Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve ball milling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TiC steel-bonded cemented carbide and its manufacturing method

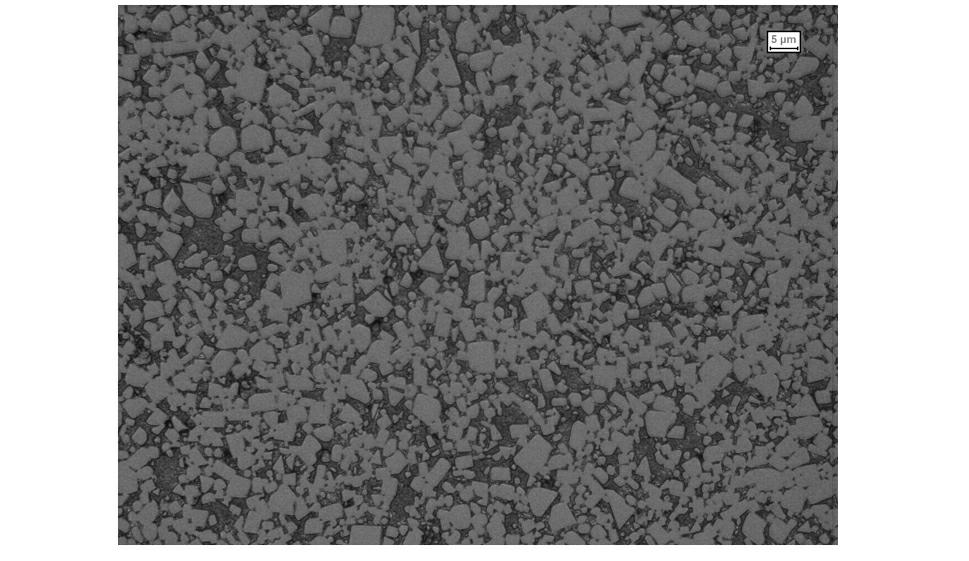

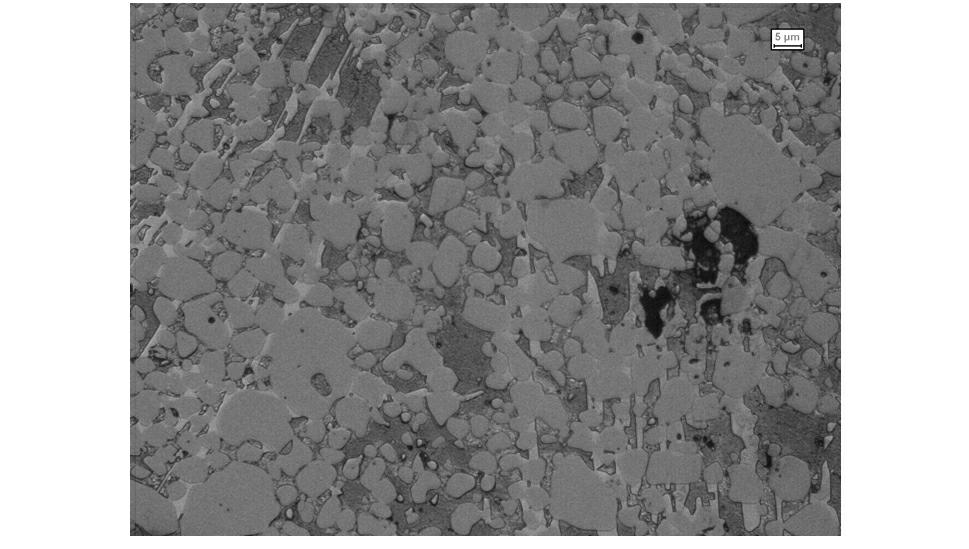

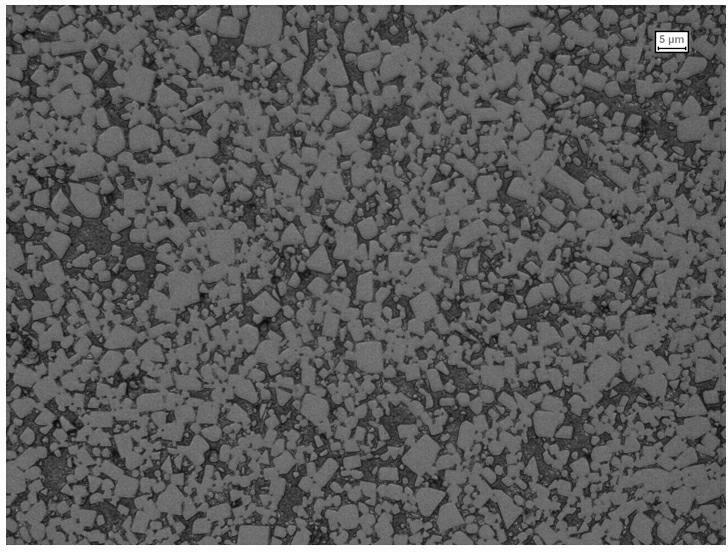

InactiveCN102492887AImproves weldability and castabilityImprove grinding efficiencyCemented carbideMicrostructure

The invention provides a TiC steel-bonded cemented carbide, which contains 54.0-60.0 wt% of a hard phase TiC and 46-40 wt% of a bonding phase high manganese steel, wherein the bonding phase contains, by weight, 4.0-6.0% of Ni, 1.5-3.0% of Mo, 13.0-15.0% of Mn, 1.0-1.3% of C and the balance being Fe. The TiC steel-bonded cemented carbide is mainly prepared by the following steps of: proportioning, ball milling, drying, compaction, sintering, and balling milling of a forming agent and the raw materials. A ball milling rod is a cemented carbide rod and the drying step is spray drying. The TiC steel-bonded cemented carbide has advantages of uniform austenite microstructure, high wear resistance, good strength and good pourability.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

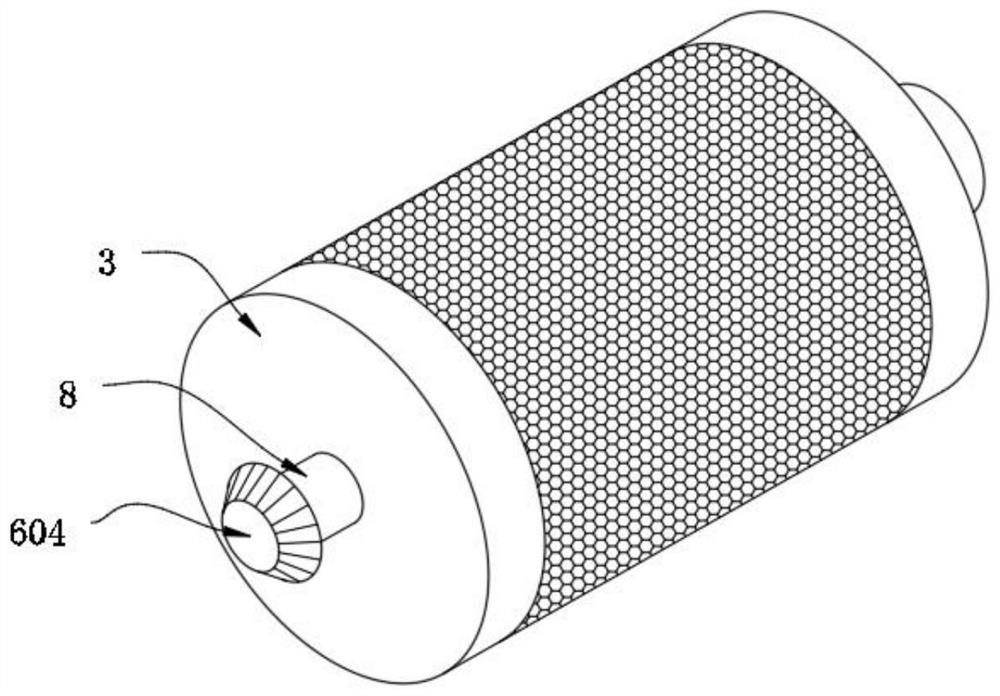

Planetary ball mill

A planetary ball grinder is composed of drive motor, transmission gear train, revolving mainshaft and rotary disc, multiple rotational axles and the ball grinding cylinders rotating around own axle. It features that said ball grinding cylinder is eccentrically installed in such manner that the central line of rotational axle is parallel with the geometric central line of the cross-section of ball grinding cylinder, and its eccentrical degree can be changed for changing the ratio of grinding action to impact action.

Owner:SUN YAT SEN UNIV

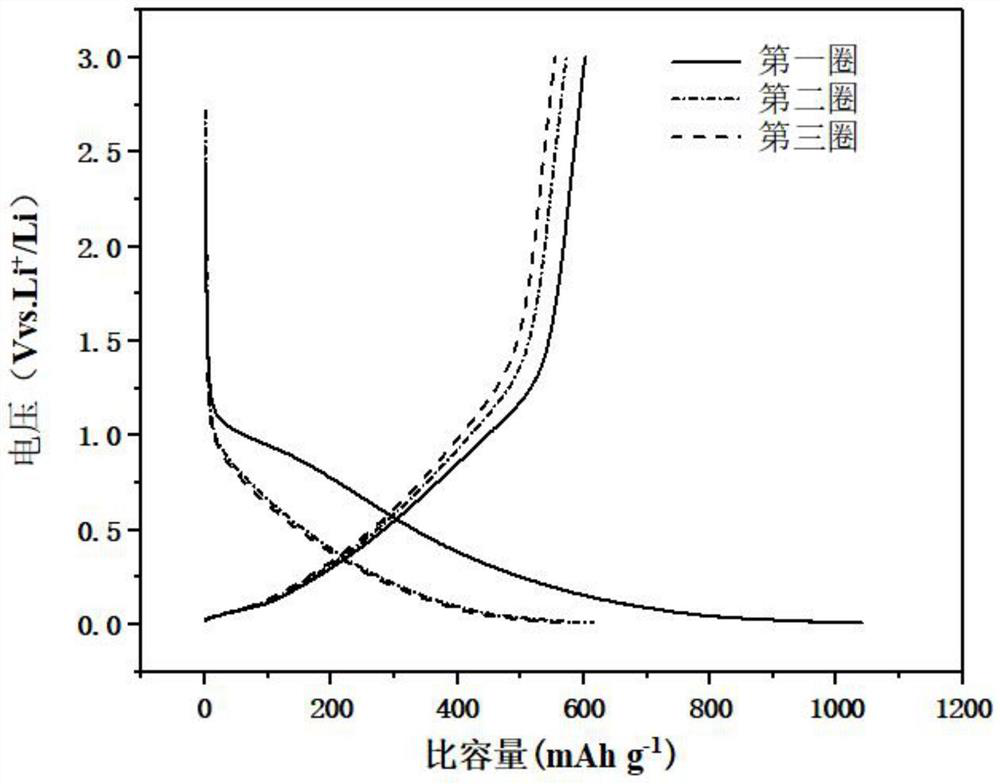

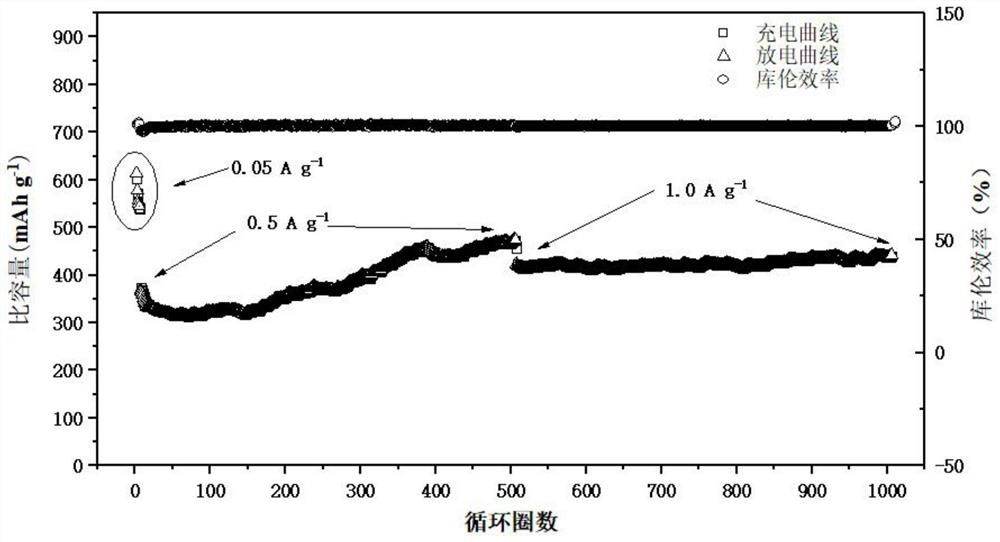

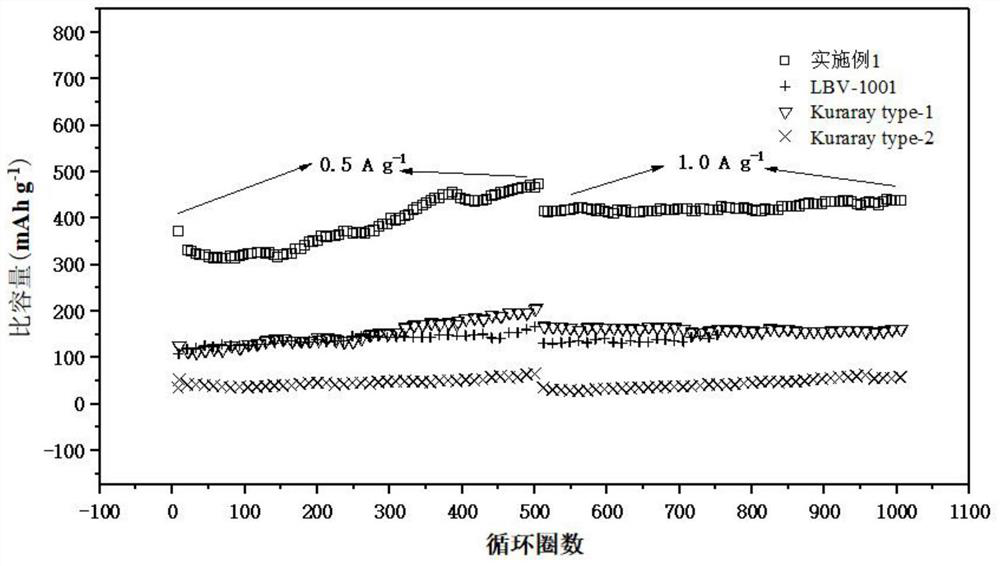

Preparation method and application of hard carbon

PendingCN112062120ASimple processSuitable for large-scale commercial applicationsNegative electrodesSecondary cellsElectrical batteryCarbonization

The invention relates to the technical field of battery materials, and particularly relates to a preparation method and application of hard carbon. The preparation method provided by the invention comprises the steps of carrying out salt leaching on biomass waste powder to obtain salt-leached biomass waste powder; and sequentially carrying out first carbonization, ball milling and second carbonization on the salt-leached biomass waste powder to obtain the hard carbon. According to the method, firstly, the biomass waste powder is subjected to salt leaching to enable the biomass waste powder tocarry salt ions, and the salt ions can change the microstructure of carbon in the subsequent second carbonization process, so that the performance of hard carbon is influenced; the two-step carbonization process is used for ensuring that a primary carbon structure can be formed and tar substances in the biomass can be removed through first carbonization, so that the relative controllability of thesize of biomass waste powder in the subsequent ball milling process is facilitated, and the formation of a more stable carbon structure can be ensured through second carbonization.

Owner:SHANDONG ZHAOWEN NEW ENERGY TECH CO LTD

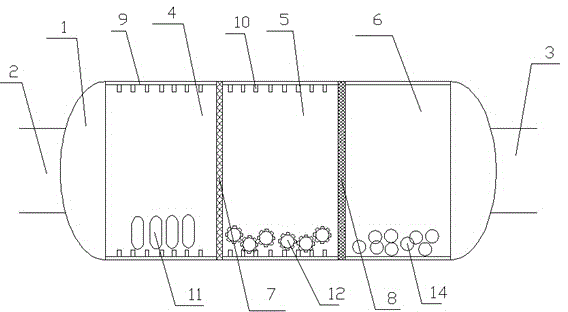

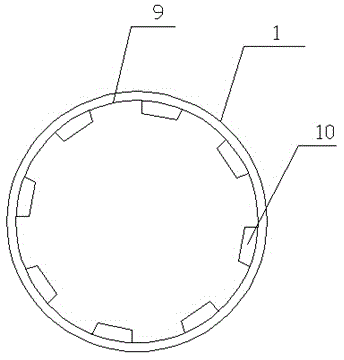

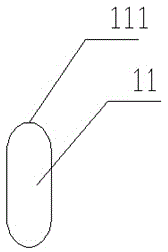

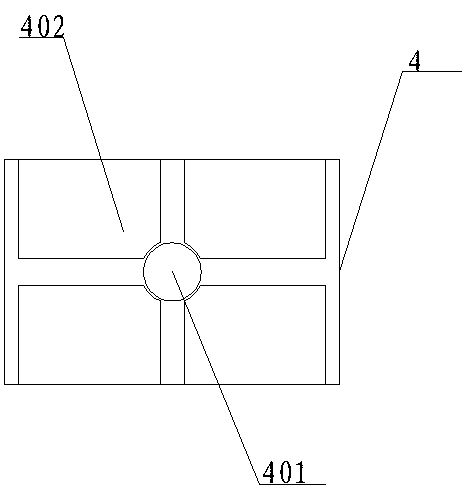

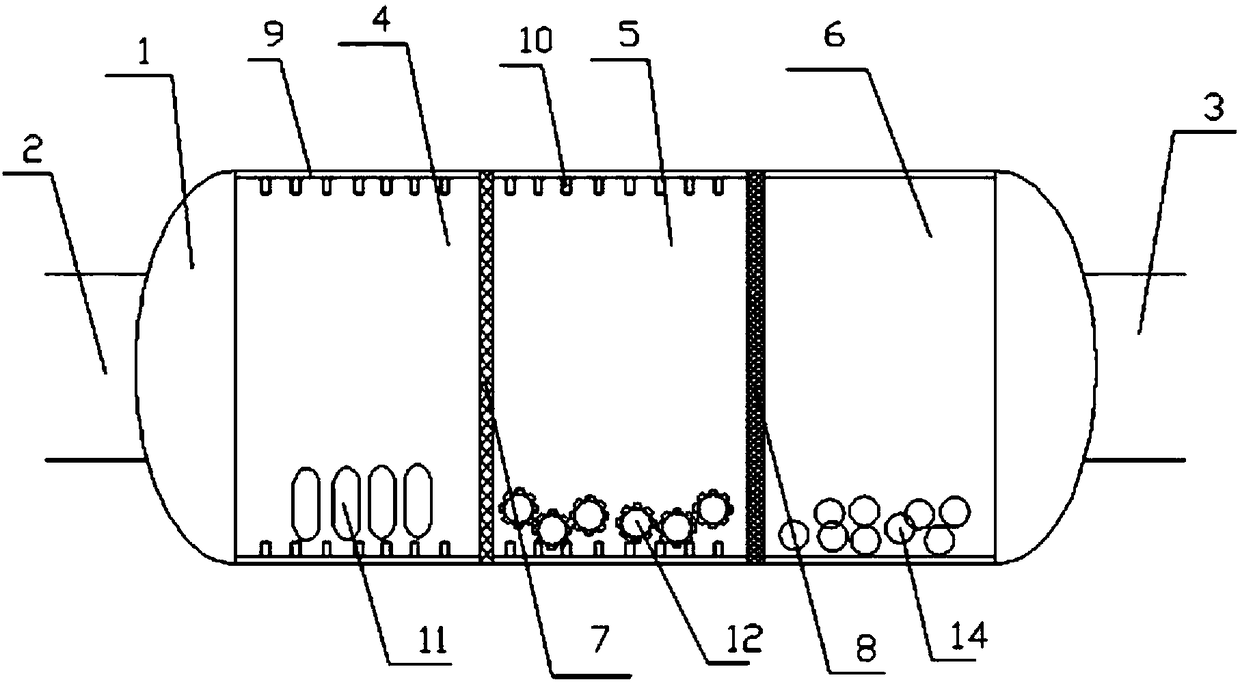

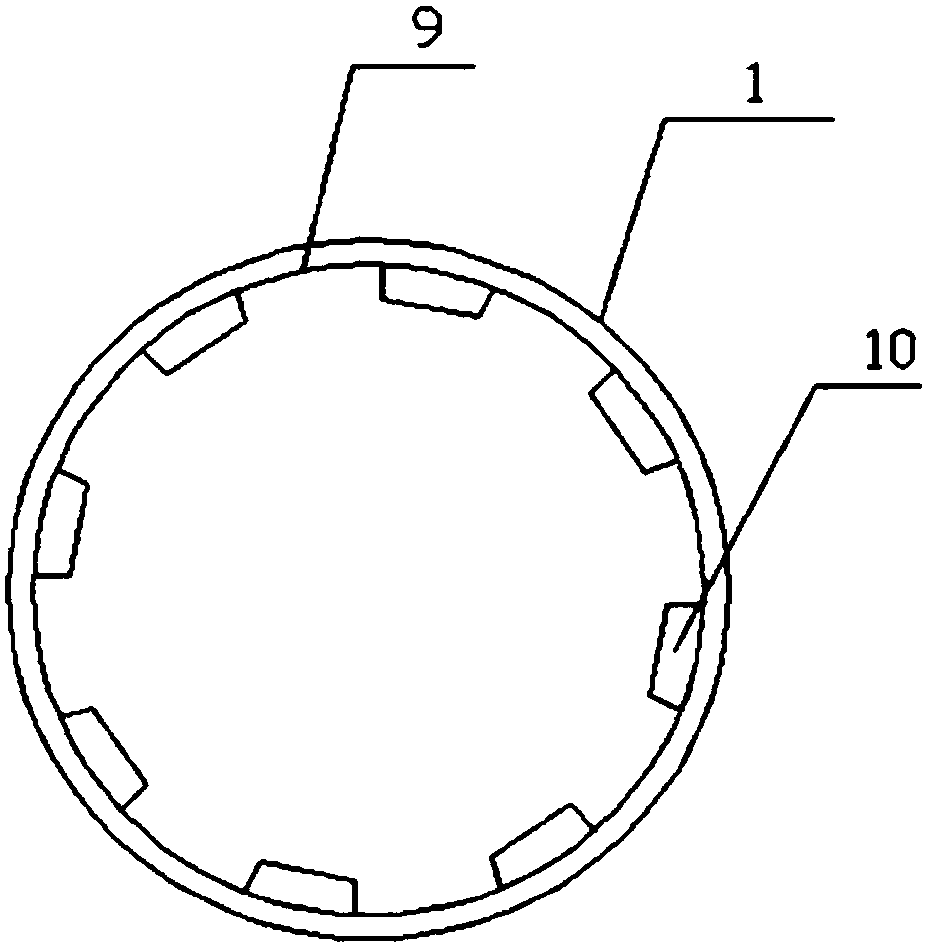

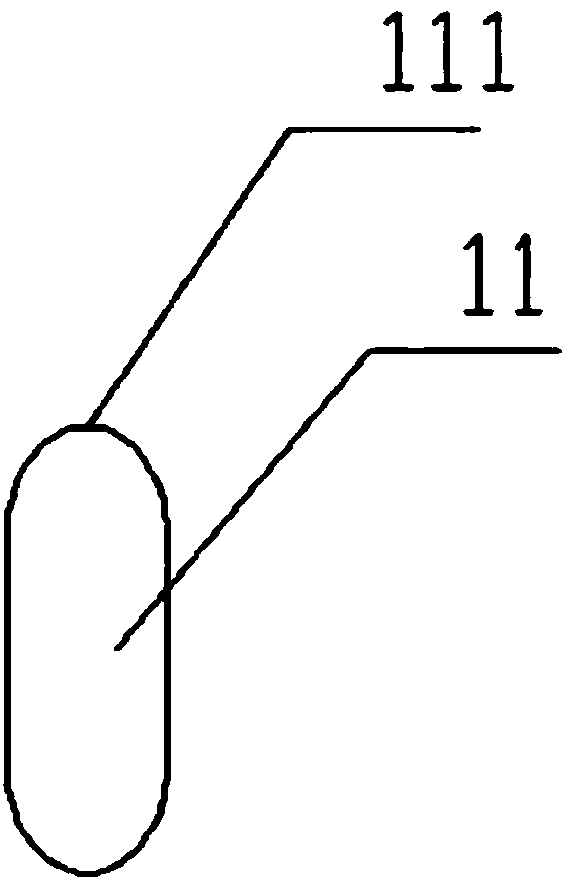

Ball-milling device for materials

The invention discloses a ball-milling device for materials. The ball-milling device comprises a barrel. A material inlet and a material outlet are formed in two ends of the barrel, a first partition plate and a second partition plate are arranged inside the barrel, filter holes are formed in the first partition plate and the second partition plate, the diameters of the filter holes in the first partition plate are larger than those of the filter holes in the second partition plate, the barrel is divided into a first barrel, a second barrel and a third barrel by the first partition plate and the second partition plate, abrasion-resistant lining plates are arranged on the inner walls of the first barrel, the second barrel and the third barrel, protrusions are arranged on the lining plates of the first barrel and the second barrel, grinding steel balls are respectively arranged in the first barrel, the second barrel and the third barrel, cylindrical steel ball bodies are arranged in the first barrel, arc-shaped ends are respectively connected to the upper ends and the bottoms of the cylindrical steel ball bodies, and a plurality of protrusions are arranged on the surfaces of the steel balls in the second barrel. The ball-milling device has the advantages that excellent ball-milling effects can be realized by the ball-milling device, the ball-milling device is short in ball-milling time, and the service lives of the lining plates can be prolonged.

Owner:江苏博拓新型建筑材料股份有限公司

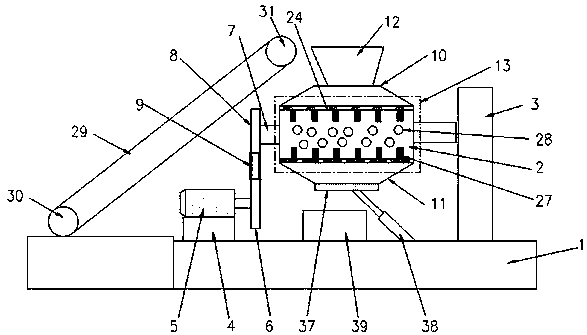

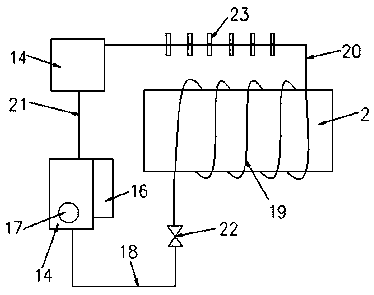

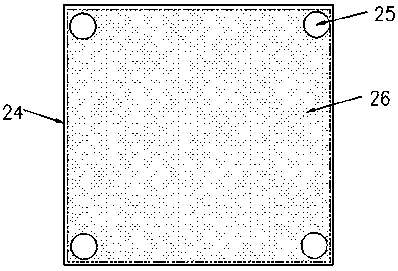

Ceramic raw material ball mill

The invention discloses a ceramic raw material ball mill. The ceramic raw material ball mill comprises a base, a ball mill cylinder and a feeding mechanism. A stand column is vertically installed on one side of the base. A motor mounting seat is mounted on the other side of the base. A motor is mounted on the motor mounting seat. A large transmission wheel is arranged on one side of the motor. A motor shaft of the motor is connected with the large transmission wheel. A bearing is fixedly mounted on one side of the ball mill cylinder. A small transmission wheel is mounted at the end of the bearing. The large transmission wheel is connected with the small transmission wheel through a belt. A feeding opening is formed in the upper portion of the ball mill cylinder, and a discharging opening is formed in the lower portion of the ball mill cylinder. A feeding hopper is arranged above the feeding opening. The feeding structure is arranged on one side of the base. The ceramic raw material ball mill further comprises a cooling mechanism. The cooling mechanism is arranged outside the ball milling cylinder. The ceramic raw material ball mill is simple in structural principle and high in degree of automation and can achieve uniform ball milling of ceramic raw materials and improve subsequent processing efficiency; and in addition, the cooling mechanism can achieve uniform cooling of the surface of the ball mill cylinder and prevent deformation caused by uneven temperature.

Owner:陶媛媛

High energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder

InactiveCN102773134AImprove work efficiencyReduce manufacturing costGrain treatmentsGear transmissionHigh energy

The invention relates to a high energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder. The equipment comprises a main motor, a driving belt, belt wheels, a main shaft, a left wheel disc, a left half axle, a right half axle, ball milling jar sleeves, a right wheel disc, a planetary gear, an internal gear, an internal gear transmission shaft, a first shaft coupling, a worm and gear speed reducer, a second shaft coupling and a vice-motor, wherein the main shaft is horizontally disposed, a plurality of the ball milling jar sleeves are horizontally disposed and are circumferentially and uniformly arranged around the main shaft and between the left wheel disc and the right wheel disc, the main motor is driven by the driving belt and drives the main shaft to rotate, circular rotation of the ball milling jar sleeves around the axis of the main shaft is realized through the rotation of the main shaft, the left wheel disc and the right wheel disc, the ball milling jar sleeves are connected with the right half axle, the planetary gear on the right half axle is engaged with the internal gear, the internal gear is arranged on the internal gear transmission shaft, and the vice-motor drives the internal gear to rotate through the worm and gear speed reducer.

Owner:CHANGCHUN CHAOWEI PHARMA TECH DEV

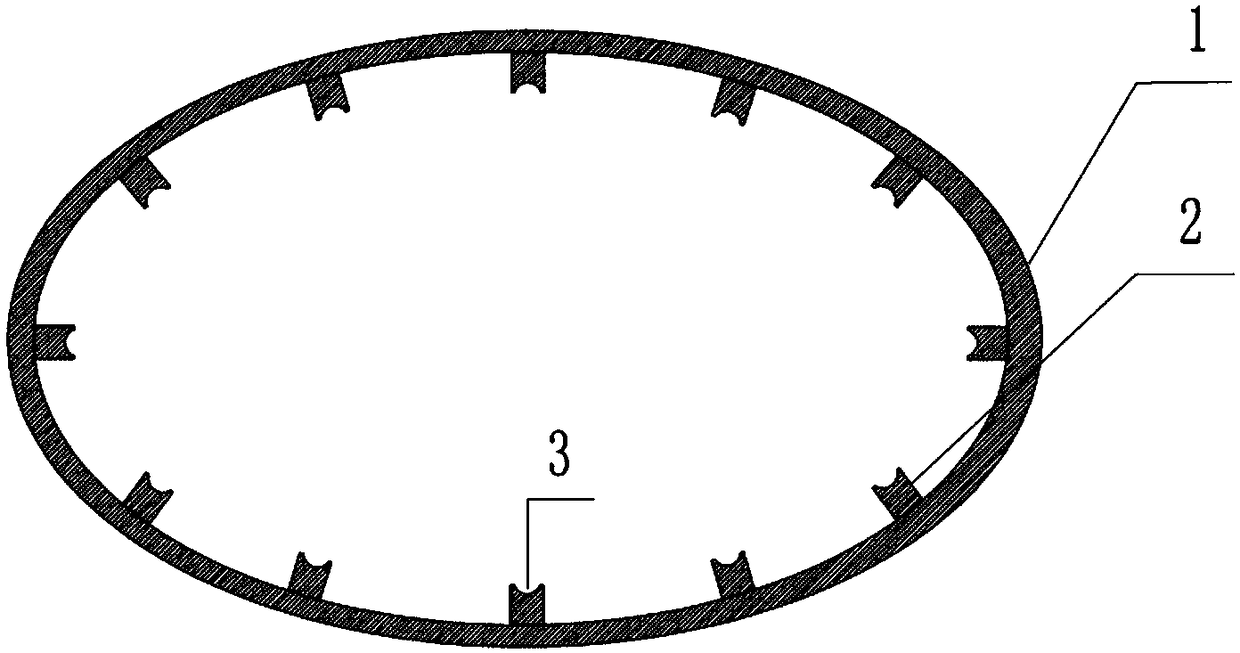

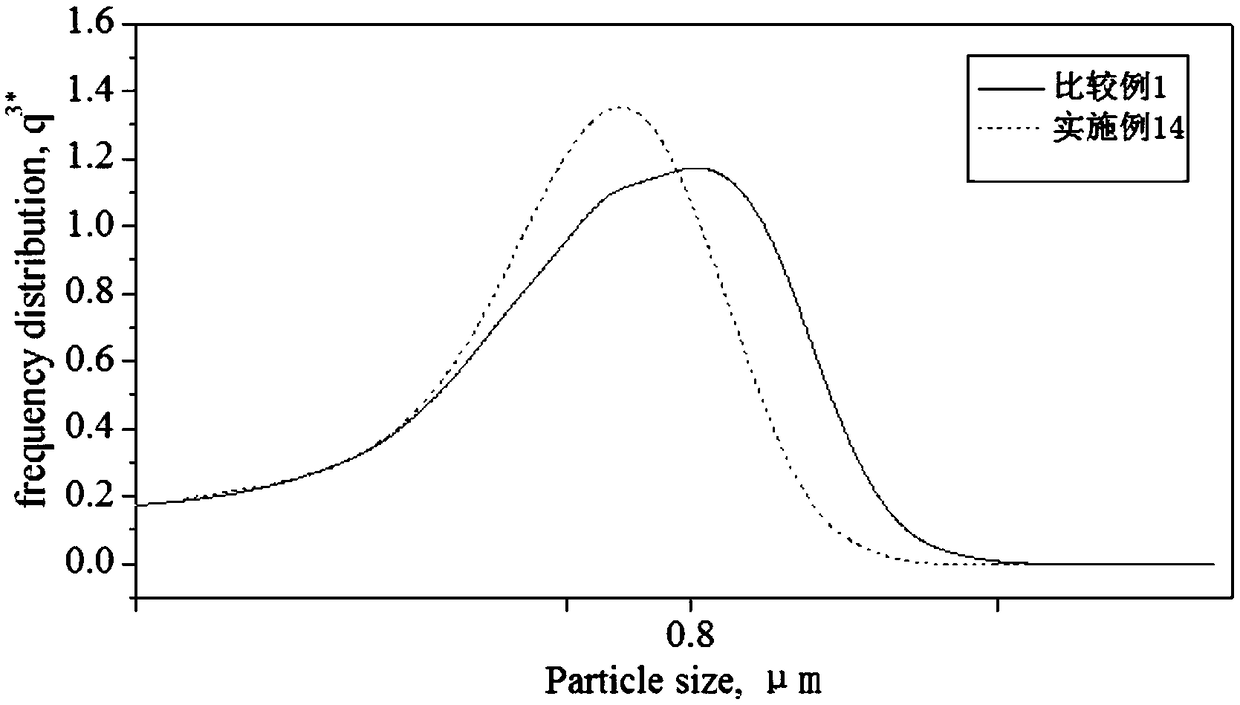

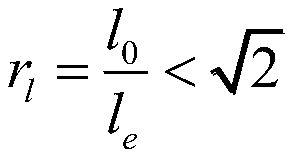

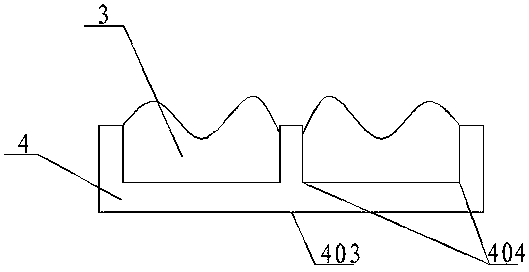

Spheroidic ball mill barrel and method for fine pulverizing of permanent magnetic ferrite through spheroidic ball mill barrel

The invention relates to the technical field of fine pulverizing, and discloses a spheroidic ball mill barrel and a method for fine pulverizing of permanent magnetic ferrite through the spheroidic ball mill barrel. The inner wall of the spheroidic barrel is provided with a plurality of strengthening ribs evenly distributed along the inner wall of the spheroidic barrel. The strengthening ribs extend to the other end from one end of a spheroidic barrel pole axis. The surfaces, close to the interior of the barrel, of the strengthening ribs are provided with arc concave parts. Welding of a liner plate is not needed for the barrel, and the problems that losses of liner plates on the two sides in a traditional cylindrical ball mill barrel are large, and abrasion of linings of cover plates on thetwo sides is fast are solved. The spheroidic barrel can be adopted for well scattering impacts caused by movement of steel balls, raw materials and a dispersing agent towards the two ends of the barrel, the whole barrel is evenly stressed, ball milling uniformity is improved, and the ball milling efficiency is improved. By the adoption of the barrel and the fine pulverizing method, the ball milling time is shortened, grain size distribution of obtained slurry is centralized, the yield is improved by 10%, residual magnetism is improved by 1%-3%, and the intrinsic value is improved by 3%-5%.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

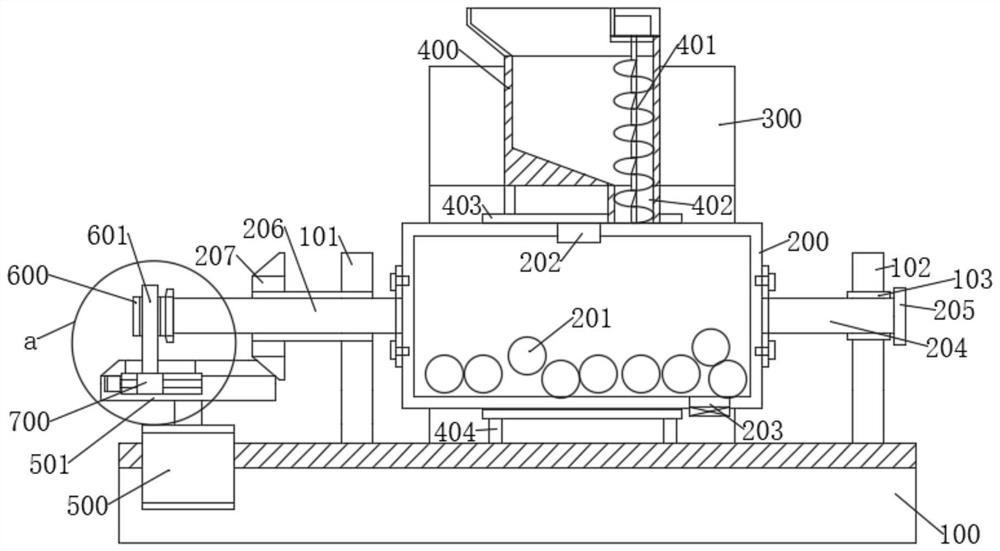

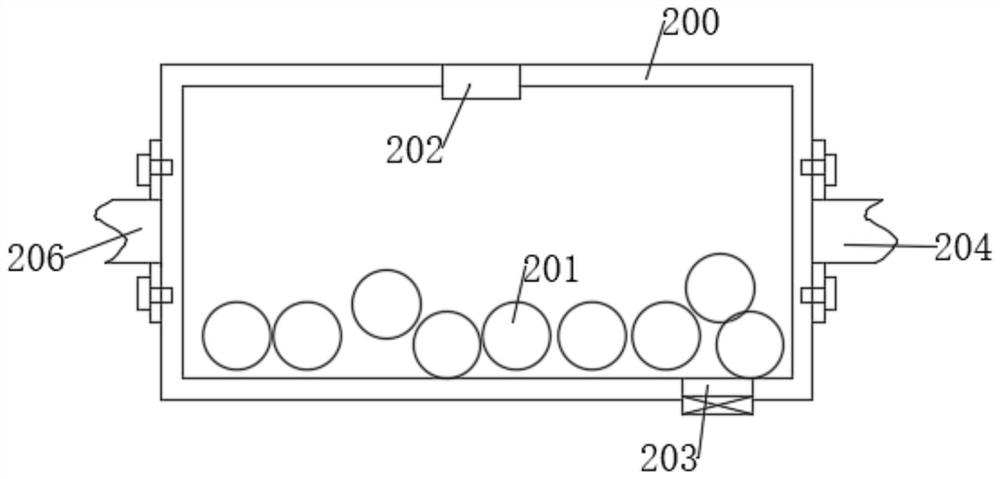

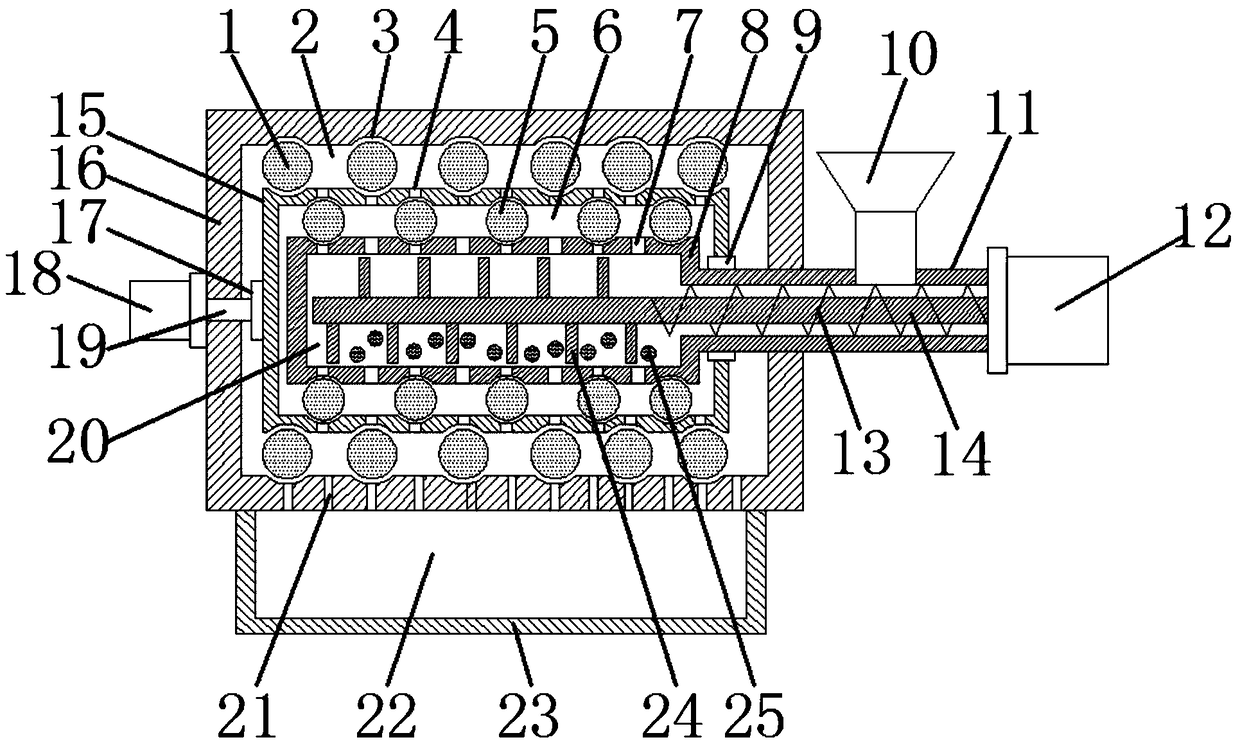

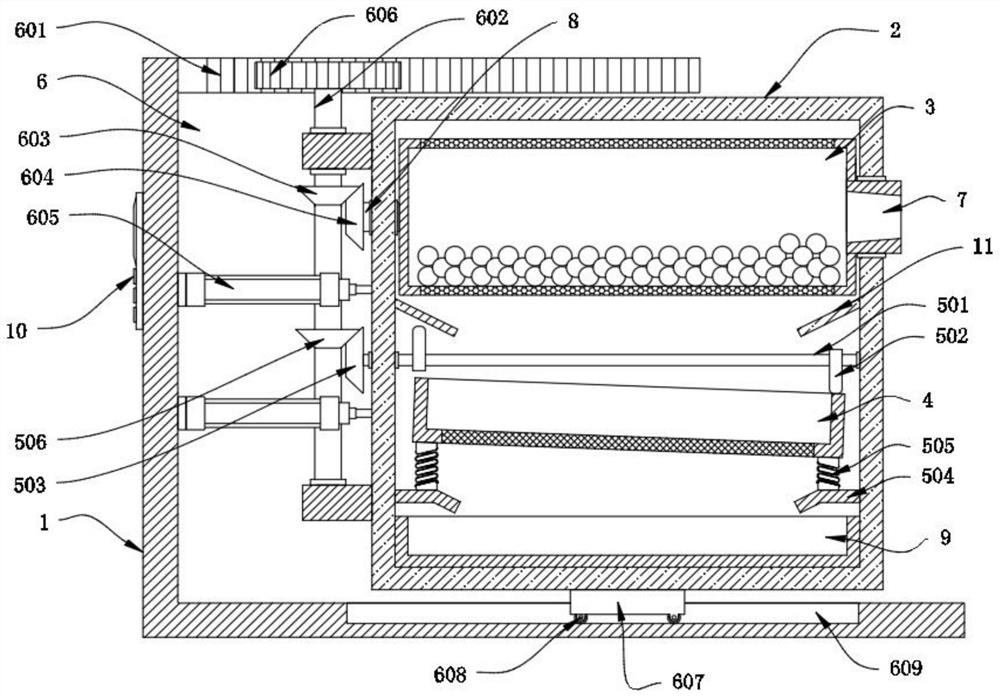

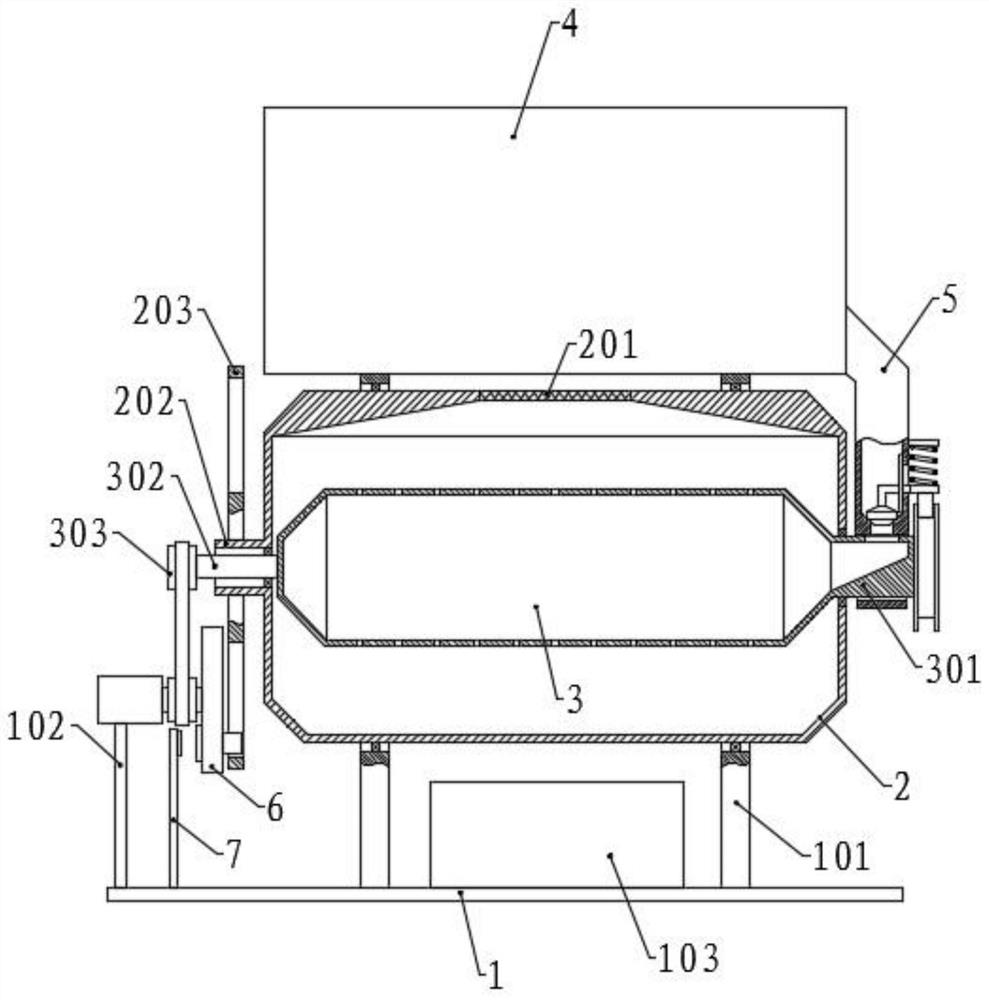

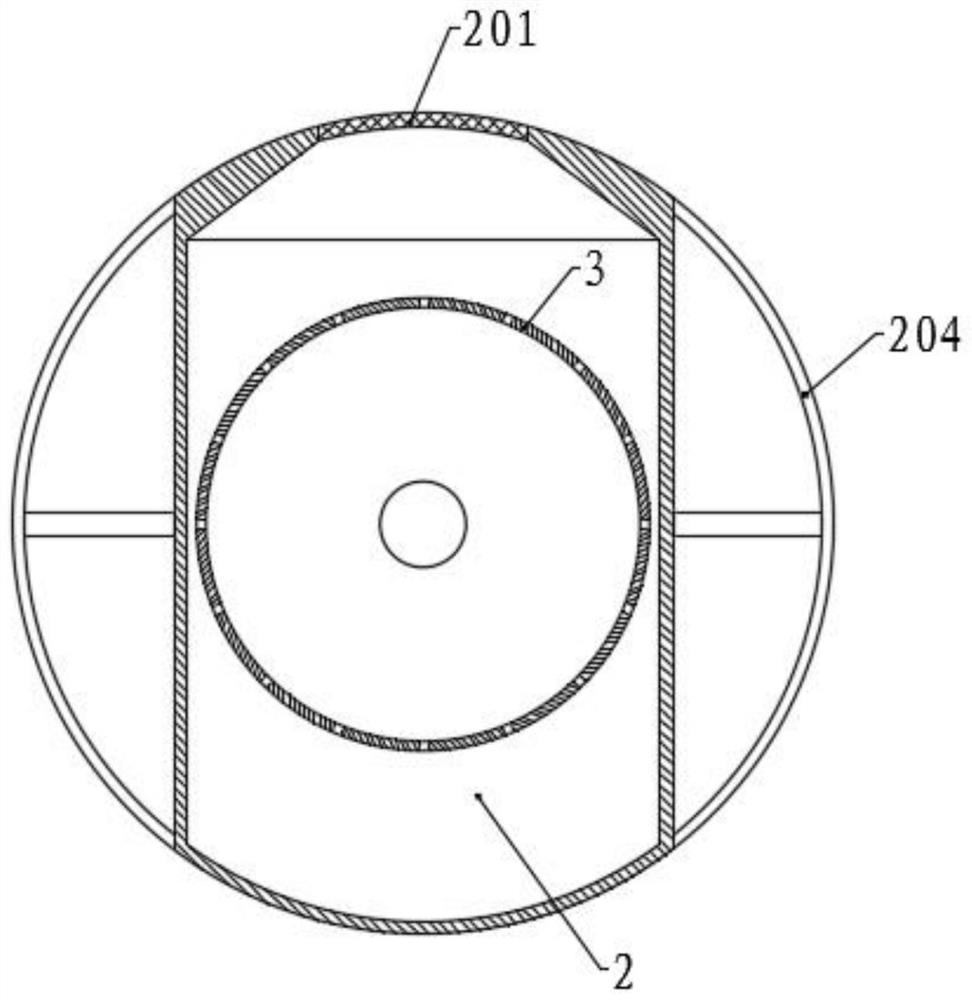

Continuous ball mill for ceramics

ActiveCN114733616AGuaranteed continuityImprove ball milling effectGrain treatmentsCeramic materials productionReciprocating motionEngineering

The invention is applicable to the field of ceramic processing, and provides a continuous ball mill for ceramics, the ball mill comprises: a treatment device, the treatment device comprises a treatment tank, the transverse reciprocating motion of the treatment tank is adjusted through a push-pull mechanism, the vertical rotation of the treatment tank is adjusted through a rotating mechanism, and the treatment tank is arranged in the treatment device; the push-pull mechanism is linked with the rotating mechanism; a plurality of steel balls are arranged in the treatment tank; the device further comprises a feeding device. When the ball mill provided by the embodiment of the invention is used, as linkage exists between the transverse reciprocating motion and the vertical rotation of the treatment tank relative to the supporting sleeve, when the treatment tank rotates relative to the supporting sleeve, the plurality of steel balls grind and crush materials in the treatment tank, and meanwhile, the materials in the treatment tank are separated from the supporting sleeve. According to the processing tank which transversely reciprocates relative to the supporting sleeve, the feeding port can be intermittently aligned with the discharging port, so that the effect of periodically adding materials into the processing tank is achieved, and the continuity of adding the materials into the processing tank is guaranteed.

Owner:广东冠星陶瓷企业有限公司

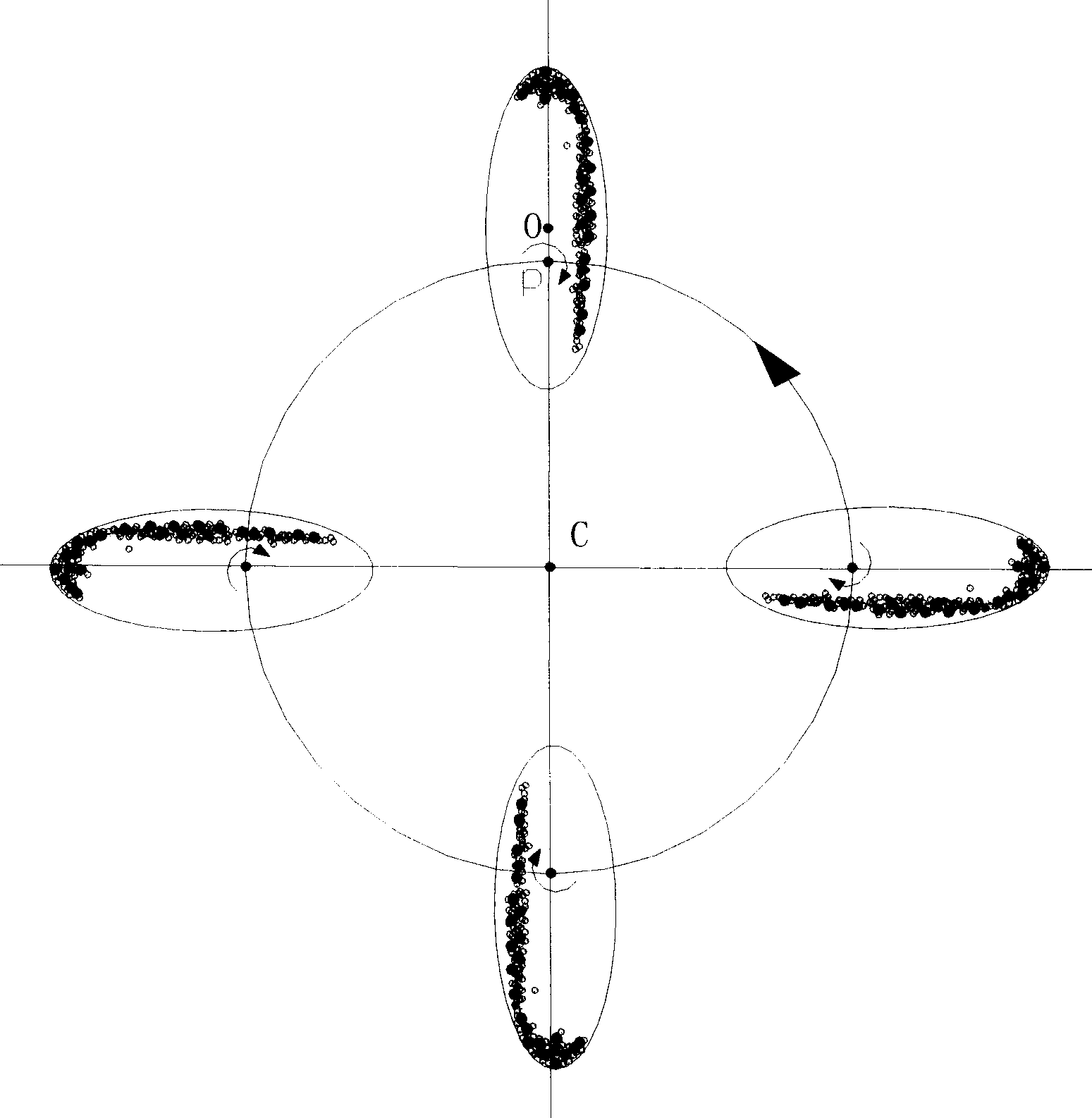

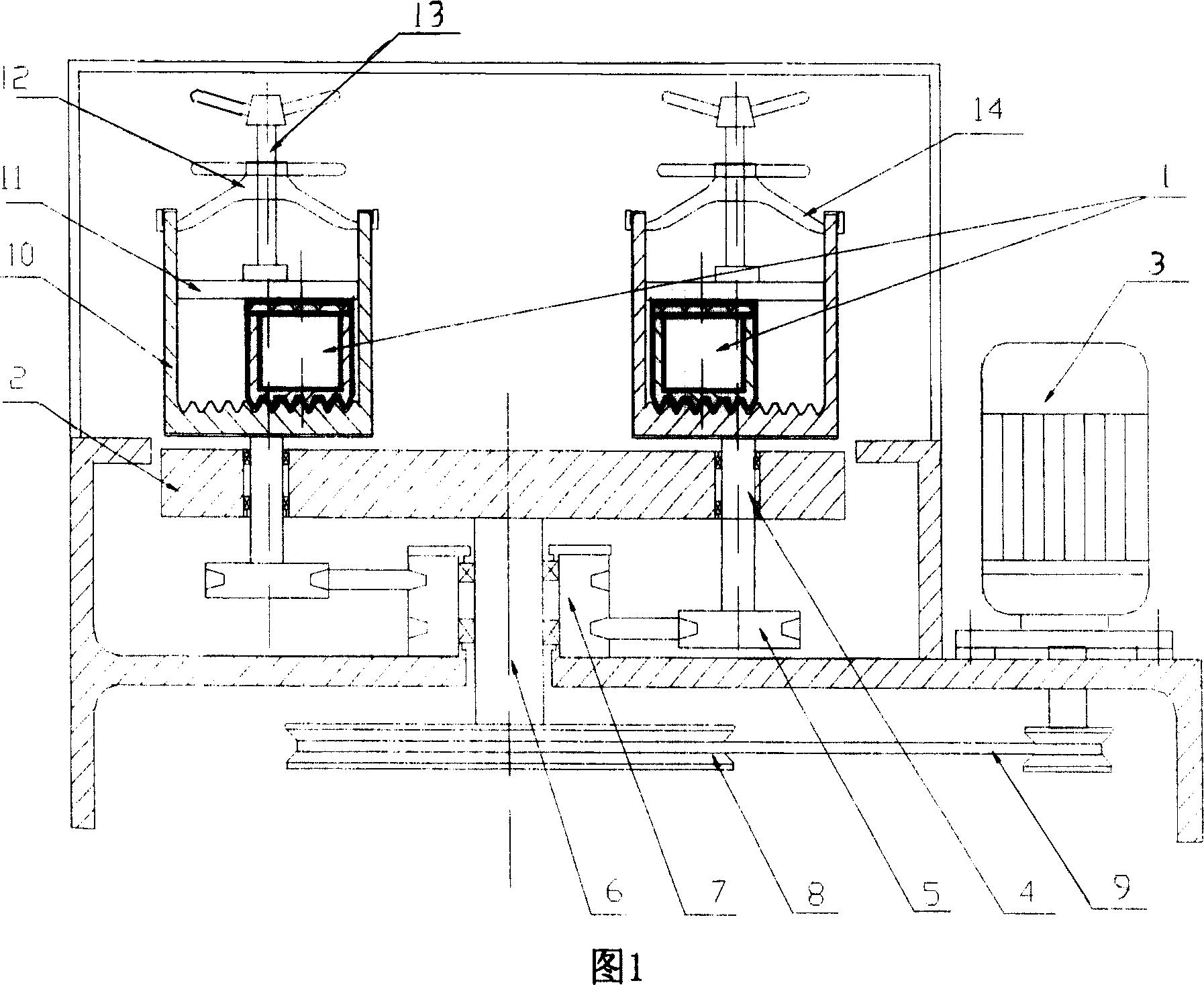

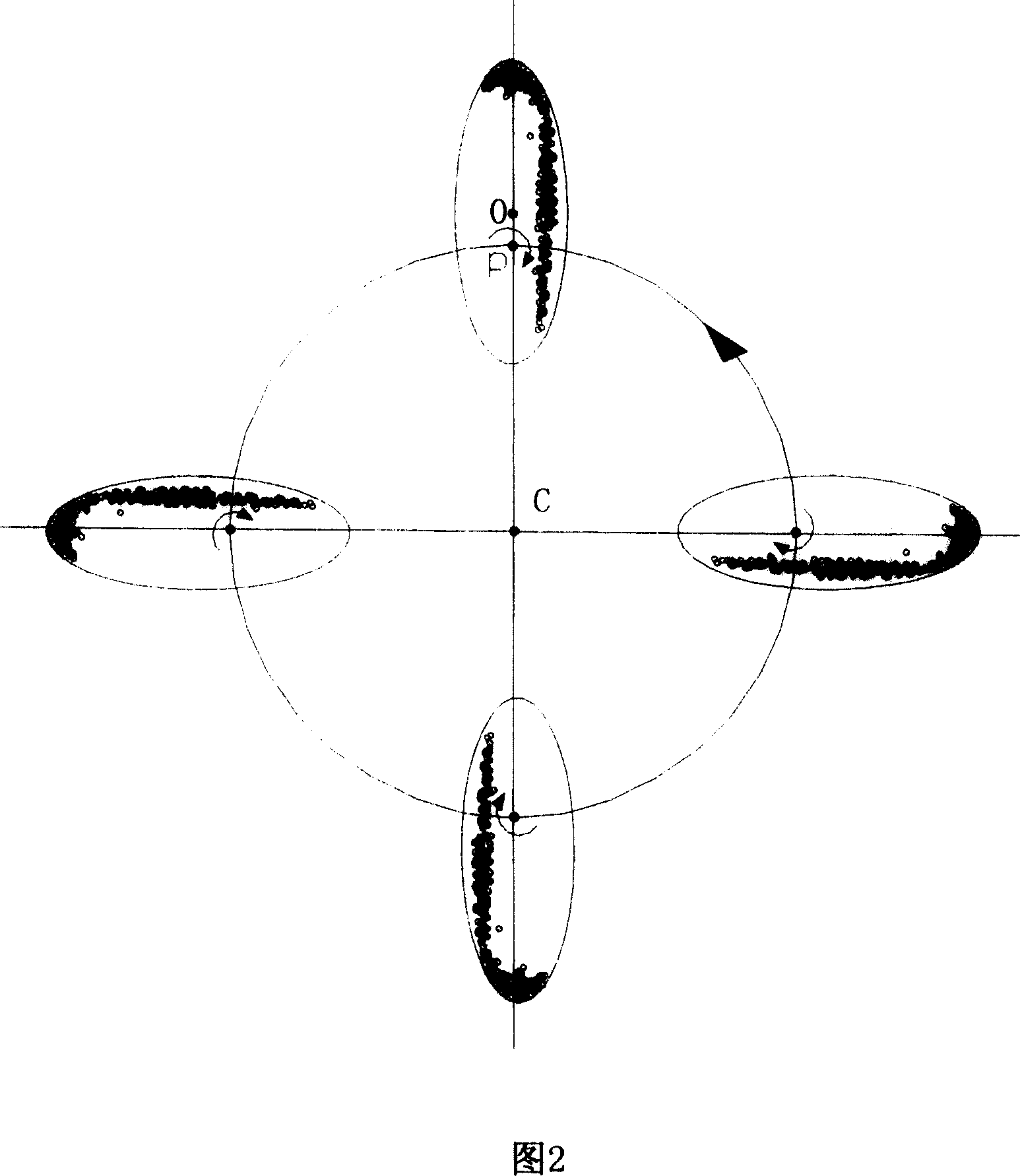

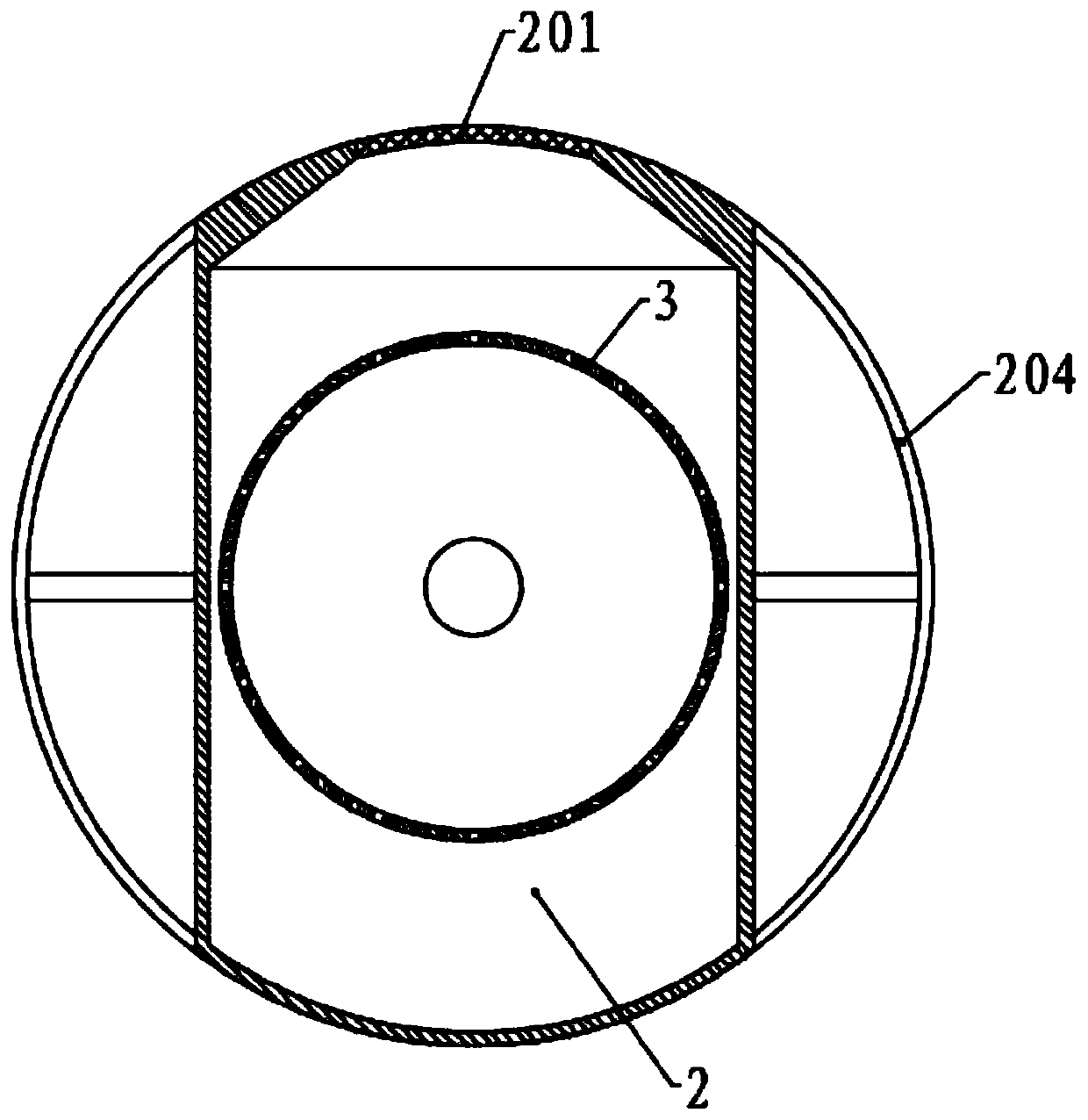

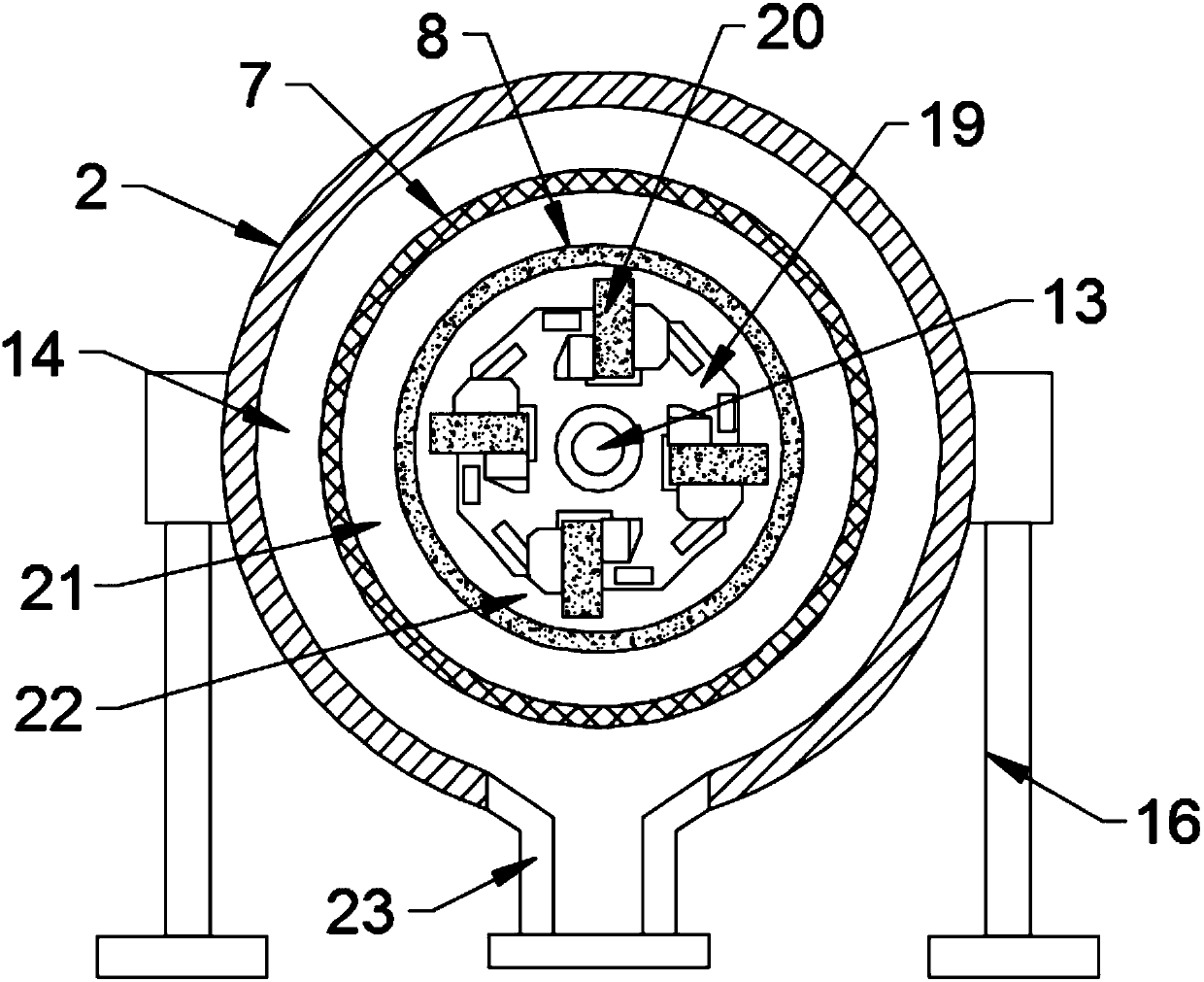

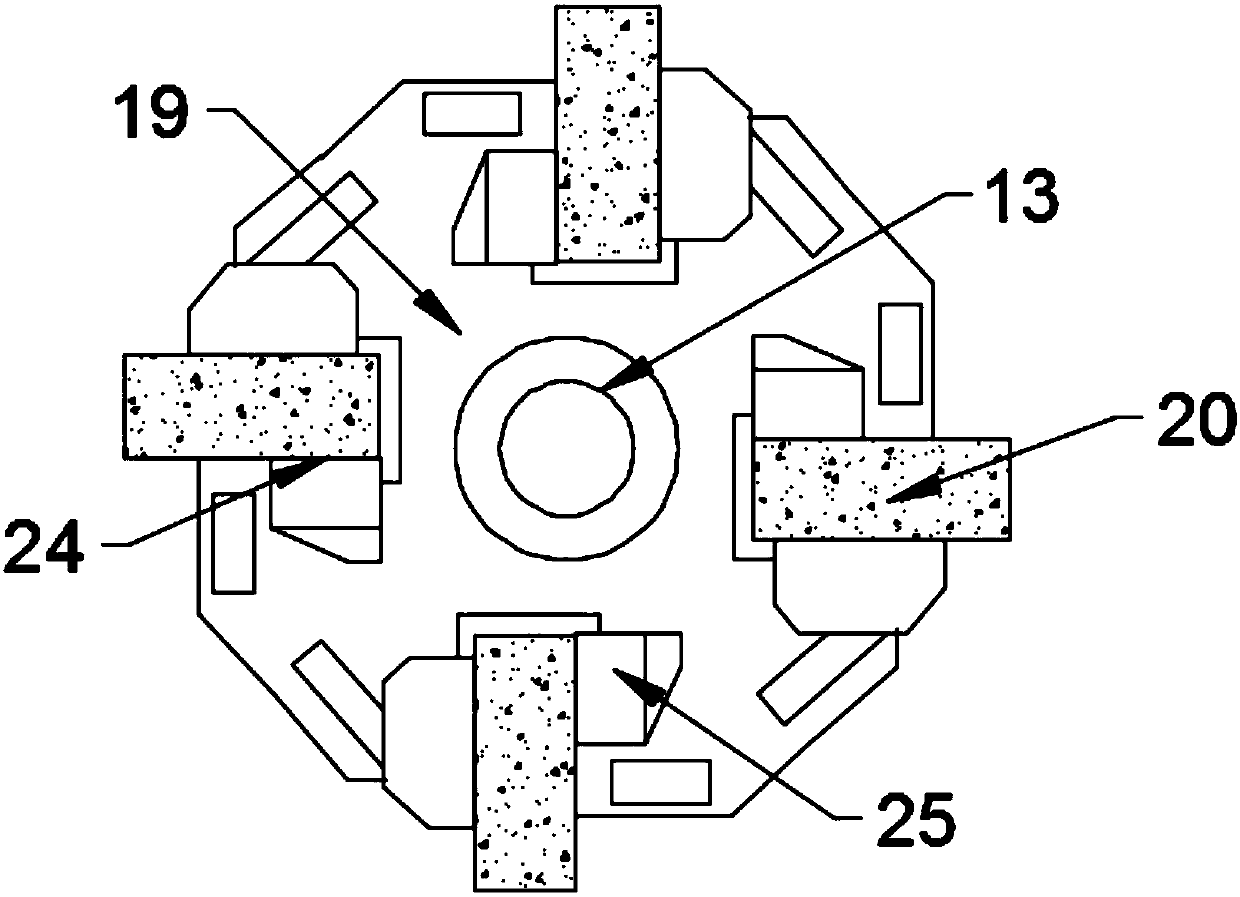

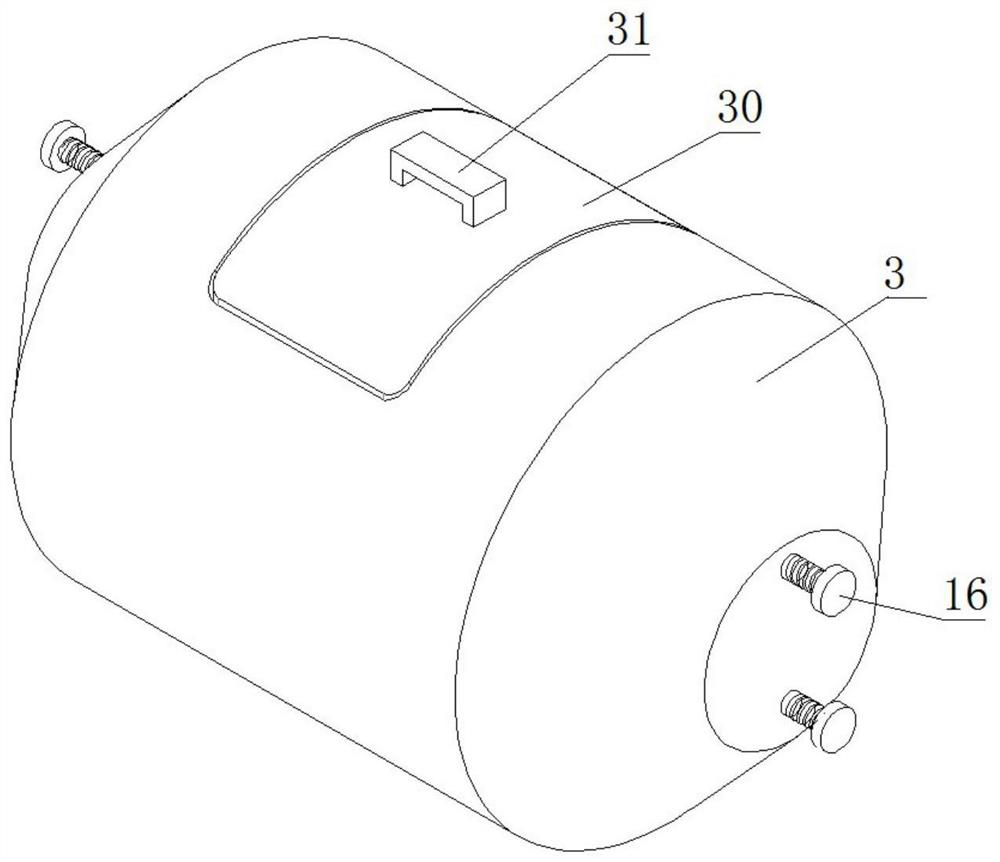

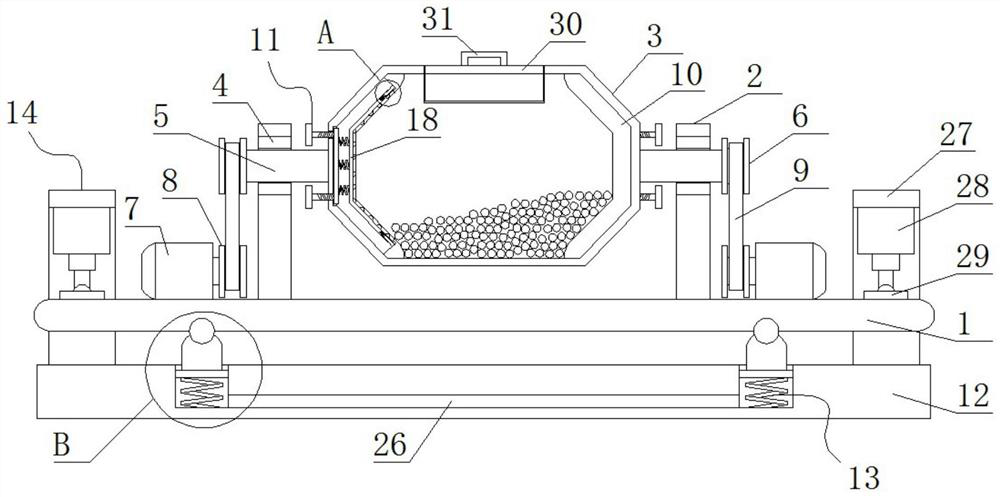

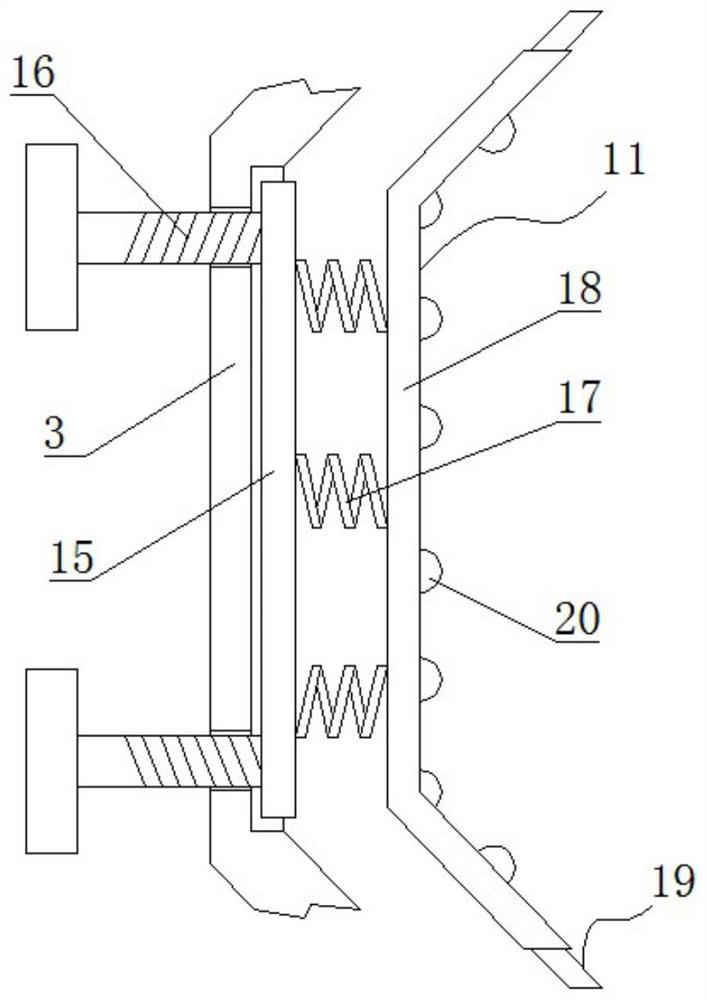

Double-motor self-synchronous driving vibration ball mill

InactiveCN109647589AIncrease vibrational energyImprove ball milling effectGrain treatmentsPhase differenceVibration exciter

The invention belongs to a grinding device, and provides a double-motor self-synchronous driving vibration ball mill. The system adopts a structure that the center of a cylinder body is eccentric witha power main shaft, the cylinder body is used as an excitation body, the mass moments of two vibration exciters are different, and m1r1 is larger than m2r2; the two vibration exciters are symmetrically installed relative to the center of a roller, the connecting line of rotating centers of the two vibration exciters is in a beta angle with the horizontal direction (beta is equal to 0-90 degrees),and the vibration exciter with the large mass moment is arranged on the left upper part; and meanwhile, the installation of the vibration exciters meets a certain position conditions, when the systemis operated stably, two motors achieve synchronization and operate stably, the steering is the same, and the phase difference is stable to be close to Pi. At the moment, the motion mode of the rolleris in the coexistence of swing and circular motion, due to the fact that the phase difference is close to Pi, so that swing occupies the main part. Ball milling medium in the roller is continuously thrown away under the action of the combined movement of swinging and the circular motion, the ball milling medium roll from a high position to a lower position, a high-strength rolling impact effect is generated, and ball milling of the materials is realized.

Owner:NORTHEASTERN UNIV

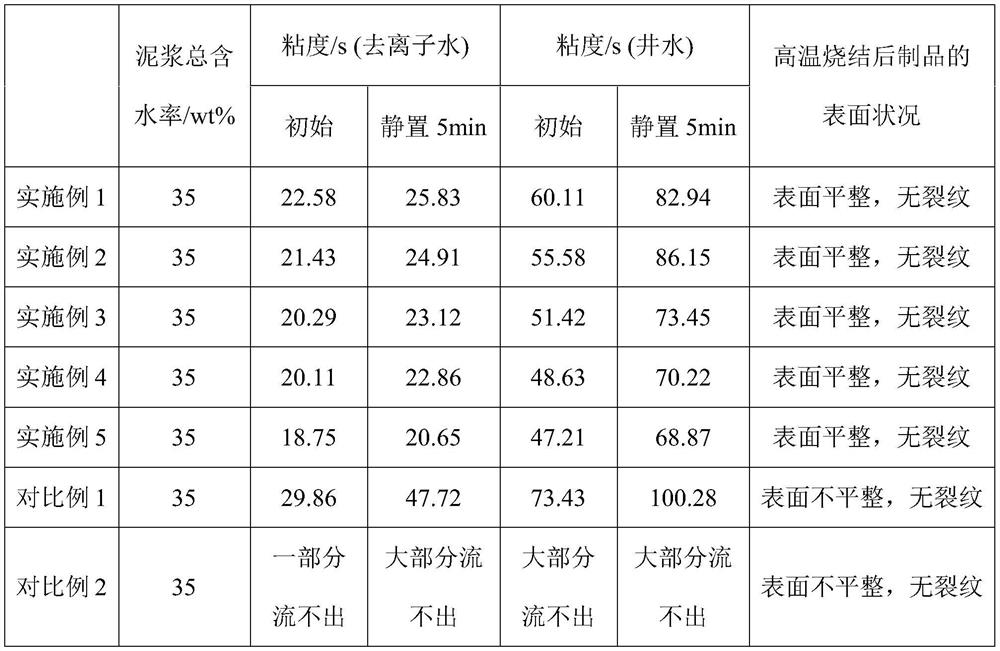

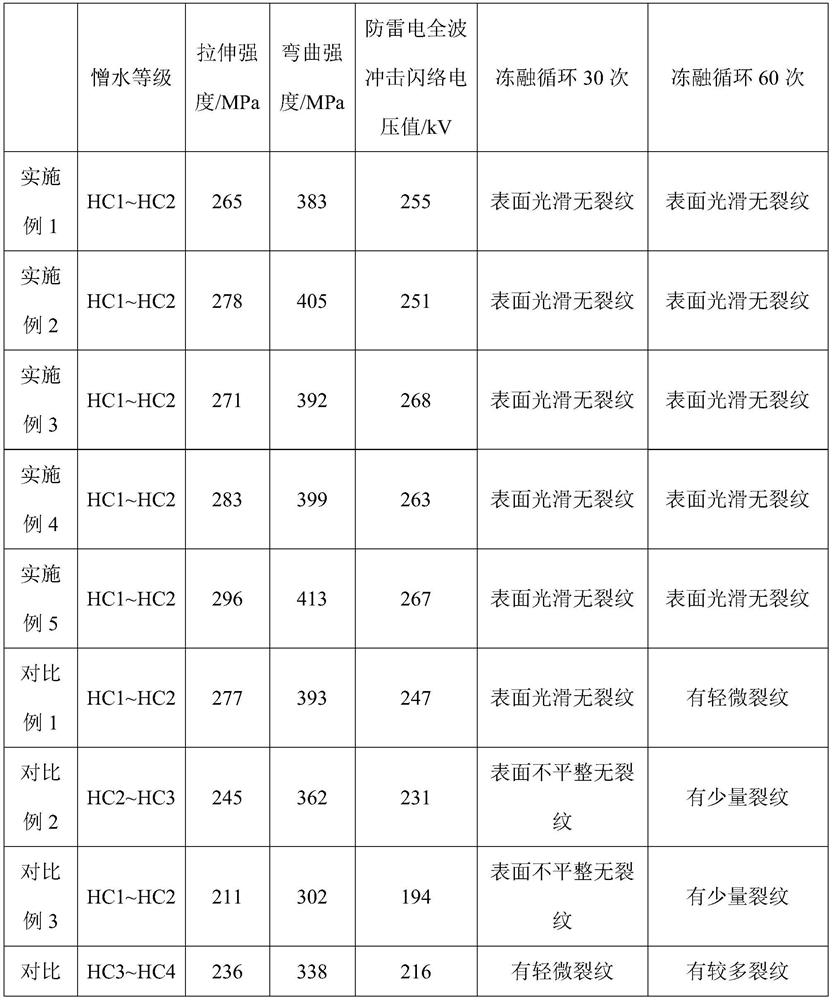

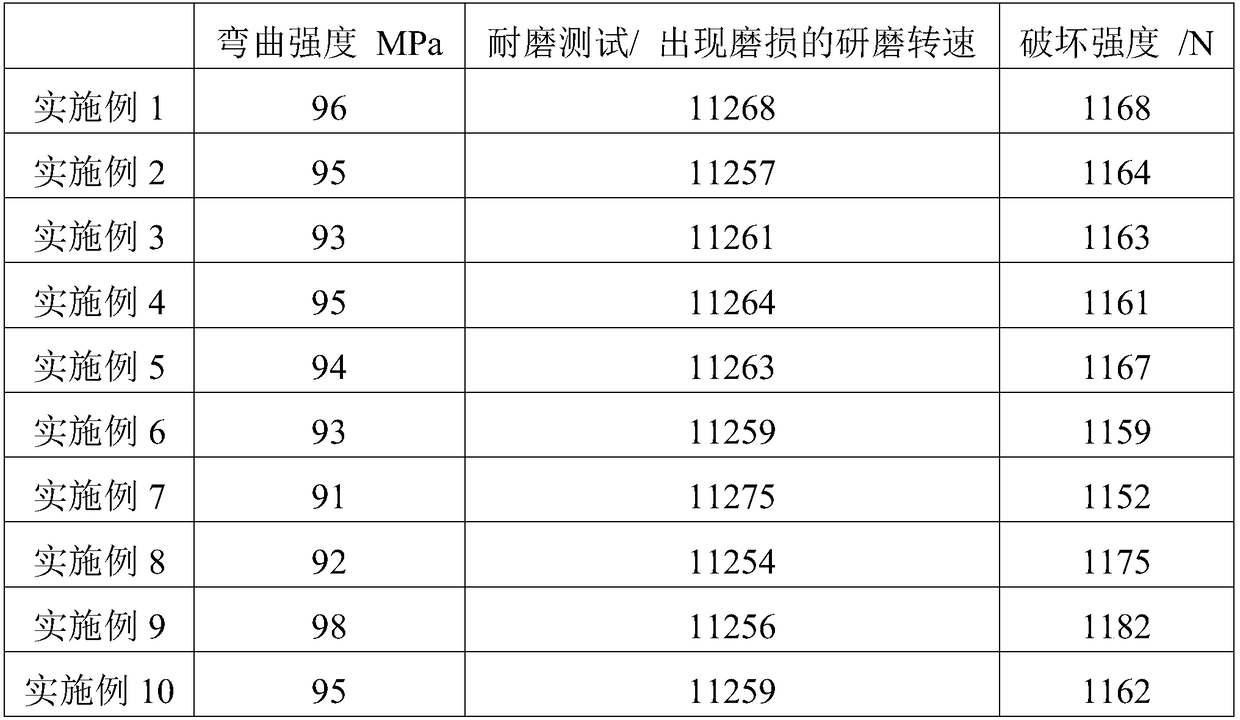

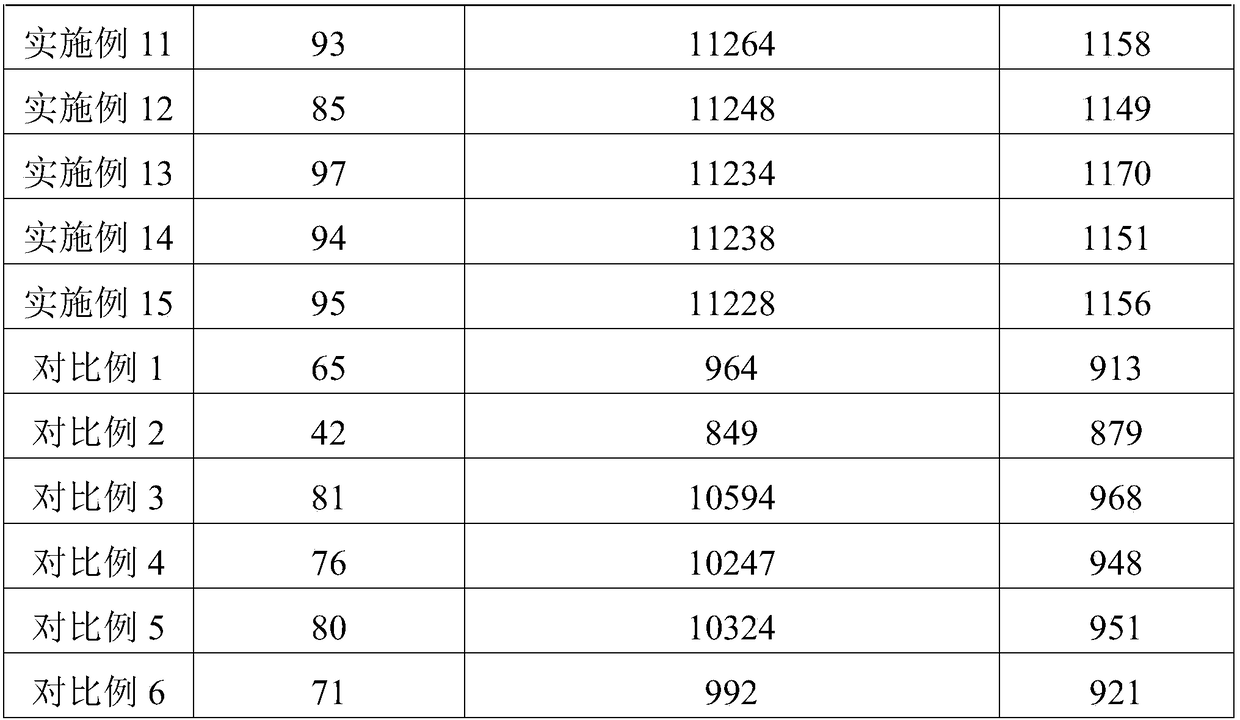

Low-temperature-resistant anti-pollution flashover porcelain insulator and manufacturing process thereof

The invention relates to the technical field of insulators, and provides a low-temperature-resistant anti-pollution flashover porcelain insulator and a manufacturing process thereof. According to the invention, the polymer is utilized to coat the modified nanoparticles and the water reducing agent containing the amino acid ionic liquid component, and the two components have a synergistic effect, so that the comprehensive performance of the porcelain insulator is jointly improved; and polyester, modified nanoparticles and olefin are copolymerized to obtain uniformly dispersed polymer coated modified nanoparticles, and the insulator raw material is subjected to ball milling twice, so that the binding property between organic matters and inorganic matters in the insulator raw material can be improved, the ball milling efficiency is improved, and the ball milling effect is improved. The porcelain insulator prepared by the invention has good electrical performance, mechanical performance, hydrophobic performance and temperature resistance.

Owner:江西新龙电瓷电器制造有限公司

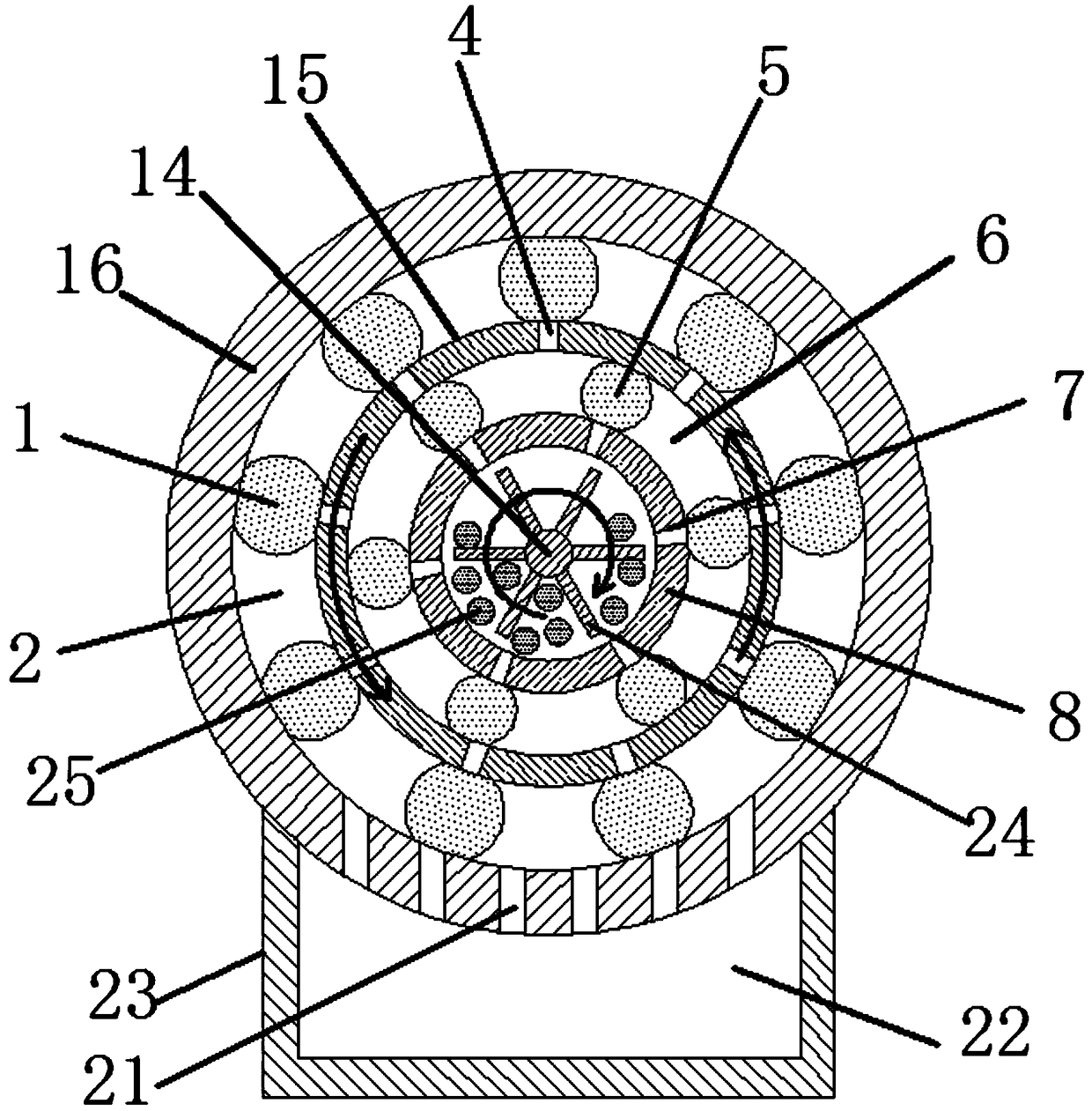

A horizontal multistage rolling ball mill

The invention discloses a horizontal type multistage rolling ball grinder. The horizontal type multistage rolling ball grinder comprises an inner ball grinding barrel, a feeding barrel, a rolling ballgrinding barrel body and an outer ball grinding barrel, wherein the inner ball grinding barrel is arranged in the outer ball grinding barrel; the feeding barrel is welded at one end of the inner ballgrinding barrel; a plurality of stirring bars are welded on a rotating shaft arranged in the inner ball grinding barrel; a primary ball grinding cavity is formed in the inner ball grinding barrel; aplurality of grinding balls are put in the primary ball grinding cavity; the rolling ball grinding barrel body is arranged between the inner ball grinding barrel and the outer ball grinding barrel; aninner ball grinding cavity is formed between the rolling ball grinding barrel body and the inner ball grinding barrel; a plurality of inner grinding balls are arranged in the inner ball grinding cavity; an outer ball grinding cavity is formed between the rolling ball grinding barrel body and the outer ball grinding barrel; and a plurality of outer grinding balls are arranged in the outer ball grinding cavity. The horizontal type multistage rolling ball grinder has the beneficial effects that the plurality of grinding balls are used for impacting materials to carry out primary ball grinding treatment; the inner grinding balls are used for secondary ball grinding treatment; the outer ball grinding cavity is used for secondary ball grinding treatment; the ball grinding effect is good; the time of ball grinding is shortened; the materials with uniform particle sizes are obtained; and the sieving and separation of the materials subjected to ball grinding are facilitated.

Owner:宝鸡正源化工科技股份有限公司

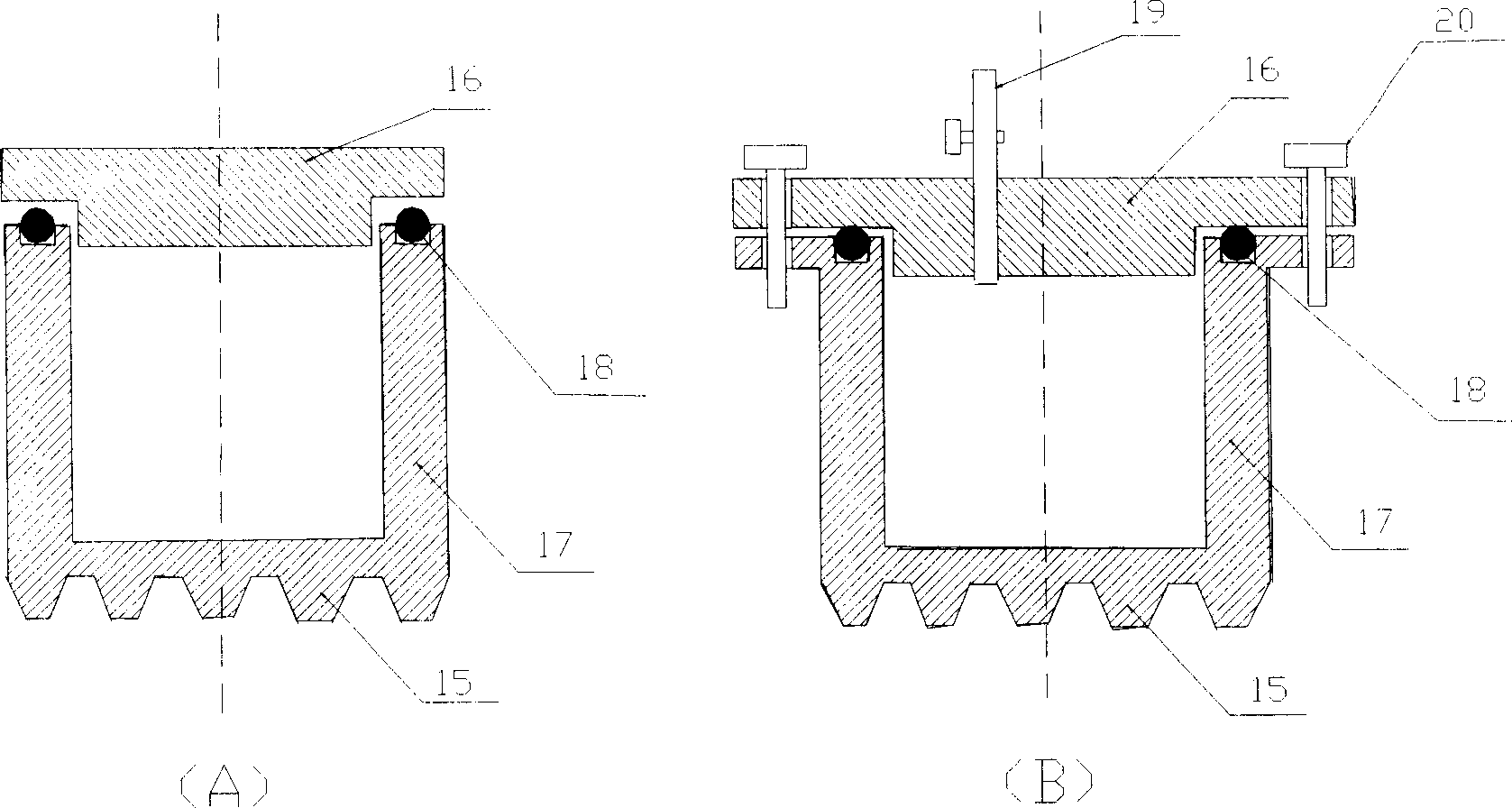

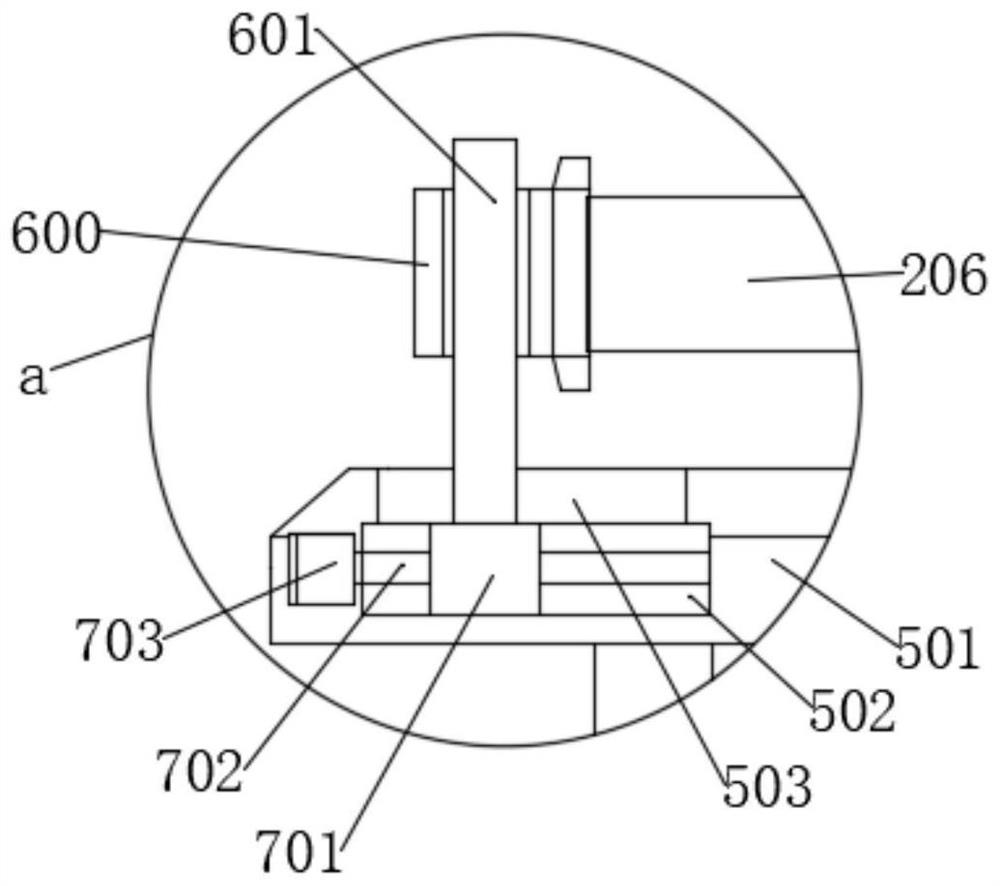

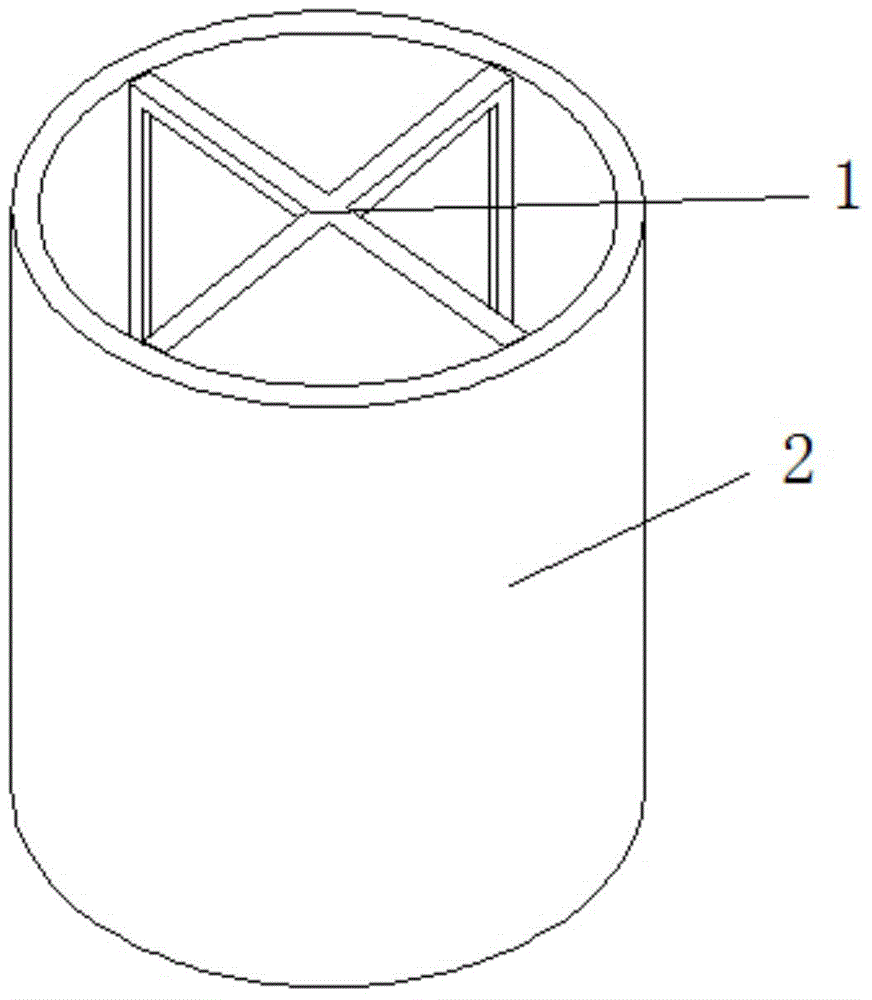

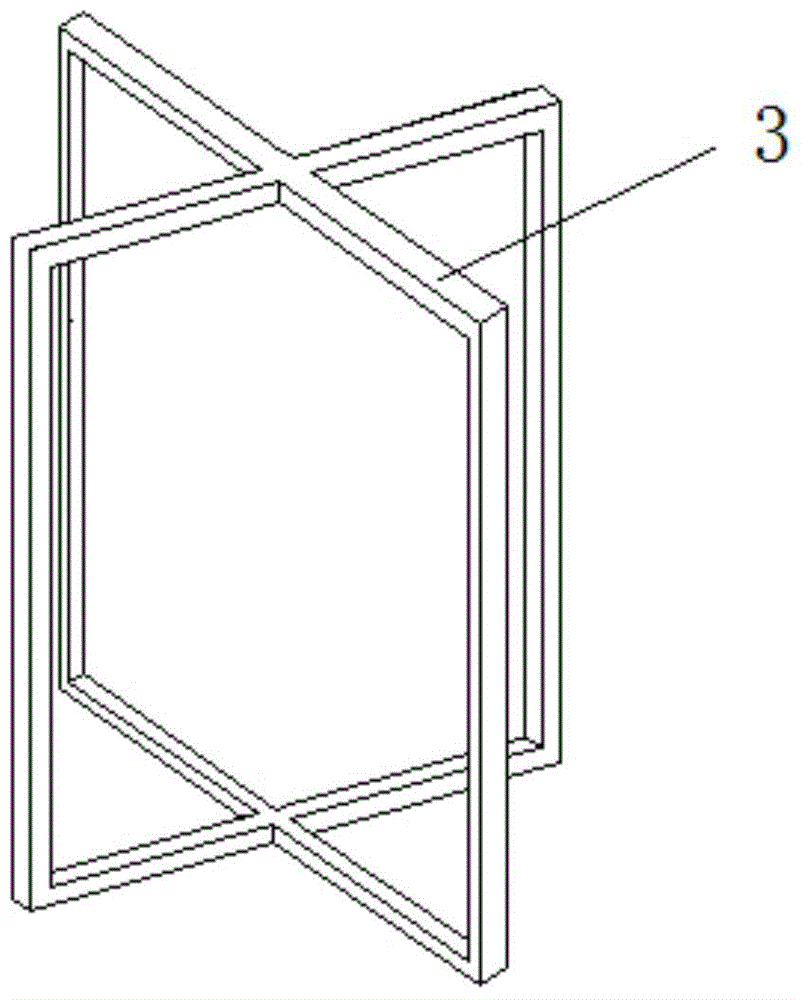

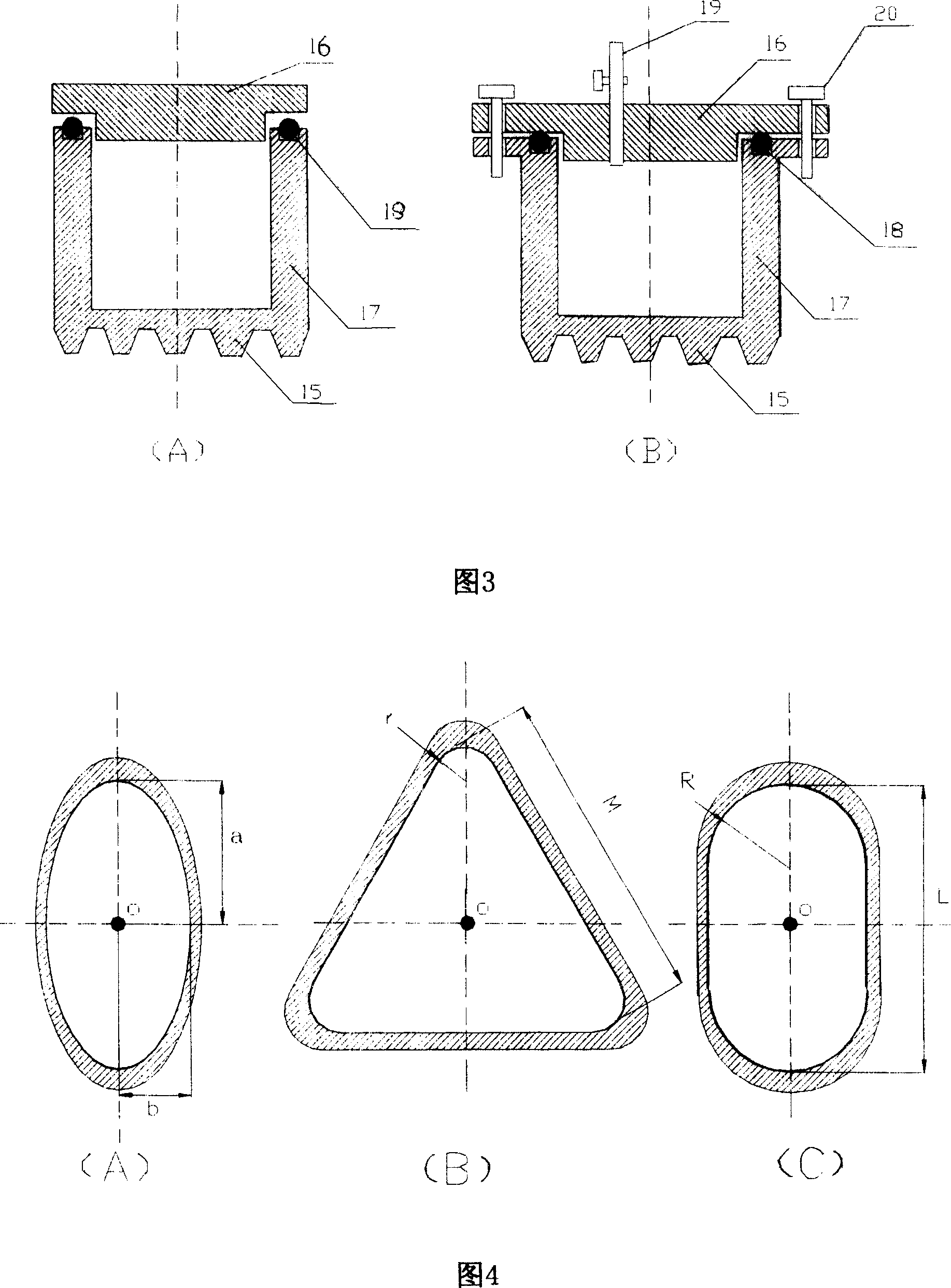

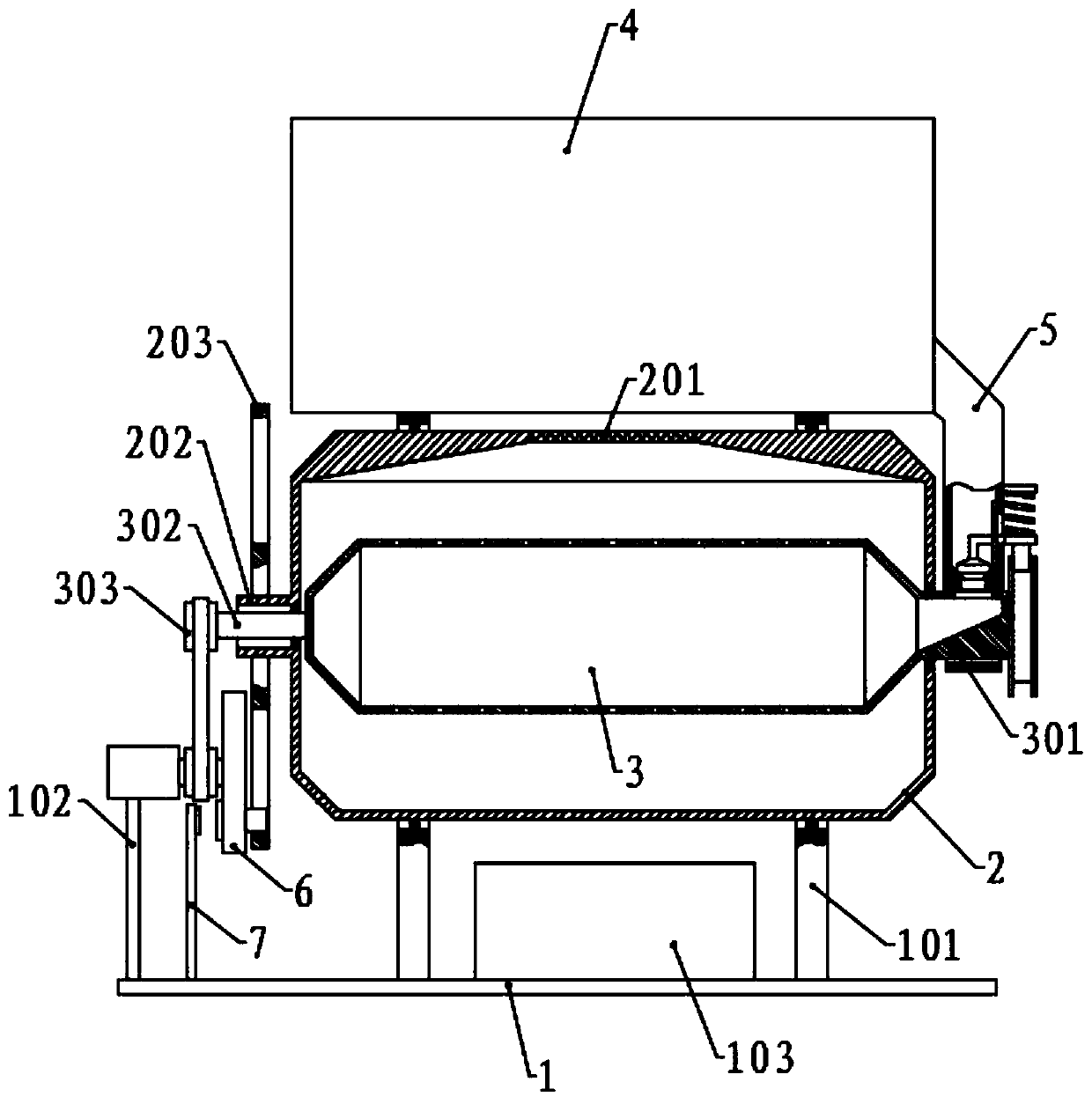

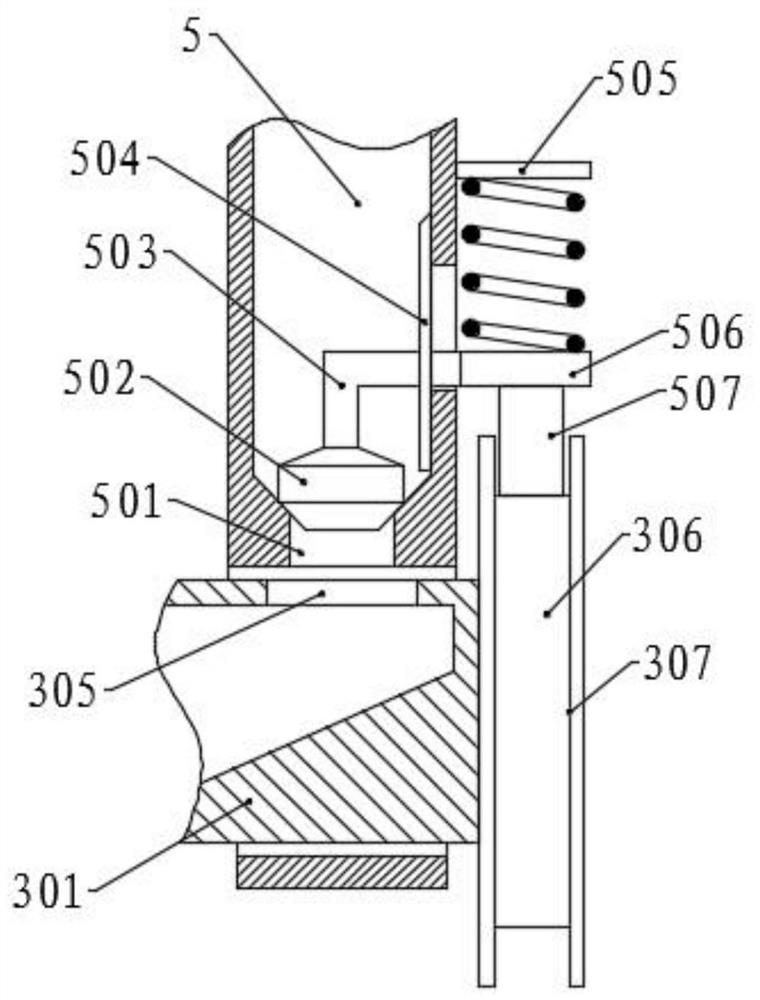

Scraper for planetary ball mill

InactiveCN105312123ASolve the bottom of the tankSolve the international problem of tank wall agglomerationGrain treatmentsEngineeringBall mill

The invention provides a scraper for a planetary ball mill. The scraper comprises a body, wherein the body is provided with a frame structure; and the body is built in a ball milling tank and is close to an inner wall of the ball milling tank. The scraper disclosed by the invention is applied to various planetary ball mills, the special scraper is arranged in the used ball milling tank, and the international problem that materials are agglomerated at the tank bottom and on the tank wall of the ball milling tank in the ball milling process of the ball mill is solved, so that the materials are always dispersed in the ball milling tank, milling balls and the materials can be fully collided and milled in the ball milling tank, and the ball milling effect is greatly improved.

Owner:南京南大仪器有限公司

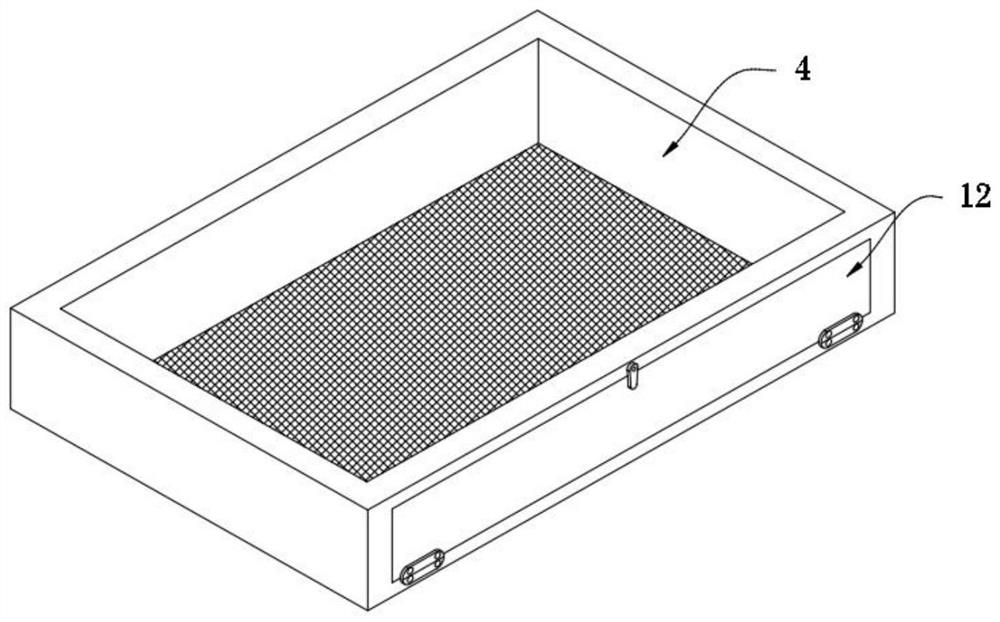

Ball-milling all-in-one machine for automatically grinding and screening metal manganese

ActiveCN114042509AImprove ball milling effectFully contactedSievingScreeningRotational axisManganese

The invention discloses a ball-milling all-in-one machine for automatically grinding and screening manganese metal, and relates to the field of ball mills. The ball-milling all-in-one machine comprises a mounting base, a fixing frame, a ball-milling cylinder and a screening groove, the ball-milling cylinder and the screening groove are both located in the fixing frame, the two ends of the ball-milling cylinder are connected with the fixing frame through a fixing shaft and a feeding port respectively, and a vibration assembly is arranged in the fixing frame. Through the arrangement of the vibration assembly, when the fixing frame linearly moves left and right, the screening groove can shake left and right, metal manganese powder obtained after ball milling can be effectively screened, and after a connecting shaft rotates, a second driving bevel gear drives a second driven bevel gear to rotate, and a rotating shaft rotates, so that an eccentric wheel rotates; the screening groove can be pressed when the eccentric wheel rotates, then the screening groove inclines leftwards and rightwards in a reciprocating manner under the cooperation of a spring, then the metal manganese powder shakes in the screening groove, so that the screening effect of the metal manganese powder is further improved, and the screening efficiency is improved.

Owner:江西省莲花水轮机厂有限公司

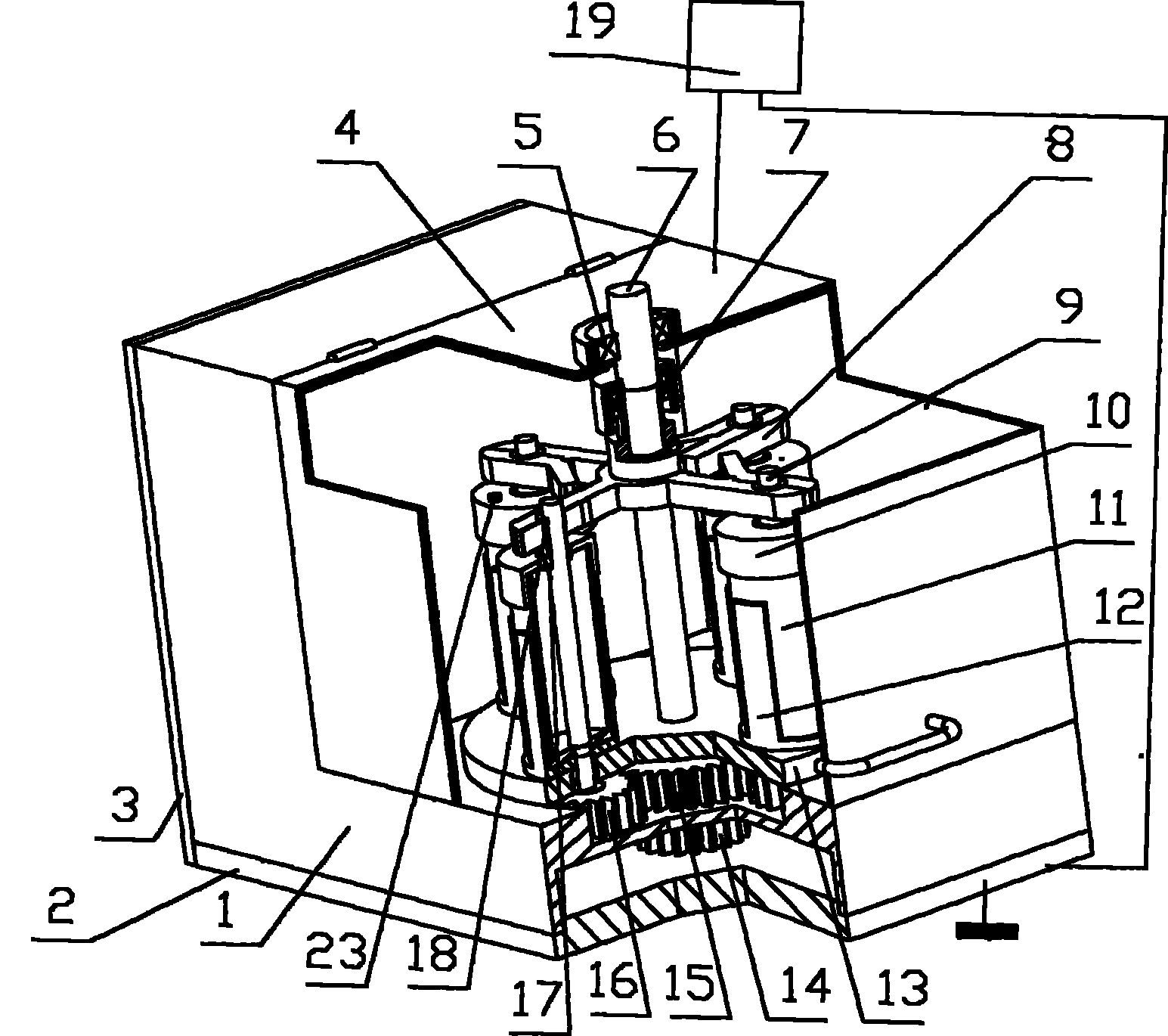

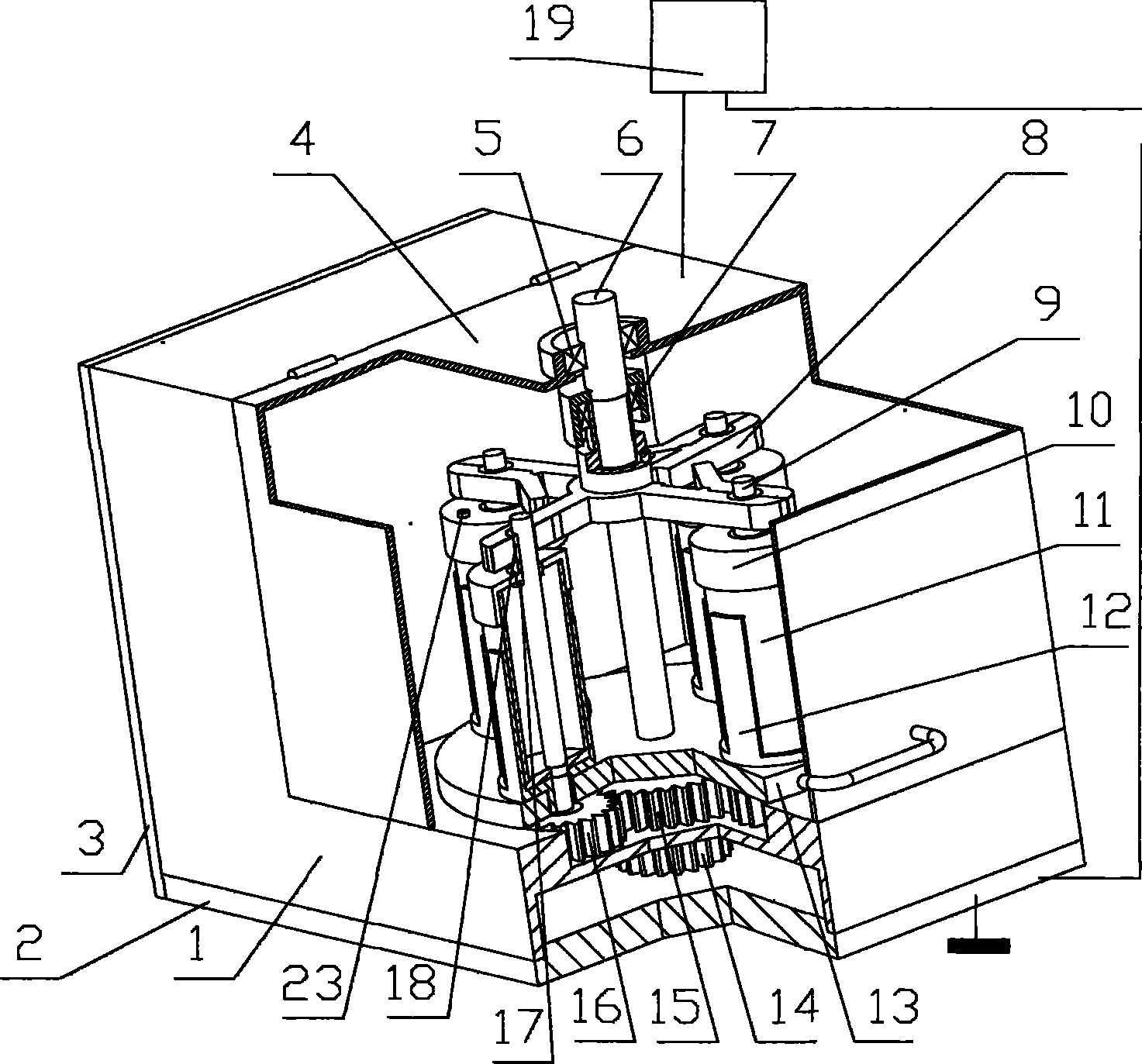

Planetary ball mill

A planetary ball grinder is composed of drive motor, transmission gear train, revolving mainshaft and rotary disc, multiple rotational axles and the ball grinding cylinders rotating around own axle. It features that said ball grinding cylinder is eccentrically installed in such manner that the central line of rotational axle is parallel with the geometric central line of the cross-section of ball grinding cylinder, and its eccentrical degree can be changed for changing the ratio of grinding action to impact action.

Owner:SUN YAT SEN UNIV

Double-layer ball milling device for high-purity quartz sand processing

ActiveCN111589533AAvoid affecting the ball milling effectRealize intermittent feedingGrain treatmentsEngineeringQuartz

The invention discloses a double-layer ball milling device for high-purity quartz sand processing in the technical field of high-purity quartz sand processing. The double-layer ball milling device comprises a base, an outer cylinder, an inner cylinder and a storage box, wherein a driving assembly is arranged on the base, and the base is connected with the inner cylinder and the outer cylinder through the driving assembly; the storage box is connected with a feeding pipe, and a sealing assembly is arranged in the feeding pipe; and the sealing assembly is correspondingly connected with a rotating wheel on the inner cylinder. According to the double-layer ball milling device, the inner cylinder is rotated through the driving assembly, so that quartz sand is subjected to primary ball milling through a ball milling ball, and enters the outer cylinder through sieve holes, and meanwhile, intermittent discharging is realized through the rotating wheel and the sealing assembly; the outer cylinder is enabled to swing in a reciprocating mode through a rotating disc and rotating rods, and the quartz sand is subjected to secondary grinding; and a connecting shaft is separated from the rotatingrods through an electromagnet, the outer cylinder is turned over until a screen is downward, so that discharging is facilitated, the connecting shaft is connected with the corresponding rotating rod again, and as a result, the outer cylinder swings and drives the quartz sand to move at the screen, and the screening and discharging effect is improved.

Owner:连云港原舜光伏材料有限公司

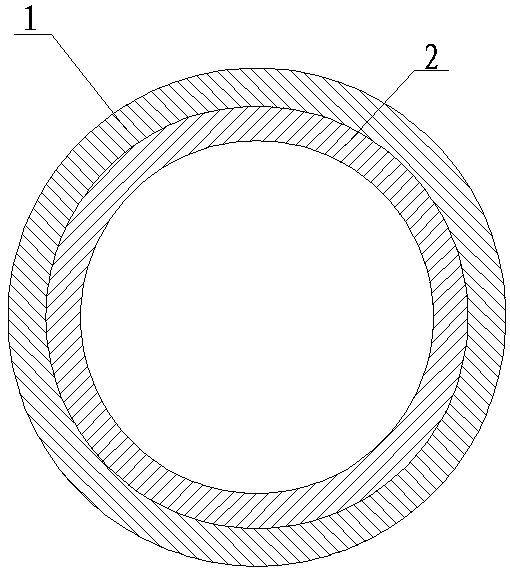

Shell device for dry ball mill

The invention discloses a shell device for a dry ball mill. The shell device comprises a shell, and a detachable wear resisting layer bonded on the inner wall of the shell; the detachable wear resisting layer is assembled by multiple wear resisting units; the wear resisting units comprise metal bases and ceramic wear resisting blocks; grooves are formed in the top surfaces of the metal bases; theceramic wear resisting blocks are arranged in the grooves; one ends of the ceramic wear resisting blocks are exposed out of the grooves; and the metal bases are provided with mounting holes for fixingthe metal bases on the inner wall of the shell through connecting pieces. The shell device adopts a double-layer structure, wherein the inner side adopts the detachable wear resisting layer; on the one hand, the wear resistance is improved through use of wear resisting materials; and on the other hand, replacement is convenient and the overall service life is prolonged through the detachable structure; the wear resisting units adopt a form of combining the metal bases with ceramic; and the ceramic wear resisting blocks are adopted on wear resisting surfaces, so that the wear resistance can beimproved, meanwhile, the overall weight is reduced, and carrying and replacement are convenient.

Owner:洛阳鹏飞耐磨材料股份有限公司

Rolling grinding type continuous sand screening device for buildings

ActiveCN110152836AAvoid problems that cannot be put into use in buildingsEasy to operateGrain treatmentsSpiral bladeArchitectural engineering

The invention discloses a rolling grinding type continuous sand screening device for buildings. The device comprises a sand screening box, an outer filter screen cylinder, a grinding cylinder, an inner filter screen cylinder, a rotating shaft, grinding balls, pushing spiral blades and grinding rollers. The sand screening box is installed on a support frame, the rotating shaft is horizontally erected in the middle of the sand screening box, the grinding rollers are welded in the middle of the rotating shaft, the pushing spiral blades are welded on the rotating shaft and located on the other sides of the grinding rollers, the rotating shaft is sleeved with the inner filter screen cylinder, a grinding cylinder is arranged in the middle of the inner filter screen cylinder, and an outer filterscreen cylinder is fixedly connected to the exterior of the inner filter screen cylinder. Screening, grinding and ball milling of building sand particles are achieved till the sand particles are completely screened out, finally the sand particles are discharged from a discharge hopper to be used in building construction, operation is convenient and fast, the screening efficiency is high, meanwhile, the grinding and ball milling effects are quite good, it is ensured that the building sand particles can be sufficiently applied to building construction, and the problem that traditional large-particle-size sand particles cannot be used in the buildings after being screened out is avoided.

Owner:安徽贵宏建工集团有限公司

Glaze material and preparation method thereof

The invention belongs to the technical field of ceramic and in particular relates to a glaze material and a preparation method thereof. The preparation method comprises the following steps: (1) weighing drying materials in a formula of the glaze material according to formula amounts; adding the drying materials into a mixing tank of a planetary mixer to perform striring and mixing until a dry rawmaterial mixture is obtained; (2) transporting the dry raw material mixture into a ball-milling machine; adding water which accounts for 5 to 10 percent of the total amount of the water to wet the dryraw material mixture; carrying out ball milling; sieving through a sieve with the size of 800 to 1200 meshes after carrying out the ball milling; (3) transporting the sieved dry raw material mixtureinto the mixing tank of the planetary mixer; adding the balance of the water and vacuumizing until the pressure is -0.05 to -0.1 MPa; stirring and mixing for 50 to 60 min in vacuum; finally, adjustingthe moisture content to be 53 to 58 percent, so as to obtain the glaze material. By adopting the preparation method of the glaze material, provided by the invention, the dispersion and mixing effectof the glaze material is remarkably improved, and the prepared glaze material has relatively high surface strength and wear-resisting performance.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

Ball milling apparatus for preparing nano silicon powder

The invention discloses material ball milling apparatus, which comprises a cylinder. Two ends of the cylinder are provided with a material inlet and a material outlet. A first partition plate and a second partition plate are arranged in the cylinder. The first partition plate and the second partition plate are both provided with a filter hole. The diameter of the filter hole of the first partitionplate is greater than that of the filter hole of the second partition plate. The first partition plate and the second partition plate divide the cylinder into a first cylinder, a second cylinder, anda third cylinder. The inner walls of the first cylinder, the second cylinder, and the third cylinder are all provided with a wear resistant lining plate. The lining plates of the first cylinder and the second cylinder are both provided with embossments. Steel balls for grinding are placed in the first cylinder, the second cylinder, and the third cylinder. The steel balls in the first cylinder arein a cylindrical shape. The upper end and bottom end of each cylindrical ball body are connected to an arc end. The surfaces of steel balls in the second cylinder are provided with multiple embossments. The ball milling apparatus has the advantages of good ball milling effect and short ball milling time, moreover, the service life of lining plates is prolonged, and the ball milling apparatus is suitable for the preparation of nano level silicon powder.

Owner:GUANGDE BAODA PRECISION CIRCUIT CO LTD

Graphene nanosheet-based toughened aluminum oxide-titanium boride composite ceramic material and preparation method thereof

InactiveCN112159242AImprove fracture toughnessImprove anti-friction and anti-wear propertiesCeramic compositeComposite ceramic

The invention discloses a graphene nanosheet-based toughened aluminum oxide-titanium boride composite ceramic material and a preparation method thereof, belongs to the field of cutter materials, and aims to solve the technical problem of how to further improve the fracture toughness and antifriction and antiwear properties of a ceramic composite material in a high-speed cutting process. Accordingto the technical scheme, the graphene nanosheet-based toughened aluminum oxide titanium boride composite ceramic material is mainly prepared from, by weight, 70-80 parts of submicron aluminum oxide, 20-30 parts of titanium boride, 0-0.6 part of graphene and 0.4-1.5 parts of a sintering aid. The graphene nanosheet-based toughened aluminum oxide titanium boride composite ceramic material is used forpreparing cutters. The invention also discloses a preparation method of the graphene nanosheet-based toughened aluminum oxide-titanium boride composite ceramic material.

Owner:QILU UNIV OF TECH

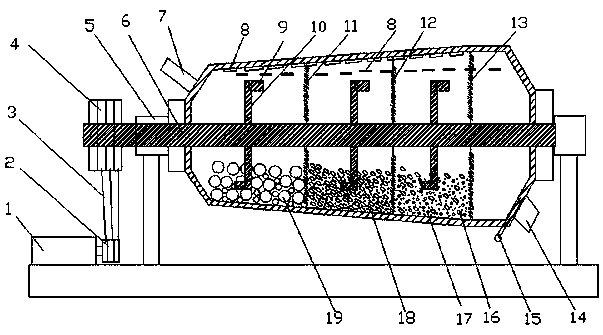

Ball mill for producing firework aluminum powder

InactiveCN110813453AImprove ball milling effectImprove efficiencySievingScreeningFireworksAluminium powder

The invention provides a ball mill for producing firework aluminum powder. The ball mill comprises a barrel body, a shaft and a support frame, wherein the barrel body is erected on the supporting frame through a shaft, a feeding opening is formed in one end of the barrel body, and a discharging opening is formed in the other end of the barrel body; a coarse grinding chamber, a middle grinding chamber and a fine grinding chamber are sequentially arranged in the barrel body, and every two of the coarse grinding chamber, the middle grinding chamber and the fine grinding chamber are separated through a mesh screen; and a stirring device is further arranged in the barrel body, and the stirring device comprises a transverse stirring blade arranged on the inner wall of the barrel body and a stirring plate arranged on the shaft. According to the ball mill, the ball milling efficiency of the ball mill is effectively improved, ball milling is carried out simultaneously in various ways, and the ball milling quality is effectively improved. Meanwhile, energy loss is reduced, the firework aluminum powder which is ball-milled through the ball mill is used for manufacturing fireworks, the setting-off effect of the fireworks is effectively improved, and the pollution to the environment is reduced.

Owner:衡东县金源铝银粉有限公司

Part ball-milling device for industrial production and using method thereof

ActiveCN112691758APlay a buffer roleReduce frictionCement productionGrain treatmentsFriction forceIndustrial engineering

The invention discloses a part ball-milling device for industrial production and a using method thereof, and belongs to the technical field of industrial production. The part ball-milling device comprises a bottom plate, two vertical plates are fixedly connected to the upper surface of the bottom plate, bearings are embedded in the two vertical plates, and a ball-milling barrel is placed on the upper portion of the bottom plate. Straight rods are fixedly connected to the left side face and the right side face of the ball-milling barrel correspondingly, the two straight rods penetrate through inner rings of bearings correspondingly and extend to the outside, adjusting mechanisms are installed in two abutting frames correspondingly, two sets of buffering mechanisms are arranged in a buffering plate, and swing mechanisms are installed on the left side and the right side of the upper surface of the buffering plate correspondingly. According to the part ball-milling device for industrial production and the using method thereof, through cooperative arrangement of the ball-milling barrel and the adjusting mechanisms, the friction force of milling balls and parts on the inner wall of the ball-milling barrel is reduced, then the service life of the device is prolonged, through cooperative arrangement of the buffering plate, the buffer mechanisms and the swing mechanisms, the left end and the right end of the device swing up and down more obviously, and the ball-milling effect of the device can be better improved.

Owner:娄底鼎源智能装备有限公司

Lead-free piezoelectric ceramic consisting of B-bit compound Bi-based compounds and preparation method thereof

The invention discloses a lead-free piezoelectric ceramic consisting of B-bit compound Bi-based compounds and a preparation method thereof. The general formula of the lead-free piezoelectric ceramic is shown in (1-x-y)Bi(Li1 / 2Me1 / 2)O[3-x]BaTiO[3-y](K1 / 2Bi1 / 2)TiO[3+z]MaOb, wherein x, y and z refer to mole fractions, x is larger than 0 and less than 1.0, y is larger than 0 and less than 0.1, z is larger than or equal to 0 and less than or equal to 0.1; Me is one or more pentavalent metallic elements, and MaOb is one or more oxides, and M is monovalent to hexavalent elements and can form a solid oxide with oxygen; and the lead-free piezoelectric ceramic is prepared by using a conventional ceramic preparation method. A prepared lead-free piezoelectric ceramic has good sintering properties, is simple and stable in preparation process and good in performance, and can partially replace a traditional lead-based piezoelectric ceramic.

Owner:GUILIN UNIV OF ELECTRONIC TECH

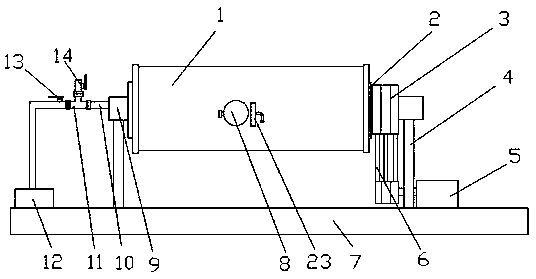

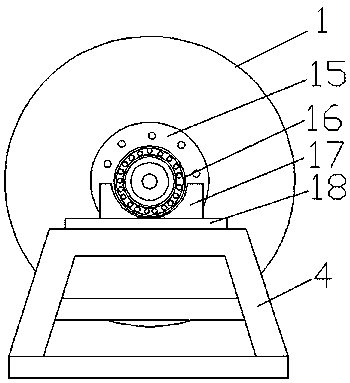

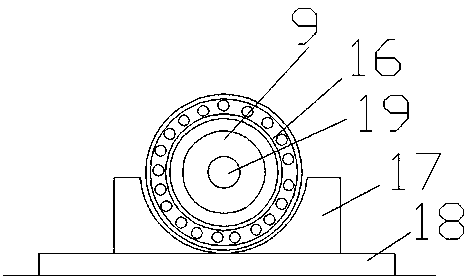

Vacuum ball mill for preparation of aluminum powder for fireworks

The invention provides a vacuum ball mill for preparation of aluminum powder for fireworks. The vacuum ball mill comprises a barrel-shaped mill body, a mounting seat and a driving motor, concentric shafts are arranged at the two ends of the mill body correspondingly and mounted and fixed on the mounting seat through a bearing, a pulley is arranged at one end of the mill body and connected to the driving motor through a belt, a through hole communicating within the mill body is formed in each concentric shaft, and the concentric shafts comprises the left concentric shaft and the right concentric shaft; and meanwhile, the through hole is formed by corresponding to the corresponding concentric shaft, the through holes comprises the left through hole and the right through hole, an observationwindow is arranged in the left through hole, and the right through hole is connected to a vacuum pump through a pipe. The scheme of the vacuum ball mill effectively improves the efficiency and qualityof aluminum raw material production, effectively improves the convenience of operation, can effectively prevent oxidation of pulp after ball milling, effectively reduces the loss of energy, and facilitates batch production.

Owner:衡东县金源铝银粉有限公司

A double-layer ball milling equipment for processing high-purity quartz sand

ActiveCN111589533BAvoid affecting the ball milling effectRealize intermittent feedingGrain treatmentsQuartzStorage tank

The invention discloses a double-layer ball milling equipment for high-purity quartz sand processing in the technical field of high-purity quartz sand processing, which includes a base, an outer cylinder, an inner cylinder and a storage box. The inner cylinder is connected with the outer cylinder, the storage box is connected with a feeding pipe, and a sealing assembly is arranged in the feeding pipe, and the sealing assembly is connected with the rotating wheel on the inner cylinder correspondingly. Quartz sand is ball milled for the first time, and enters the outer cylinder through the sieve hole, and intermittent feeding is realized through the rotating wheel and sealing assembly at the same time; the outer cylinder is reciprocally swayed by the rotating disc and rotating rod, and the quartz sand is subjected to secondary grinding; through the electromagnet Disconnect the connecting shaft from the rotating rod, turn the outer cylinder to the bottom of the screen to facilitate unloading, and reconnect the connecting shaft to the corresponding rotating rod, so that the outer cylinder can swing and drive the quartz sand to move on the screen, improving Filter the output effect.

Owner:连云港原舜光伏材料有限公司

A method for preparing tetrabasic lead sulfate

ActiveCN106564941BShorten mixing timeShorten heating timeFinal product manufactureLead sulfatesSulfateReaction temperature

The invention relates to a method for preparing tetrabasic lead sulfate, which comprises the following steps: A. Prepare the reaction, send the pre-mixed lead material into the reaction kettle, and carry out internal circulation stirring while adding sulfuric acid solution into the reaction kettle After uniformity, feed compressed air into the reaction kettle to cool the lead slime; B. Ball milling reaction, transport the lead slime in step A to a drying ball milling device, and perform drying and ball milling simultaneously to obtain a tetrabasic lead sulfate product. The present invention adopts the method of directly reacting the premixed lead material with sulfuric acid, makes full use of the heat generated by the exothermic reaction of concentrated sulfuric acid to rapidly heat up the reactor, thereby shortening the preparation reaction time, and the reaction product is rapidly cooled by compressed air, further Effectively inhibit the 4BS crystal particles from becoming larger, and the formed 4BS has a small and uniform particle size, which effectively solves the problem in the prior art that the reaction product crystal particles are large and uneven due to the high reaction temperature and long reaction time for the preparation of tetrabasic lead sulfate. technical problem.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

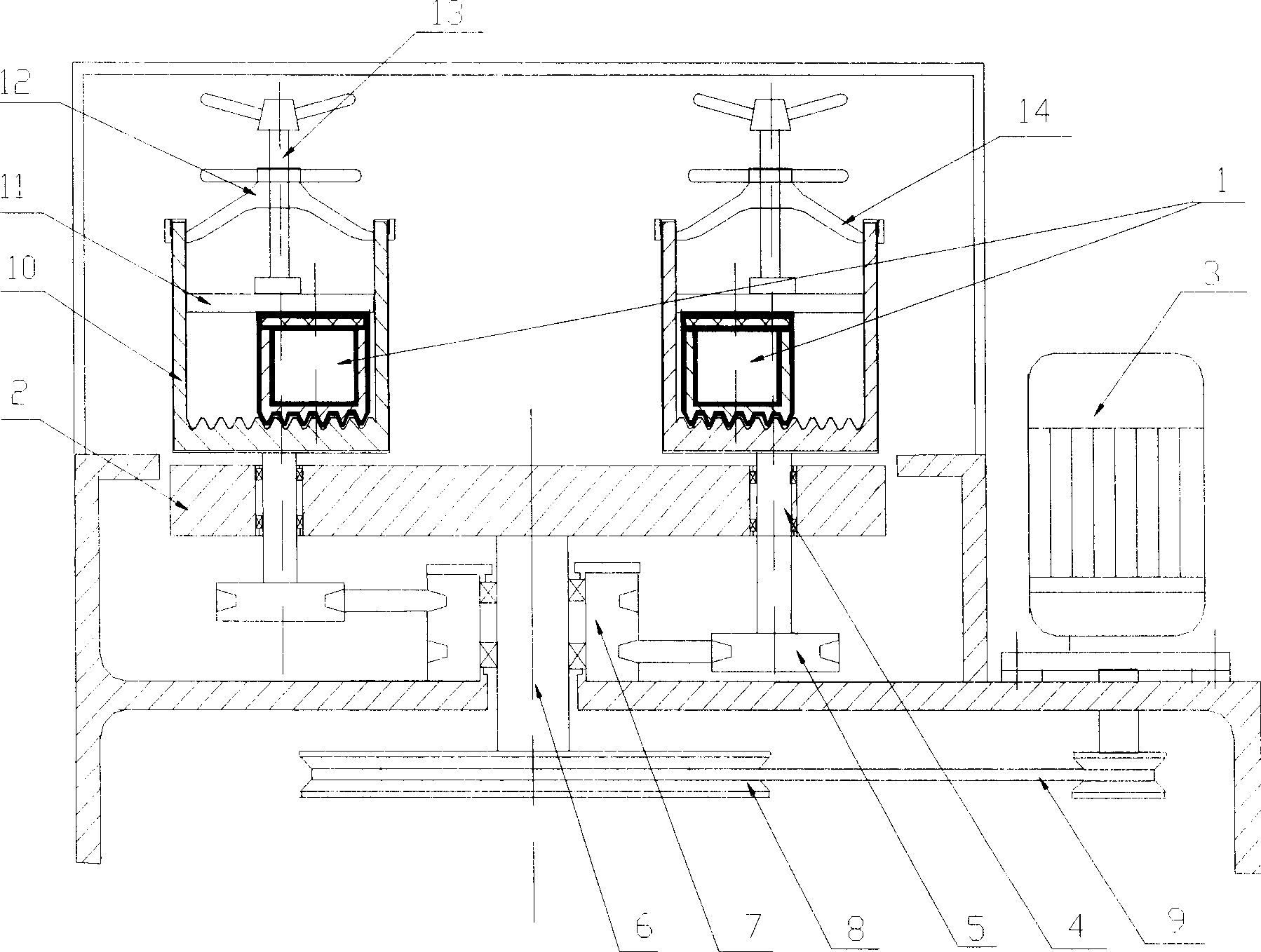

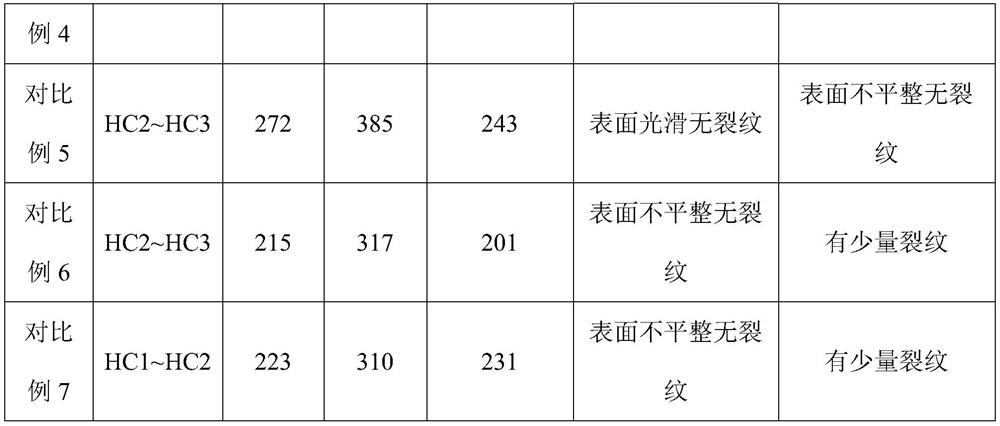

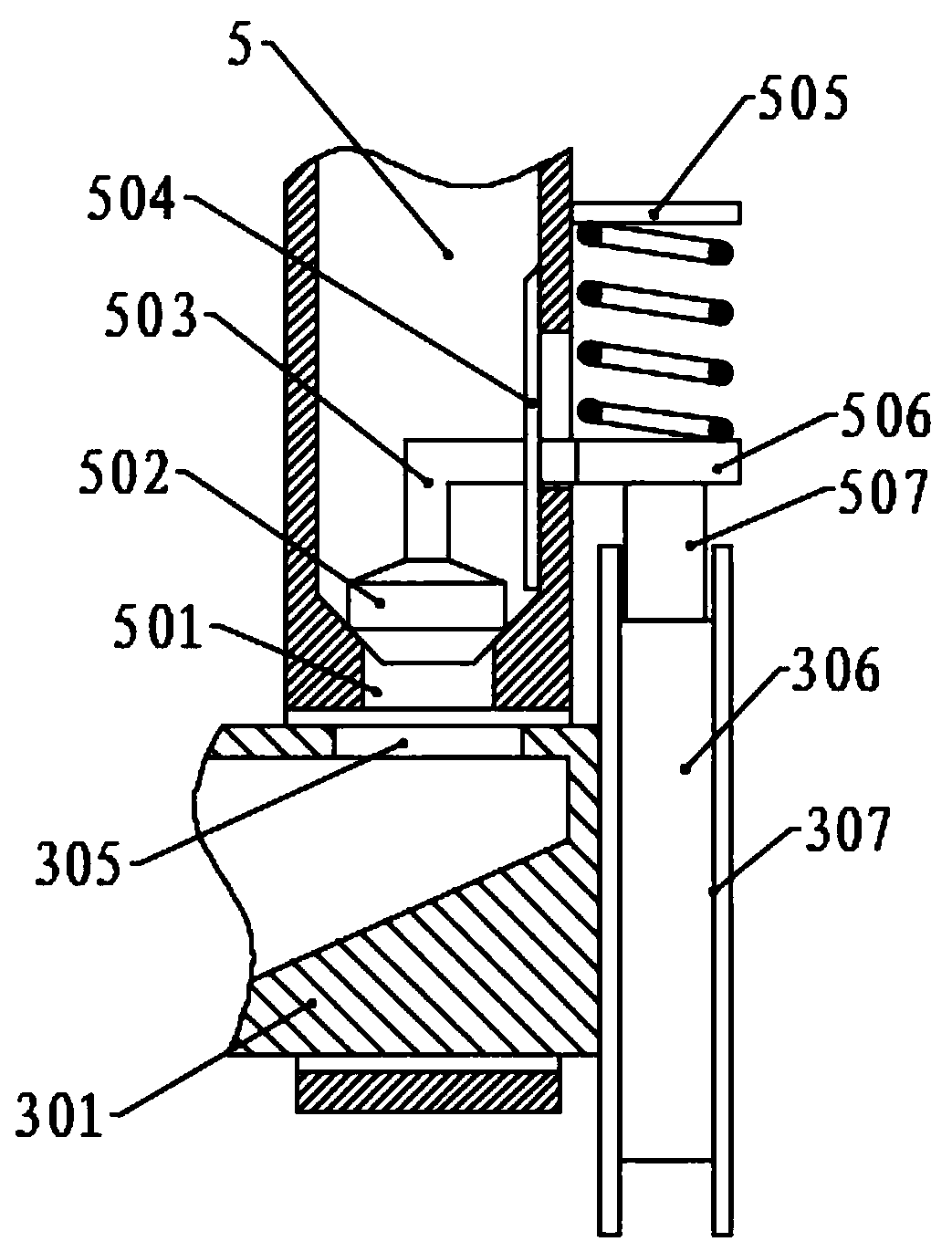

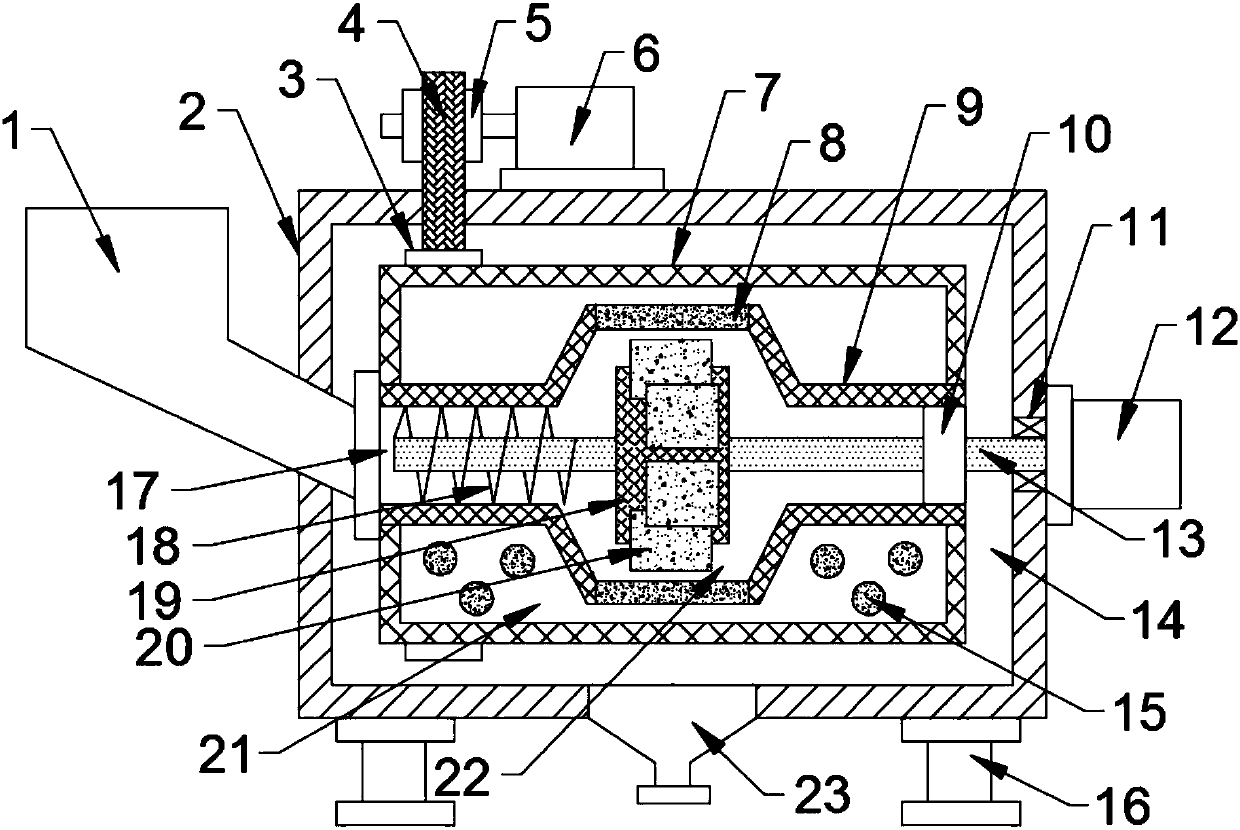

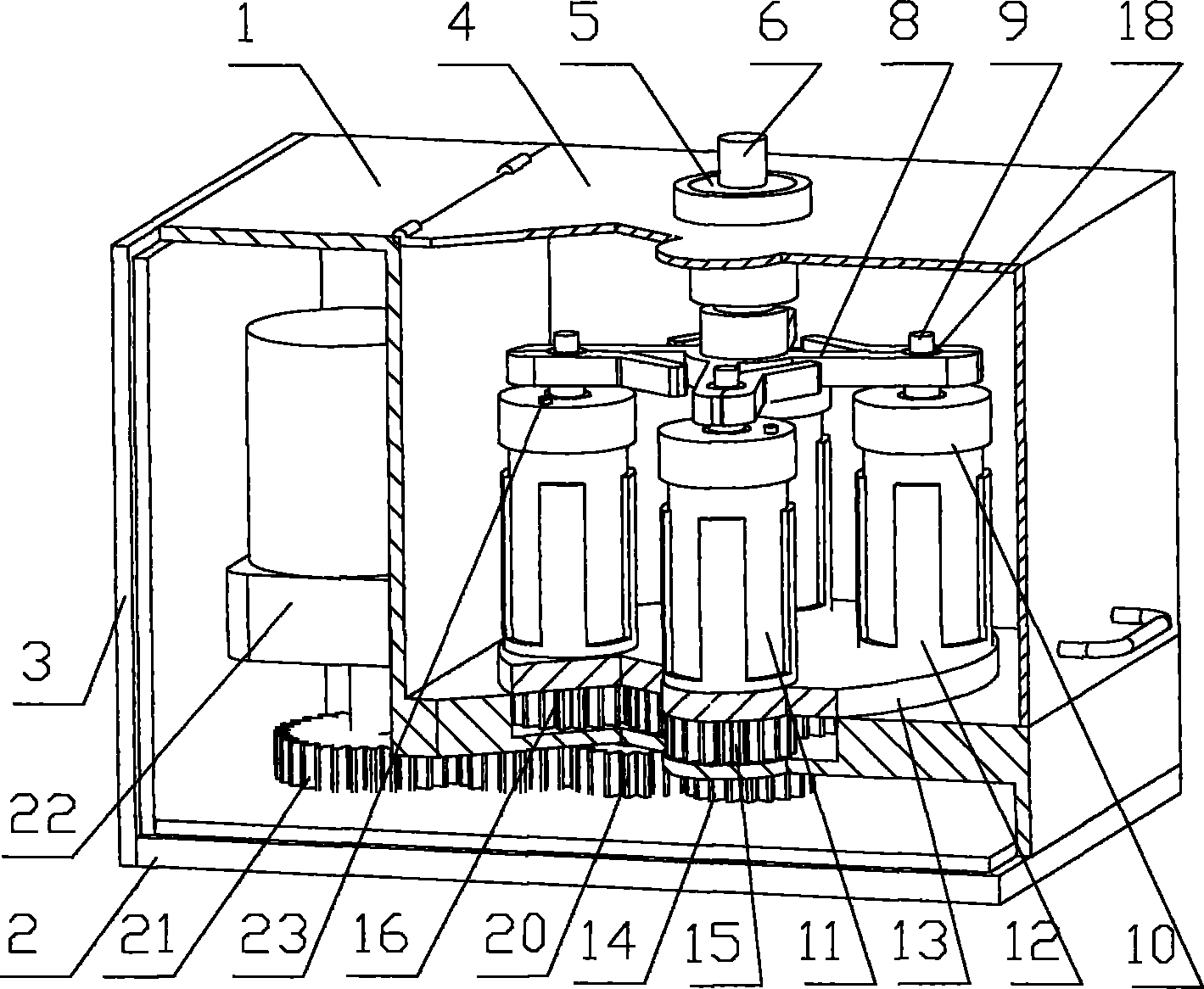

Plasma auxiliary high-energy planetary ball mill device

The invention relates to a high-energy ball mill technique, in particular a plasma-assistant high-energy ball mill device. The device is made by modification based on the traditional planet ball miller. The electrode shaft is secured on the can lid by an electrode seal ring, is connected movably with an electrode clamping frame by an electrode bear. The electrode clamping frame for claming the electrode shaft is mounted movably on one end of the planetary plate center shaft. The electrode clamping frame connects with an electrode spindle with a bearing pore at one end. The electrode spindle connects with the anode of the power source, and the cabinet connects with the cathode of the power source and is grounded. The invented technique introduces plasma into the planet ball miller, enhances the ball milling speed with a narrow distribution of particle size, and improves ball mill efficiency at the same time. The invented device is provided with a reliable and reasonable structure, and is easy to be produced. The application and popularization of the plasma-assistant high-energy ball mill technique in nano commercial scale production are promoted.

Owner:SOUTH CHINA UNIV OF TECH

A kind of amnion gel freeze-dried powder processing technology

ActiveCN111054486BActive ingredients are not affectedImprove solubilityGrain treatmentsPhysical chemistryRefrigeration

The invention discloses a process for processing amniotic membrane gel freeze-dried powder. The powder-making process includes the following steps: (1) setting a temperature-controlled ball mill in a ball mill; (2) selecting high-wear-resistant ball mills; (3) mixing a refrigerant Add the agent into the low-temperature circulator, and then add the stirring rotor to make the circulation temperature ‑30~‑40℃; (4) Adjust the ball milling speed of the ball mill to 1800‑2000rpm / min; Substances are continuously frozen and ball-milled for 10-15mins under the conditions of ‑30~‑40℃ to obtain powders that meet the required particle size specifications. The advantages of the present invention lie in: optimizing the existing pulverizing process by adjusting the temperature of the low temperature circulator, the rotating speed of the ball mill and the ball milling time in the pulverizing process, so that the prepared corresponding powder retains the original characteristics and has better comprehensive performance.

Owner:杭州倍荣生物科技有限公司

Unleaded piezoelectric ceramic consisting of B-site composite Bi-based compound and preparation method thereof

The invention discloses an unleaded piezoelectric ceramic consisting of a B-site composite Bi-based compound and a preparation method thereof. The components of the unleaded piezoelectric ceramic are shown by the general formulae of (1-x) Bi (Li1 / 2Me1 / 2) O3 - xBaTiO3 + zMaOb, (1-x) Bi (Li1 / 2Me1 / 2)O3 - x (Na1 / 2Bi1 / 2)TiO3 + zMaOb, (1-x-y) Bi (Li1 / 2Me1 / 2) O3 - xBaTiO3 - y (Na1 / 2Bi1 / 2) TiO3 + zMaOb, (1-x-y) Bi (Li1 / 2Me1 / 2) O3 - xBaTiO3 - y (K1 / 2Bi1 / 2) TiO3, + zMaOb or (1-x-y-v) Bi (Li1 / 2Me1 / 2) O3 - xBaTiO3 - y (Na1 / 2Bi1 / 2) TiO3 - v(K1 / 2Bi1 / 2) TiO3 + zMaOb, wherein x, y, z and v denote mole fractions, 0 (x (1.0,0 (y (1,0 (v (1, 0< / = z< / =0.1, Me represents one or five pentavalent metallic elements, MaOb represents one or a plurality of oxides, M is an element of +1 to +6 valence, and can be formed into a solid oxide with oxygen, and the ceramic is prepared in a conventional ceramic preparation method. The prepared unleaded piezoelectric ceramic has a good sintering characteristic, the preparation process is simple and stable, the performance is excellent, and the unleaded piezoelectric ceramic can partially replace the conventional lead based piezoelectric ceramic to be used.

Owner:GUILIN UNIV OF ELECTRONIC TECH

High-strength ceramic product and processing method thereof

The invention belongs to the technical field of ceramics, and particularly relates to a high-strength ceramic product and a processing method thereof. The processing method comprises the following steps: (1) treating a blank material, forming and processing a blank body, forming the blank material into the shape of the ceramic product, performing high-speed spraying on the surface of the blank body by adopting a mixed grinding material, and then performing drying treatment to obtain a green blank; (2) preparing a glaze material; (3) performing glazing treatment; and (4) firing and forming. According to the high-strength ceramic product and the processing method thereof, the surface which is formed initially by the blank material is subjected to high-speed spraying treatment by utilizing the mixed grinding material, so that the compactness of the formed blank material surface can be further improved through the mixed grinding material which is sprayed at a high speed, and then the mechanical strength of the ceramic product after being fired and formed is improved; moreover, inorganic non-metal components contained in the mixed grinding material can be adhered to the structure surface of the blank body and can be integrated with the ceramic blank body in a firing process. Therefore, a surface structure with high strength is obtained.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com