A welding jig for robotic welding of automobile door lower hinge reinforcement plate assembly

A hinge reinforcement plate and robot welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Quality defects and other problems, to achieve the effect of easy implementation, high stability of welding quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

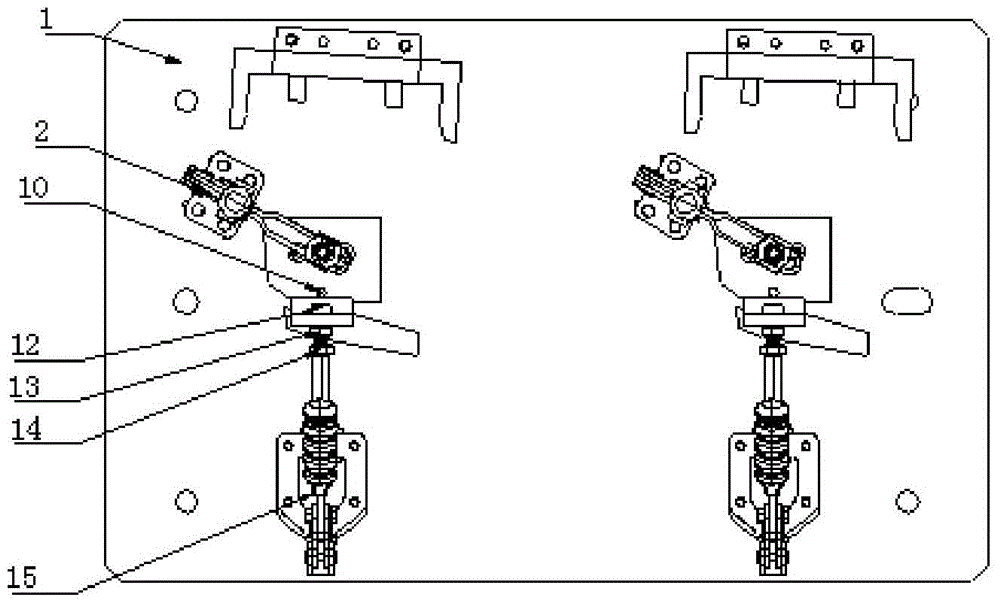

[0035] Such as Figure 1~5 As shown, a welding jig for robot welding of automobile door lower hinge reinforcement plate assembly, including a jig bottom plate 1 and a coaxial positioning mechanism installed on the jig bottom plate 1, an anti-rotation mechanism for parts to be welded, and a door lower hinge reinforcement Plate anti-rotation mechanism and quick clamp 2. When welding accessories, the coaxial positioning mechanism will coaxially position the accessories to be welded and the reinforcement plate of the lower hinge of the door, and the anti-rotation mechanism of the accessories to be welded and the anti-rotation mechanism of the reinforcement plate of the lower hinge of the door are treated separately Welding fittings and the lower hinge reinforcement plate of the car door are limited, and the quick press pliers 2 press the fittings to be welded on the lower hinge reinforcement plate of the car door.

[0036] A plurality of circular holes 18 and waist holes 19 are ar...

Embodiment 2

[0049] The coaxial positioning mechanism, the anti-rotation mechanism of the accessories to be welded, the anti-rotation mechanism of the lower hinge reinforcement plate of the car door and the quick press pliers 2 are provided with three groups, which are arranged in parallel on the left and right, and can simultaneously adjust the lower hinge reinforcement plate 16 of the three groups of doors. Welding fittings 17 are positioned and assembled.

[0050] The positions of the anti-rotation mechanism of the parts to be welded and the anti-rotation mechanism of the door lower hinge reinforcement plate can also be adjusted according to the shape of the door lower hinge reinforcement plate 16 and the accessories to be welded 17 of different models, as well as the welding position and the position of the positioning hole. For example, it is arranged on the left and right sides of the jig bottom plate 1 .

[0051] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com