Processing technology of multilayer material composite waterproof and dustproof net

A waterproof and dustproof, multi-layer material technology, applied in the direction of lamination, lamination equipment, layered products, etc., can solve the problems of low product yield, product reverse release, product easy to drop, shift, etc., to achieve The product has high precision, solves anti-release and delamination, and improves production yield and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

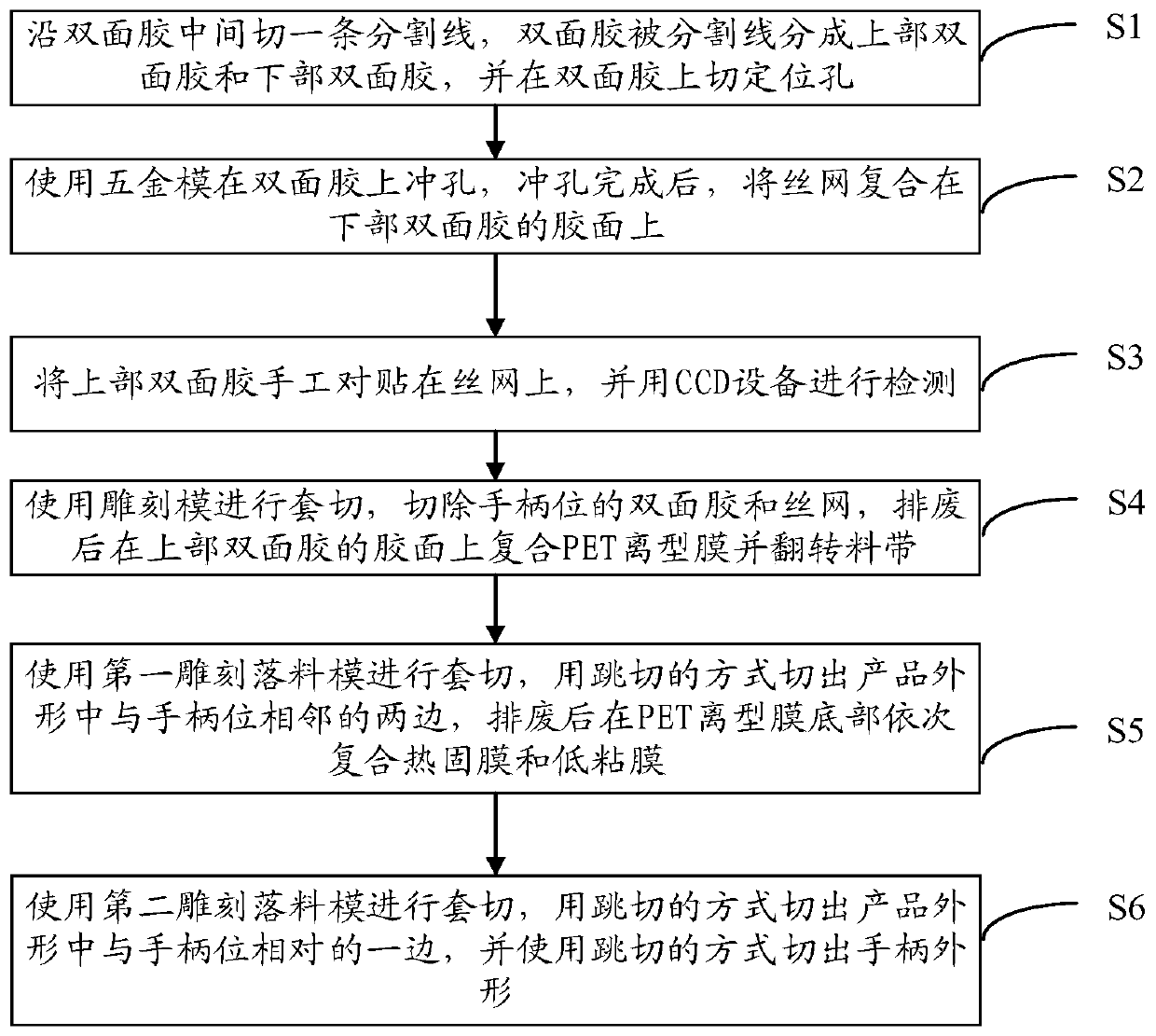

[0042] Such as figure 1 As shown, the multilayer material composite waterproof and dustproof net processing technology includes the following steps:

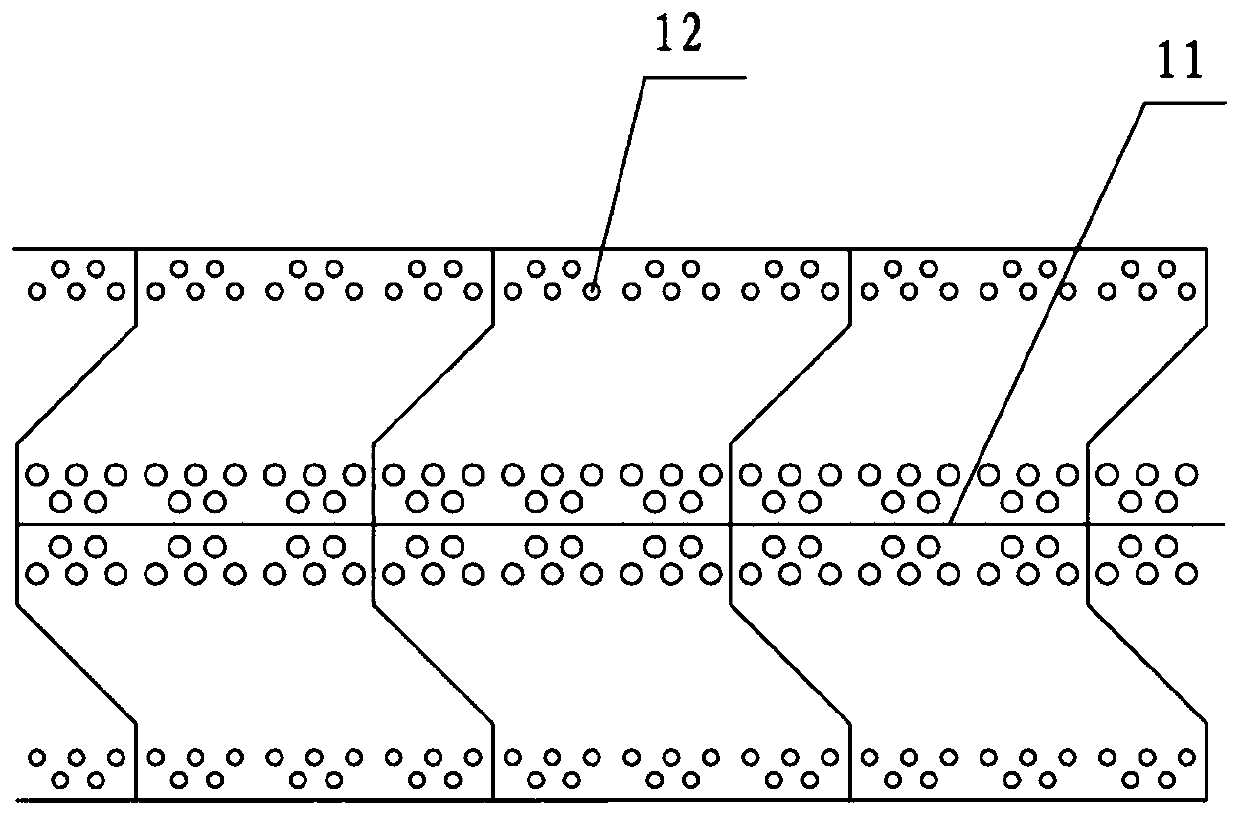

[0043] S1: Cut a dividing line 11 along the middle of the double-sided adhesive tape, the double-sided adhesive tape is divided into upper double-sided adhesive tape and lower double-sided adhesive tape by the dividing line 11, and cut positioning holes 12 on the double-sided adhesive tape.

[0044] The dividing line 11 can be a zigzag line or a dotted line, which is convenient for facing up in subsequent processing steps.

[0045] The thickness of the upper double-sided tape can be 0.12mm, and the thickness of the lower double-sided tape can be 0.2mm.

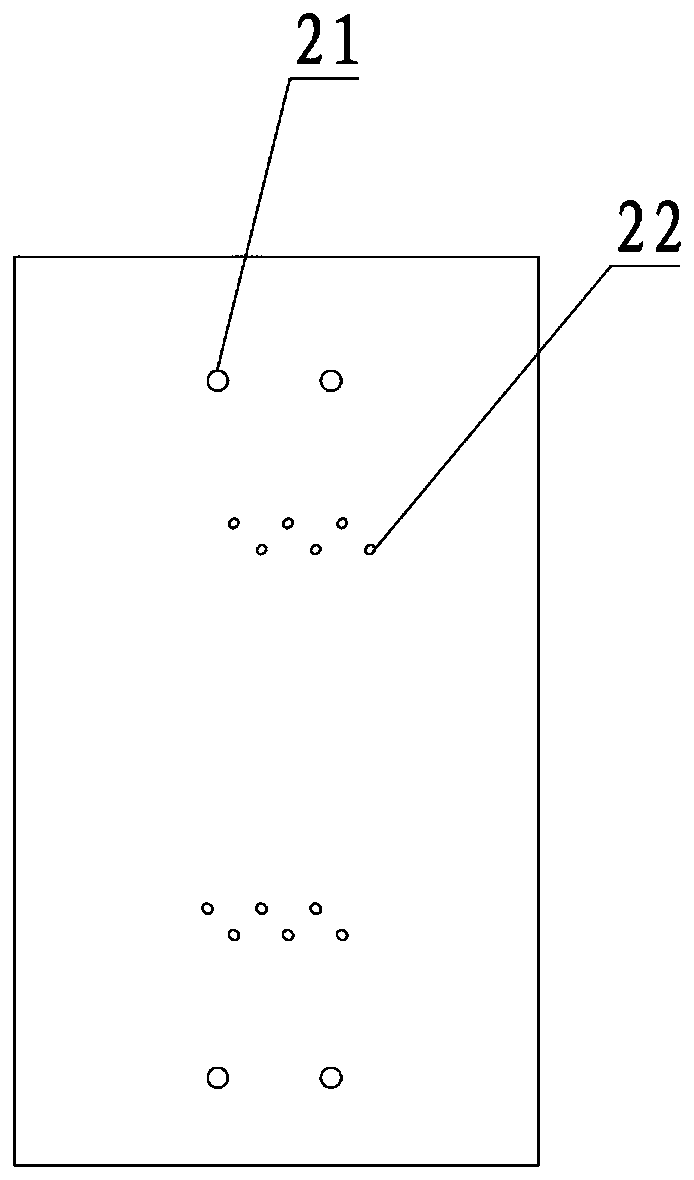

[0046] The bottom of the double-sided tape can cover the base film and the first low-mucosa in sequence. S1 can be die-cut with a circular knife. After cutting the positioning hole 12 on the double-sided adhesive, the first low-mucosa is removed to eliminate hole waste.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com