Continuous ball mill for ceramics

A continuous ball milling and ceramics technology, applied in the field of ceramics processing, can solve the problems of adding materials, reducing the efficiency of the ball mill, and the single structure of the ball mill, so as to improve the effect of ball milling and ensure the continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

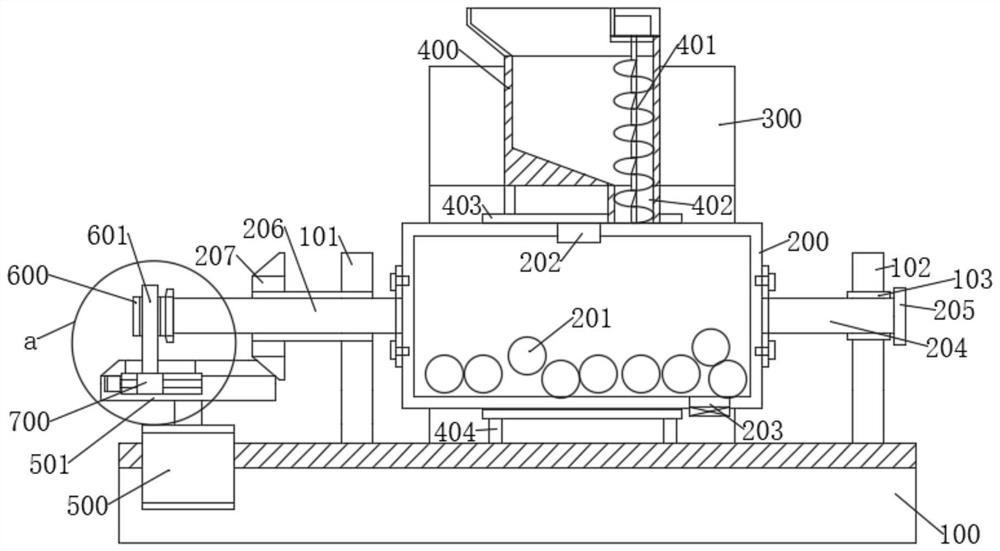

[0033] like figure 1 As shown, in an embodiment provided by the present invention, a continuous ball mill for ceramics, the ball mill comprises:

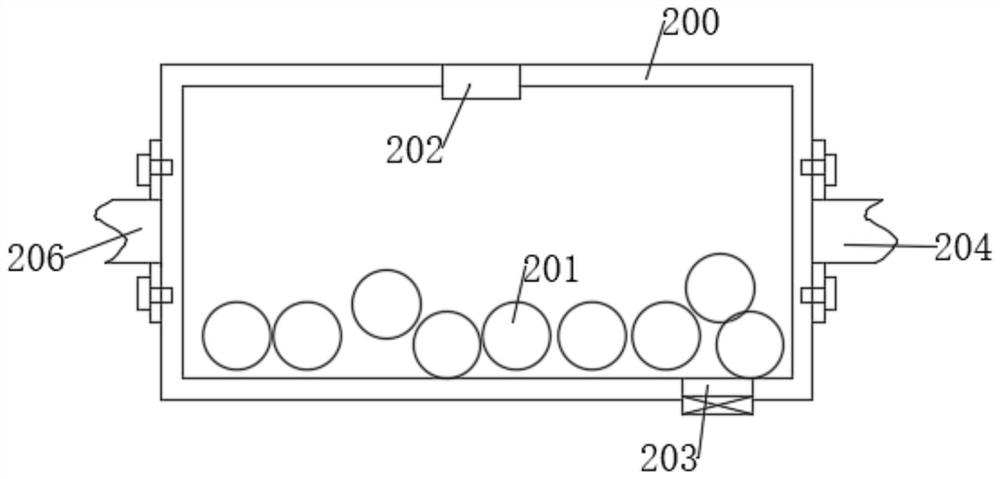

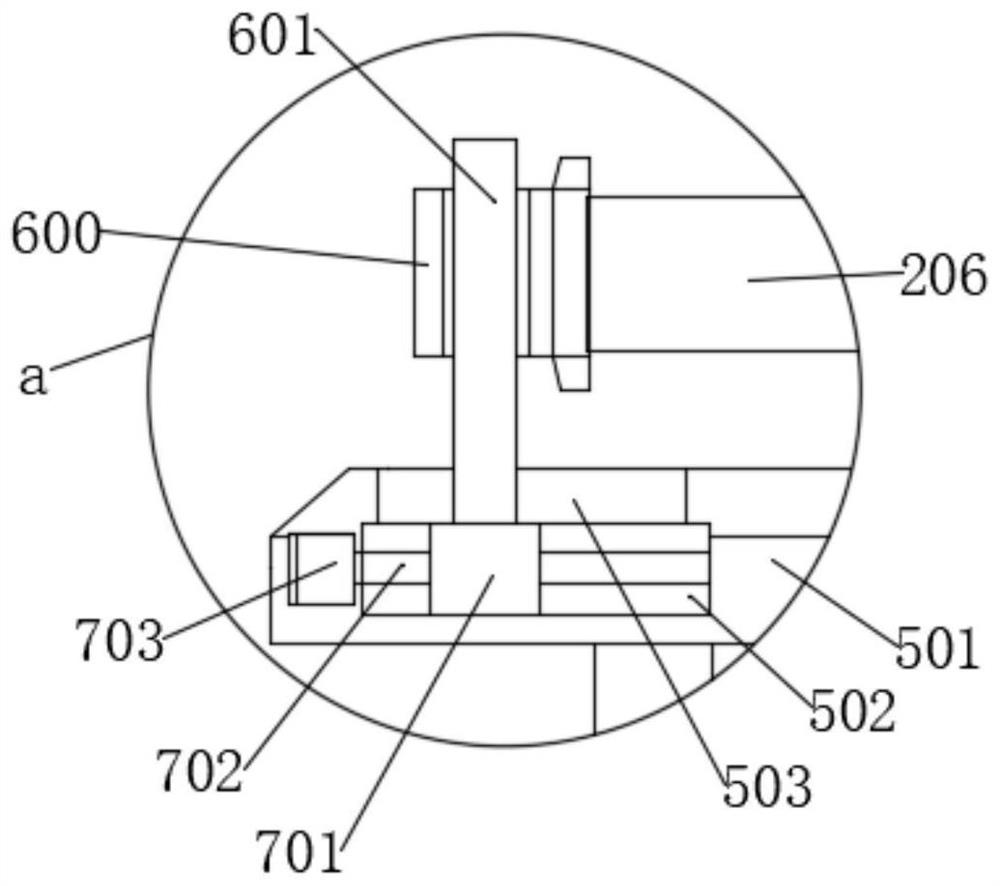

[0034] A processing device, the processing device includes a processing tank 200, the lateral reciprocating movement of the processing tank 200 is adjusted by a push-pull mechanism, and the vertical rotation of the processing tank 200 is adjusted by a rotating mechanism, the push-pull mechanism and the rotation There are several steel balls 201 in the processing tank 200. When the processing tank 200 rotates relative to the support sleeve 403, the several steel balls 201 grind and pulverize the materials in the processing tank 200 to form a ball mill. processing effect;

[0035] A feeding device, the feeding device includes a support sleeve 403 fixedly arranged on the bracket device, the support sleeve 403 is coaxially rotated and slidably sleeved on the processing tank 200, and the processing tank 200 is relative to the support slee...

Embodiment 2

[0038] like figure 1 As shown, in one embodiment provided by the present invention, a continuous ball mill for ceramics, the ball mill comprises:

[0039] A processing device, the processing device includes a processing tank 200, the lateral reciprocating movement of the processing tank 200 is adjusted by a push-pull mechanism, and the vertical rotation of the processing tank 200 is adjusted by a rotation mechanism, the push-pull mechanism and the rotation There are several steel balls 201 in the processing tank 200. When the processing tank 200 rotates relative to the support sleeve 403, the several steel balls 201 grind and pulverize the materials in the processing tank 200 to form a ball mill. processing effect;

[0040] A feeding device, the feeding device includes a support sleeve 403 fixedly arranged on the bracket device, the support sleeve 403 is coaxially rotated and slidably sleeved on the processing tank 200, and the processing tank 200 is relative to the support s...

Embodiment 3

[0053] like figure 1 As shown, in one embodiment provided by the present invention, a continuous ball mill for ceramics, the ball mill comprises:

[0054] A processing device, the processing device includes a processing tank 200, the lateral reciprocating movement of the processing tank 200 is adjusted by a push-pull mechanism, and the vertical rotation of the processing tank 200 is adjusted by a rotation mechanism, the push-pull mechanism and the rotation There are several steel balls 201 in the processing tank 200. When the processing tank 200 rotates relative to the support sleeve 403, the several steel balls 201 grind and pulverize the materials in the processing tank 200 to form a ball mill. processing effect;

[0055] A feeding device, the feeding device includes a support sleeve 403 fixedly arranged on the bracket device, the support sleeve 403 is coaxially rotated and slidably sleeved on the processing tank 200, and the processing tank 200 is relative to the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com