Shell device for dry ball mill

A ball mill and shell technology is applied in the field of shell devices for dry ball mills, which can solve the problems of short overall service life and excessive consumption of worn parts, and achieve the effects of improving service life, saving energy and facilitating handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] As shown in the figure, the specific implementation method is as follows:

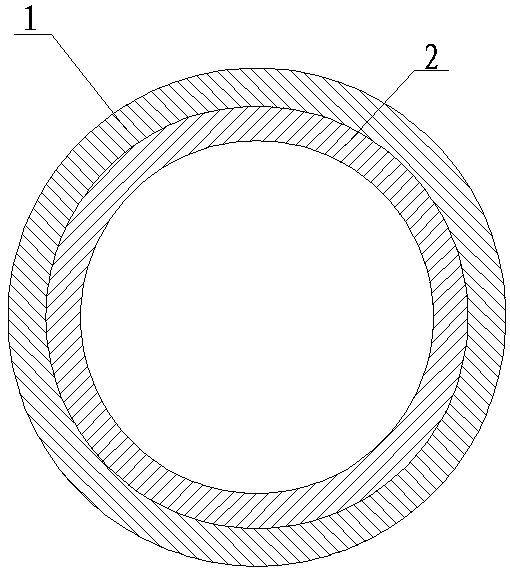

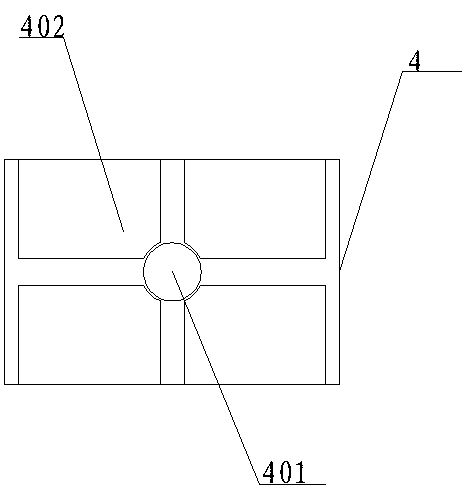

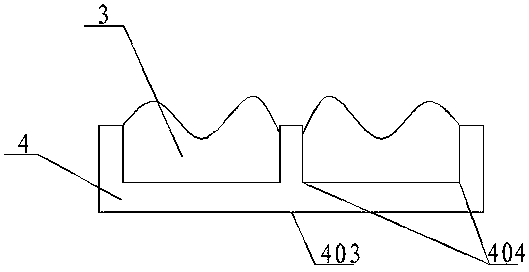

[0017] A shell device for a dry-process ball mill, comprising a shell 1 and a detachable wear-resistant layer 2 attached to the inner wall of the shell 1. The detachable wear-resistant layer 2 is composed of several wear-resistant units spliced with each other. The grinding unit includes a metal base 4 and a ceramic wear-resistant block 3. The bottom surface 403 of the metal base 4 has an arc surface structure and the arc surface matches the shape of the inner wall of the housing 1 so that the two can be closely attached. The top surface of the metal base 4 Four grooves 402 are opened on the top, and a ceramic wear-resistant block 3 is arranged in each groove 402, and one end of the ceramic wear-resistant block 3 is exposed outside the groove 402, and one end of the ceramic wear-resistant block 3 is exposed outside the groove 402 It is a corrugated curved surface to provide a ball grinding sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com