Preparation method and application of hard carbon

A hard carbon and biomass technology, which is applied in the preparation/purification of carbon, active material electrodes, electrical components, etc., can solve the problems of high cost, unsatisfactory cycle specific capacity and rate performance, and achieve good cycle life and realize Effects of waste utilization and virtuous cycle, excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

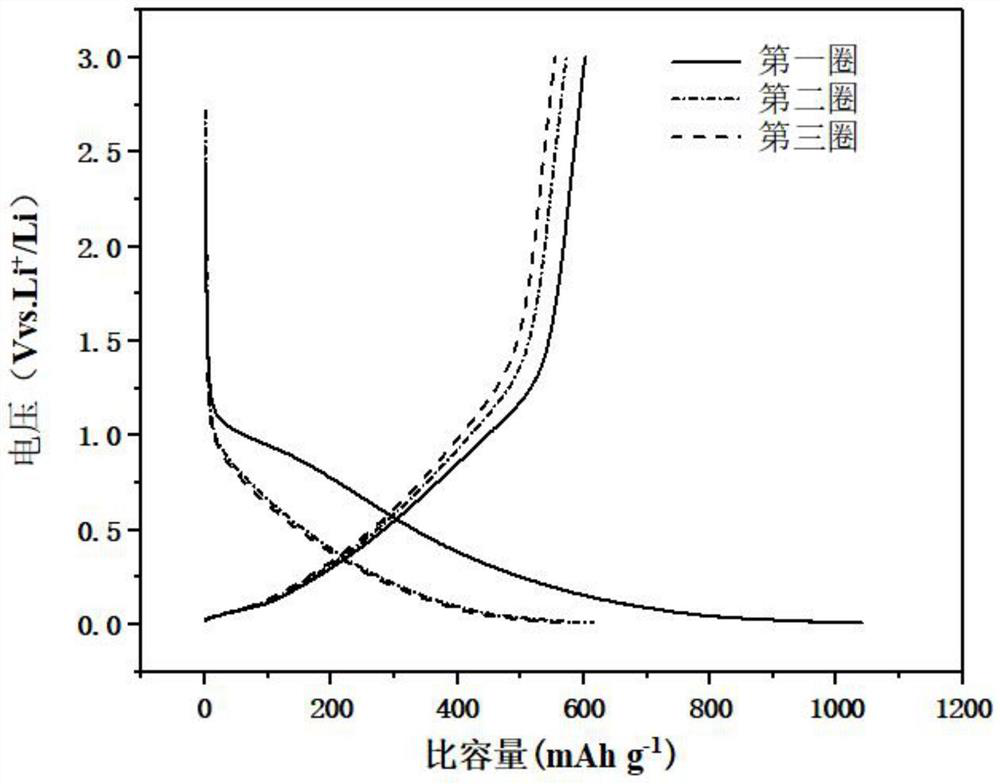

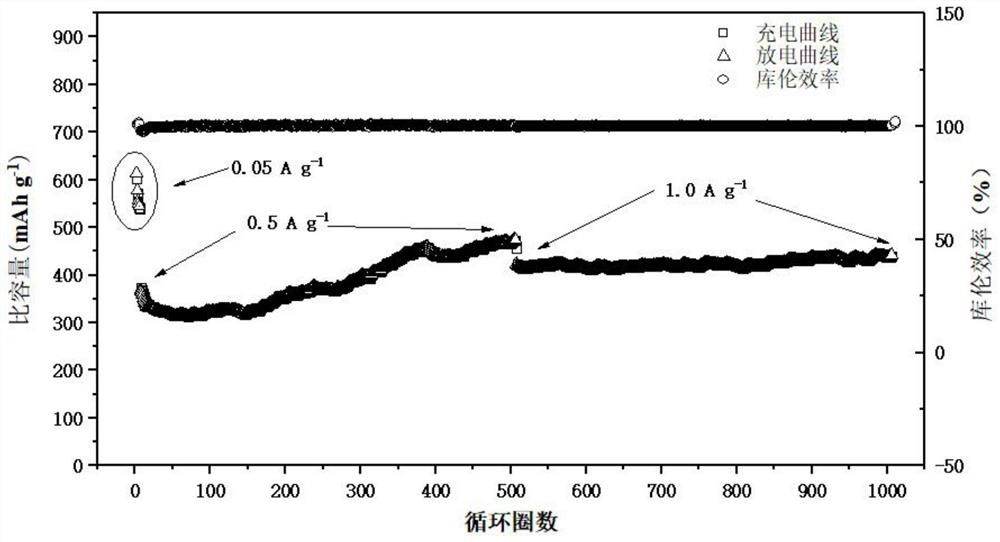

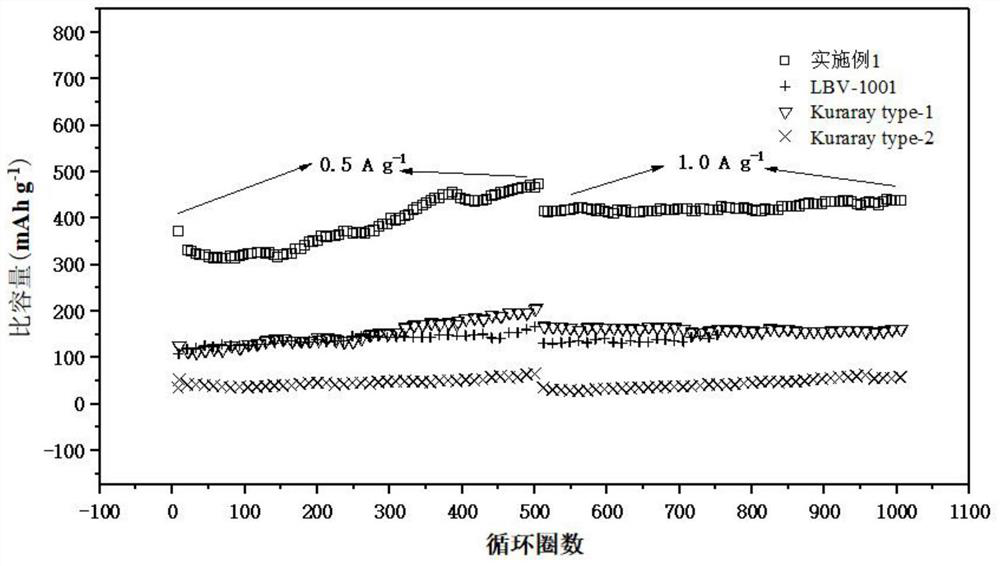

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of hard carbon, comprises the following steps:

[0041] salt leaching the biomass waste powder to obtain the salt leached biomass waste powder;

[0042] The first carbonization, ball milling and second carbonization are performed sequentially on the salted biomass waste powder to obtain the hard carbon.

[0043] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0044] In the invention, the biomass waste powder is subjected to salt leaching to obtain the salt-leached biomass waste powder.

[0045] In the present invention, the biomass waste powder is preferably prepared; the preparation method of the biomass waste powder is preferably: the biomass waste is subjected to ultrasonication, cleaning, drying and crushing in sequence to obtain the biomass waste powder.

[0046] In the present invention, the biomass waste is pr...

Embodiment 1

[0064] Place the coconut shell in distilled water for ultrasonication and cleaning, dry it at a temperature of 60° C., and pulverize it with a pulverizer for 30 minutes to obtain coconut shell powder (with a particle size of 100 to 500 μm);

[0065] Soak 10 g of the coconut shell powder in 0.1 L of potassium carbonate solution with a concentration of 0.1 mol / L for 12 hours, and dry at a temperature of 60° C. to obtain the salted coconut shell powder;

[0066] Under a nitrogen atmosphere, the coconut shell powder after the salt immersion was heated up to 350° C. at a heating rate of 5° C. / min and kept warm for 120 minutes to carry out the first carbonization. After being naturally cooled to room temperature, ball milling (with a diameter of 3 mm) The number ratio of balls and balls with a diameter of 10mm is 3, the ball milling speed is 400rpm, the time is 90min, and the ball-to-material ratio is 1:20), after the second carbonization (nitrogen atmosphere, at a heating rate of 5°...

Embodiment 2

[0070] Place the coconut shell in distilled water for ultrasonication and cleaning, dry it at a temperature of 60° C., and pulverize it with a pulverizer for 30 minutes to obtain coconut shell powder (with a particle size of 100 to 500 μm);

[0071] Soak 10 g of the coconut shell powder in 0.05 L of potassium chloride solution with a concentration of 0.5 mol / L for 12 hours, and dry at a temperature of 60° C. to obtain the salted coconut shell powder;

[0072] Under a nitrogen atmosphere, the coconut shell powder after the salt immersion was heated up to 400° C. at a heating rate of 5° C. / min and kept warm for 120 minutes to carry out the first carbonization. After being naturally cooled to room temperature, ball milling (with a diameter of 3 mm) The number ratio of balls and balls with a diameter of 10mm is 1, the ball milling speed is 600rpm, the time is 90min, and the ball-to-material ratio is 1:30), then carry out the second carbonization (nitrogen atmosphere, with a heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com