Fan blade mould releasing prevention process

A fan blade, anti-dropping technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of waste of materials, complicated operation, low safety factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Example.

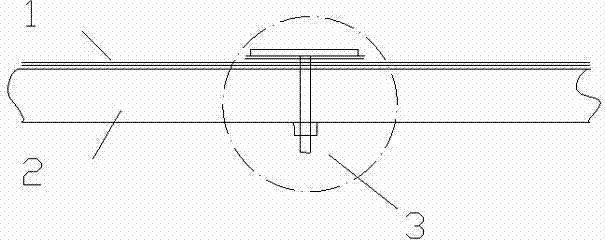

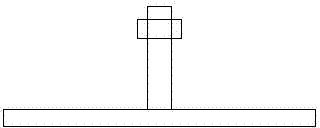

[0021] according to figure 1 and figure 2 , the fan blade anti-release process, including the following steps:

[0022] 1) On the mold flanging 2, according to the distribution of blade weight, a certain number of holes are punched on the front and rear edges, and the holes correspond to the flanging holes of the flanging cloth layer 1;

[0023] 2) Before laying the flanging cloth layer, seal the hole; the flanging cloth layer 1 covers the hole, and add a cloth layer at the hole;

[0024] 3) The flanging cloth layer 1 is pre-cured to form the blade shell, and the cloth layer on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com