Screw box fixing structure of short-stress-path rolling mill

A technology of pressing down nuts and short stress lines, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of loss of anti-rotation ability, unqualified quality of rolled products, low structural strength, etc. , to achieve the effect of maintaining balance, fast installation and adjustment, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

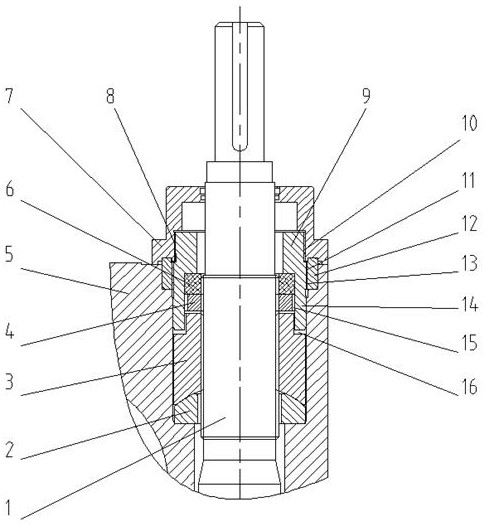

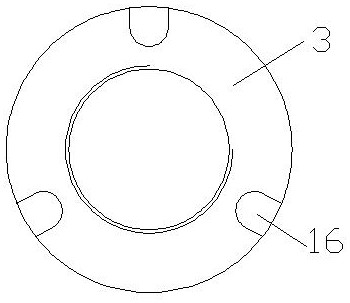

[0019] Such as Figure 1~3 As shown, a short stress line rolling mill depressing nut fixing structure of the present invention includes a bearing seat 5, a pull rod 1 passing through the bearing pedestal 5, and a depressing nut 3 threaded on the pull rod 1, and the pull rod 1 is equipped with The spherical pad 2 located below the depressing nut 3 is provided with a spherical surface corresponding to the spherical pad 2 on the lower end surface of the depressing nut 3 .

[0020] The bearing seat 5 is provided with a counterbore adapted to the depressing nut 3, and the depressing nut 3 compresses the spherical pad 2 at the bottom of the counterbore.

[0021] It also includes a positioning sleeve 9 set on the pull rod 1, the positioning sleeve 9 is located above the pressed nut 3 and fixedly connected with the bearing seat 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com