Two-component sealant sewing agent and method for preparing same

A technology of sealant and beautifying agent, applied in the field of sealant, can solve the problems of unreliable sealing of corner gaps, low compressive shear strength, easy to fall off, etc., and achieve the effect of improving the curing performance at room temperature and improving the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0075] 2.2 parts by weight of polyhexamethylene biguanide hydrochloride with a viscosity average molecular weight of 800 (Shanghai Shande Industrial Co., Ltd., PHMB) was dissolved in 5.8 parts by weight of tetrahydrofuran at 40° C. to obtain a guanidine salt solution. 2.5 parts by weight of γ-glycidoxypropyltrimethoxysilane was dissolved in 3 parts by weight of tetrahydrofuran to obtain a silane solution. Add the two solutions into the reactor for mixing, then heat the mixture to 76°C, and stir for 3 hours; after the reaction, remove the solvent in the reaction mixture under reduced pressure to obtain liquid The silane coupling agent product has a viscosity (25°C, cps) of 1665.

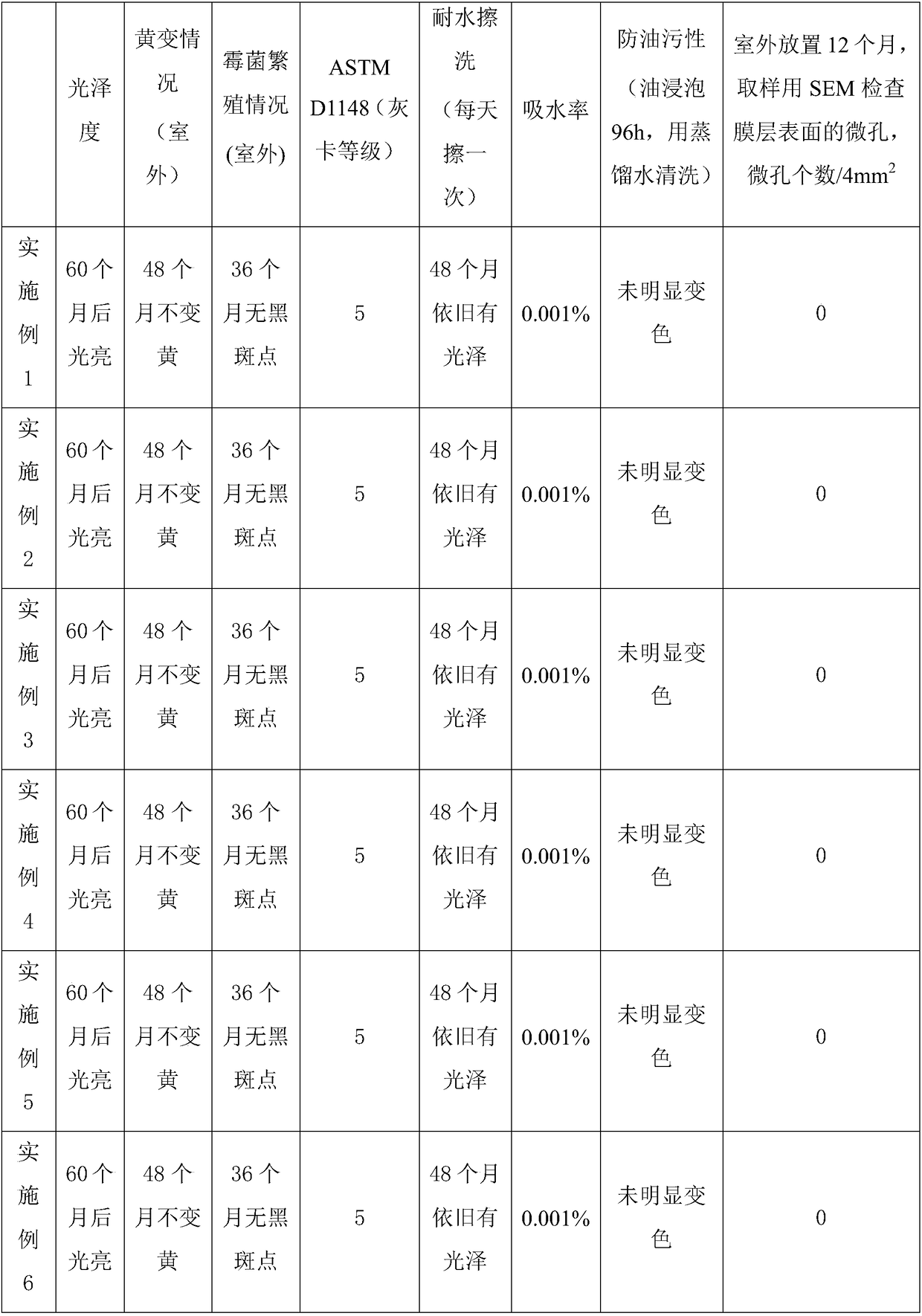

Embodiment 1

[0077] A preparation method of a two-component sealant beautifying agent, the method comprising the following steps:

[0078] 1) Preparation of component A

[0079] 50g E-51 epoxy resin, 5g E-44 epoxy resin, 15g 133L epoxy resin, 6g benzyl glycidyl ether, 0.08g BYK-088, 2gγ-aminopropyltriethoxysilane (KH-550 ), 0.5g UV-531, 0.05g purple-blue phase toner, and 0.2g antioxidant 1010 were mixed uniformly under the condition of rising temperature, and 7g hydrogenated castor oil was added, stirred and mixed uniformly to obtain component A;

[0080] 2) Preparation of component B

[0081] Add 3g of 2,4,6-tris(dimethylaminomethyl)phenol to 65g of alicyclic amine modified curing agent and 12g of polyether amine modified curing agent, stir and mix evenly, then add 7g of hydrogenated castor oil, 5g of titanium White powder and 8g of γ-aminopropyltriethoxysilane (KH-550), stirred and mixed evenly to obtain component B;

[0082] 3) Preparation of two-component sealant beauty joint agent ...

Embodiment 2

[0087] A preparation method of a two-component sealant beautifying agent, the method comprising the following steps:

[0088] 1) Preparation of component A

[0089] 65g E-51 epoxy resin, 4g E-44 epoxy resin, 16g 133L epoxy resin, 7g butyl glycidyl ether, 0.1g BYK-088, 1.5g coupling agent KH-560, 0.8g UV-531 , 0.08g purple-blue phase toner, 0.3g antioxidant 1076, stir and mix at 70°C, add 7g of fumed silica (Cabot TS720), stir and mix evenly, and the stirring time is 45min to obtain component A;

[0090] 2) Preparation of component B

[0091] In 62g alicyclic amine modified curing agent and 16g polyether amine modified curing agent, add three-(2-ethylhexanoic acid) salt of 4g 2,4,6-three (dimethylaminomethyl) phenol and stir Mix evenly, then add 7g fumed silica (Cabot TS720), 5g pearl powder and 8g coupling agent KH-560, stir and mix evenly for 50min to obtain component B;

[0092] 3) Preparation of two-component sealant beauty joint agent

[0093] Store component A and compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com