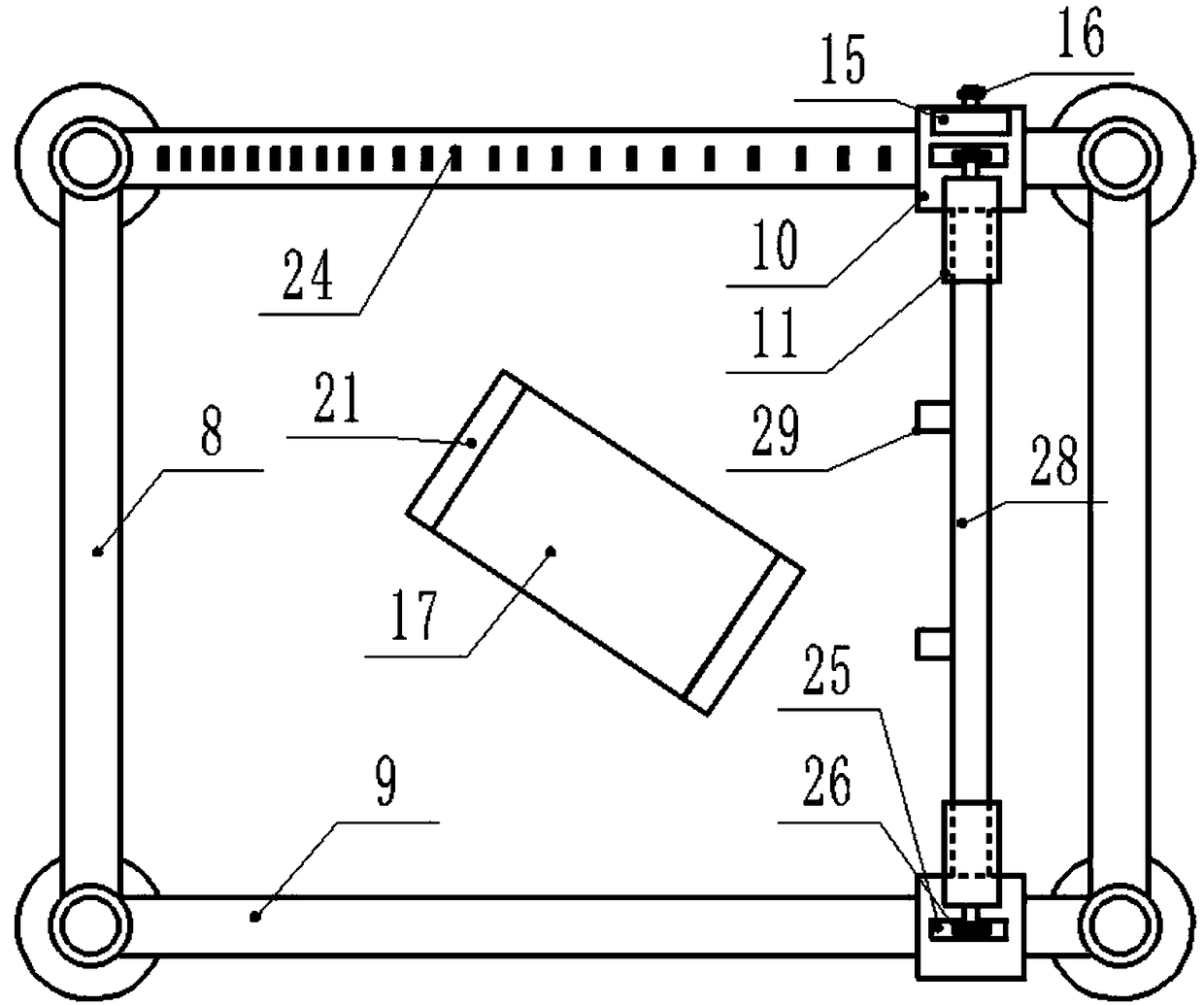

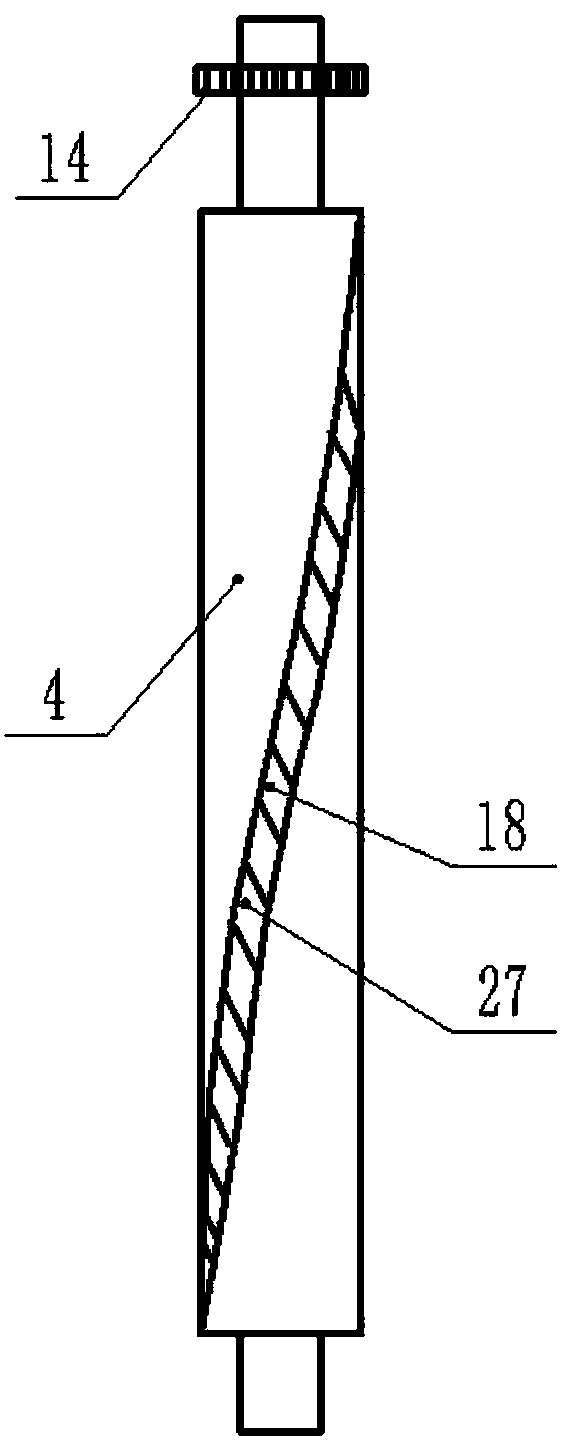

[0038] Such as Figure 1-5 As shown, an electromechanical scraping device of the present invention includes a scraping shoe base 1, a lifting pillar 2, a bearing pad clamping platform 3 and a hob shaft 4. The tile base 1 is used to support the entire scraping device, and the scraping shoe base The four corners of 1 are provided with elevating motors 5 respectively, and each elevating motor 5 is connected with elevating struts 2, and the upper end of said elevating struts 2 is provided with elevating sleeves 7, and elevating sleeves 7 can rotate on elevating struts 2, because there are The lifting shaft of the table lifting motor 5 is rotated to raise or lower, and the four lifting sleeves 7 are connected end to end by two transverse bars 8 and two longitudinal bars 9 to form a square frame structure. The two transverse bars 8 are symmetrically arranged in parallel, Two longitudinal rods 9 are symmetrically arranged in parallel, two horizontal rods 8 and two longitudinal rods 9...

Embodiment 2

[0056] Such as Figure 1-5 Shown, a kind of electromechanical scraping tile method of the present invention comprises steps:

[0057] Step 1 Place the bearing bush 17 on the clamping table 20, and set the two ends of the bearing bush 17 corresponding to the sliding clamp block 21, and firmly clamp the bearing bush 17 by turning the hand wheel or the hand wheel motor 23, and control the rotation of the clamping table rotating motor 19 The end face of the bearing bush 17 is set at an angle of 45° with the hob shaft 4;

[0058] Step 2 Install the matching hob 18 on the hob shaft 4 according to the model of the bearing bush 17, then start the moving motor 11 and the lifting motor 5 to drive the hob 18 and the scraping arc surface of the bearing bush 17 to perform knife alignment, and determine the scraping tile through the knife alignment The three-dimensional coordinates of the arc bottom and the upper arc edge of the arc surface, so as to determine the spatial position of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com