A heat insulation layer for heaters used in high-flow, high-temperature, high-pressure, and high-speed gas environments

A high-temperature, high-pressure, high-speed gas technology, used in instruments, measuring devices, aerodynamic tests, etc., can solve problems such as increasing the difficulty of heater installation foundation construction, affecting the quality of the wind tunnel flow field, and polluting the air flow in the test, improving reliability. performance and thermal insulation performance, avoiding the risk of local thermal insulation failure, and improving the quality of test data

Active Publication Date: 2022-04-12

中国空气动力研究与发展中心超高速空气动力研究所

View PDF18 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The direct use of the traditional heat insulation layer in the hypersonic wind tunnel regenerative heater has the following disadvantages: a. Lightweight high-aluminum castables have high density and high thermal conductivity, resulting in thicker and heavier heat insulation layers of the heater, resulting in energy loss It is large, and increases the weight of the heater, which increases the difficulty of heater installation foundation construction; b. Light high-alumina castables may crack under repeated high-temperature and high-pressure conditions for a long time, causing hot gas inside the heater to leak to the shell, affecting the heater The shell is safe to use; c. Lightweight high-alumina castables have slag falling under the high-speed and large-flow airflow, which pollutes the test airflow and affects the quality of the wind tunnel flow field; d. Aluminum silicate fiber cotton is vacuum pumped, high-speed and large There is a displacement under the flow of air flow, which leads to the failure of local heat insulation and affects the safety of the shell.

e. Aluminum silicate fiber cotton has serious slag falling under vacuum suction and high-speed and large-flow airflow, which pollutes the test airflow and affects the quality of the wind tunnel flow field

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

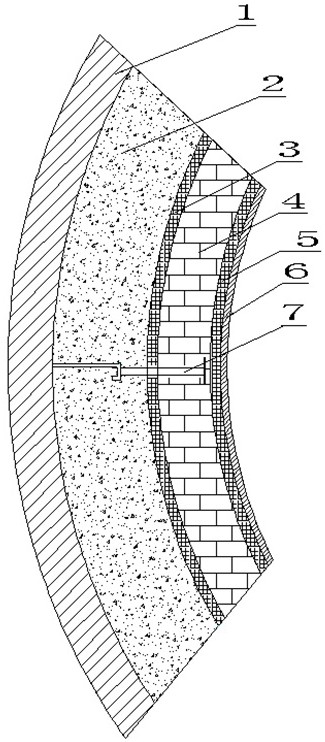

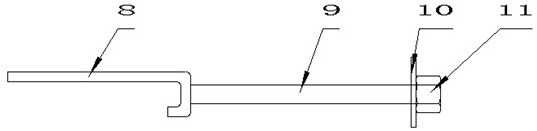

[0040] The heat insulation layer of the heater used in the high-flow, high-temperature, high-pressure, and high-speed gas environment of the present invention is used for image 3 , Figure 4 The regenerative heater shown is composed of an electric heating element, a heat storage element, a heat insulation layer, and a casing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of hypersonic wind tunnel test equipment, and discloses a heat insulation layer for a heater used in a high-flow, high-temperature, high-pressure, and high-speed gas environment. The heat insulation layer of the heater includes shell layer, castable layer, isolation layer I, fiber stack insulation layer, isolation layer II and inner liner stacked sequentially from outside to inside; it also includes through castable layer, isolation layer Ⅰ and anchors for fiber laminate insulation. The heat insulation layer of the heater has the characteristics of light weight, reliability, high efficiency, no slag dropping, and no displacement under harsh working conditions such as high temperature, high pressure, vacuum suction, and large flow scouring, which ensures that the test air flow is clean and pollution-free, and improves Wind tunnel flow field quality and test data quality.

Description

technical field [0001] The invention belongs to the technical field of hypersonic wind tunnel test equipment, and in particular relates to a heat insulation layer for a heater used in a high-flow, high-temperature, high-pressure, high-speed gas environment. Background technique [0002] In a conventional hypersonic wind tunnel using air as the test medium, due to the extremely high gas flow velocity, reaching Mach number 5 to Mach number 10, the violent expansion of the gas flow through the nozzle will cause water vapor and carbon dioxide to condense, resulting in irregularities in the flow field. The uniformity makes the test data inaccurate, which is not allowed in the hypersonic wind tunnel aerodynamic test. Therefore, in a conventional hypersonic wind tunnel with a large flow of high-speed air as the medium, it is necessary to install a regenerative heater to heat the airflow to the required anti-condensation temperature. Since the main purpose of the hypersonic wind tu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M9/04

CPCG01M9/04

Inventor 陈久芬茆青章起华陈俊兴朱涛蒋万秋徐洋范孝华孙启志

Owner 中国空气动力研究与发展中心超高速空气动力研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com