Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "High welding quality stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

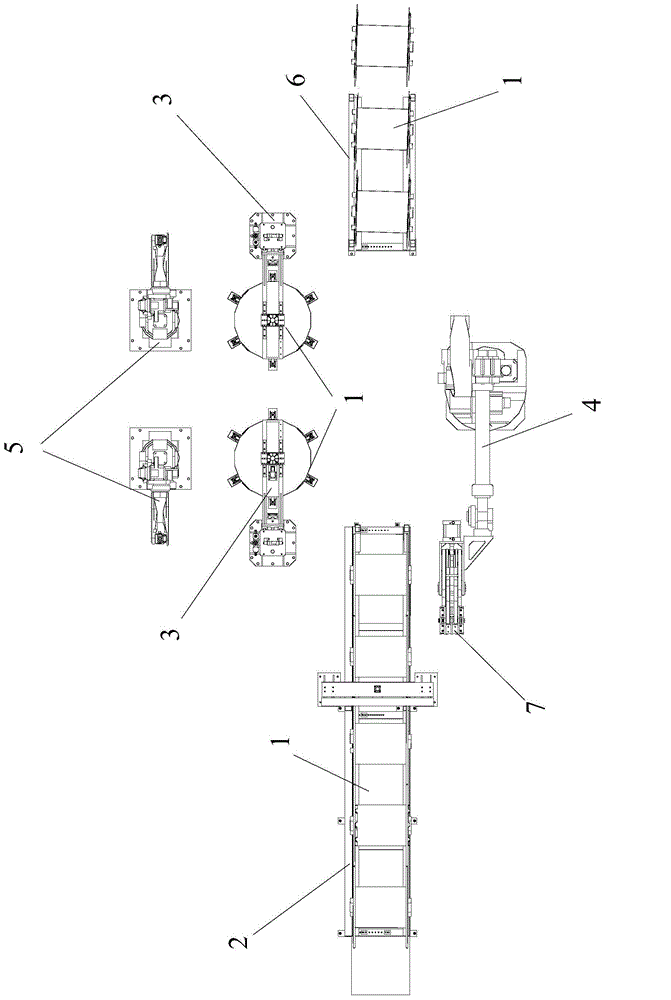

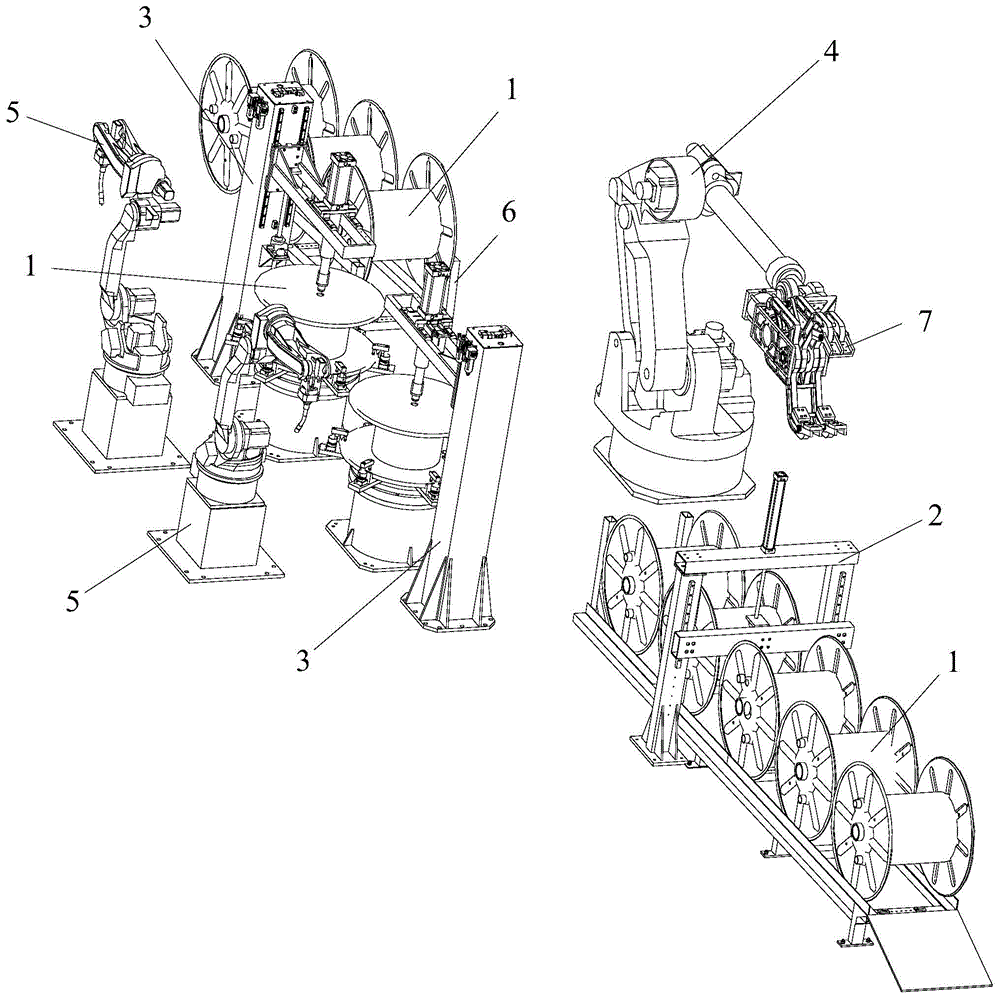

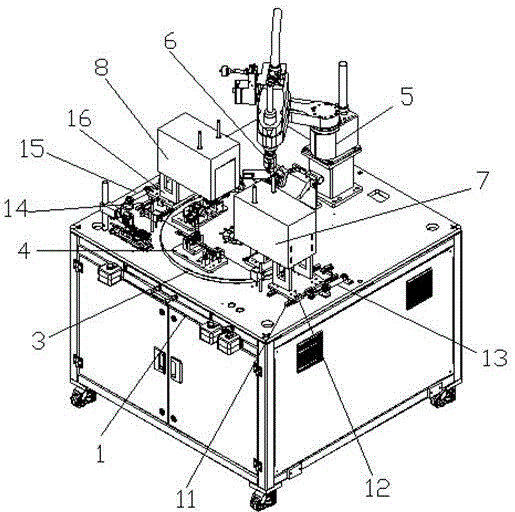

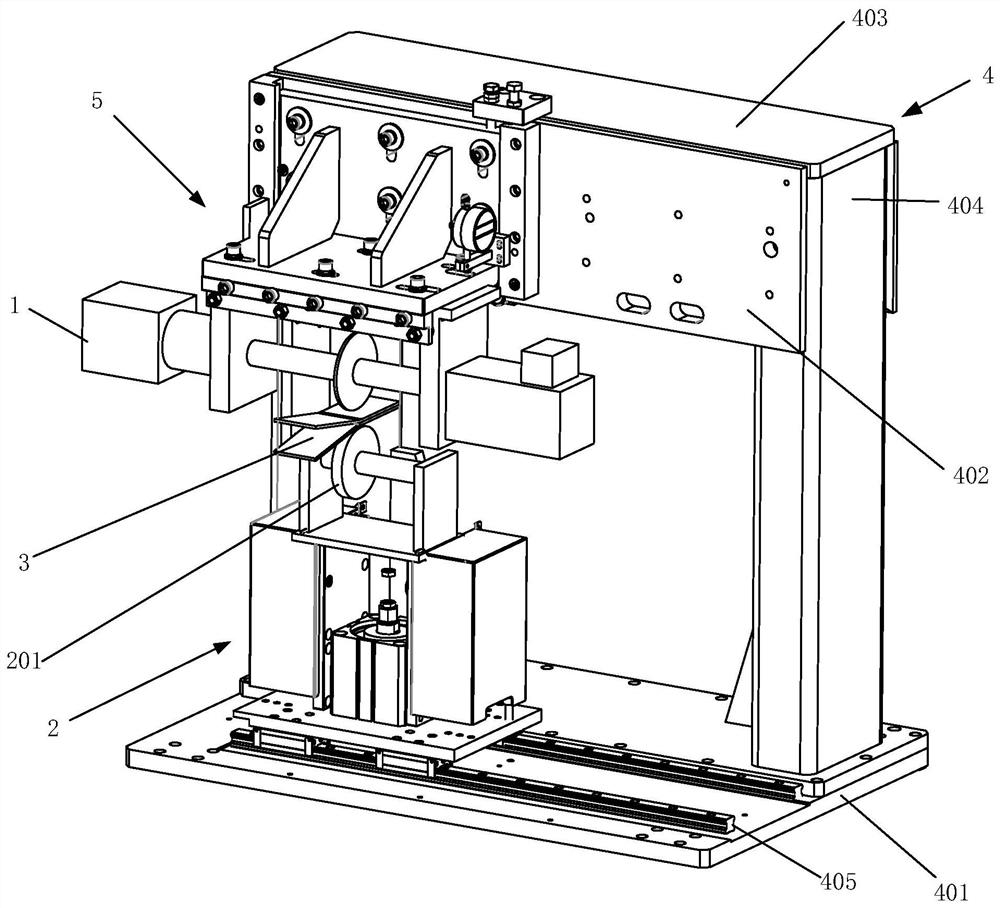

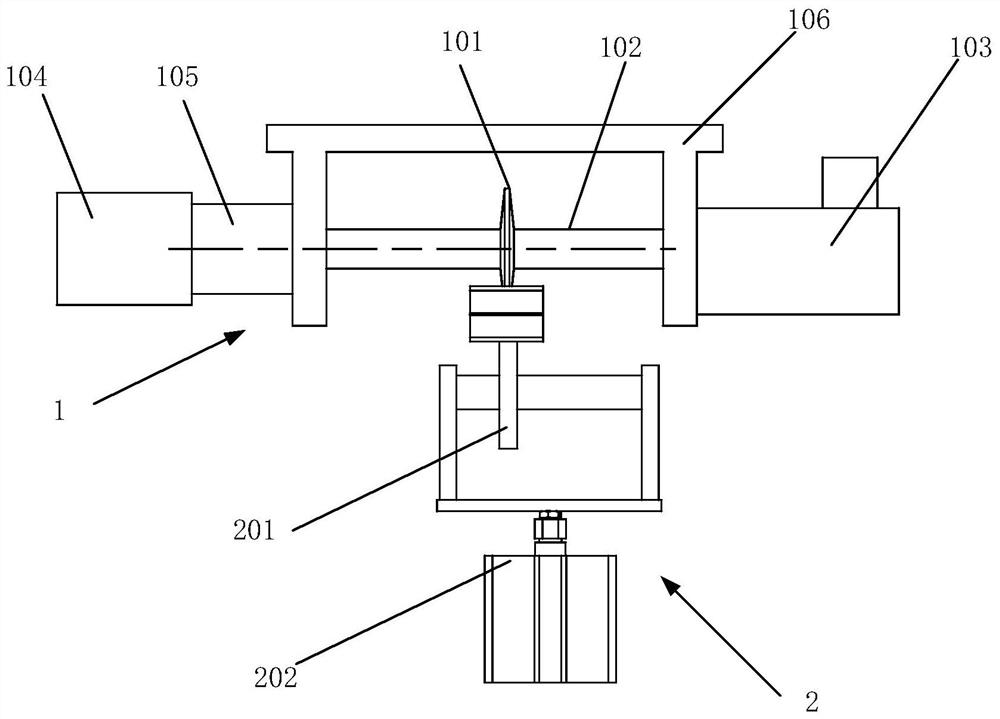

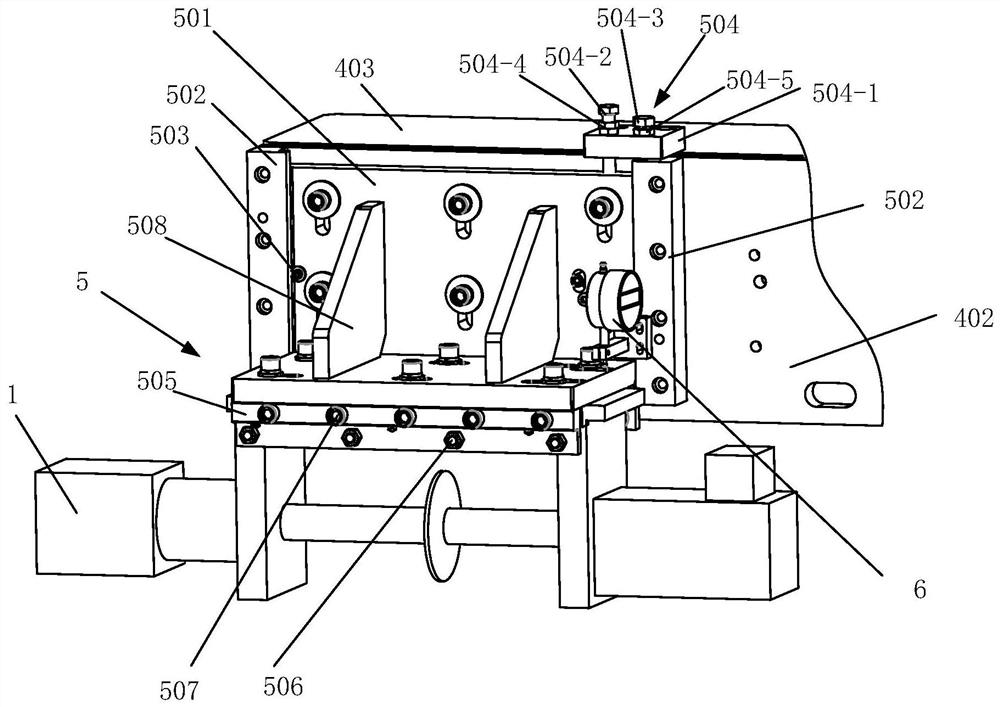

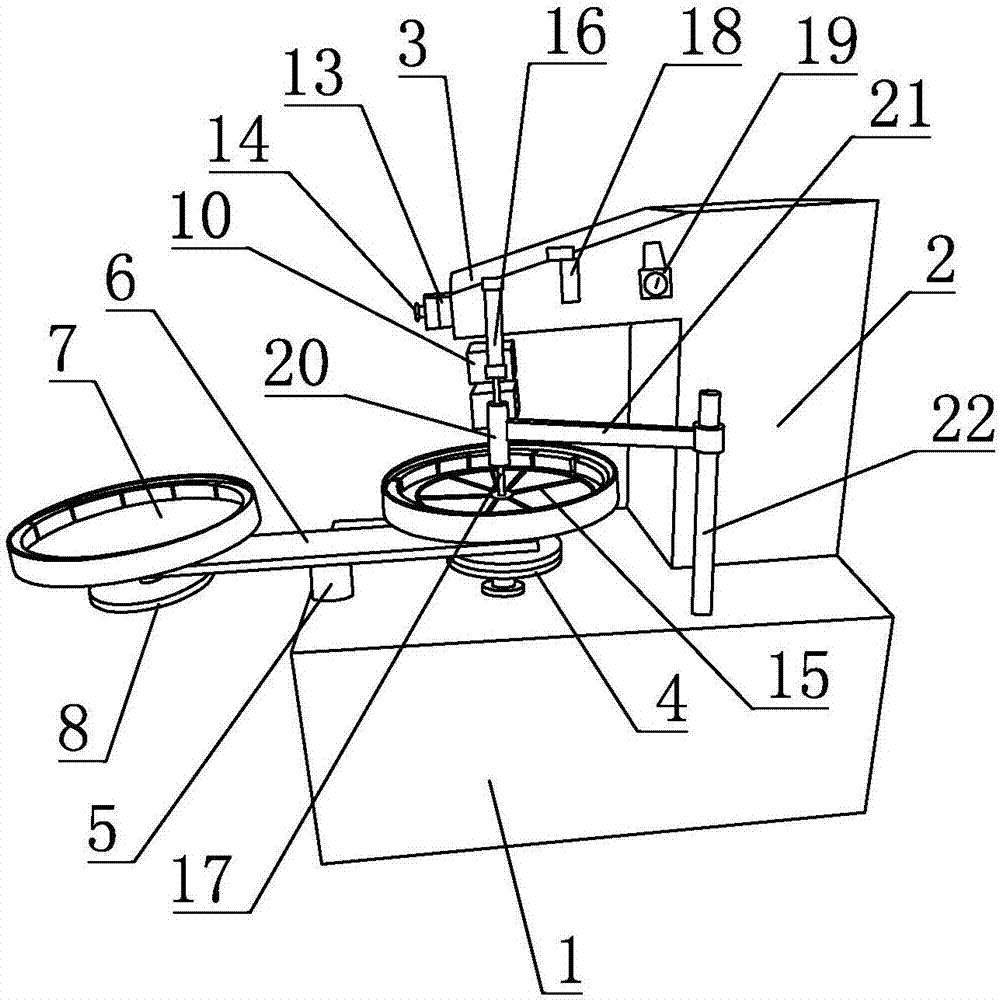

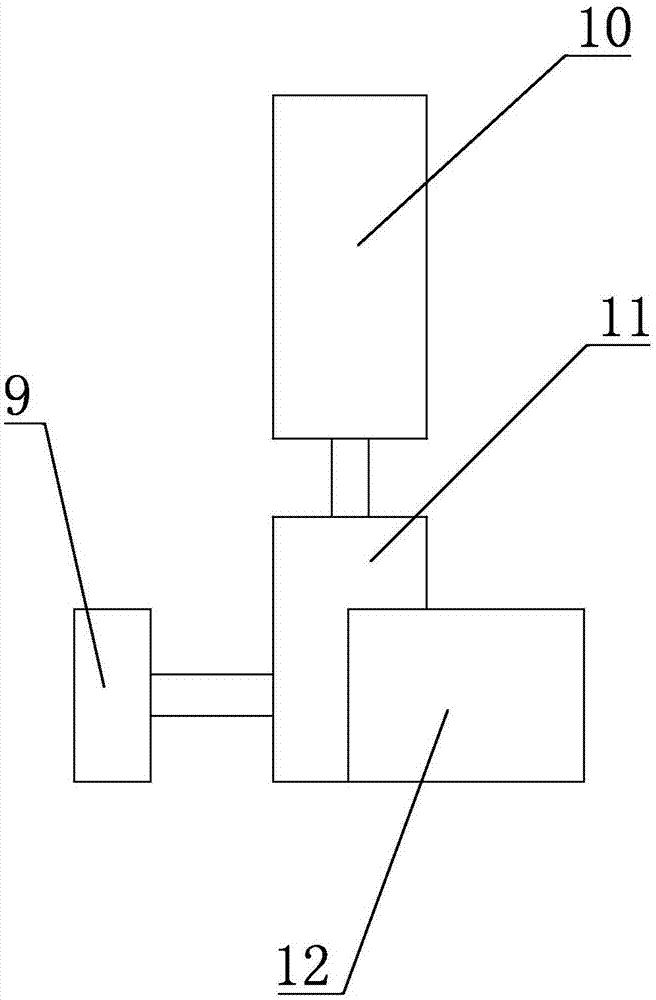

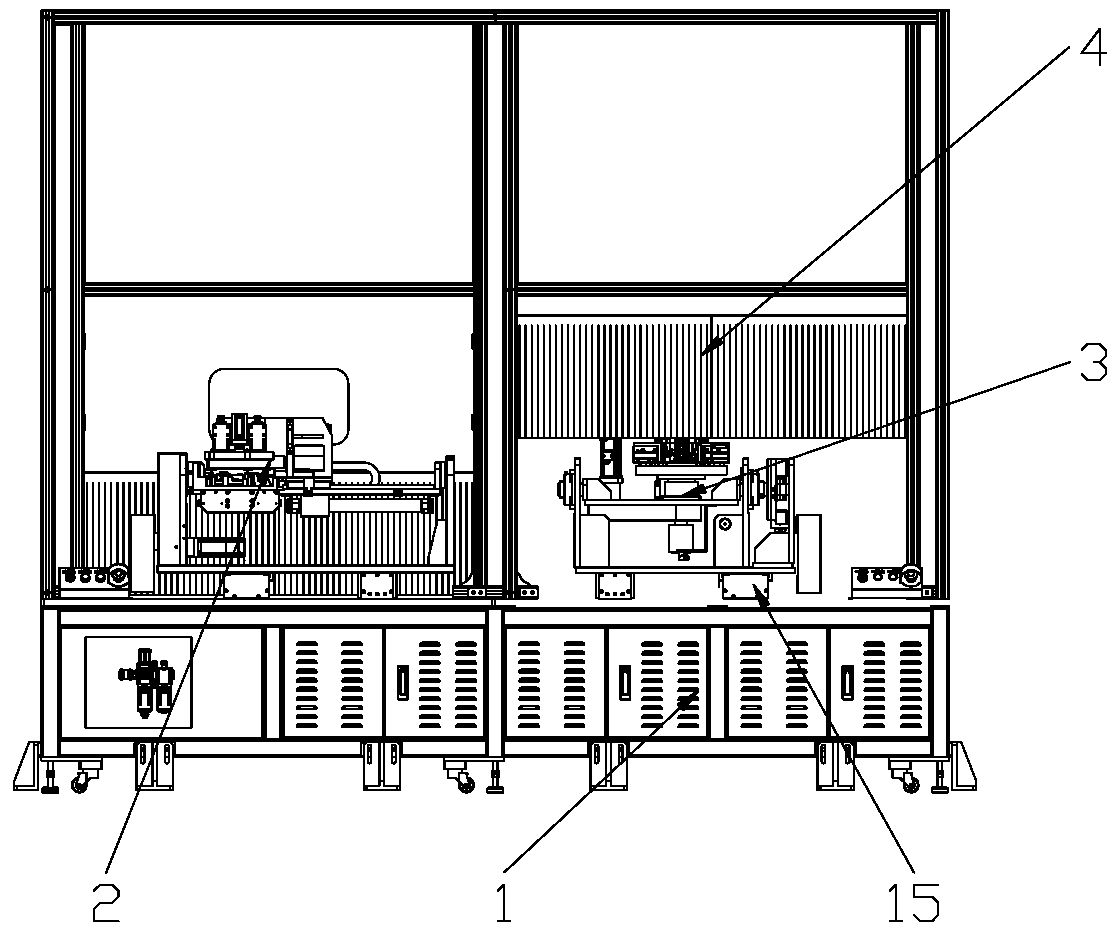

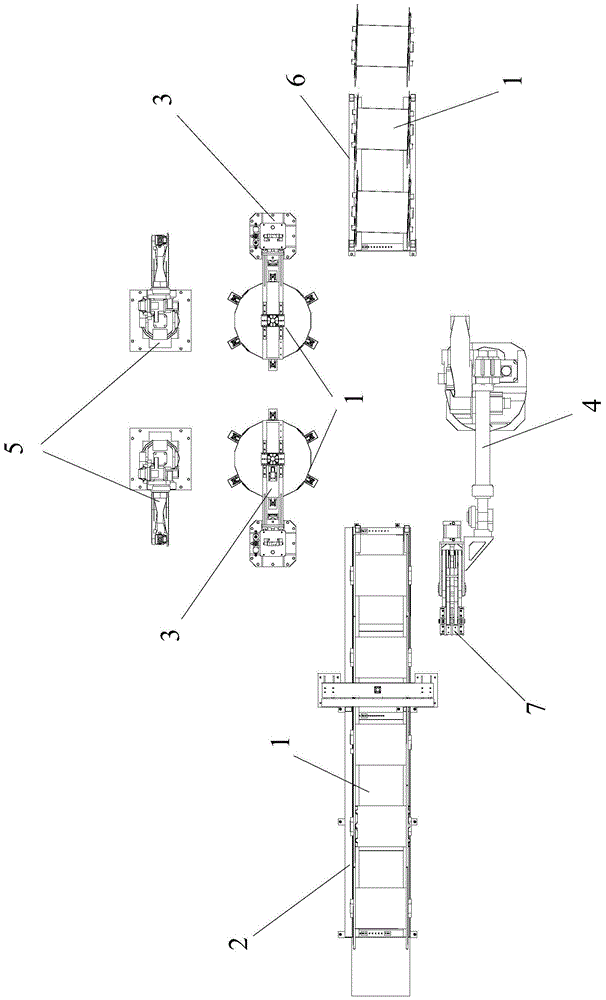

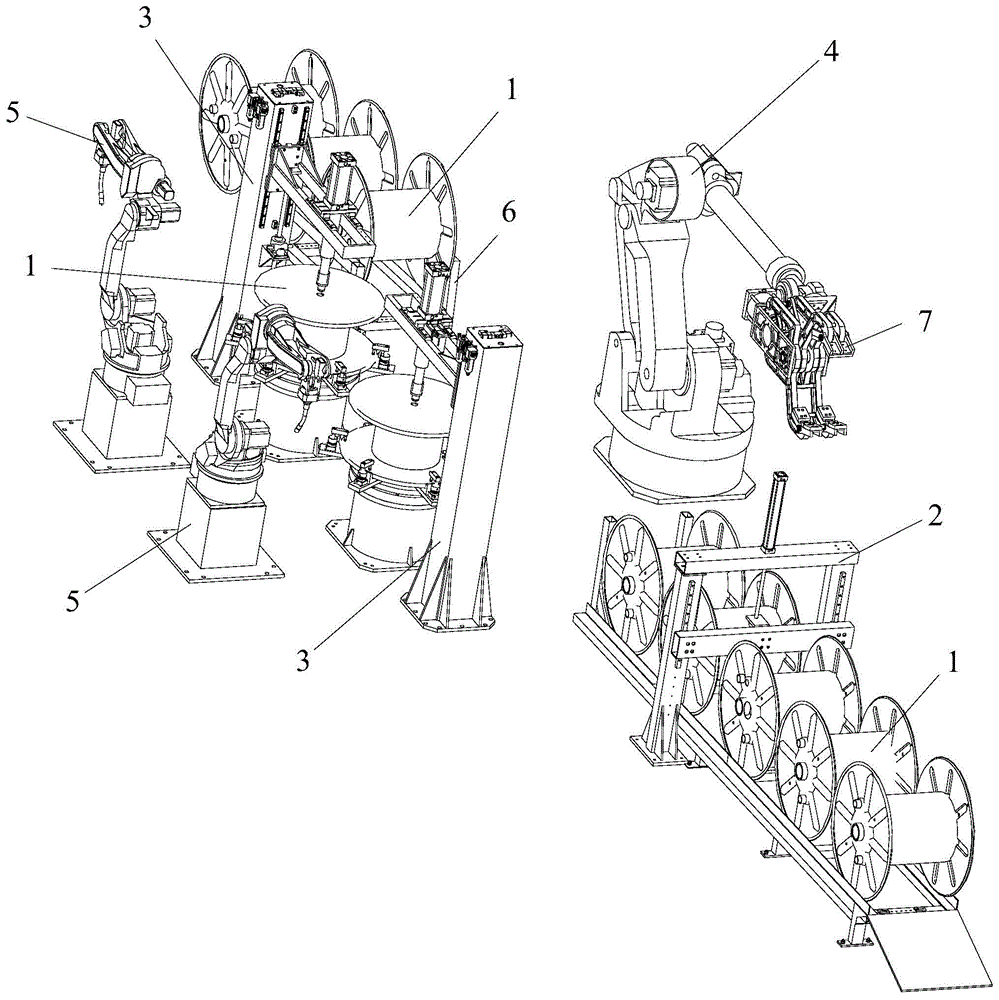

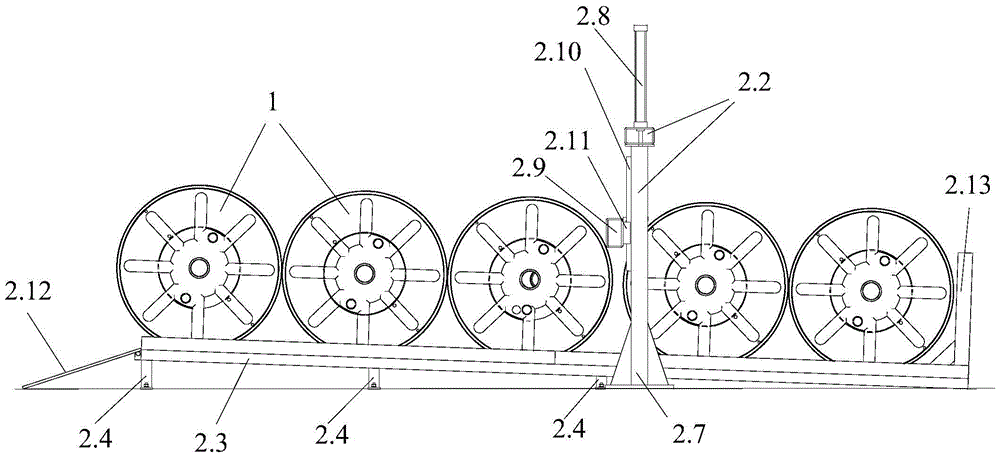

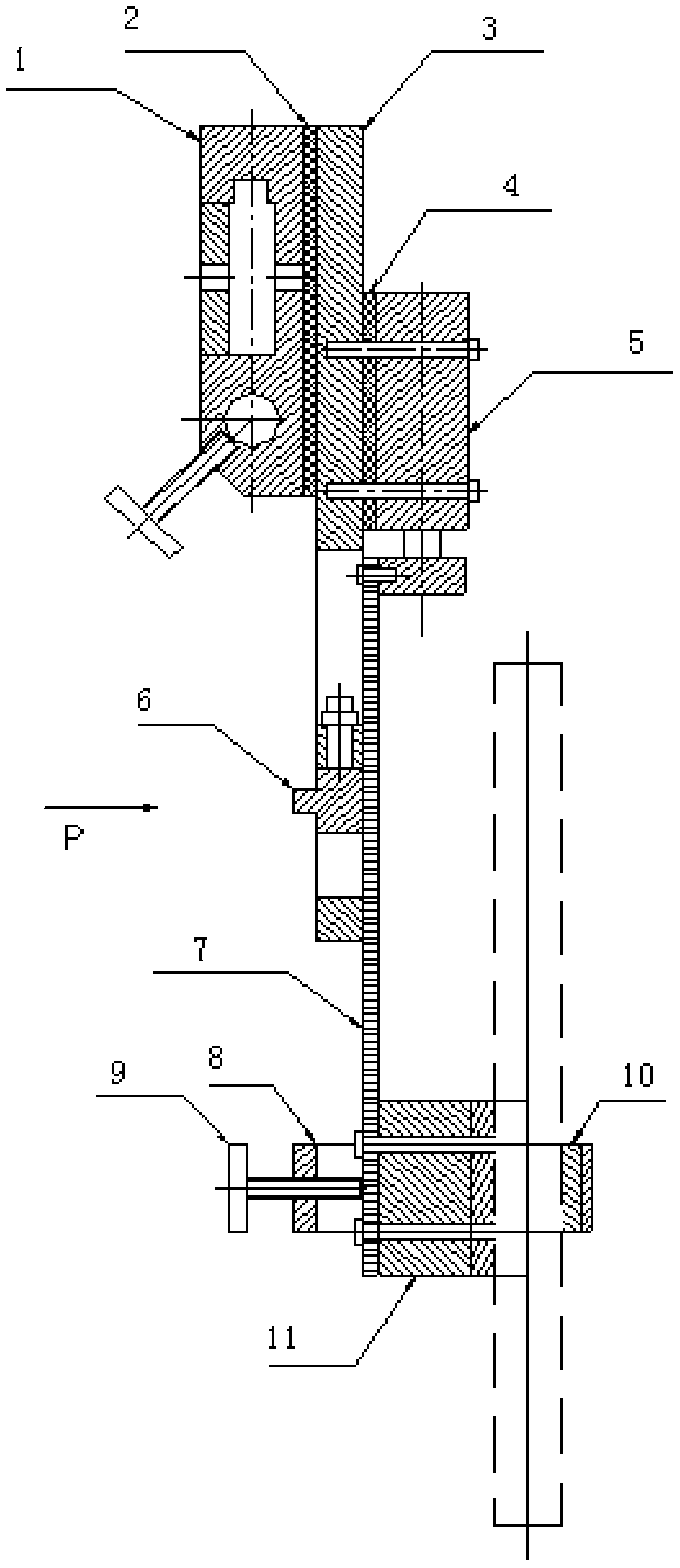

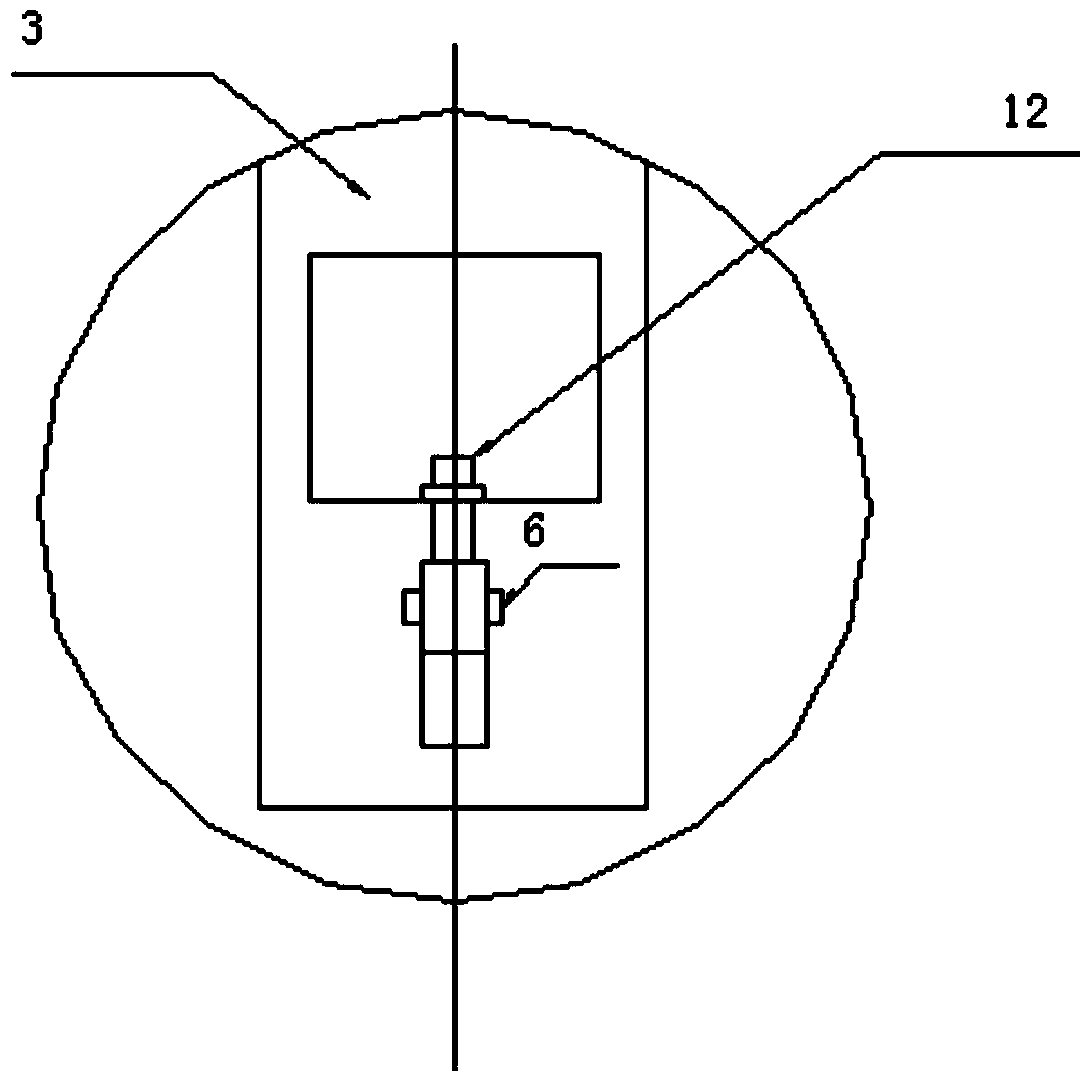

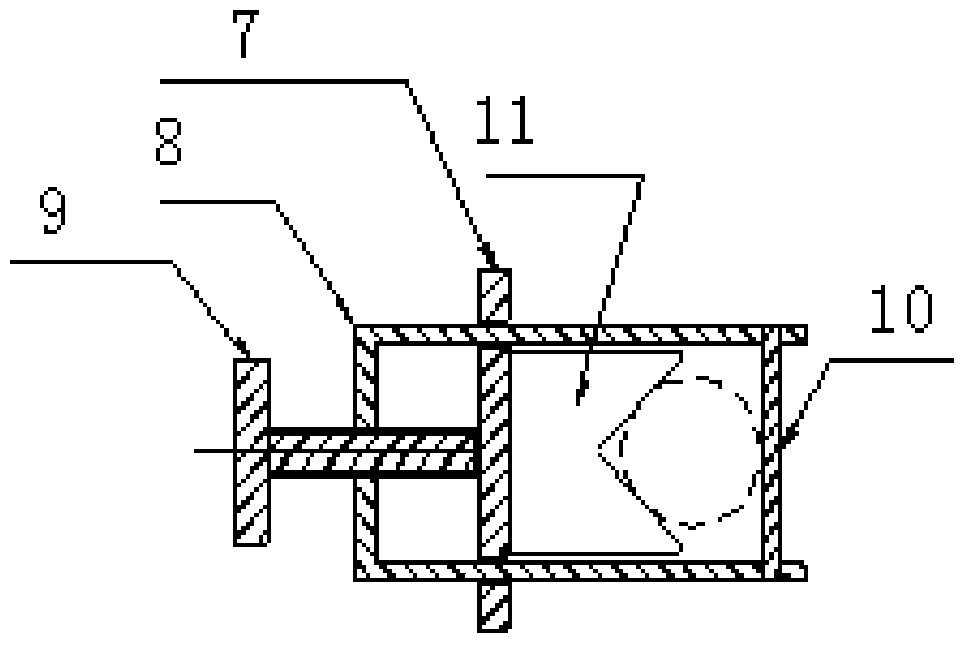

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

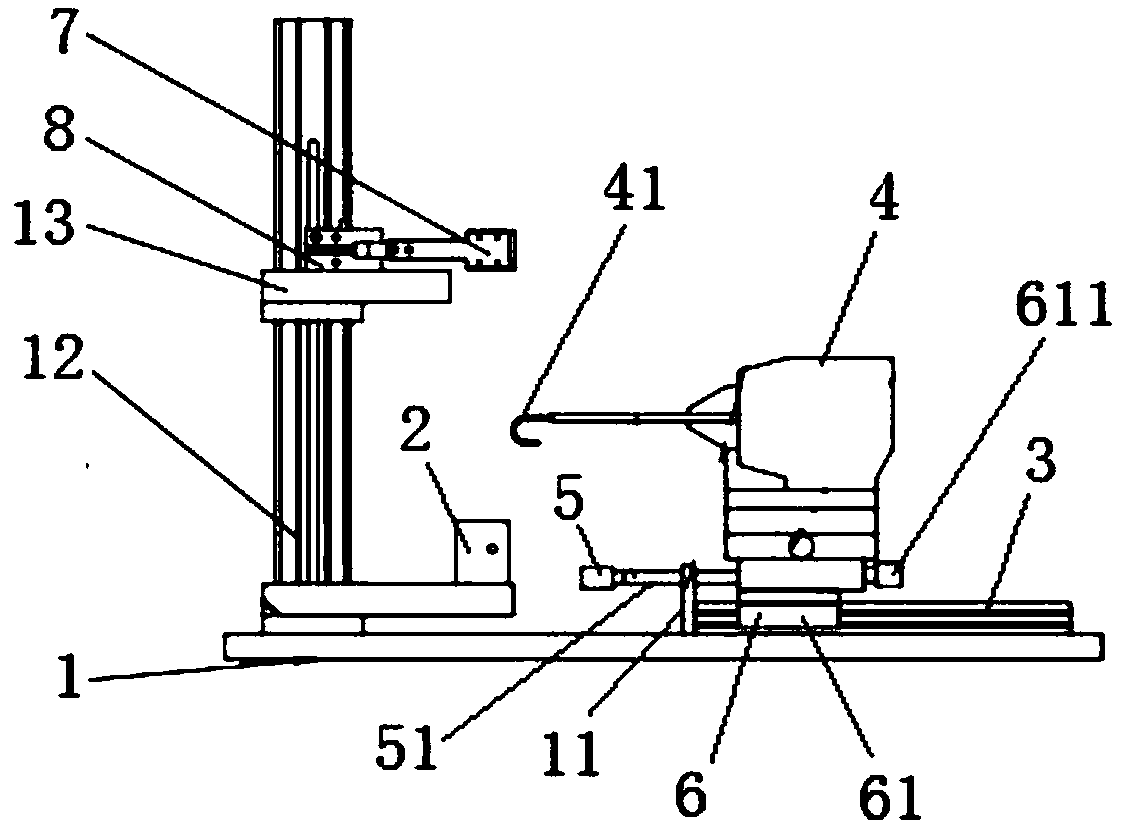

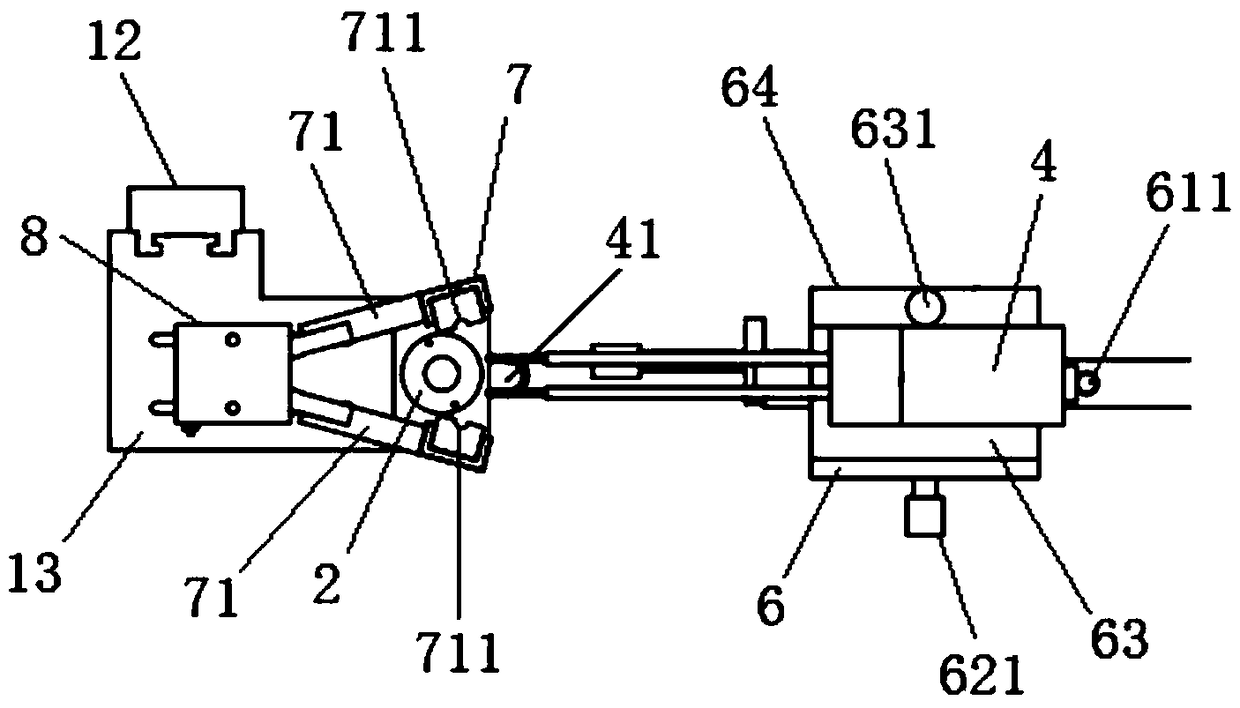

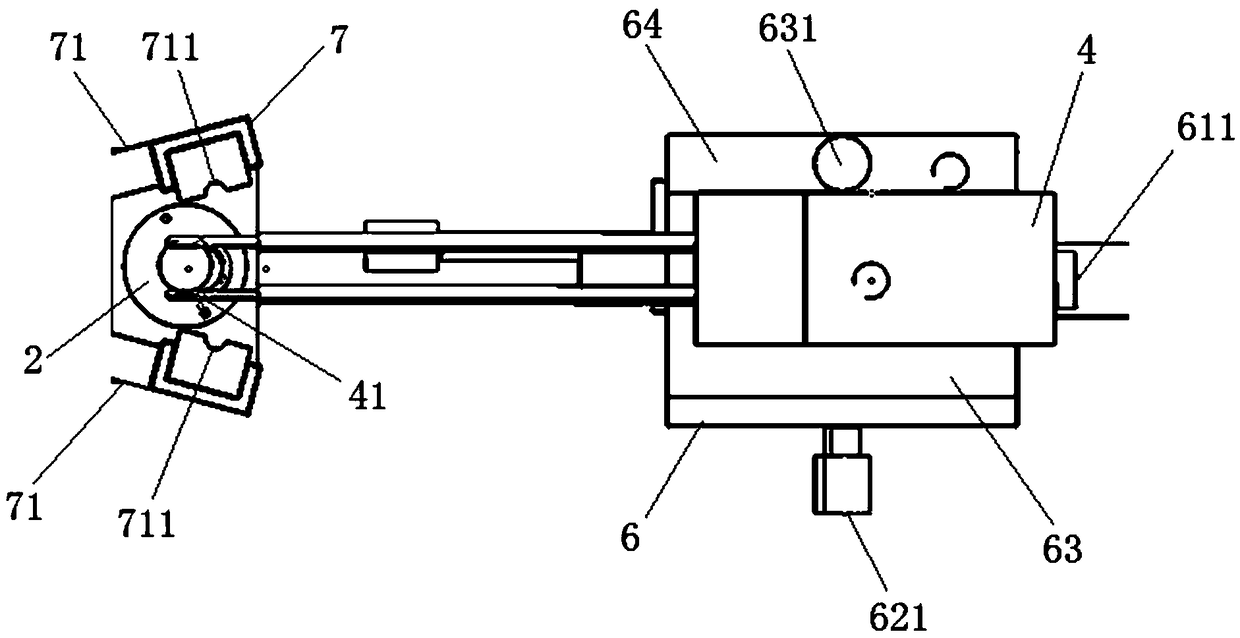

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

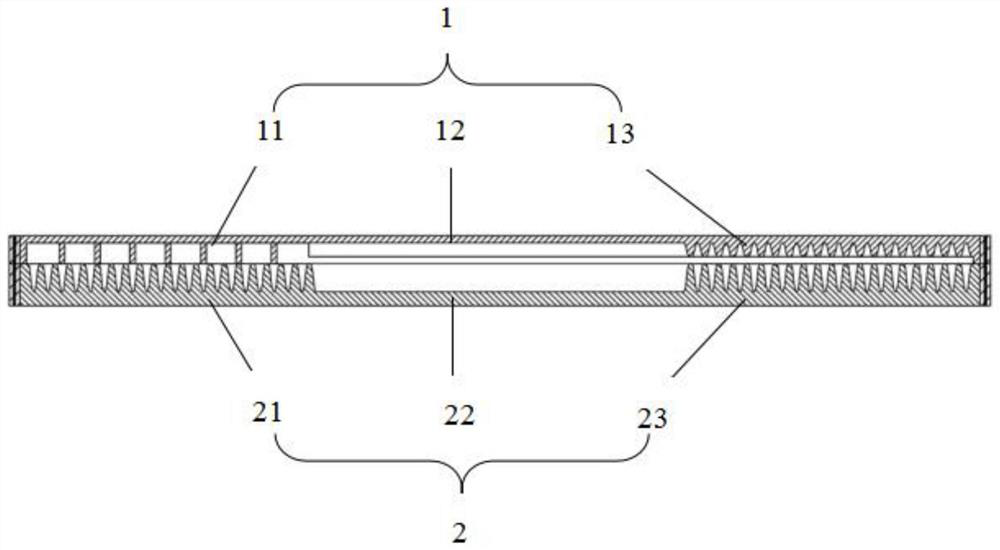

Partition-optimized ultrathin VC with thickness of 0.1-0.4 mm and preparation method

PendingCN111879158AEmission reductionSpeed up distributionIndirect heat exchangersMicro nanoNano structuring

The invention discloses a partition-optimized ultrathin VC with the thickness of 0.1-0.4 mm and a preparation method. The ultrathin VC comprises an upper cover plate and a lower cover plate, and the upper cover plate and the lower cover plate are welded. Each of the upper cover plate and the lower cover plate comprises an evaporation section, a heat insulation section and a condensation section; the surface of the evaporation section of the upper cover plate is of a super-hydrophilic cavity-shaped micro-nano structure, the surface of the heat insulation section of the upper cover plate is of asuper-hydrophilic equal-width groove micro-nano structure, and the surface of the condensation section of the upper cover plate is of a super-hydrophobic conical micro-nano structure; and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the evaporation section of the lower cover plate, a super-hydrophilic cactus-like wedge-shaped groove micro-nano structure is arranged on the surface of the area of the heat insulation section, and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the condensation section. The invention further discloses a preparation method of the ultrathin VC. A steam cavity structure, a liquid cavity structure and volume distribution in a heat pipe can be optimized, and good capillary water absorption performance and low water resistance and heat resistance of the heat pipe can be guaranteed.

Owner:绍兴镭纳激光科技有限公司

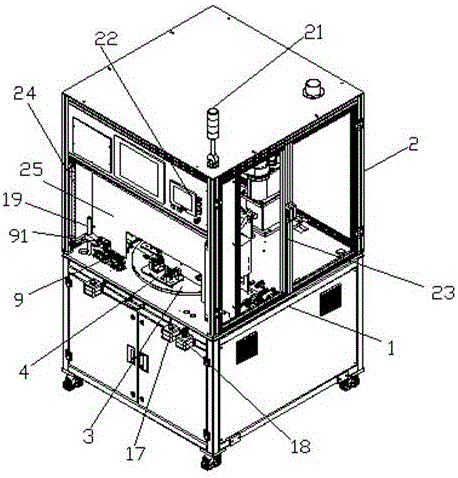

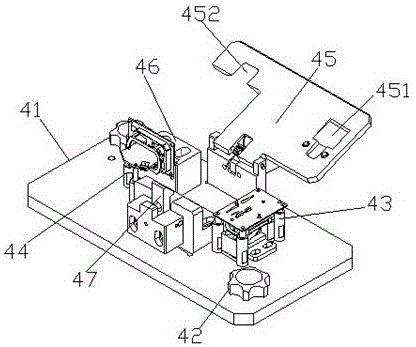

Welding device for automobile antenna PCB product

InactiveCN106392399AEnsure the stability of welding qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCircular discEngineering

The invention discloses a welding device for an automobile antenna PCB product. The welding device comprises a lower rack and an upper rack, wherein a rotary disc and a four-shaft robot are arranged on the lower rack; a plurality of PCB jigs are arranged on the rotary disc in ring array; a first detection device and a second detection device, positioned on the two sides of the rotary disc, are symmetrically arranged on the lower rack; and a soldering device which points to the rotary disc below is arranged on the four-shaft robot. According to the welding device for the automobile antenna PCB product, PCBs are placed on the PCB jigs, after fixation, through the anticlockwise rotation of the rotary disc, the PCB jigs are continuously sent to the positions below the soldering device to be welded, the first detection device detects whether the PCB jigs correspond to corresponding welding procedures or not and detects whether missing placing and mistaken placing exist or not, the second detection device detects whether the PCBs are successfully welded or not and whether welding spots are qualified or not, abnormity warning is carried out, and the stability of welding quality is guaranteed.

Owner:苏州德机自动化科技有限公司

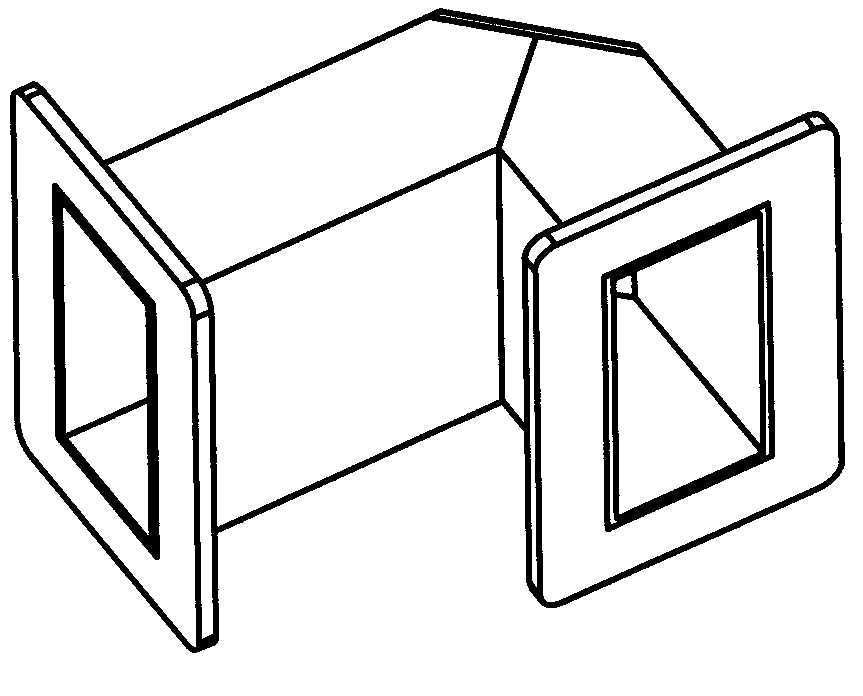

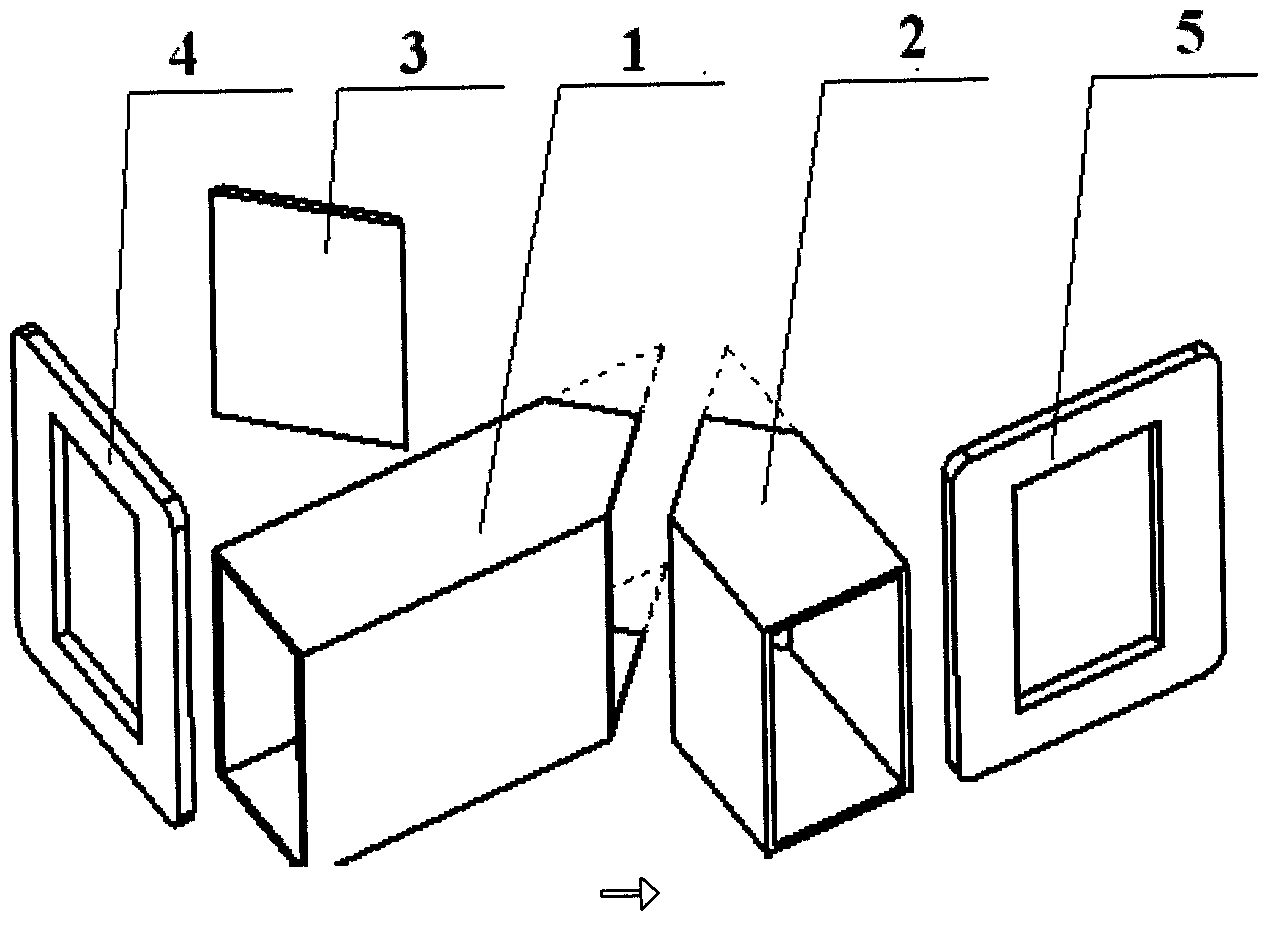

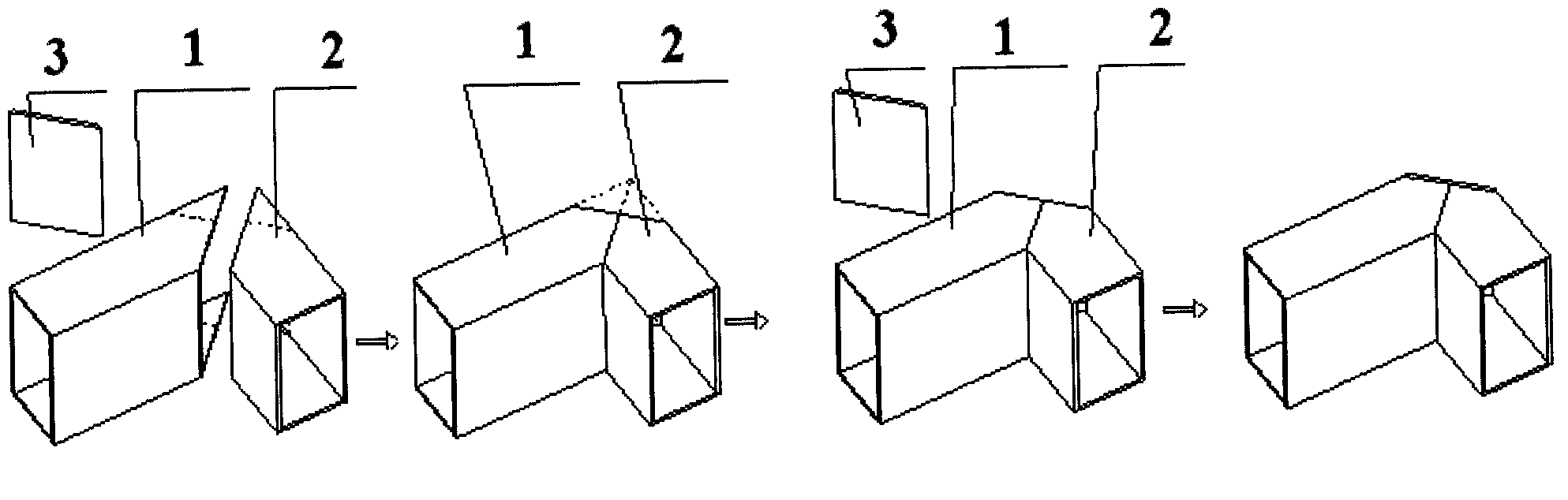

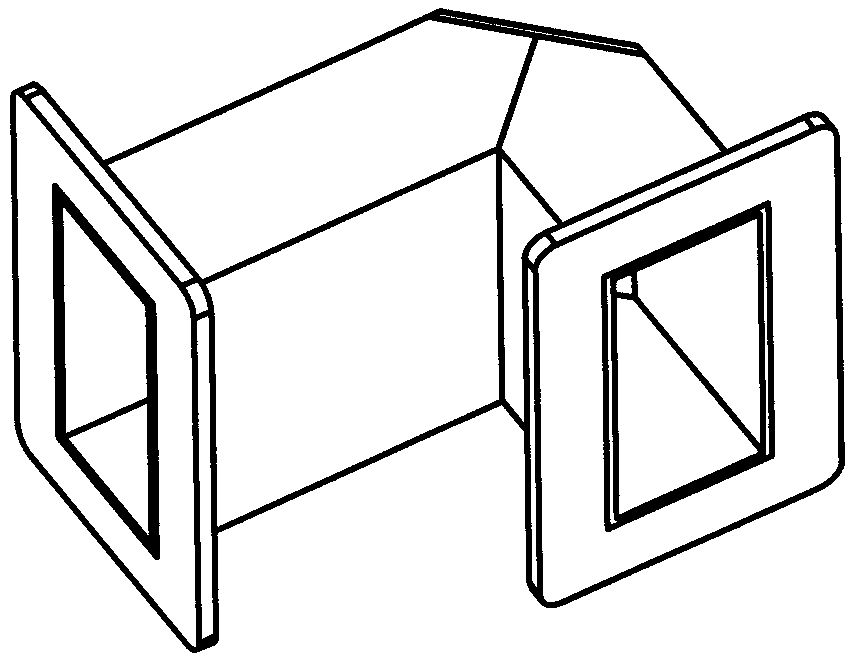

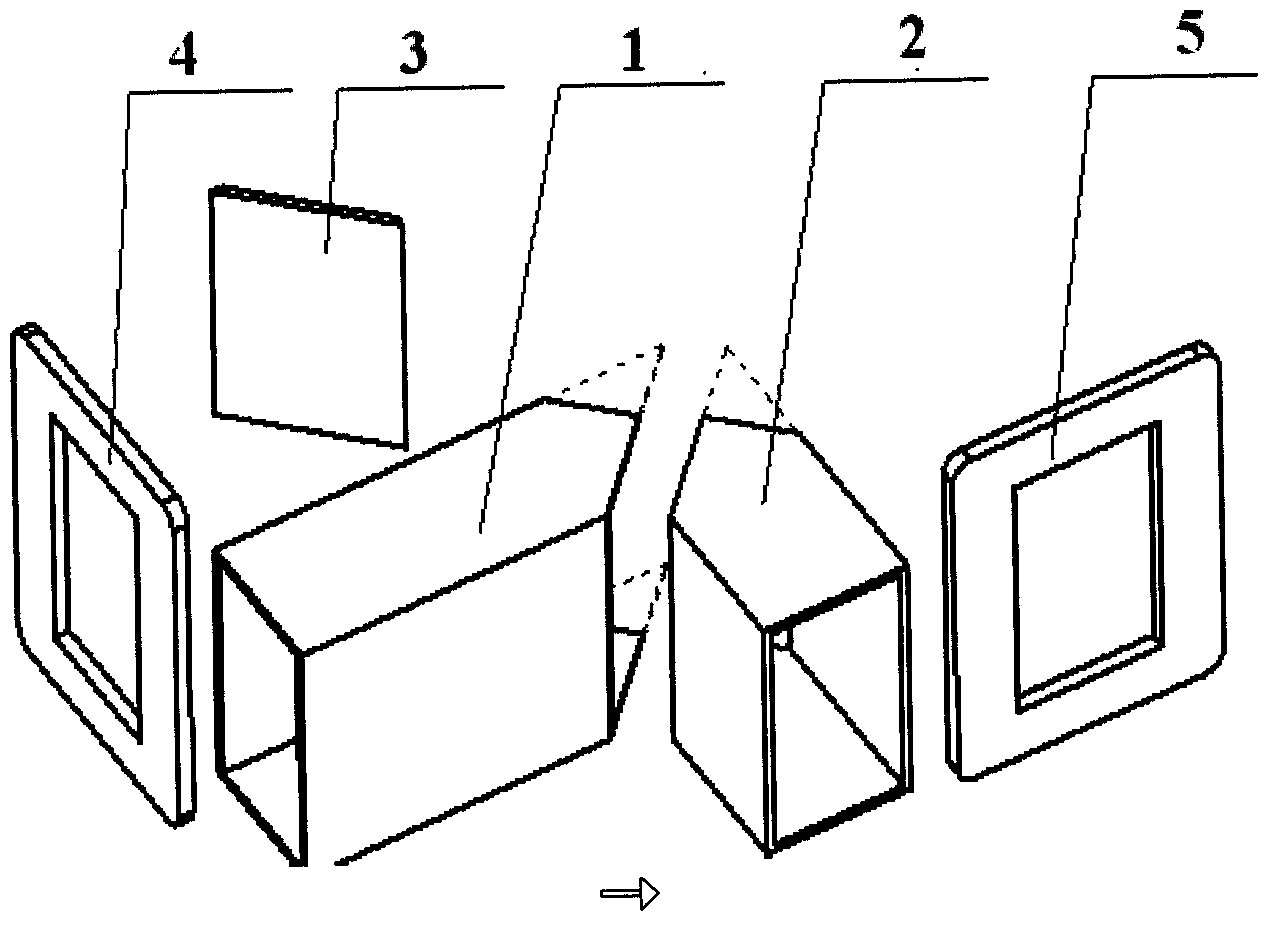

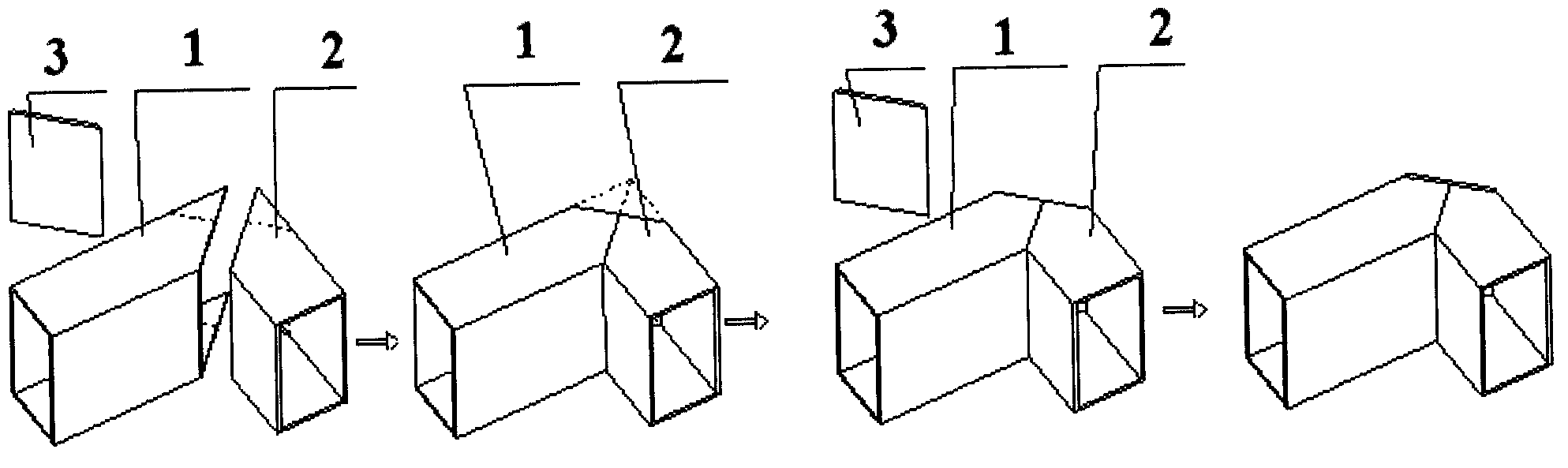

Bending type forming method of corner cut waveguide bend

The invention relates to a bending type forming method of a corner cut waveguide bend, which belongs to the technical field of waveguide forming. Two triangular bending grooves are formed in the rear surface of a waveguide tube and divide the waveguide tube into three parts in the length direction, wherein the center part of the waveguide tube is a bending area. Bending gaps are processed in the front surface, the upper surface and the lower surface of the waveguide tube; the rectangular waveguide tube is folded forwards along the two triangular bending grooves; and flanges are welded at the two ends of the formed waveguide tube to obtain the corner cut waveguide bend. According to the bending type forming method, the same waveguide tube is adopted for forming, so that the dimension error of an inner cavity assembled by different waveguide tube blanks is reduced, and the probability of dislocation deficiency of the splicing surface of the inner cavity is reduced; a bending type self-positioning structure is adopted to control the inner cavity forming, so that the effects of assembling and welding on the precision of the dimension, shape and position of the inner cavity are reduced, and the forming precision of the inner cavity is improved; the waveguide tube part is subjected to once weld forming, so that welded joints of the inner cavity are decreased; the difficulty in welding is reduced; the stability of the welding quality is improved; and the welding efficiency is improved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

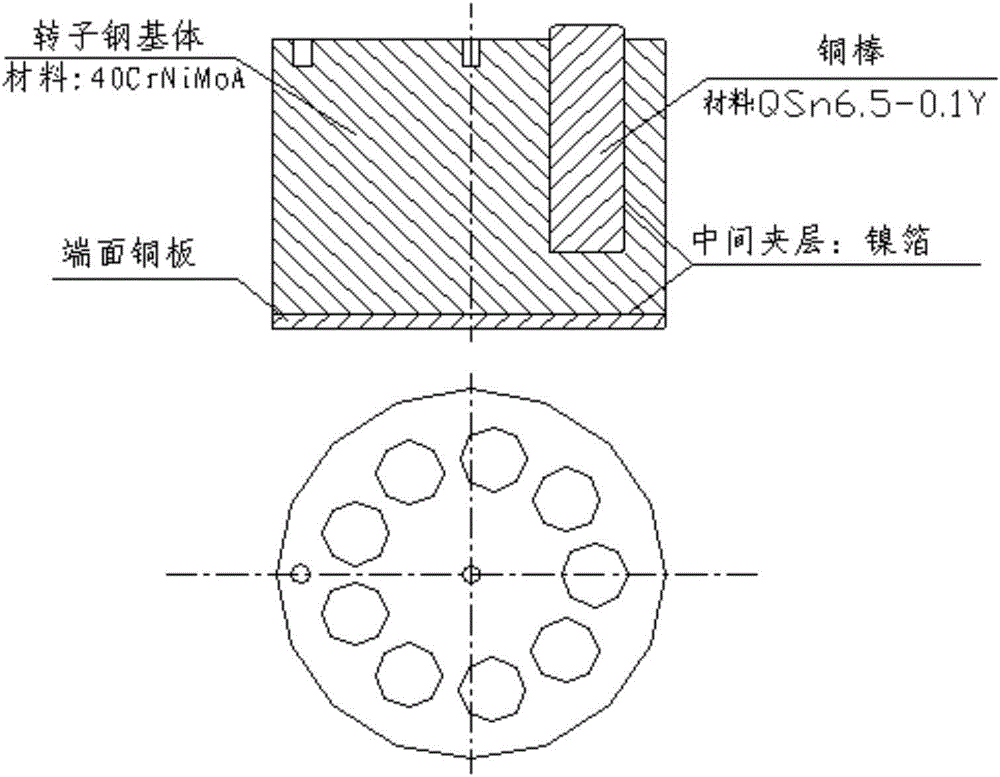

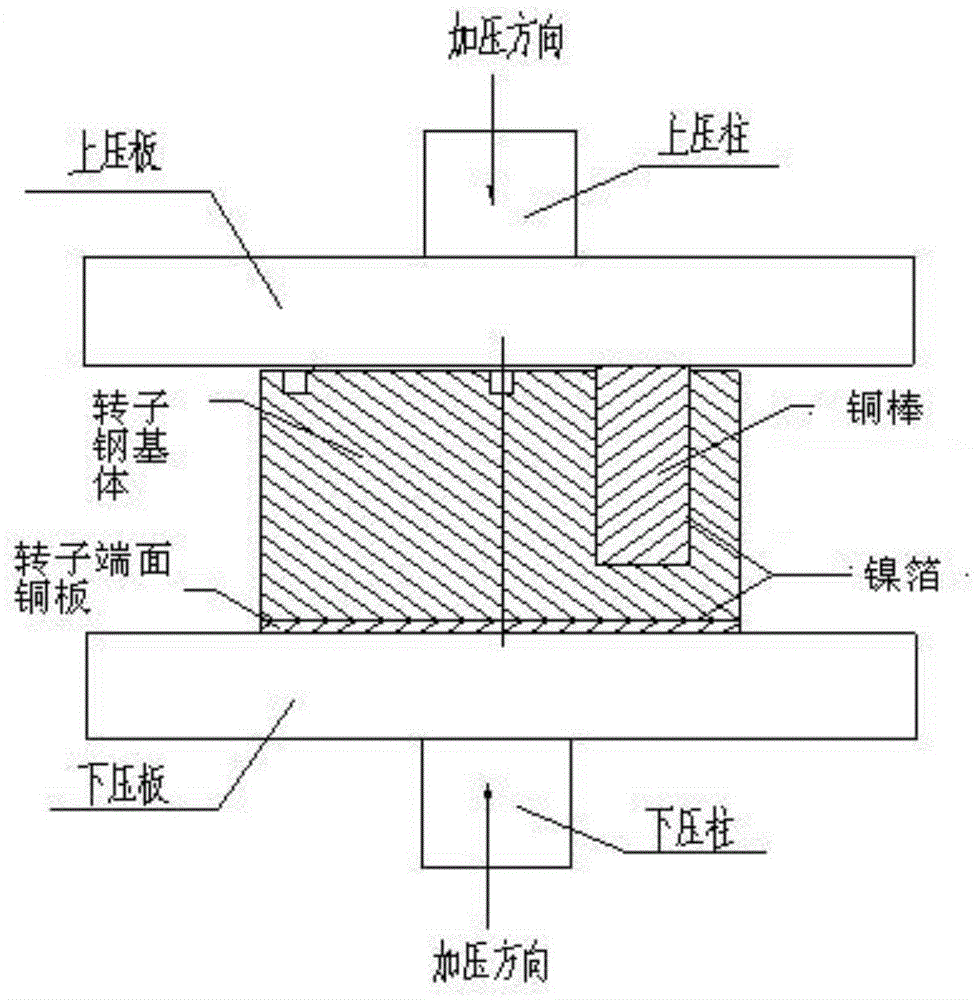

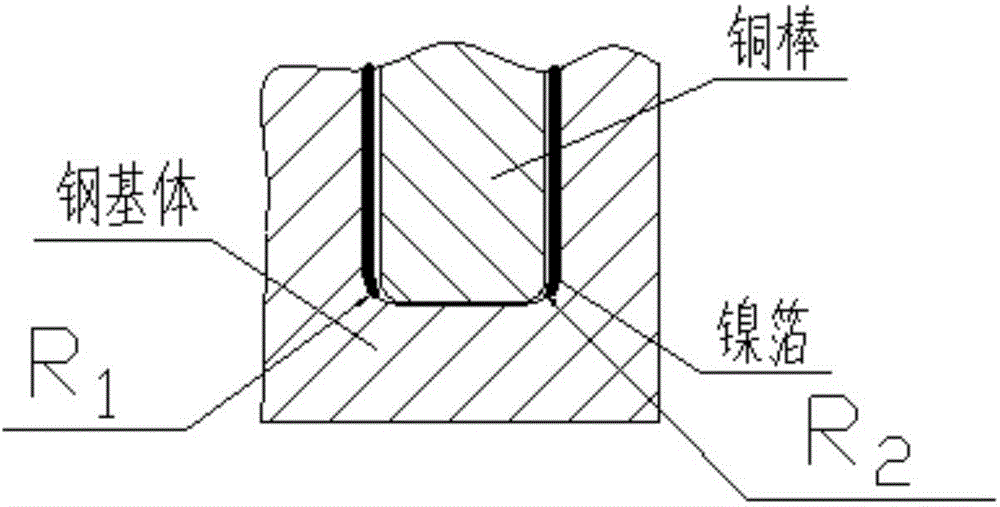

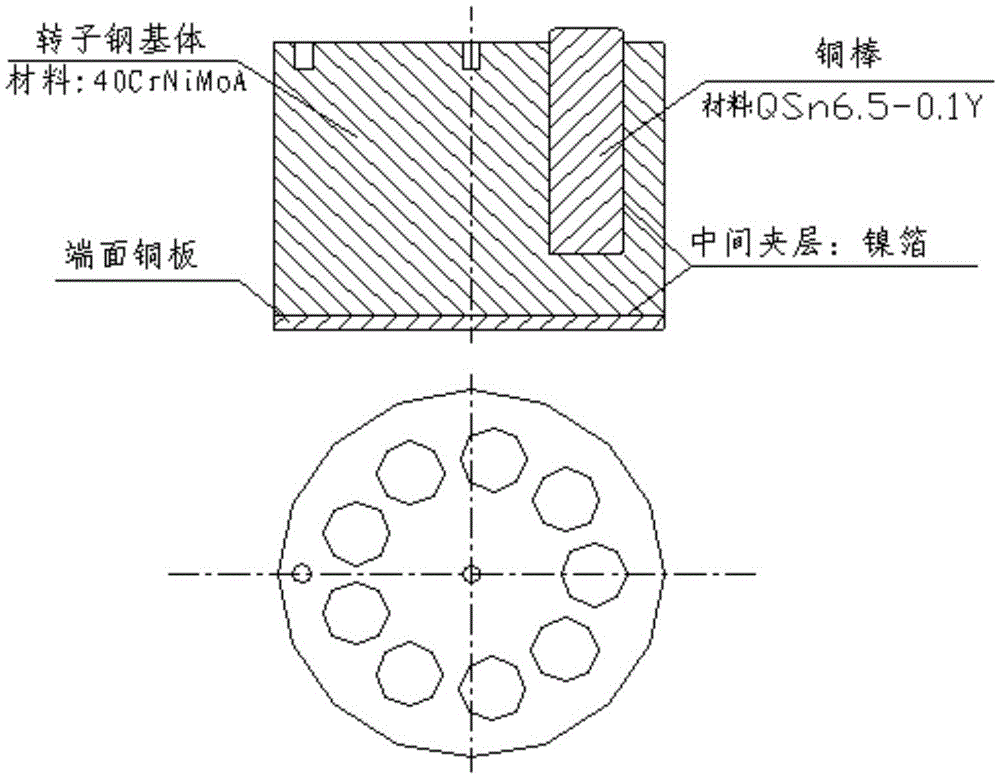

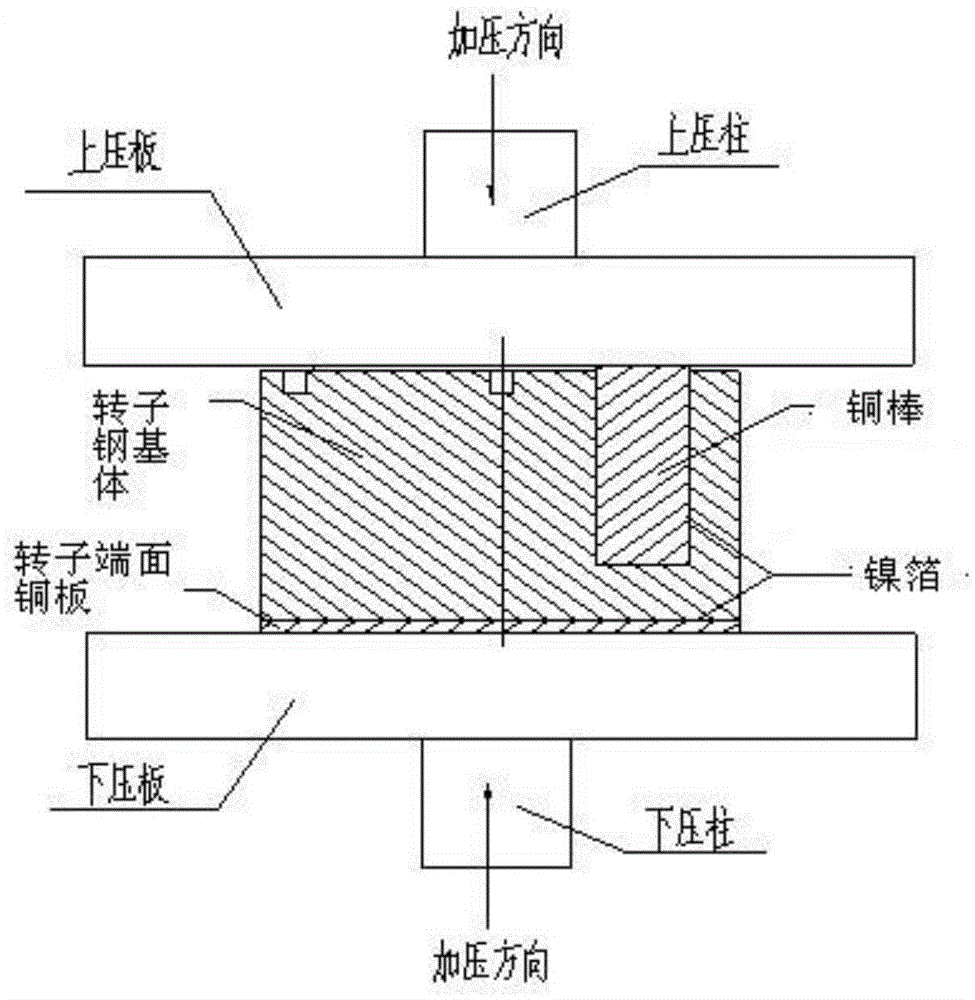

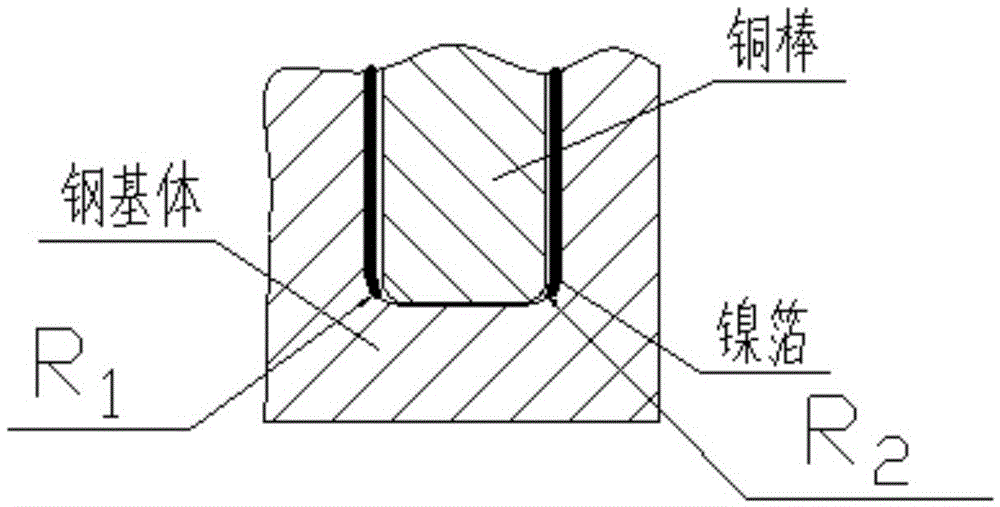

Plunger piston hydraulic pump motor rotor dual alloy structure diffusion welding method

ActiveCN104057201AImprove stabilityImprove assembly effectWelding/soldering/cutting articlesNon-electric welding apparatusCopperWelding joint

The invention discloses a plunger piston hydraulic pump motor rotor dual alloy structure diffusion welding method, which comprises the following steps that 1, the dimension of a workpiece to be welded is subjected to pretreatment; 2, the gasoline soaking ultrasonic processing, the blowing drying, the acid washing ultrasonic wave processing, the water flushing, the absolute ethyl alcohol soaking ultrasonic wave processing and the blowing drying are sequentially carried out; 3, a nickel foil is adopted to be used as a welding transition layer material, and a rotor steel substrate, a copper rod and a rotor end surface copper plate are assembled; 4, through the axial pressurization, an assembled rotor welding assembly is placed into a welding hearth to be subjected to diffusion welding. The method provided by the invention has the advantages that through the conventional diffusion welding on a rotor, a welding joint meeting the use requirements can also be obtained, and in addition, the problems caused by welding deformation can be avoided.

Owner:AVIC LIYUAN HYDRAULIC

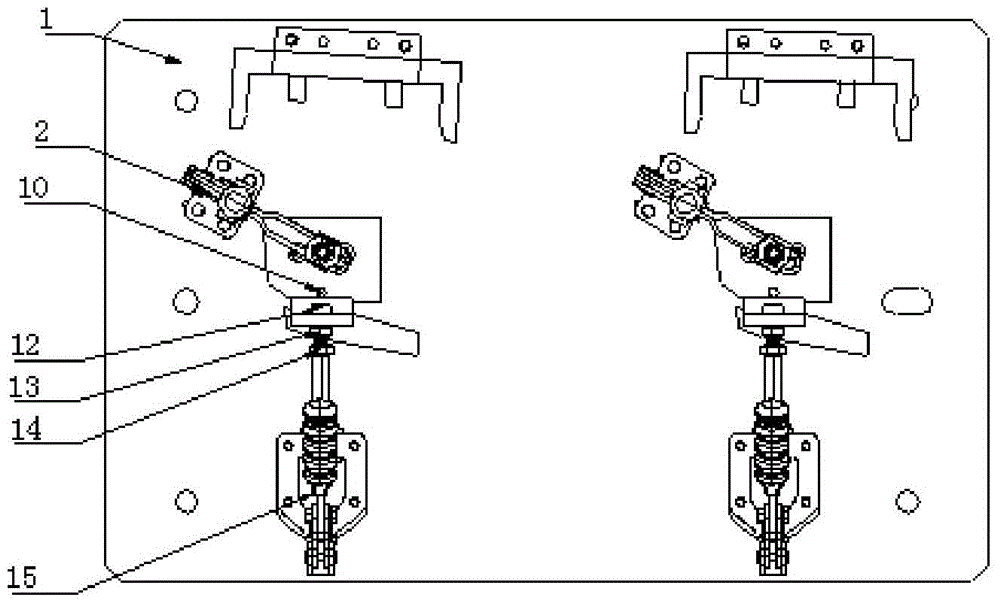

Welding jig for robot to weld automobile door lower hinge reinforcing plate assemblies

ActiveCN105081644ANot shiftNot badWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding jig for a robot to weld automobile door lower hinge reinforcing plate assemblies. The welding jig is used for coaxially positioning automobile door lower hinge reinforcing plates and accessories to be welded of the automobile door lower hinge reinforcing plate assemblies, so that the accessories to be welded are welded on the automobile door lower hinge reinforcing plates. The welding jig comprises a jig bottom plate, coaxial positioning mechanisms, rotation preventing mechanisms for the accessories to be welded, rotation preventing mechanisms for the automobile door lower hinge reinforcing plates and rapid press pliers. The coaxial positioning mechanisms, the rotation preventing mechanisms for the accessories to be welded, the rotation preventing mechanisms for the automobile door lower hinge reinforcing plates and the rapid press pliers are arranged on the jig bottom plate. Compared with the prior art, the welding jig has the advantages of being easy to operate, convenient to overhaul, dismount and mount, good in error detection, good in welding quality stability, high in production efficiency and the like.

Owner:SHANDONG AOLIN CAR FITTINGS

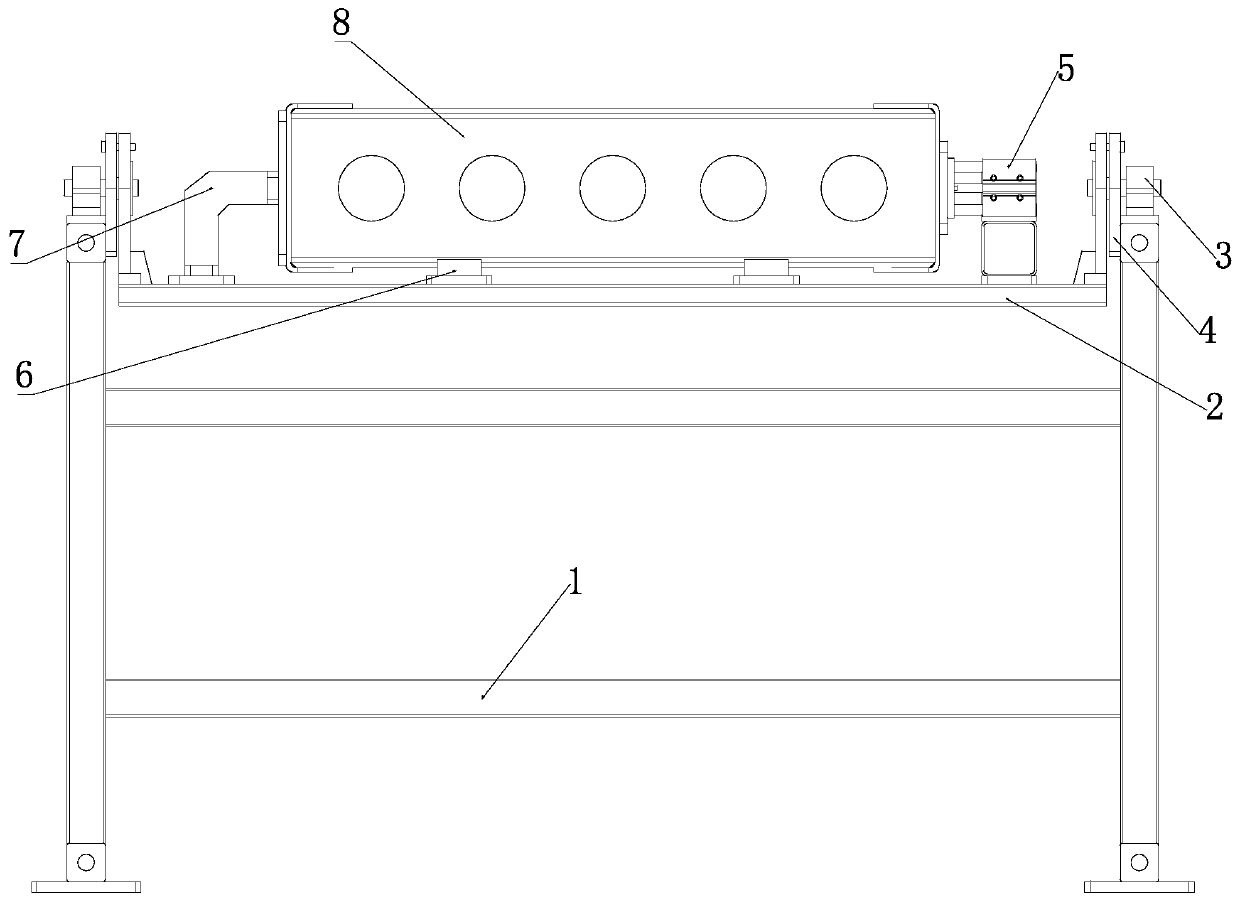

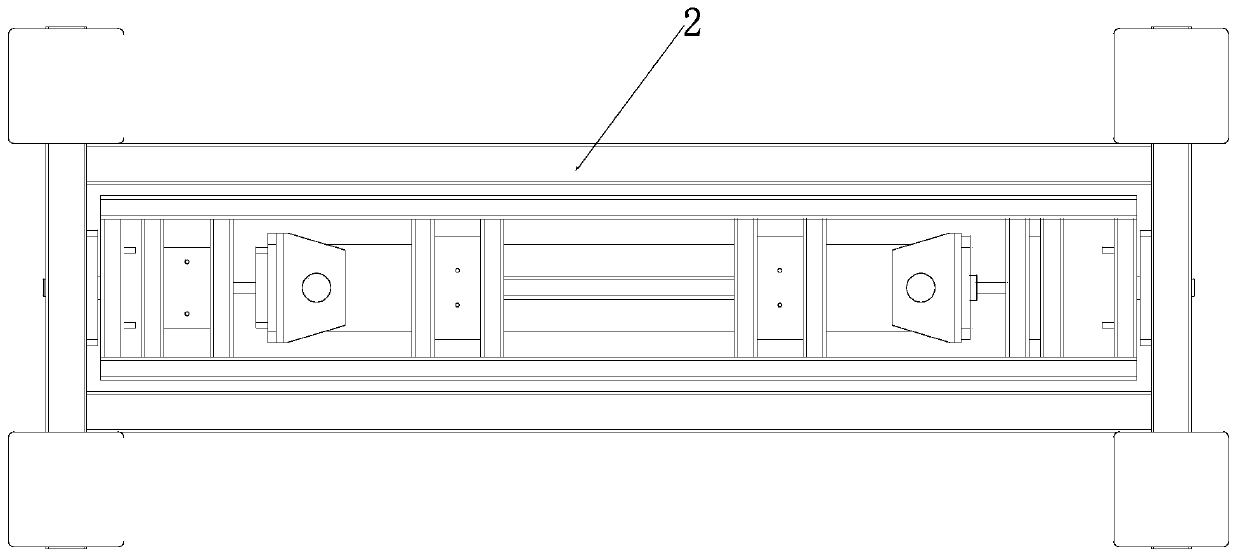

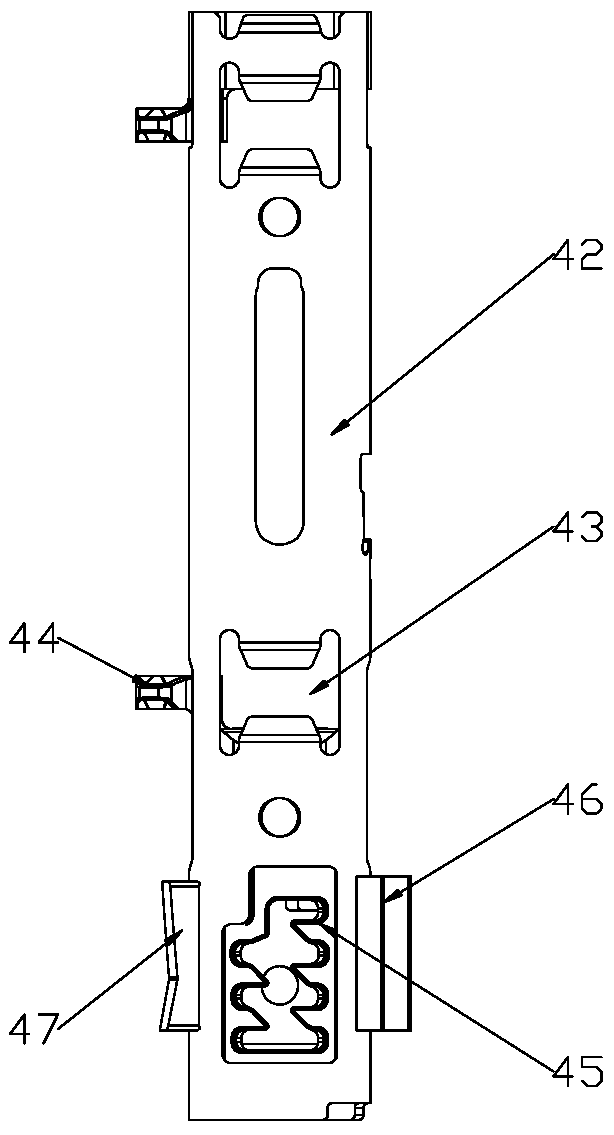

Portal ultrasound rolling welding device

ActiveCN111659995AHigh welding quality stabilityImprove welding stabilityNon-electric welding apparatusEngineeringWelding

The invention belongs to the technical field of ultrasound rolling welding, and discloses a portal ultrasound rolling welding device. The portal ultrasound rolling welding device comprises an ultrasonic welder, a bottom die assembly, a portal machine frame, and a welder adjusting assembly, wherein the bottom die assembly is in sliding connection to a baseplate of the portal machine frame; the welder adjusting assembly comprises a body part and a spacing adjusting part; a concave guide rail is arranged on the body part; the ultrasonic welder is in sliding connection to the concave guide rail; the body part is adjustably connected to side plates of the portal machine frame; and the spacing adjusting part is used for spacing the body part to the side plates, and can drive the body part to rotate relative to the side plates. According to the portal ultrasound rolling welding device disclosed by the invention, the welder adjusting assembly is arranged, so that the posture and the position of the ultrasonic welder can be adjusted, and the welding quality and the welding stability are improved; the portal machine frame is connected with the ultrasonic welder and the bottom die assembly, so that replacement of consumptive materials is more convenient, the portal ultrasound rolling welding device is suitable for different types of welders, and the effectiveness and the adaptability of products are improved.

Owner:SBT ULTRASONIC TECH CO LTD

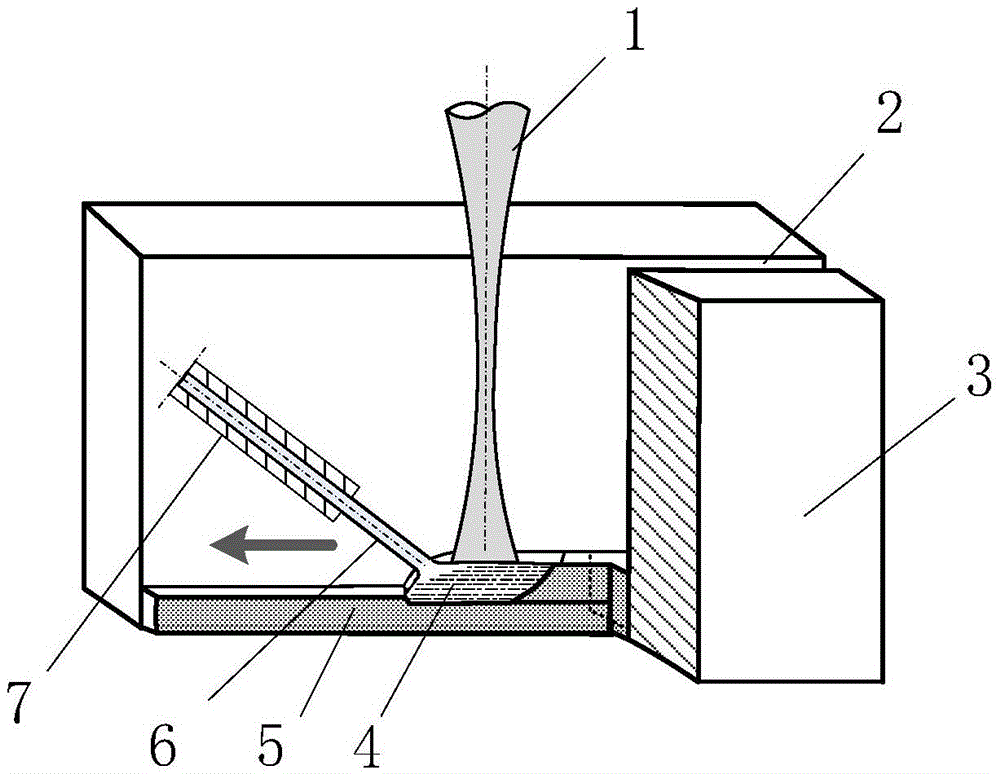

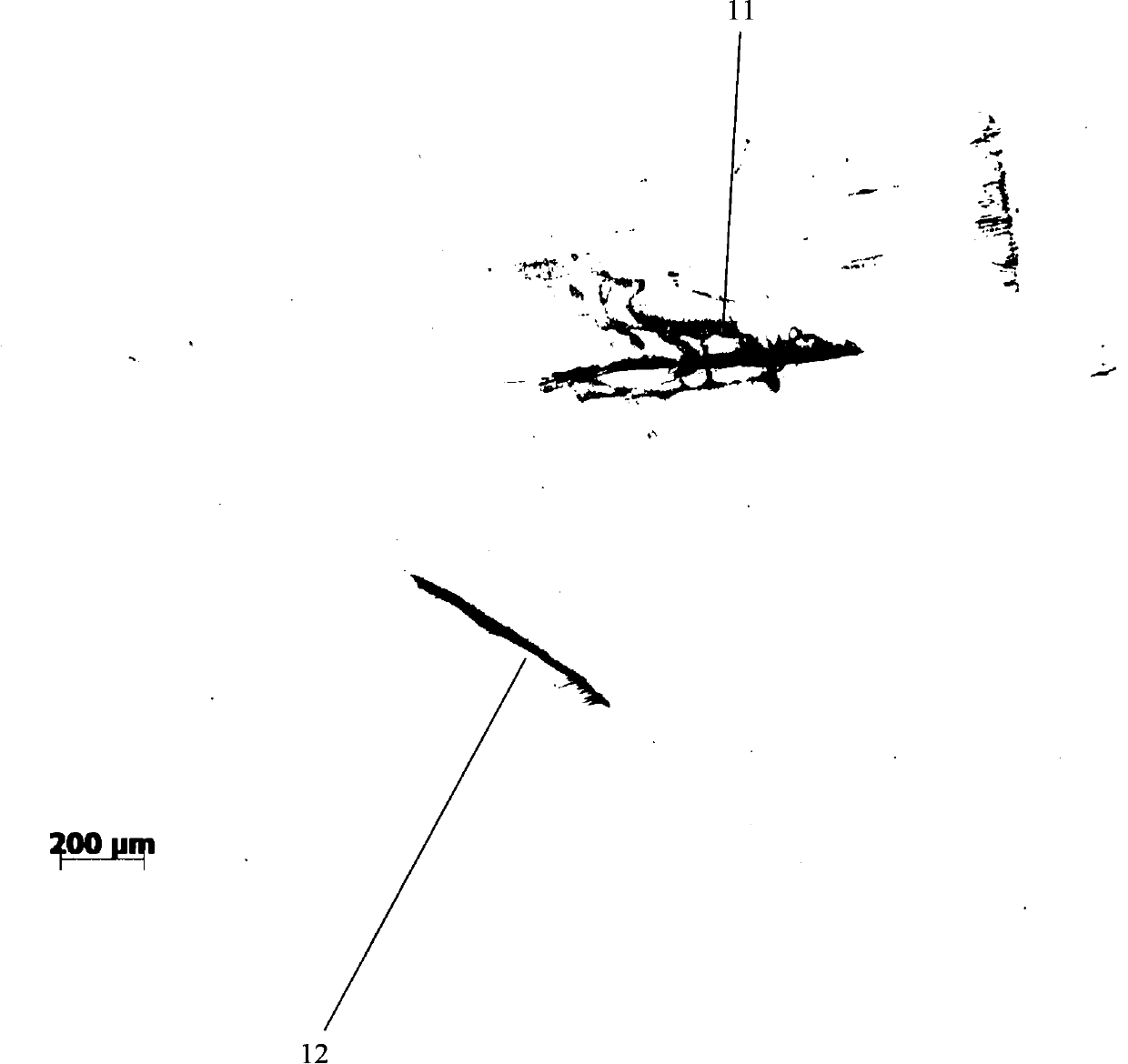

Laser wire-filling welding method for thick plate with narrow gap

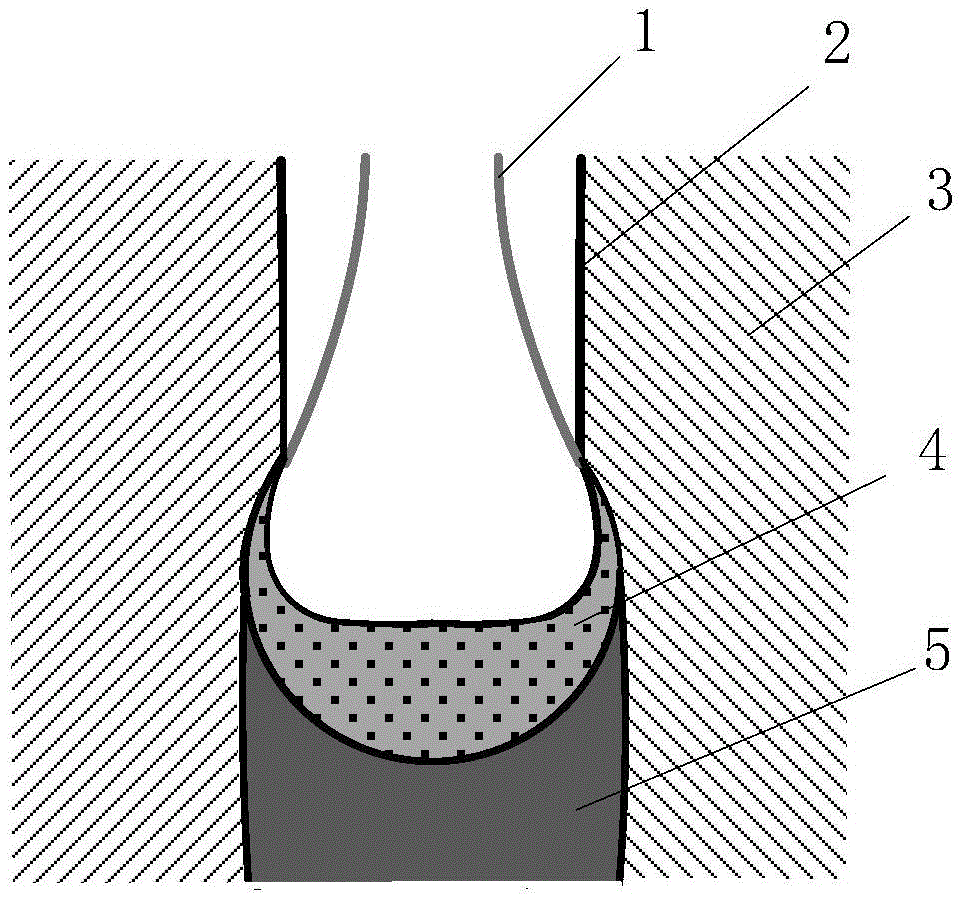

ActiveCN103801833BAvoid it happening againReduce generationWelding/soldering/cutting articlesMetal working apparatusThick plateMolten bath

The invention relates to a laser filler wire welding method for a thick plate narrow gap, and belongs to the technical field of laser material processing. The laser filler wire welding method for the thick plate narrow gap is characterized by comprising the steps that positive out-of-focus laser beams are adopted, the laser beams enter a narrow gap groove of a workpiece to be welded and act on the bottom and the side wall of the groove, and a welding pool is formed in a thermal conducting welding mode; a filler wire enters the welding pool in a wire forward feeding mode and is heated through the welding pool to be molten, the gap is filled with the molten wire to form a weld joint, and a thick plate is connected in a single-path multi-layer welding mode. According to the laser filler wire welding method for the thick plate narrow gap, the thermal conducting welding mode and the mode that the filler wire is heated through the welding pool to be molten are adopted, and the welding process is stable; meanwhile, the laser beams act on the side wall of the groove so that the welding defects such as the defect that the side wall is incompletely fused can be effectively avoided.

Owner:BEIJING UNIV OF TECH

Welding device of cable assembly

PendingCN109365941AQuality improvementHigh welding quality stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric cables

The invention provides a welding device of a cable assembly. The welding device comprises a bottom plate, a connector positioning seat mounted on the bottom plate, a sliding rail mounted on the bottomplate, a welding machine mounted on the bottom plate, and a limiting part mounted on the bottom plate. The connector positioning seat is provided with a positioning groove, the welding machine is provided with an induction coil, the welding machine can move along the welding machine in the direction of being close to and away from the connector positioning seat, and the limiting part is used forlimiting the movement route of the welding machine in the direction of being close to the connector positioning seat. According to the welding device of the cable assembly, a connecting device and thewelding machine are positioned through the connector positioning seat and the limiting part, thus, it can be guaranteed that a terminal of the connecting device is accurately located at the set position in the induction coil, and it is guaranteed that the welding quality and the welding percent of pass of the welding device of the cable assembly are higher.

Owner:SHANGHAI RADIALL ELECTRONICS

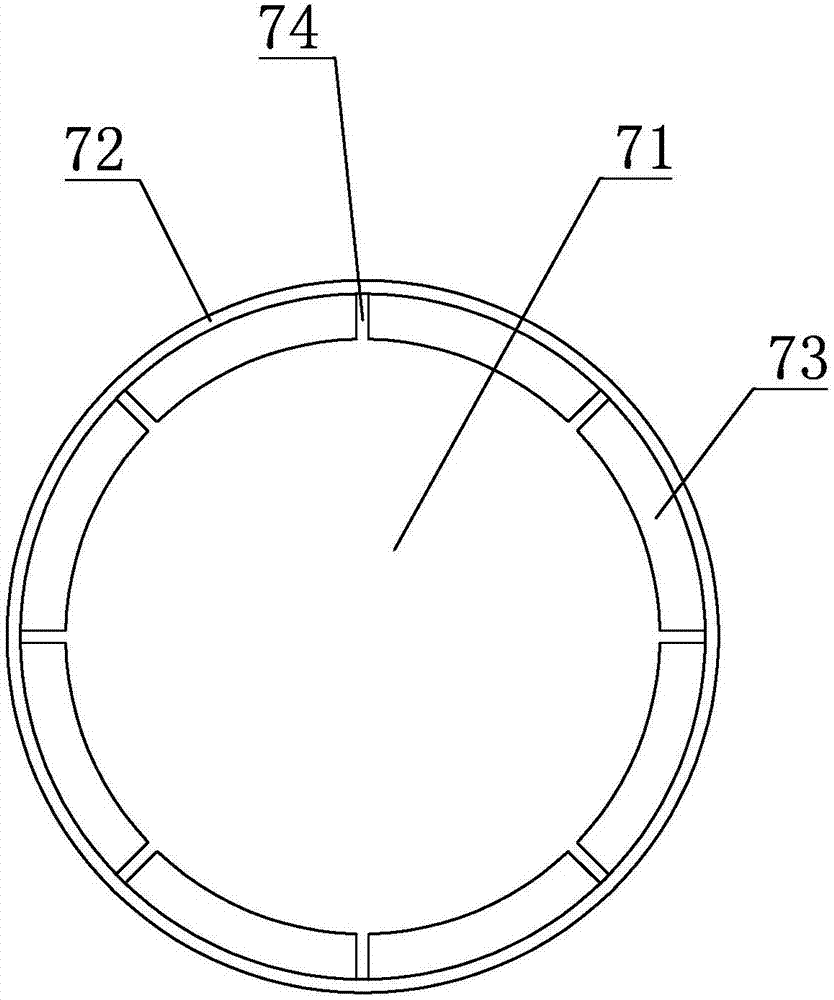

Safe net hood frame welding machine

InactiveCN107470842APrecise positioningEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesControl systemBaseboard

The invention discloses a safe net hood frame welding machine. The machine comprises a machine table, a rack arranged on the machine table, a welding unit and a control system, wherein the rack is fixed to the rear portion of the machine table, a suspending arm facing forwards is arranged at the upper portion of the rack, a driving disc which can rotate at equal gaps is arranged on the machine table below the suspending arm, a supporting pillar is arranged on the machine table at the front side of the driving disc, a veering beam of which the middle is rotatably connected to the supporting pillar is arranged at the top of the supporting pillar, rotatable locating discs are arranged at both ends of the veering beam, each locating disc comprises a baseboard and an outer ring matched with the outer diameter of a safe net hood frame, multiple arc locating tiles are uniformly arranged at the inner side of the outer ring, the seaming width between the two adjacent locating tiles is matched with a safe net hood framework, the arc length of each locating tile corresponds to the angle that the driving disc rotates by for every gap rotation, and the height of each locating tile is smaller than that of the safe net hood framework. The locating discs make the frame and the framework accurately located, the welding stability is improved, and the welding quality and the quality stability are improved.

Owner:余伟宏

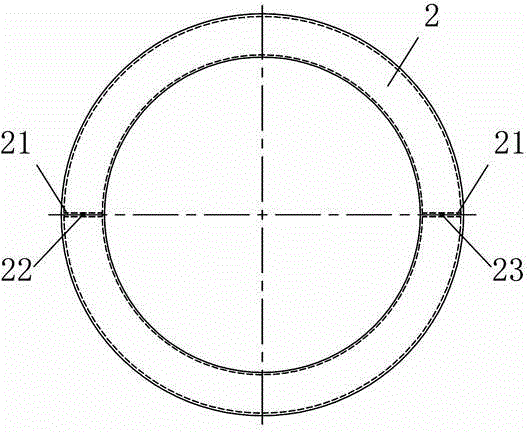

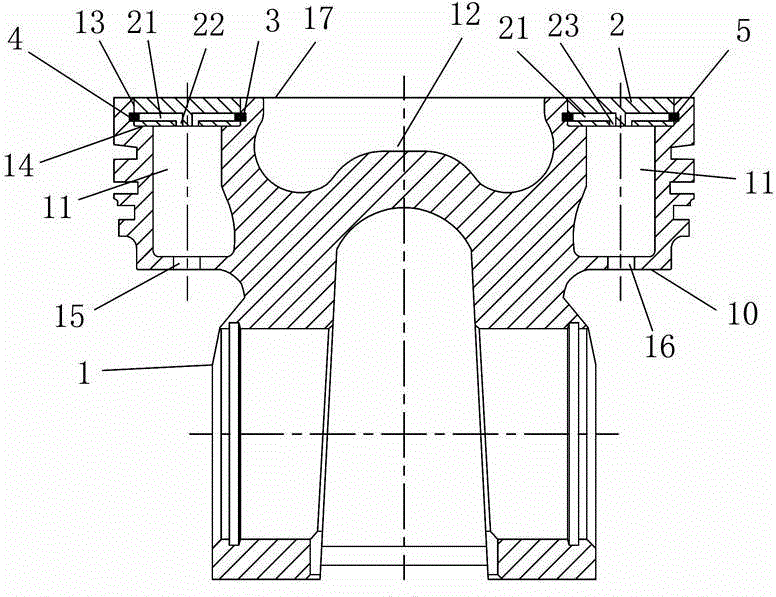

Steel piston forming inner cooling oil way based on laser welding and machining method of steel piston

ActiveCN106150749AExtended service lifeReduce weightMachines/enginesPistonsCombustion chamberEngineering

The invention discloses a steel piston forming an inner cooling oil way based on laser welding and a machining method of the steel piston. The steel piston comprise a piston body and an annular sealing plate; a piston head part of the piston body is provided with the inner cooling oil way and a combustion chamber; the inner cooling oil way surrounds the combustion chamber, and the piston head part is further provided with an oil inlet hole and an oil outlet hole which communicate with the inner cooling oil way; an annular opening is formed in the upper end of the inner cooling oil way and located in the top end of the piston head part; the annular sealing plate is embedded in the annular opening and connected and fixed through laser welding, the upper end of the inner cooling oil way is sealed, an inner annular channel is formed by the inner circle of the annular sealing plate and the side wall of the annular opening in a surrounding manner, an outer annular channel is formed by the outer circle of the annular sealing plate and the side wall of the annular opening in a surrounding manner, and the inner annular channel and the outer annular channel are filled with high-temperature-resisting heat isolation rings used for forming a laser welding pool. The method comprises the first step of component machining, the second step of laser welding and assembling, the third step of heat treatment and the fourth step of post machining. The steel piston and the machining method have the beneficial effects of being high in machining cost, good in quality stability and low in machining cost.

Owner:强哲菲

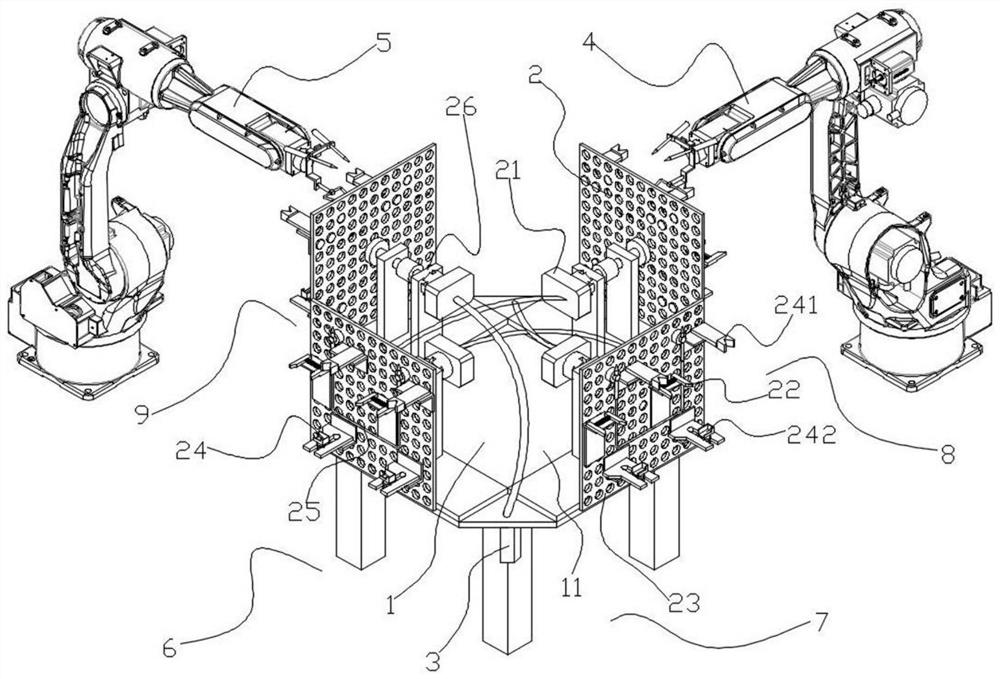

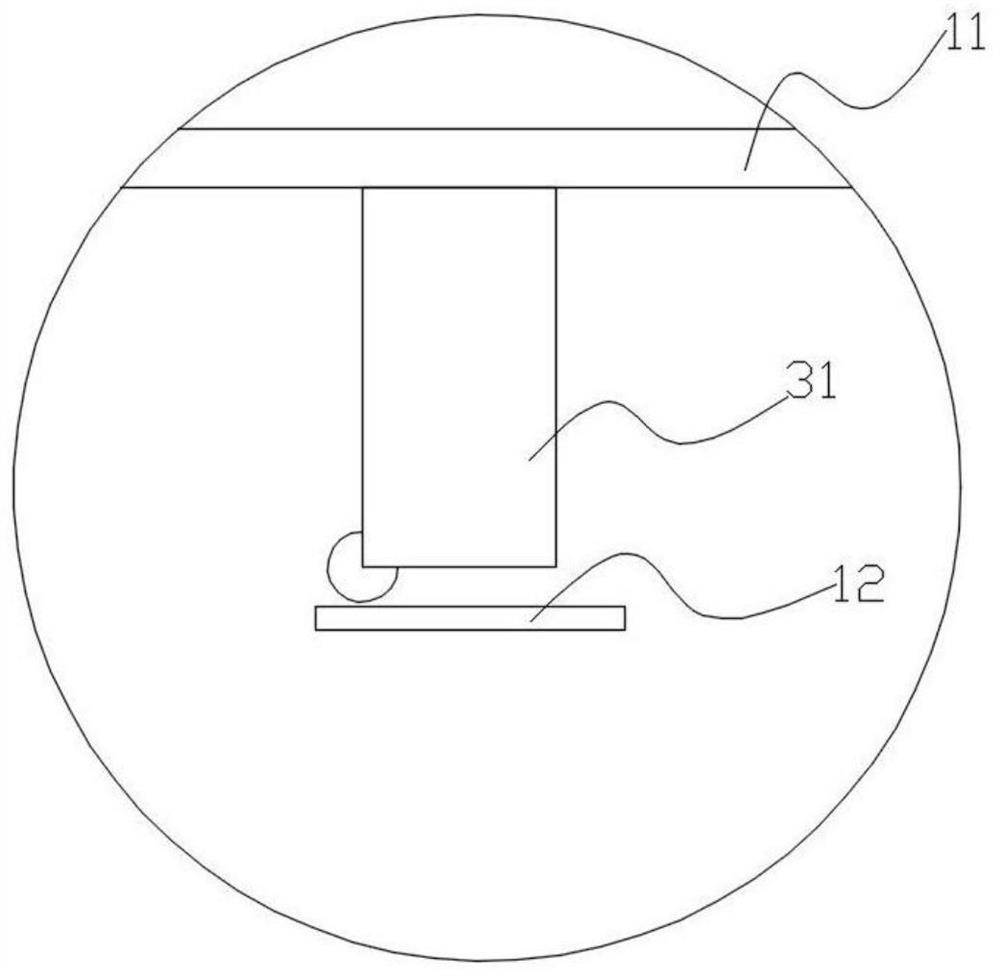

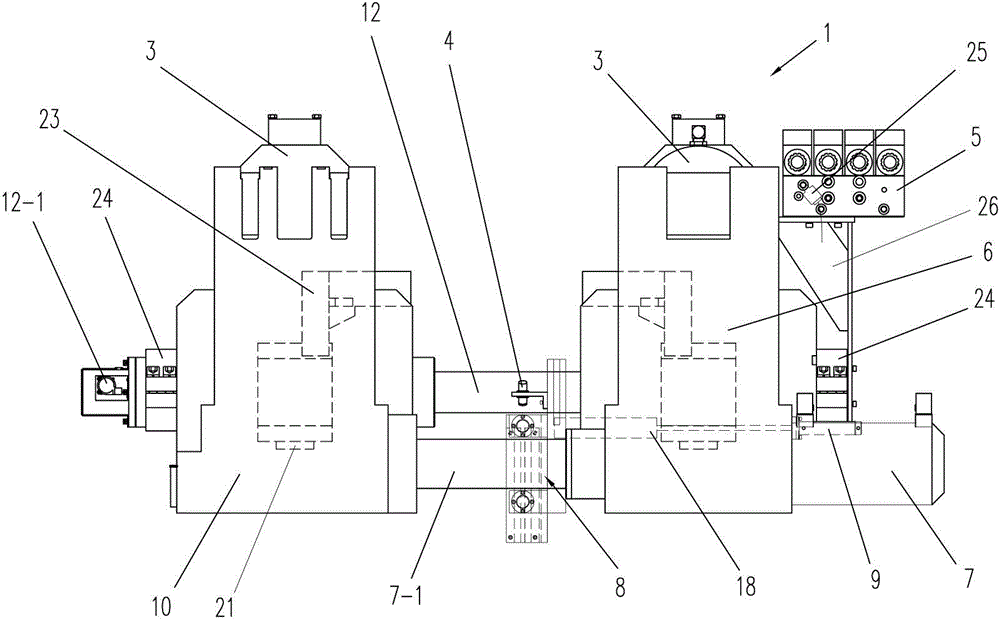

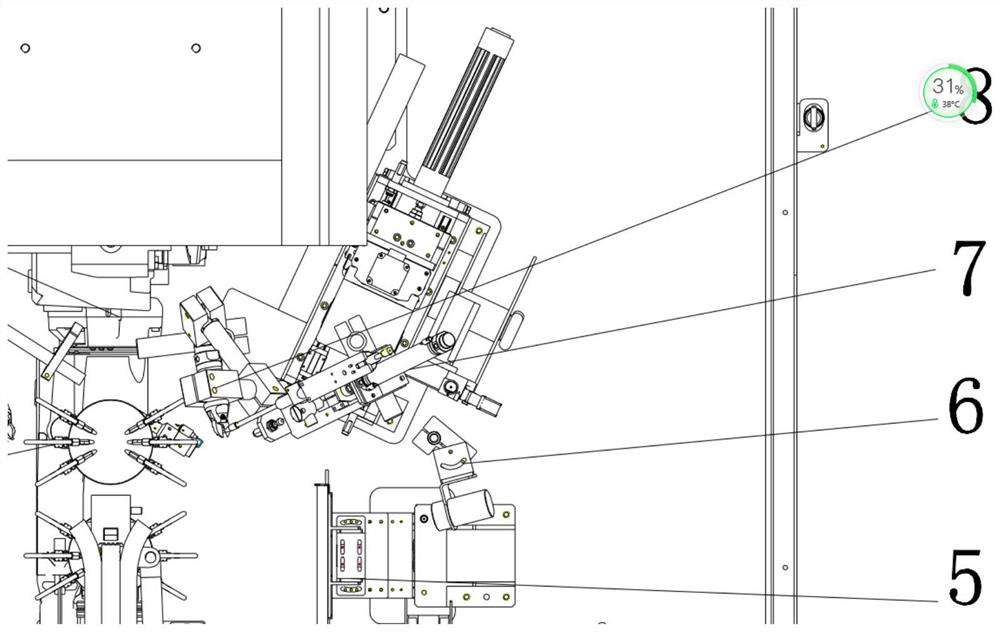

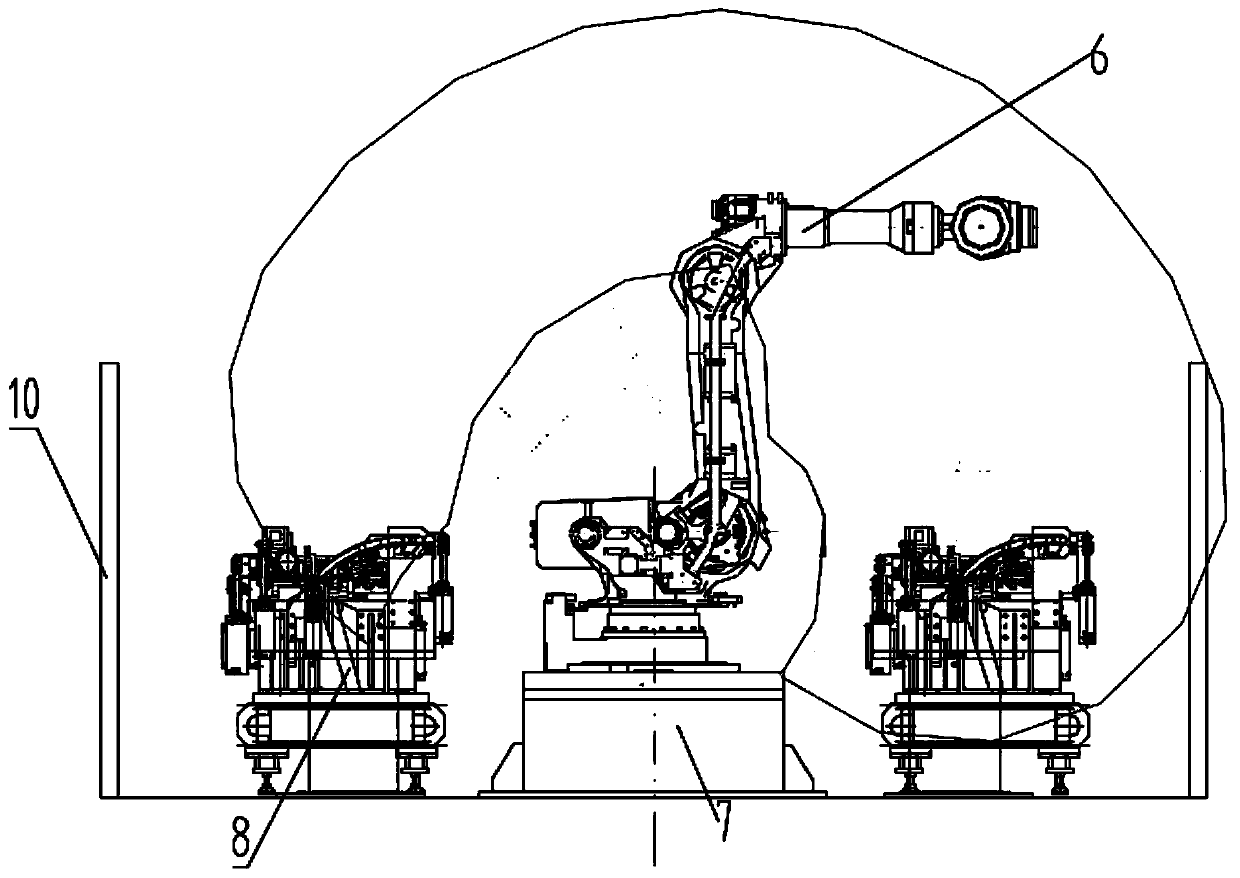

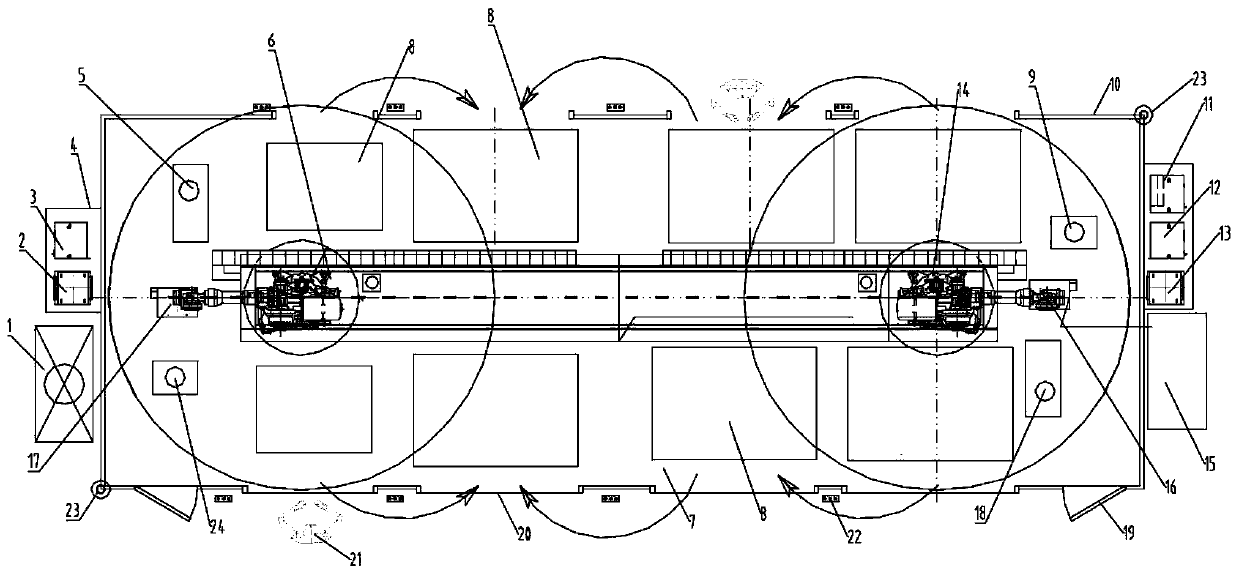

Automatic rotating tool and machining system and welding method adopting automatic rotating tool

PendingCN111673333AReduce labor intensityShorten welding processing timeWelding/cutting auxillary devicesAuxillary welding devicesVertical planeAutomatic control

The invention discloses an and machining system and welding method adopting automatic rotating tool. The automatic rotating tool is provided with a horizontal rotating assembly, a vertical rotating assembly and a control system, and the horizontal rotating assembly and the vertical rotating assembly are automatically controlled to rotate along the horizontal plane and the vertical plane correspondingly; and the machining robot is arranged and controlled to automatically weld the silencer assembly, so that the time consumed in the welding process is shortened, the labor intensity of operators is reduced, the labor cost is reduced, the welding efficiency and the welding quality stability are improved, and abnormal welding quality phenomena such as weld beading, welding leakage and overburning are avoided.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

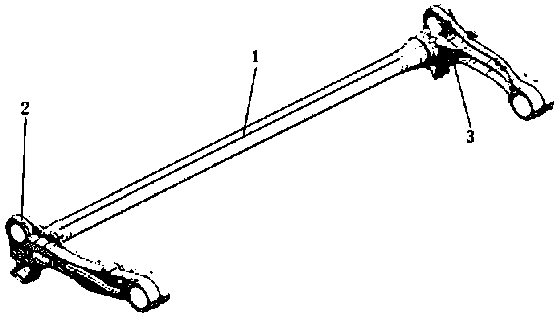

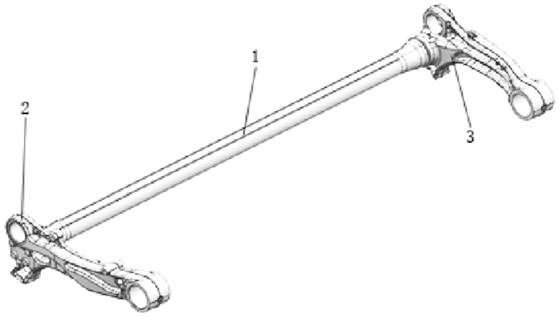

Cab stabilizer bar and assembly process thereof

ActiveCN109435619AHigh dimensional accuracyImprove welding efficiencyInterconnection systemsPivoted suspension armsButt weldingEngineering

The invention discloses a cab stabilizer bar and an assembly process thereof. The stabilizer bar comprises a hollow pipe body, a left swing arm and a right swing arm, the hollow pipe body is an alloysteel pipe, the left swing arm and the right swing arm are foundry goods of steels or aluminum alloys, the two ends of the hollow pipe body are subjected to upsetting processing and then welded synchronously with the left swing arm and the right swing arm by magnetic arc welding, after welding, a welding zone is locally heated to eliminate the welding stress, the length difference of the hollow pipe body, the left swing arm and the right swing arm is controlled within +-0.5 mm, and the coaxiality of a connection hole connected with the left swing arm and the right swing arm with an inner holeof the hollow pipe body is within phi0.4 mm. The cab stabilizer bar has a weight reduction of 30%-50% compared with a conventional solid stabilizer bar, which reduces the manufacturing cost, and the dimensional accuracy, the welding efficiency and the welding quality stability are significantly improved compared with conventional arc welding.

Owner:YANGZHOU DONGSHENG AUTOMOBILE PARTS LTD BY SHARE LTD

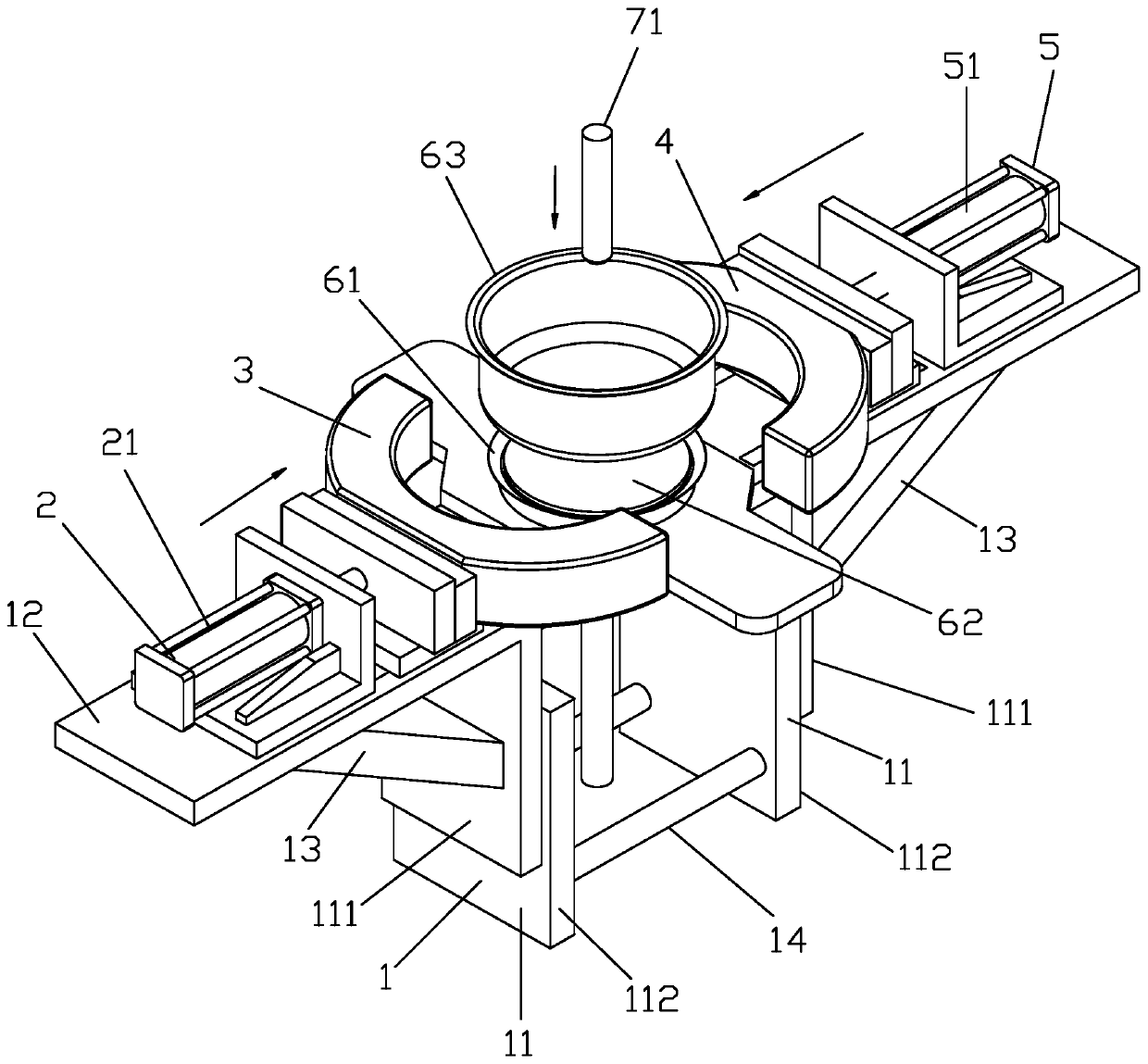

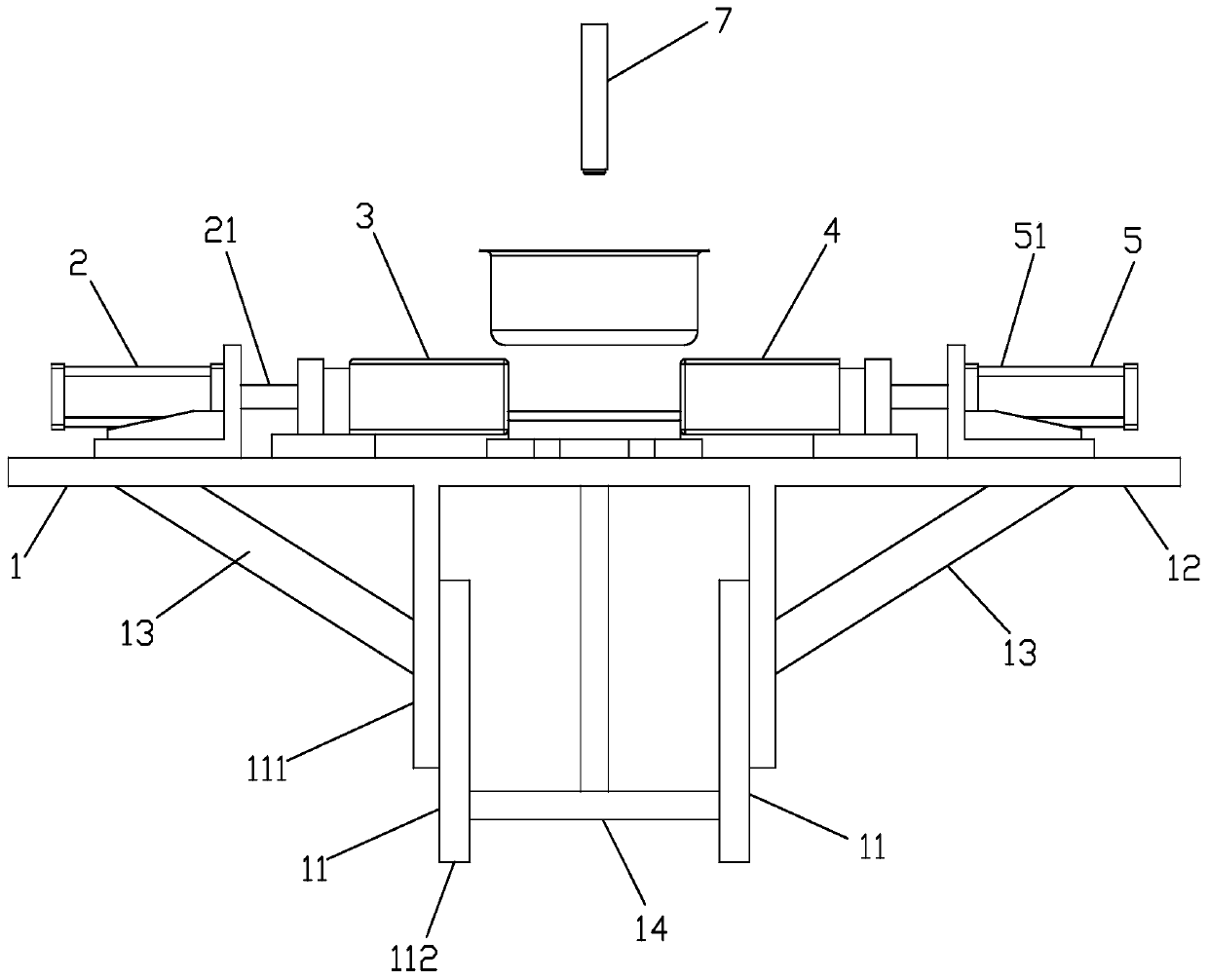

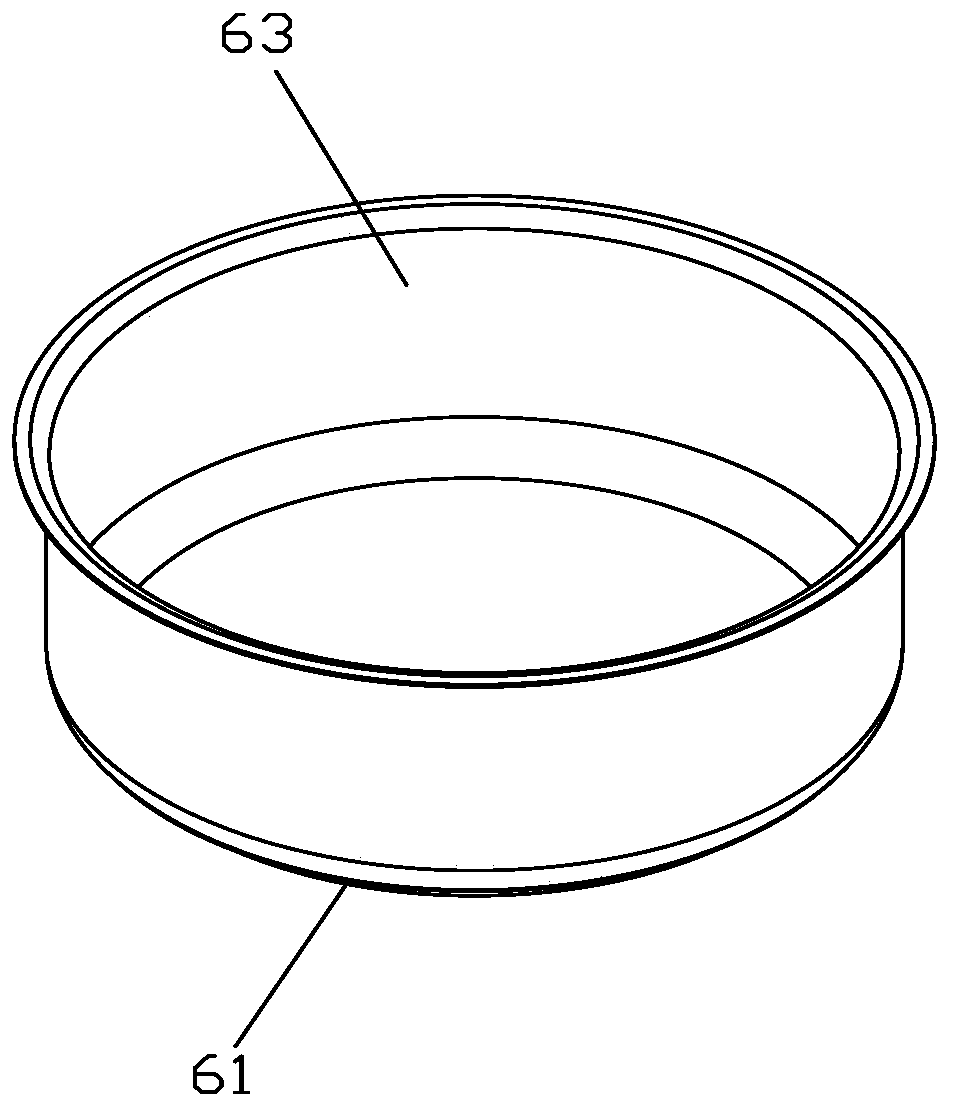

Cookware production tool and production process

PendingCN110142552AImprove efficiencyImprove securityCooking-vessel materialsWelding/cutting auxillary devicesBiochemical engineeringExplorator

The invention provides a cookware production tool which comprises a support, a first drive device arranged on the support, a first explorator connected with the first drive device, and a second explorator arranged on the support. The first drive device can drive the first explorator to move along the directions close to and far away from the second explorator. In the cookare production process, apackage film and an aluminum plate welded together can be placed on the support and can be located between the first explorator and the second explorator; a cookware body is then placed on the packagefilm and the aluminum plate; the first drive device drives the first explorator to move along the direction close to the second explorator until the first explorator and the second explorator to clamp the cookware body and the package film; then the cookware body, the package film and the aluminum plate are welded together by utilizing a welding machine and the like; and finally the cookware body, the package film and the aluminum plate which are welded together are processed through a redriving process, and a cookware is finally produced. The cookware production efficiency and the safety arehigh, and the product quality stability is high.

Owner:SHANGHAI GUANHUA COOKWARE CO LTD

Semitrailer beam welding tool and welding process thereof

InactiveCN109986272AGuaranteed pair clearanceGuaranteed welding sizeWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringAir cylinder Press

The invention belongs to the technical field of aluminum alloy welding, and relates to a semitrailer beam welding tool and a welding process thereof. The tool comprises a tool fixing frame, a turnoversupport rotationally arranged on the tool fixing frame, an air cylinder pressing device and a connecting groove fixing end limiting device, wherein the air cylinder pressing device and the connectinggroove fixing end limiting device are fixedly arranged at the two ends of the turnover support, a to-be-assembled-and-welded welding beam wing plate is clamped between the air cylinder pressing device and the connecting groove fixing end limiting device, and a plurality of beam turnover limiting blocks used for clamping the to-be-assembled-and-welded welding beam wing plate are fixedly arranged on the turnover support. The tool solves the problems that in the prior art, when a semitrailer framework cross beam is independently welded, grouping errors are prone to occur, and the welding efficiency is low.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

Grounding device and method for wind power steel pipe pile welding

PendingCN112317923AImprove reliabilityImprove stability and productivityWelding accessoriesSteel tubeManufacturing quality

The invention discloses a grounding device and method for wind power steel pipe pile welding. The device comprises a guide rail, a guide rail and steel pipe pile connecting device, and a grounding device body, and can be used for welding grounding in a manufacturing process of a steel pipe pile of an offshore wind power generation project. In the manufacturing and welding process of the steel pipepile, a circle of aluminum alloy guide rail is additionally arranged on the outer wall of the steel pipe pile, and then grounding is conducted through a carbon rod with a balance weight device. By means of the grounding device, indirect grounding communication between the steel pipe pile and a welding machine is achieved, the influence of adverse effects such as the surface cleanliness and flatness of the steel pipe pile can be avoided, the welding grounding reliability is improved, and the influence of welding grounding faults on the manufacturing quality and efficiency of the steel pipe pile is effectively reduced.

Owner:西安西热产品认证检测有限公司 +1

Bending type forming method of corner cut waveguide bend

The invention relates to a bending type forming method of a corner cut waveguide bend, which belongs to the technical field of waveguide forming. Two triangular bending grooves are formed in the rear surface of a waveguide tube and divide the waveguide tube into three parts in the length direction, wherein the center part of the waveguide tube is a bending area. Bending gaps are processed in the front surface, the upper surface and the lower surface of the waveguide tube; the rectangular waveguide tube is folded forwards along the two triangular bending grooves; and flanges are welded at the two ends of the formed waveguide tube to obtain the corner cut waveguide bend. According to the bending type forming method, the same waveguide tube is adopted for forming, so that the dimension error of an inner cavity assembled by different waveguide tube blanks is reduced, and the probability of dislocation deficiency of the splicing surface of the inner cavity is reduced; a bending type self-positioning structure is adopted to control the inner cavity forming, so that the effects of assembling and welding on the precision of the dimension, shape and position of the inner cavity are reduced, and the forming precision of the inner cavity is improved; the waveguide tube part is subjected to once weld forming, so that welded joints of the inner cavity are decreased; the difficulty in welding is reduced; the stability of the welding quality is improved; and the welding efficiency is improved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

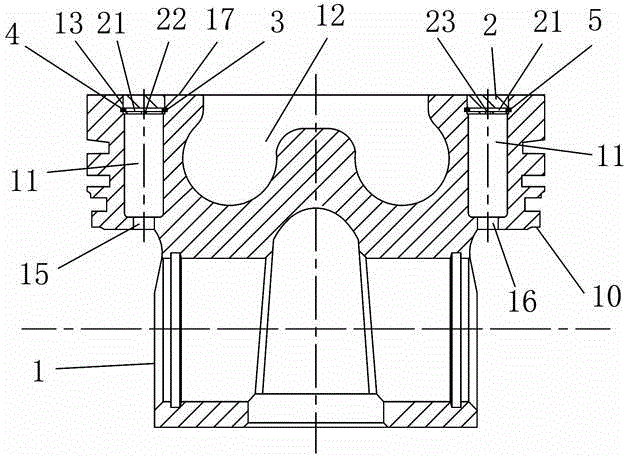

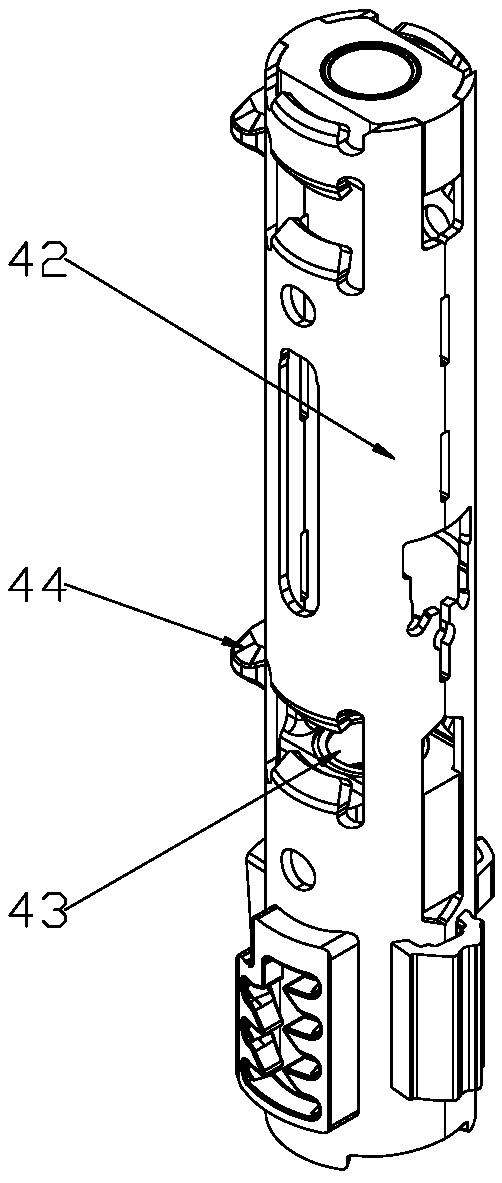

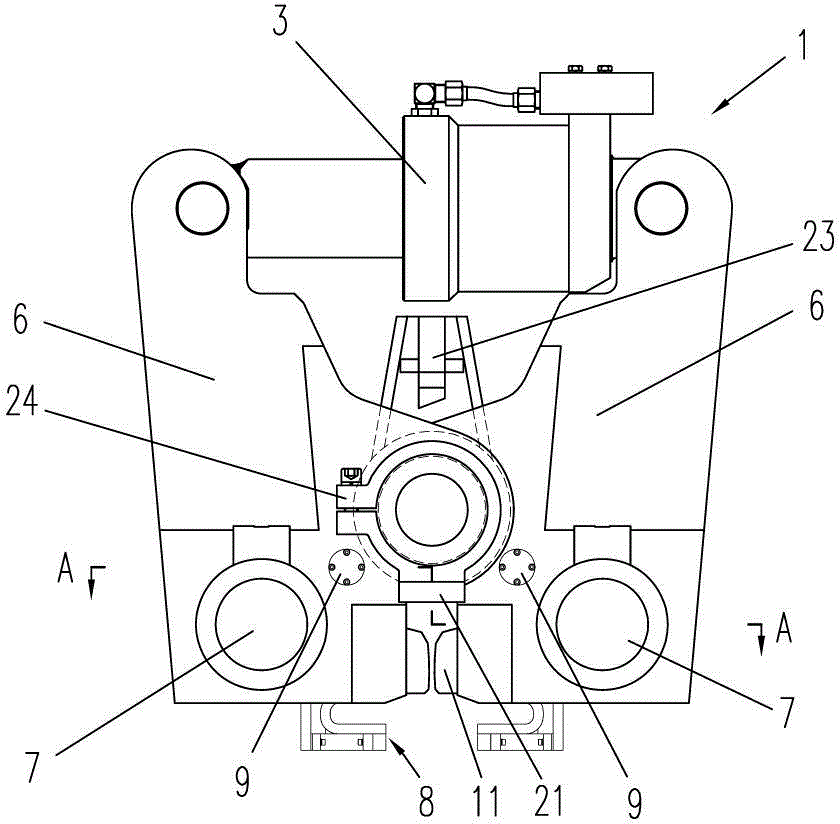

Moving sleeve assembly automatic welding equipment and its clamping device

InactiveCN106862786BEasy to weld and fixEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an automatic welding and clamping device of a movable sleeve assembly. The device comprises a working platform; the working platform is provided with a movable sleeve main body welding and clamping tool and a flitch welding and clamping tool side by side; the working platform is provided with two sets of parallel slide rails; a first base and a second base are slidingly matched and mounted on the two sets of slide rails correspondingly; and the working platform is respectively provided with pneumatic devices for driving the first base and the second base to move along the corresponding slide rails. The invention further discloses automatic welding equipment of the movable sleeve assembly; the equipment comprises the automatic welding and clamping device of the movable sleeve assembly; and welding robots are respectively arranged on one side of the working platform corresponding to the two sets of slide rails one to one. The automatic welding equipment of the movable sleeve assembly can realize welding production of the movable sleeve assembly through cooperation between the movable sleeve main body welding and clamping tool and the flitch welding and clamping tool, and has the advantages of high welding quality stability, high production efficiency and low production cost.

Owner:CHONGQING YONGCHUAN FEIDA MACHINERY LIABILITY

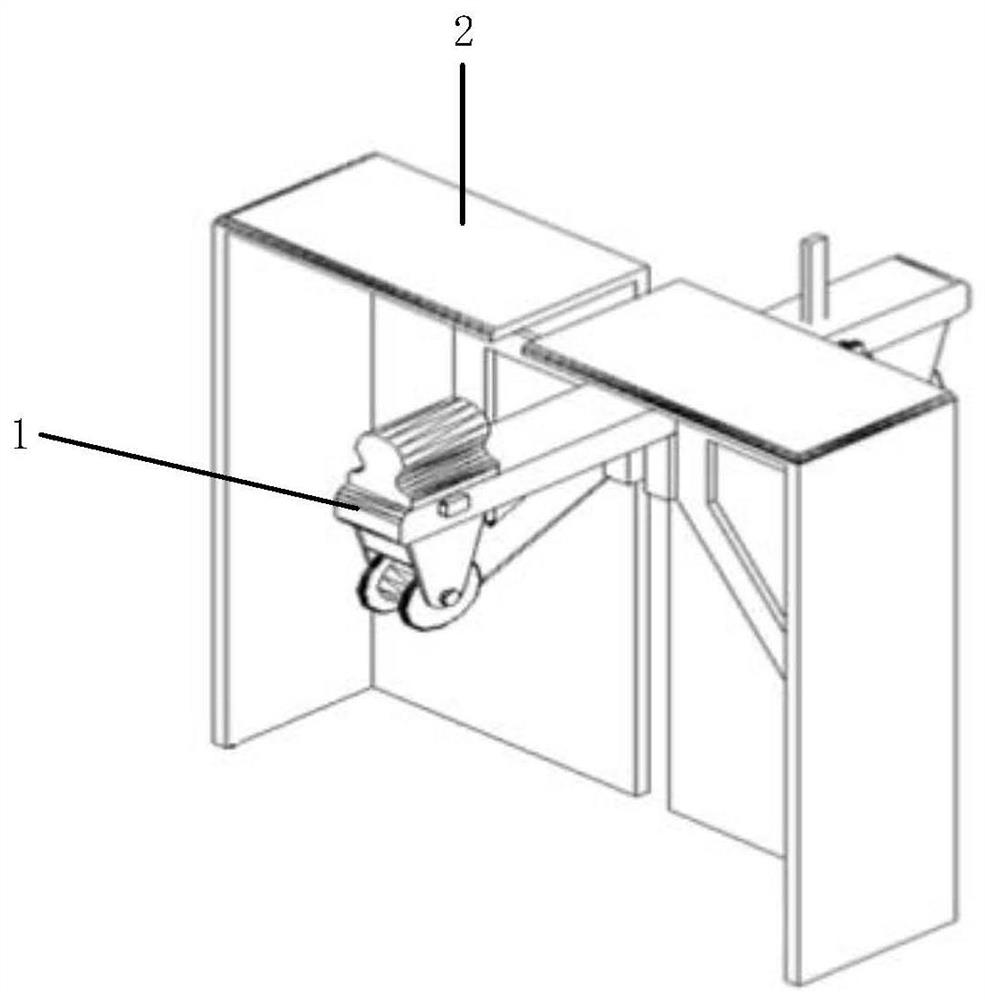

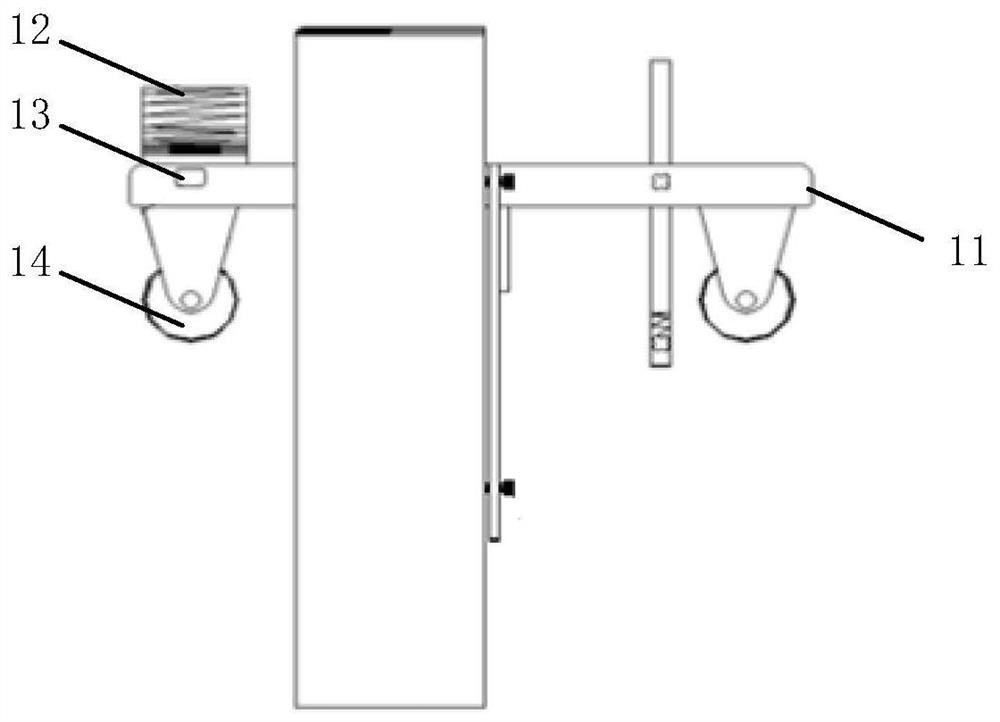

A windshield device used for welding flat steel structure of hull

ActiveCN111390441BEasy to moveGood windproof performanceWelding/cutting auxillary devicesAuxillary welding devicesMarine engineeringWindshield

The invention discloses a windshield device for welding flat steel structures of hulls, comprising: a power unit, a windshield plate, an anti-overturning fixing device, etc., the power unit is fixedly connected with the windshield board, and the anti-overturning fixing device Fixedly connected with the power device, the windshield device has a stable windproof effect, can prevent the windshield device from being unstable or overturned under the action of wind, reduces the welding time of hull flat steel, improves welding efficiency, and improves the stability of welding quality, etc. advantage.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

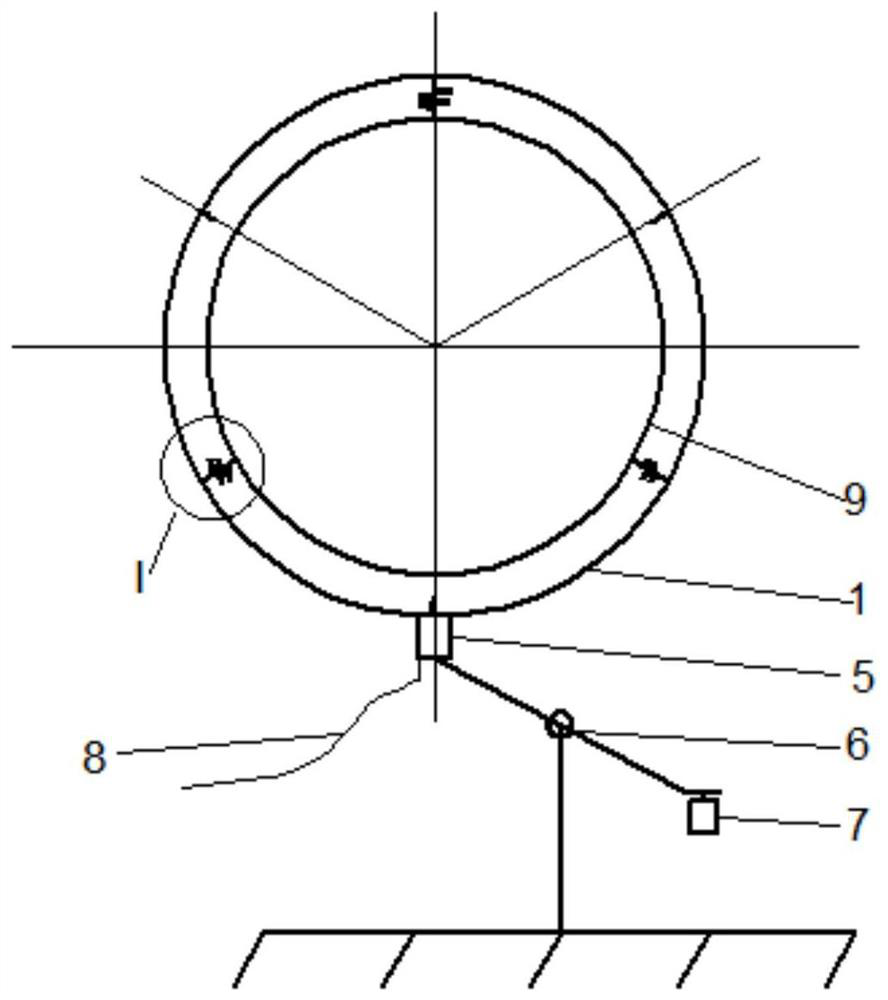

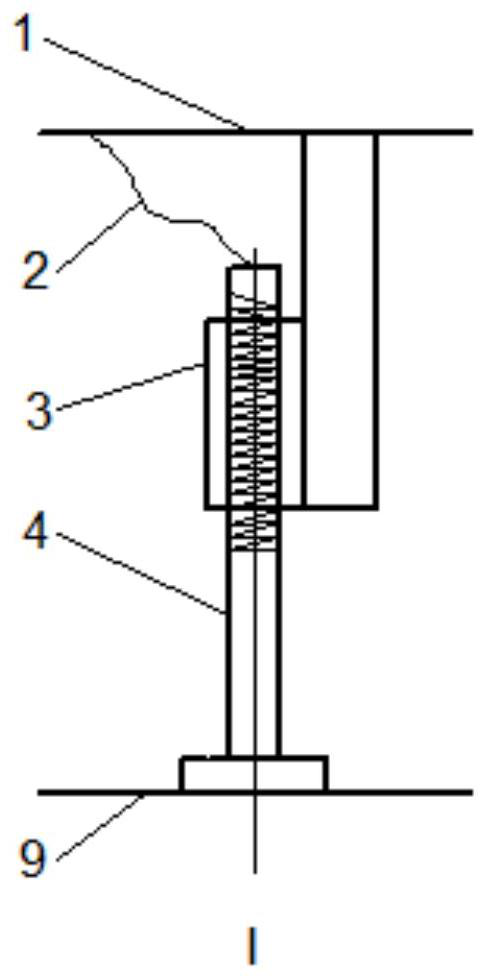

Universal type lifting pipe robot automatic TIG welding tool and welding method thereof

ActiveCN112317926AGuaranteed coaxialityAvoid the problem of welding deviationWelding accessoriesRotary stageSoldering gun

The invention discloses a universal type lifting pipe robot automatic TIG welding tool. The welding tool comprises a welding rotary table, a pressing device, a welding robot and a positioner, whereinthe welding rotary table is connected to the output end of the positioner, a centering device is arranged on the welding rotary table, the pressing device is located above the welding rotary table, the welding rotary table and the pressing device are used for positioning and assembling a lifting pipe assembly composed of flanges and a circular pipe, and a welding gun used for welding the lifting pipe assembly is arranged on the welding robot. The invention further discloses a welding method of the universal type lifting pipe robot automatic TIG welding tool. With the welding tool and the welding method, the welding efficiency and the welding quality of a lifting pipe can be improved, and the manufacturing cost of the lifting pipe is reduced.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

Cab stabilizer bar and assembly process thereof

ActiveCN109435619BHigh dimensional accuracyImprove welding efficiencyInterconnection systemsPivoted suspension armsButt weldingPipe

The invention discloses a cab stabilizer bar and an assembly process thereof. The stabilizer bar comprises a hollow pipe body, a left swing arm and a right swing arm, the hollow pipe body is an alloysteel pipe, the left swing arm and the right swing arm are foundry goods of steels or aluminum alloys, the two ends of the hollow pipe body are subjected to upsetting processing and then welded synchronously with the left swing arm and the right swing arm by magnetic arc welding, after welding, a welding zone is locally heated to eliminate the welding stress, the length difference of the hollow pipe body, the left swing arm and the right swing arm is controlled within +-0.5 mm, and the coaxiality of a connection hole connected with the left swing arm and the right swing arm with an inner holeof the hollow pipe body is within phi0.4 mm. The cab stabilizer bar has a weight reduction of 30%-50% compared with a conventional solid stabilizer bar, which reduces the manufacturing cost, and the dimensional accuracy, the welding efficiency and the welding quality stability are significantly improved compared with conventional arc welding.

Owner:YANGZHOU DONGSHENG AUTOMOTIVE CO LTD

The robot mag surfacing process of the corrosion-resistant layer of the inlet and outlet of the pressure vessel of the civilian nuclear reactor

ActiveCN110421232BPrevent unfused defectsImprove welding efficiencyArc welding apparatusMetallurgyShielding gas

The invention provides a robot MAG overlay welding process for a civil nuclear reactor pressure vessel access adapter pipe anti-corrosion layer. The robot MAG overlay welding process for the civil nuclear reactor pressure vessel access adapter pipe anti-corrosion layer comprises the steps of welding at least two welding layers, adopting low alloy steel as base metal and a welding material as austenitic stainless steel, providing a tail drag protection gas hood for a welding gun, providing a protection gas for the tail drag protection gas hood, and enabling to eh protection gas to cover a welding pass adjacent to a molten pool, wherein the protection gas is He+CO2+Ar, and the dilution rate is controlled to be smaller than 27 percent. According to the robot MAG overlay welding process provided by the invention, an overlay welding layer has no defects such as air holes, microcracks, and incomplete fusion between passes.

Owner:上海电气核电集团有限公司

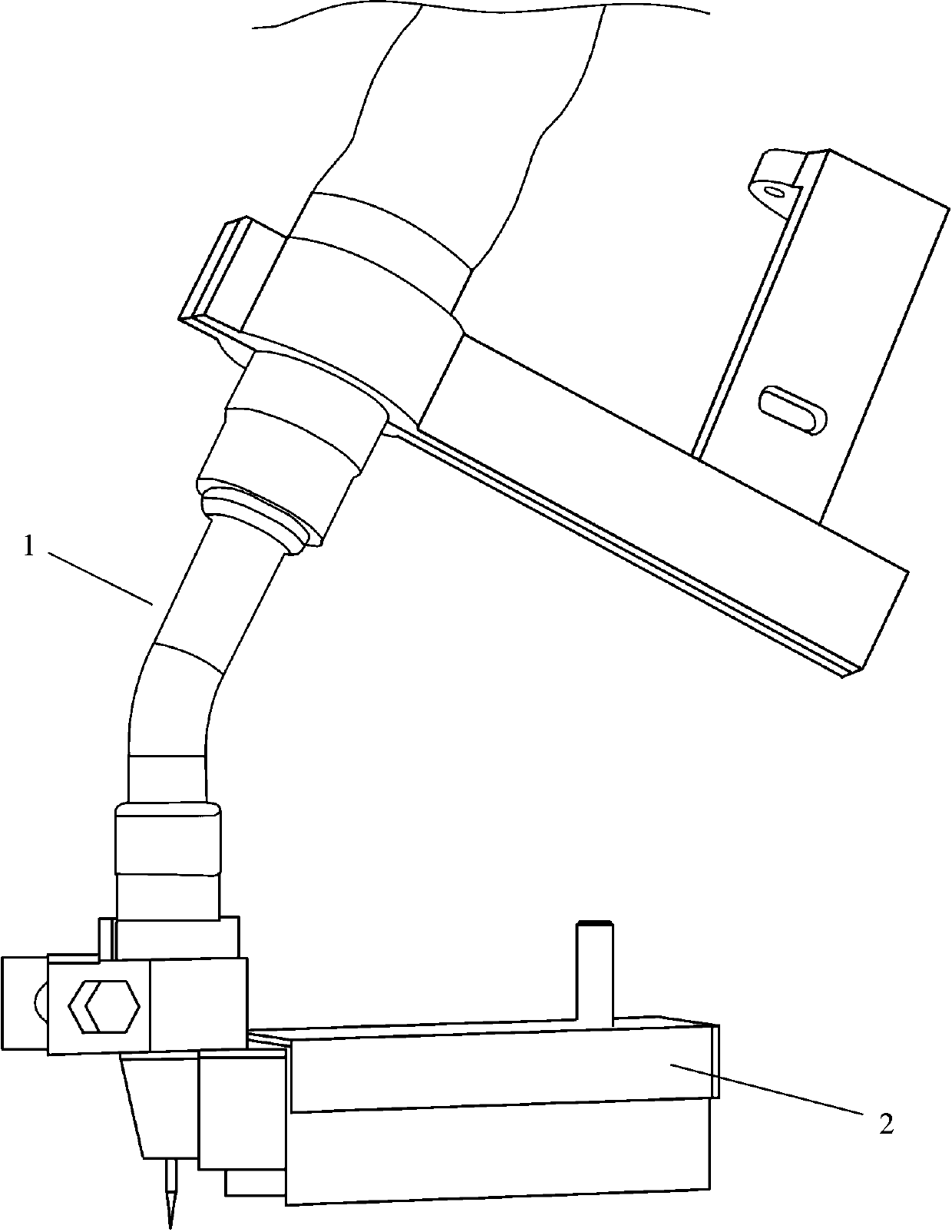

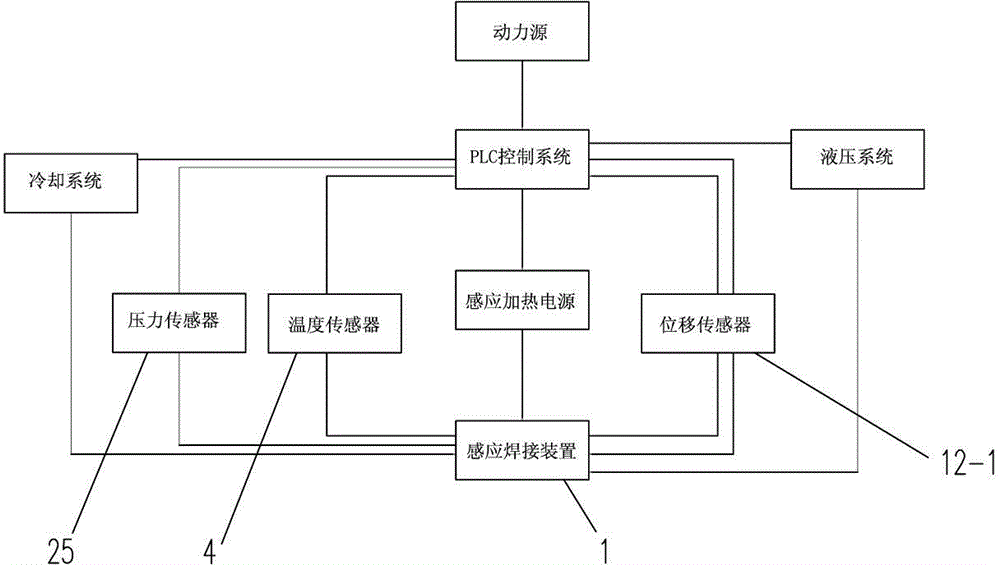

Profile induction welding device and method

ActiveCN103521908BQuality improvementHigh degree of automationWelding/cutting auxillary devicesHigh frequency current welding apparatusButt jointControl system

Provided are an induction welding device and method for sectional materials. The device comprises an induction welding device body, a PLC control system, a hydraulic system, a cooling system and an induction heating power supply, and further comprises a left mounting plate, a right mounting plate and two sub-coils. The method includes the following steps that two pieces of sectional materials to be welded are located through locating pieces installed on the lower portion of a center shaft of the induction welding device body in a connected mode; a clamping oil cylinder drives two sets of clamp bodies to rotate around the center shaft respectively to clamp and center the sectional materials to be welded; an opening-closing induction heating coil moves the butt joint of the sectional materials with the help of an auxiliary oil cylinder, a locating oil cylinder pushes and wraps the two sub-coils and makes contact with an electrode structure; the PLC control system starts the induction heating coil to heat; when the preset welding temperature is reached, the induction heating power supply is closed, the locating oil cylinder separates the two sub-coils, and an upset forging oil cylinder applies set upset forging force in a heating process of the but joint of the sectional materials all the time to enable end faces of the sectional materials to be welded together; a jaw opens, and the sectional materials are loosened. The induction welding device achieves automatic operation and is high in efficiency.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

A welding jig for robotic welding of automobile door lower hinge reinforcement plate assembly

ActiveCN105081644BNot shiftNot badWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding jig for a robot to weld automobile door lower hinge reinforcing plate assemblies. The welding jig is used for coaxially positioning automobile door lower hinge reinforcing plates and accessories to be welded of the automobile door lower hinge reinforcing plate assemblies, so that the accessories to be welded are welded on the automobile door lower hinge reinforcing plates. The welding jig comprises a jig bottom plate, coaxial positioning mechanisms, rotation preventing mechanisms for the accessories to be welded, rotation preventing mechanisms for the automobile door lower hinge reinforcing plates and rapid press pliers. The coaxial positioning mechanisms, the rotation preventing mechanisms for the accessories to be welded, the rotation preventing mechanisms for the automobile door lower hinge reinforcing plates and the rapid press pliers are arranged on the jig bottom plate. Compared with the prior art, the welding jig has the advantages of being easy to operate, convenient to overhaul, dismount and mount, good in error detection, good in welding quality stability, high in production efficiency and the like.

Owner:SHANDONG AOLIN CAR FITTINGS

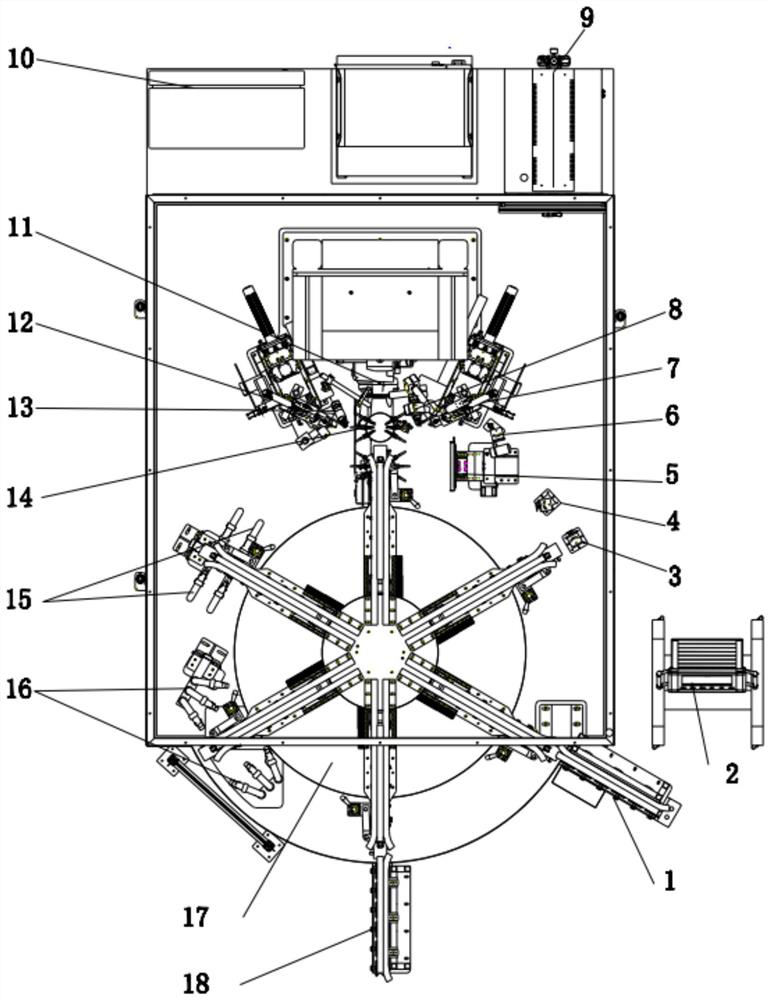

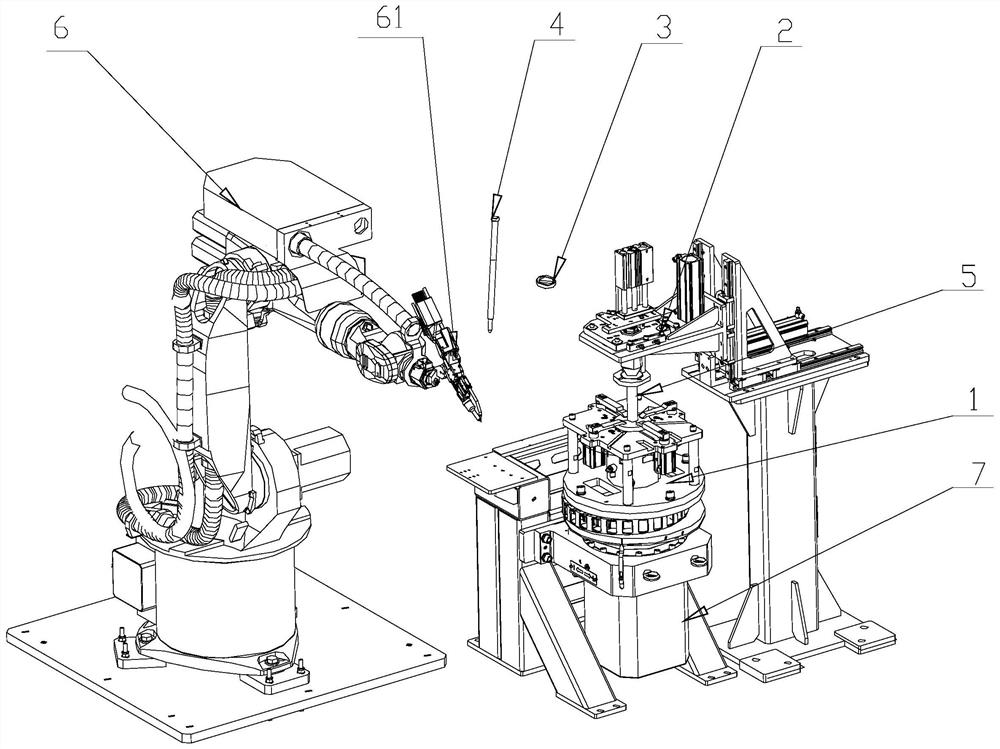

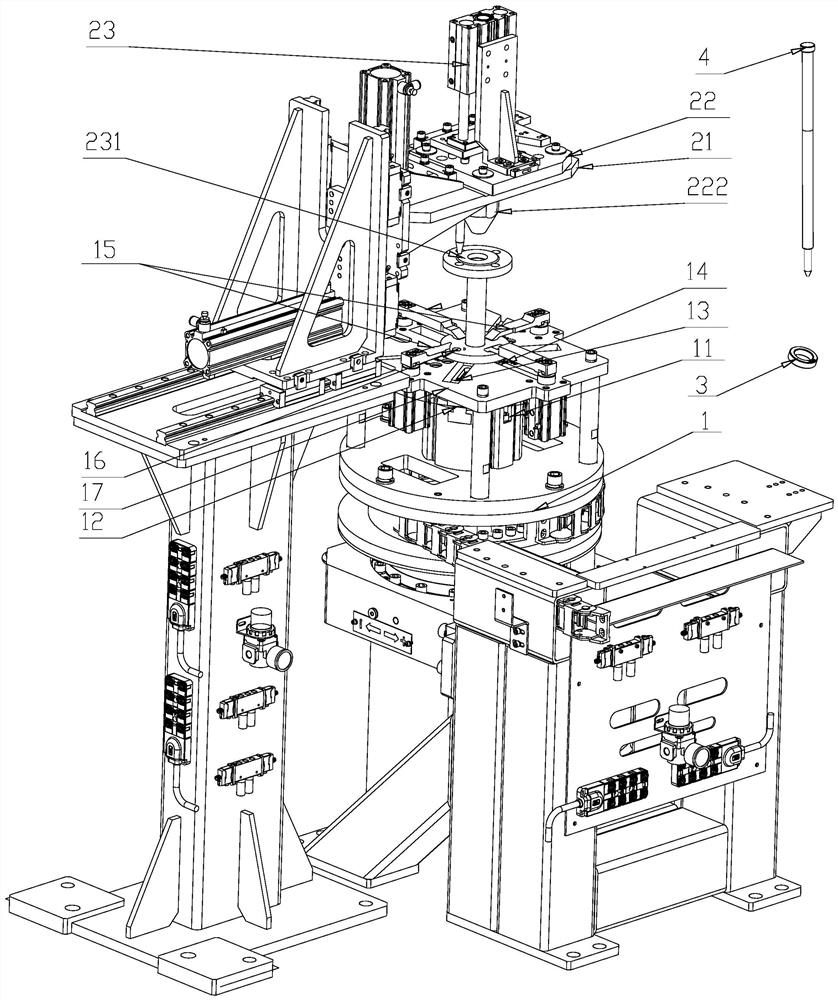

Automatic flame brazing machine for copper and aluminum welding

PendingCN114160910AIncrease productivityHigh welding quality stabilityHeating appliancesHeat exchange apparatusElectrical controlRobot control

The invention discloses an automatic flame brazing machine for copper and aluminum welding, which comprises a multi-station turntable mechanical structure, an electrical control system, a gas flow control system, a six-axis robot control heating flame gun and an automatic wire feeding mechanism, and is characterized by comprising a welding wire head shearing component, after wire feeding is completed, a wire feeding nozzle returns to an initial position, and the welding wire head shearing component is cut off. And the cutting component cuts off the welding wire head. Automatic copper-aluminum flame brazing of multiple types of aluminum micro-channel heat exchangers is achieved, manual operation can be replaced, the production efficiency is improved, and the welding quality stability applied to the products of the type is improved.

Owner:DAISHIN XINRUI BRAZING EQUIP +1

A general-purpose lifting pipe robot automatic tig welding tool and its welding method

ActiveCN112317926BGuaranteed coaxialityAvoid the problem of welding deviationWelding accessoriesRotary stagePipe welding

The invention discloses a universal automatic TIG welding tool for a water pipe robot, which includes a welding rotary table, a pressing device, a welding robot and a positioner, the welding rotary table is connected to the output end of the positioner, and the welding rotary table There is a centering device on the top, and the down-pressing device is located above the welding rotary table. The welding rotary table and the down-pressing device are positioned and assembled with the lifting pipe assembly composed of flanges and round pipes. The welding robot is equipped with a welding pipe assembly. welding torch. The invention also discloses a welding method of the general-purpose automatic TIG welding tool for the water lifting pipe robot. The invention can improve the working efficiency and welding quality of the water raising pipe welding, and reduce the manufacturing cost of the water raising pipe.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

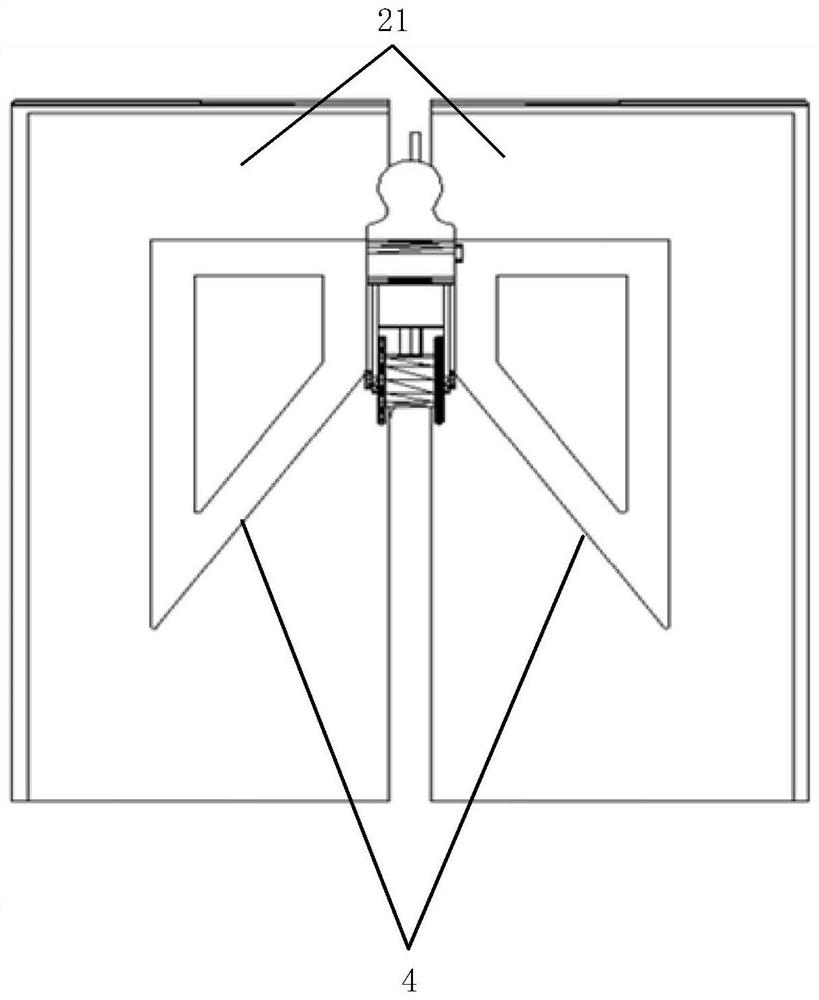

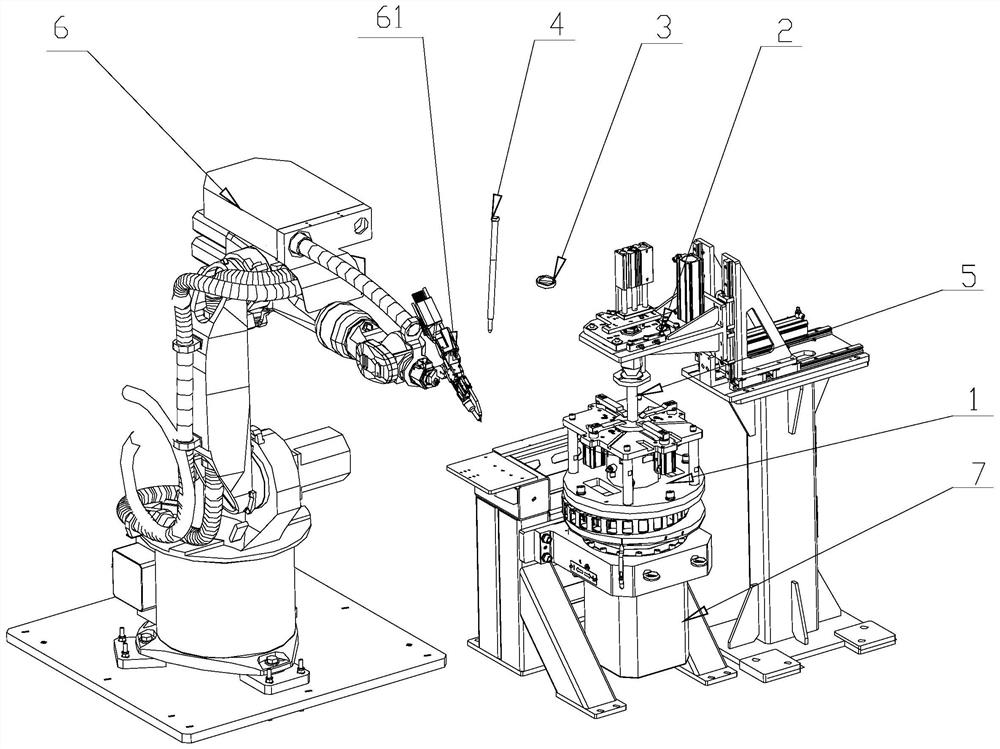

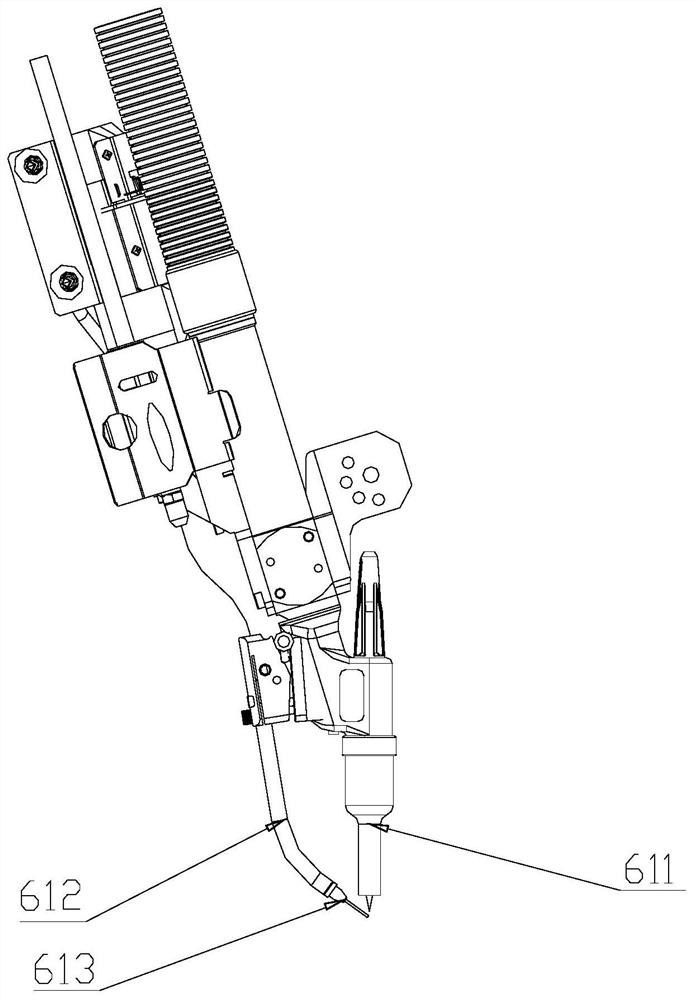

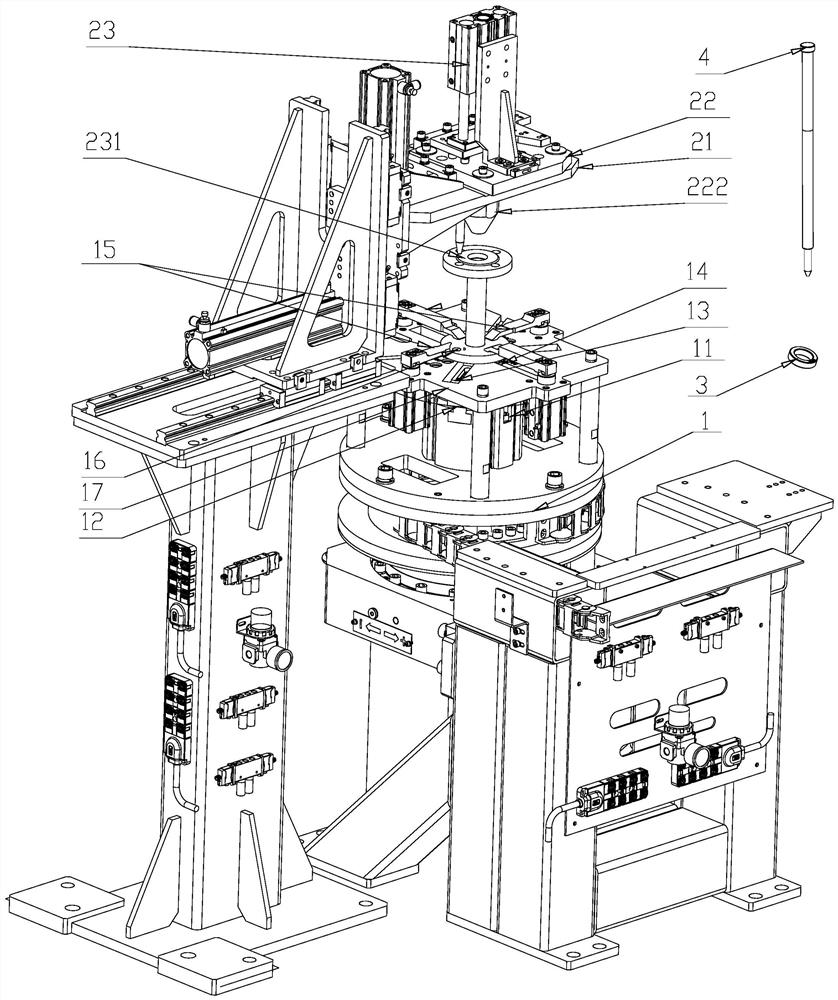

A wire reel automatic welding production line and its automatic welding method

ActiveCN104625454BImprove welding efficiencyHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

Diffusion welding method for double alloy structure of plunger hydraulic pump motor rotor

ActiveCN104057201BImplement production applicationsIdeal welding stateWelding/soldering/cutting articlesNon-electric welding apparatusAcid washingHydraulic pump

Owner:AVIC LIYUAN HYDRAULIC

Steel bar submerged arc stud welding gun

ActiveCN105689861BImprove welding efficiencyReduce labor intensityElectrode supporting devicesAxis cylinderTorch

The invention belongs to the technical field of welding, and in particular relates to a steel bar submerged arc stud welding torch. The slider is fixed on the bracket; the support plate A fixes the double-axis cylinder and is installed on the slider; an insulating block A is set between the slider and the support plate A, and an insulating block B is set between the support plate A and the double-axis cylinder The cylinder block of the biaxial cylinder is fixed on the support plate A, the support plate B is fixed on the moving shaft of the biaxial cylinder, and the support plate B drives the steel bars to complete the welding sequence action; the relative sliding between the support plate A and the support plate B can be done, The lifting block controls the lifting height of the support plate A; the adjustment screw is set on the lifting block; the lower part of the support plate B is provided with a locking device, a knob, a steel bar stopper, and a steel bar support, and the steel bar support is fixed on the support plate B. The tightening device and the steel bar block form a back-shaped structure to fix the steel bar, and the clamping force on the steel bar is adjusted by rotating the knob. The operation of the invention is simple and reliable, and the welding efficiency of submerged arc stud welding of steel bars is improved.

Owner:CHINA NUCLEAR IND 24 CONSTR

A walking robot welding station

ActiveCN108356457BIncrease productivityReasonable designWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention discloses a walking robot welding station which comprises a workbench, a welding clamp, handover devices, electrode grinders and walking type welding robots. The handover devices comprises the first handover device, the second handover device, the third handover device and the fourth handover device, the electrode grinders comprise the first electrode grinder and the second electrodegrinder, the walking type welding robots comprise the first walking type welding robot and the second walking type welding robot, the workbench is provided with a welding station, the welding clamp is installed on the welding station, the welding station is provided with an appointed start button, the edge of the workbench is provided with a photoelectric safety door, the two sides of the workbench are provided with safety fences correspondingly, and the safety fences are provided with alarm indication lamps. Operation is easy, people can cooperate with the walking type welding robots to complete welding, the welding efficiency is improved, the welding quality and welding stability are improved, repair time is shortened, and production efficiency of manufacturers is improved.

Owner:华翔金属科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com