A walking robot welding station

A walking robot and welding station technology, applied in the field of robots, can solve problems such as undercuts and easy generation of pores, and achieve the effects of reducing repair time, improving production efficiency and improving welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

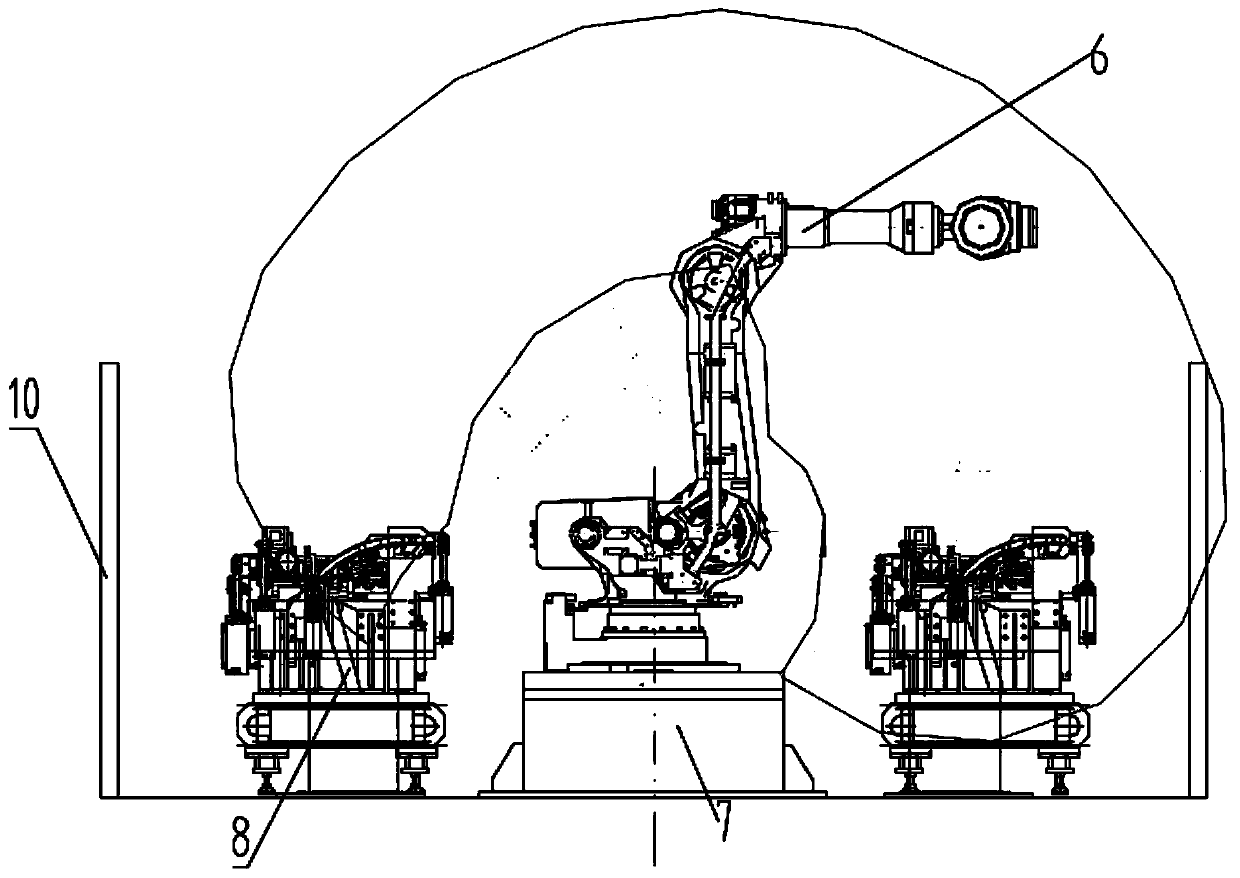

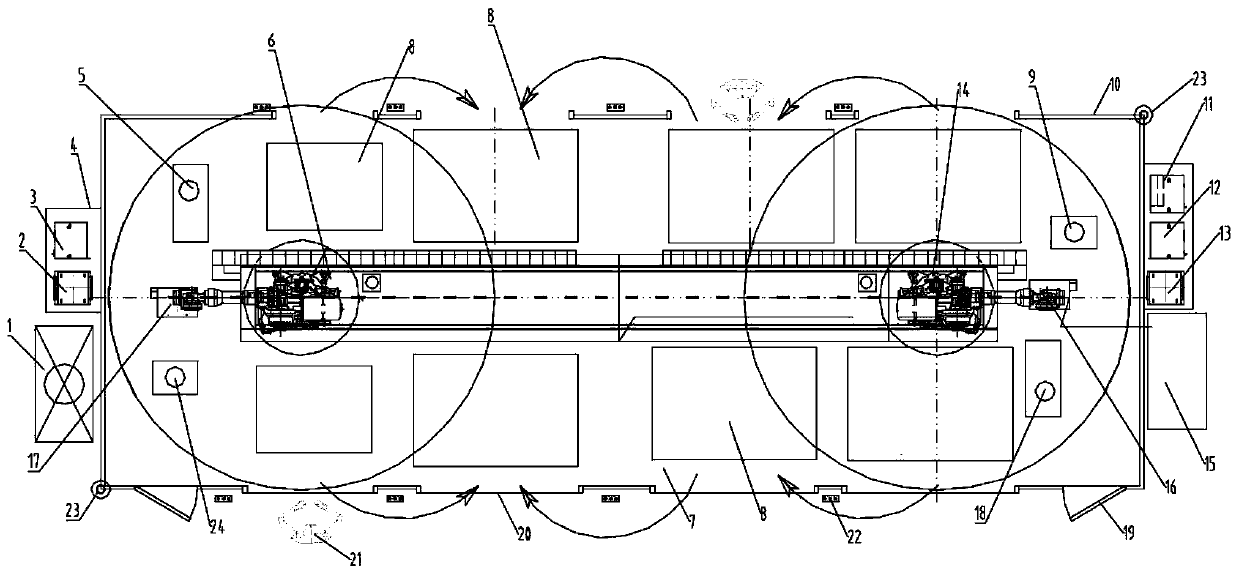

[0017] see Figure 1-2 , a walking robot welding station, comprising a workbench 7, a welding fixture 8, a hand-changing device, an electrode dresser and a walking welding robot, and the hand-changing device includes a first hand-changing device 18, a second hand-changing device Device 9, the third hand-changing device 5 and the fourth hand-changing device 24, the electrode dresser includes the first electrode dresser 16 and the second electrode dresser 17, and the walking welding robot includes the first walking welding robot 6 With the second walking type welding robot 14, the first hand-changing device 18, the second hand-changing device 9, the 3rd hand-changing device 5 and the 4th hand-changing device 24 are respectively arranged on the four corners of the workbench 7, in the middle of the workbench 7 A track is provided and the first walking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com