Grounding device and method for wind power steel pipe pile welding

A grounding device and steel pipe pile technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of steel pipe pile welding quality not meeting the standard requirements, reduce steel pipe pile manufacturing efficiency, etc., and achieve improved stability And the effect of improving production efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

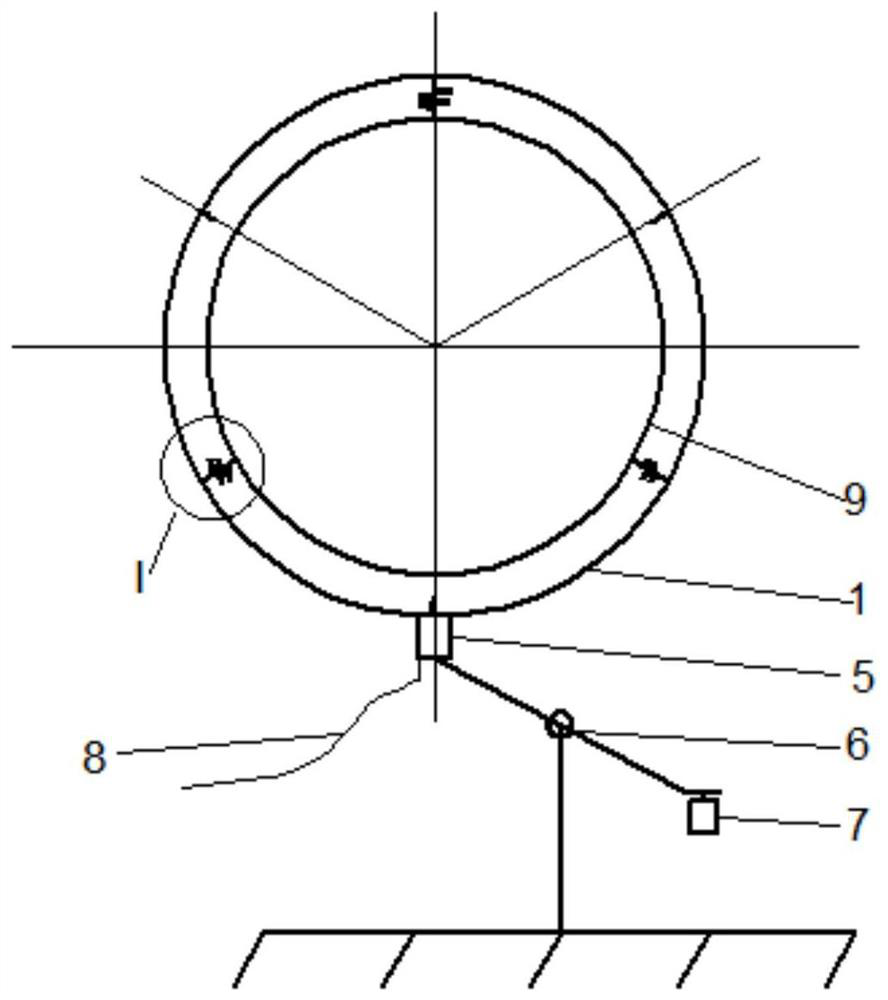

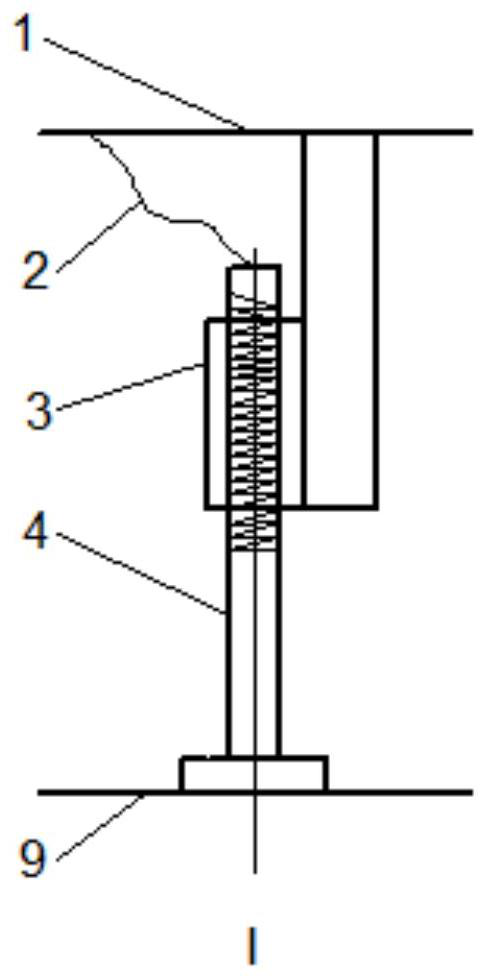

[0038] see figure 1 , A grounding device for welding of wind power steel pipe piles provided by the present invention includes a guide rail 1, a connecting device between the guide rail and the steel pipe pile, and a grounding device; wherein, the guide rail 1 is an annular guide rail, and its inner diameter is larger than that of the steel pipe pile 9. Outer diameter, the guide rail 1 is sleeved outside the steel pipe pile 9, and the two are connected to the steel pipe pile connecting device through several guide rails evenly arranged in the circumferential direction. Conductor 2 and nut 3, as well as screw 4 whose one end is threadedly connected with nut 3, and the other end is in contact with the outer surface of steel pipe pile 9, and conductor 2 is connected with screw 4; the grounding device includes carbon rod 5, movable support 6, count...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com