Double-motor self-synchronous driving vibration ball mill

A self-synchronizing, vibrating ball technology, applied in the direction of grain processing, etc., can solve the problems of complex structure, large particle size and high weight of finished products, and achieve the effect of good ball milling effect and large vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with examples.

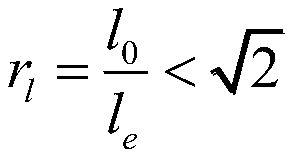

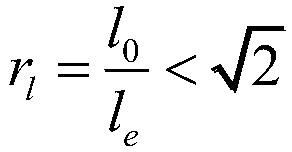

[0017] The dual-machine self-synchronous drive vibrating ball mill of the present invention mainly includes a drum 2, a vibration exciter and a vibration isolation spring. There are two exciters, namely exciter A1 and exciter B5, and their mass moments are m 1 r 1 And m 2 r 2 , Satisfy m 1 r 1 >m 2 r 2 ; Vibration exciter A1 and vibration exciter B5 are installed symmetrically with respect to the center of the drum 2. The connecting line of the rotation centers of the two exciters forms a β angle with the horizontal direction (β=0~90°), and the excitation with larger mass moment Vibrator A1 is installed on the upper left side of the drum; at the same time, the installation of the vibration exciter also satisfies the conditional formula:

[0018]

[0019] Where

[0020] l 0 —The distance between the rotation center of the exciter and the symmetric center of the drum;

[0021] l e —The equivale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com