Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Guaranteed Position Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

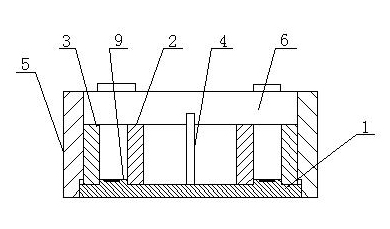

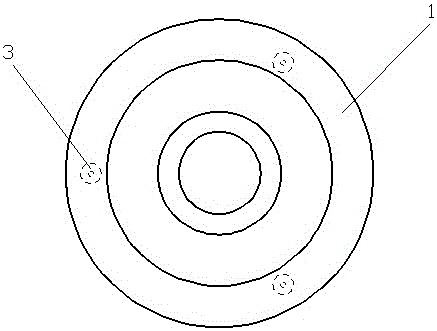

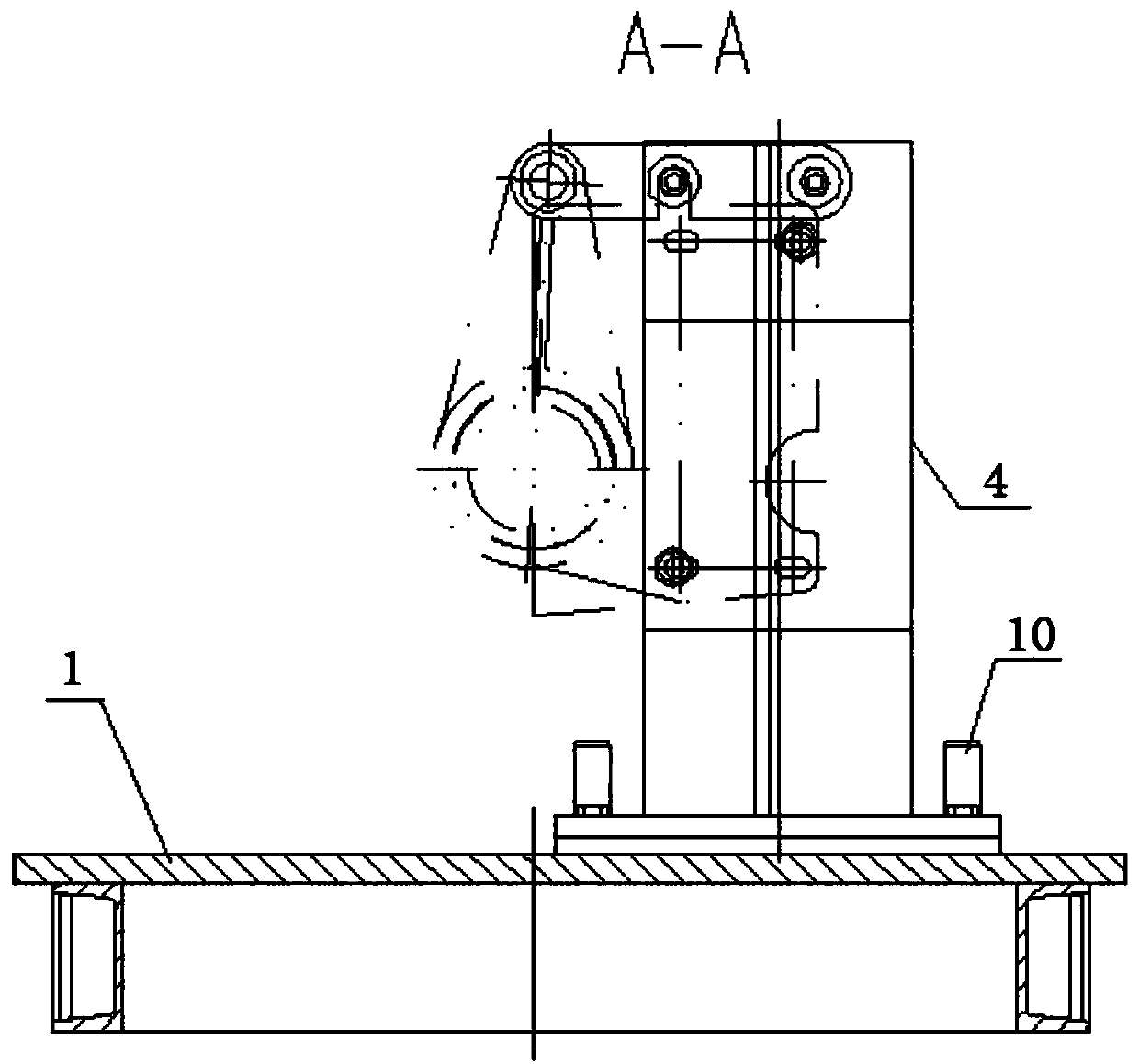

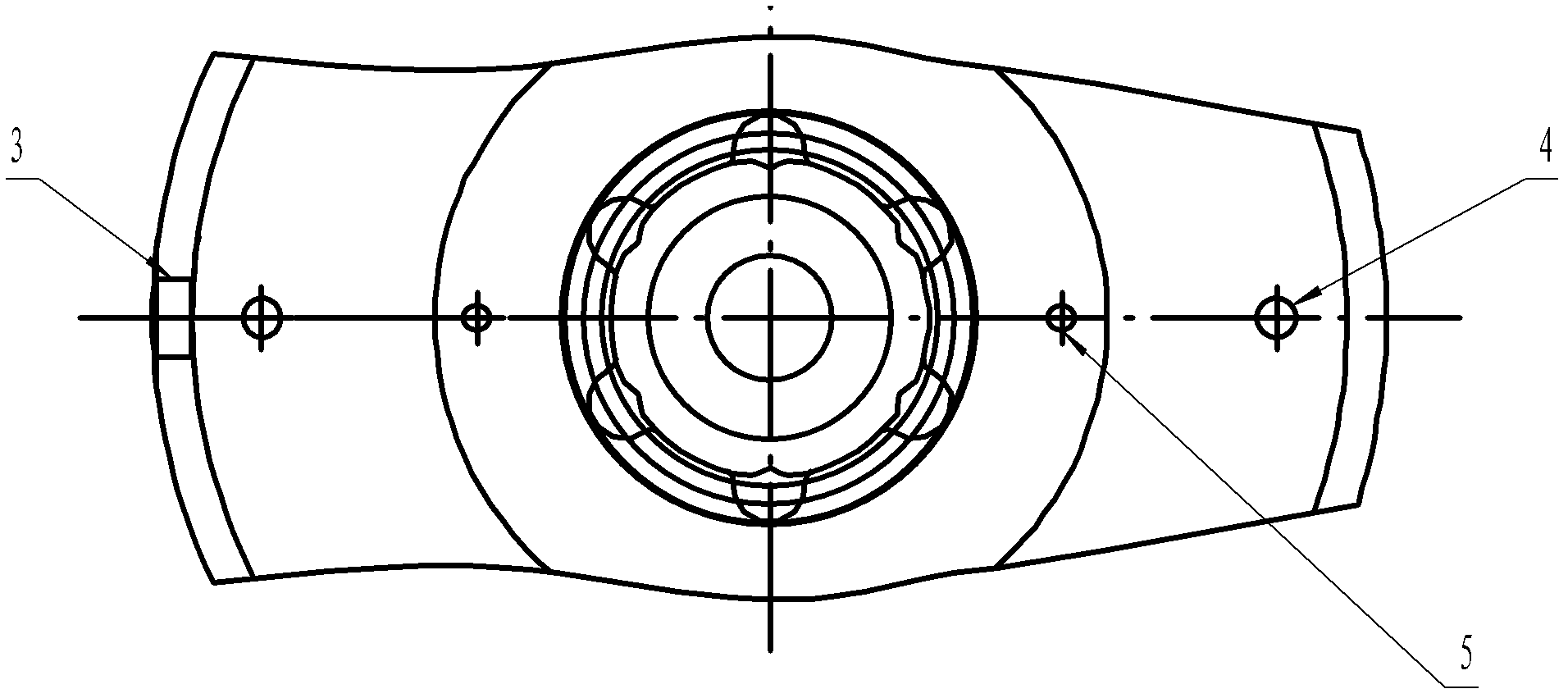

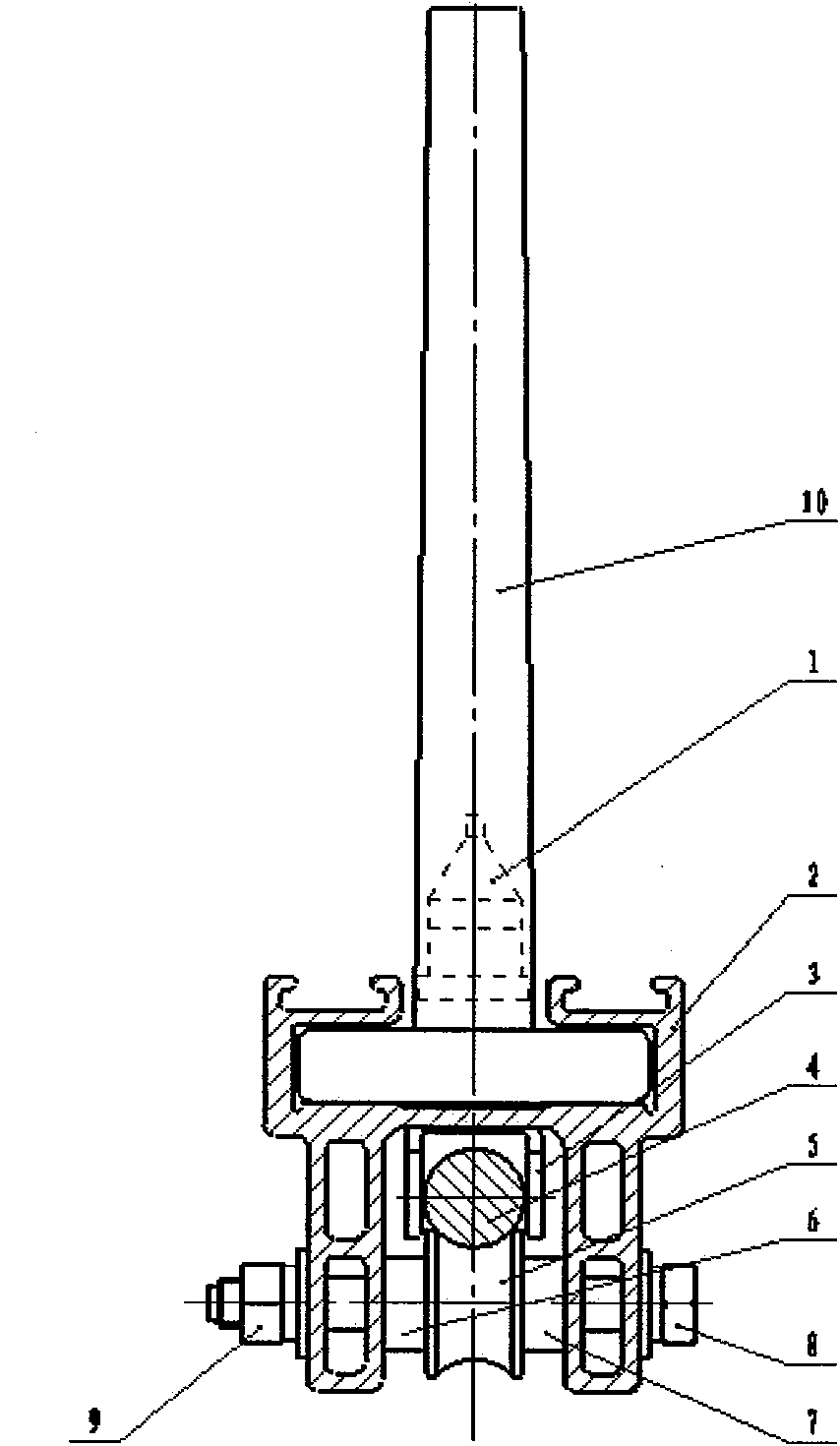

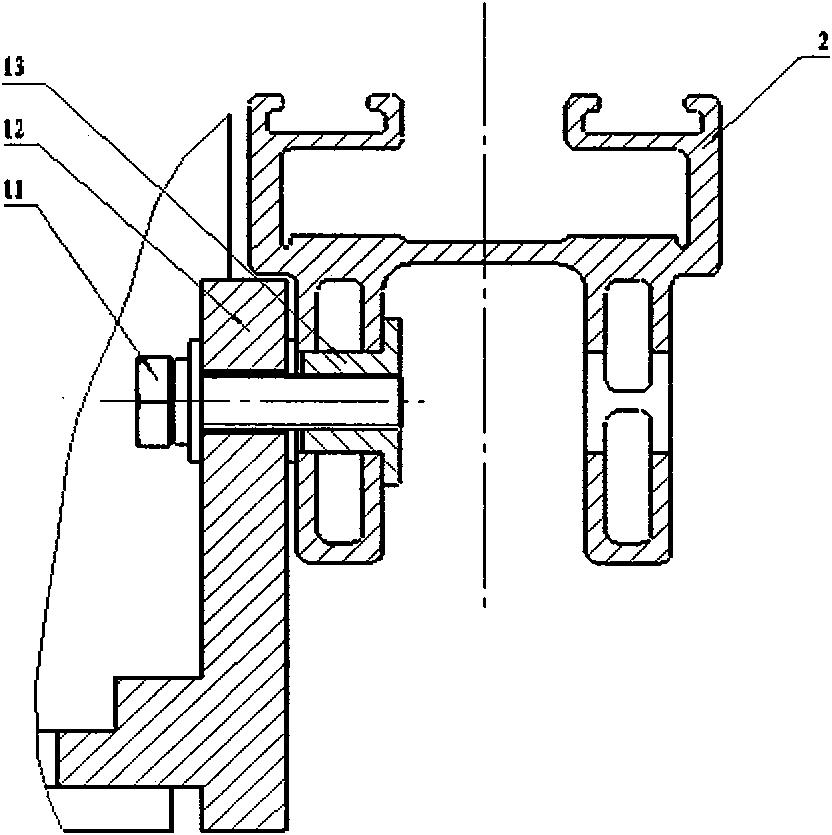

Periphery supporting mechanism of reflecting mirror in space remote sensing camera

InactiveCN101718899AGuaranteed accuracy requirementsGuaranteed Position RequirementsWave based measurement systemsMountingsSpace opticsFace shape

The invention provides a periphery supporting mechanism of a reflecting mirror in a space remote sensing camera, and belongs to the periphery supporting mechanism of the reflecting mirror related in the technical field of space optics. The technical problem to be solved is to provide the periphery supporting mechanism of the reflecting mirror in the space remote sensing camera. The supporting mechanism comprises a mirror cell, flexible supporting slices and a bottom supporting plate, wherein the three flexible supporting slices are positioned between the mirror cell and the bottom supporting plate; the bottom of each flexible supporting slice is fixedly connected with the bottom supporting plate; the upper part of each flexible supporting slice is fixedly connected with the mirror cell; the three flexible supporting slices form a triangle structure opposite to the middle part of the mirror cell and the bottom supporting plate; the three flexible supporting slices are of class spring sheet structure in the form of a structure having thick upper side and thin lower side with the same width. The structure can pass large-magnitude vibration tests and can effectively reduce influence of temperature change and the like on surface figure precision on the premise of ensuring the surface figure precision of optical elements.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

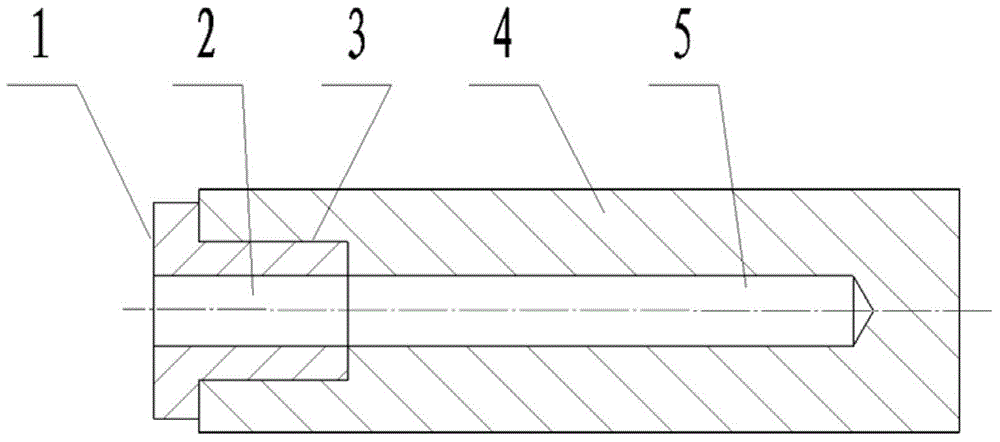

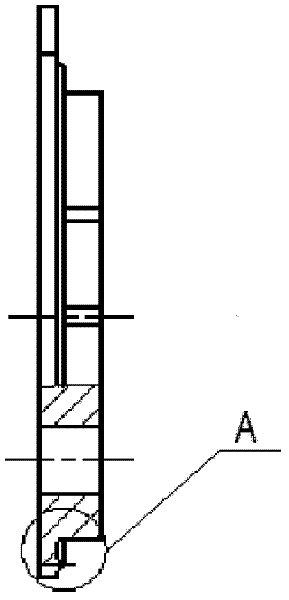

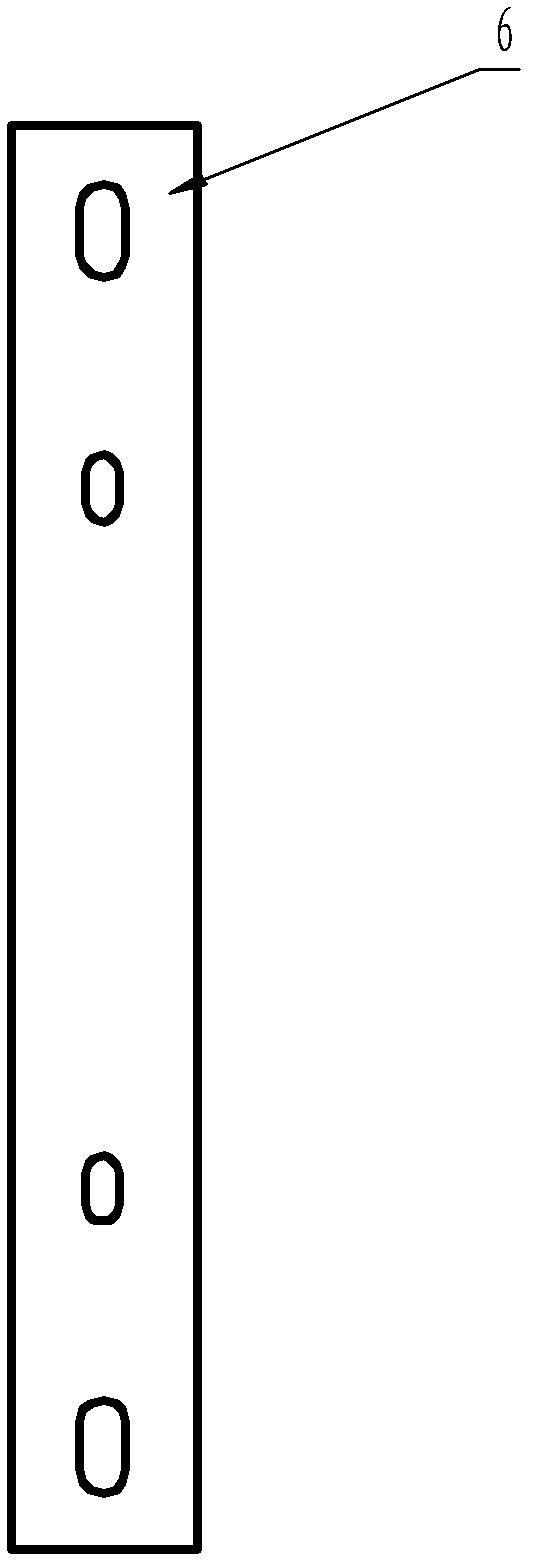

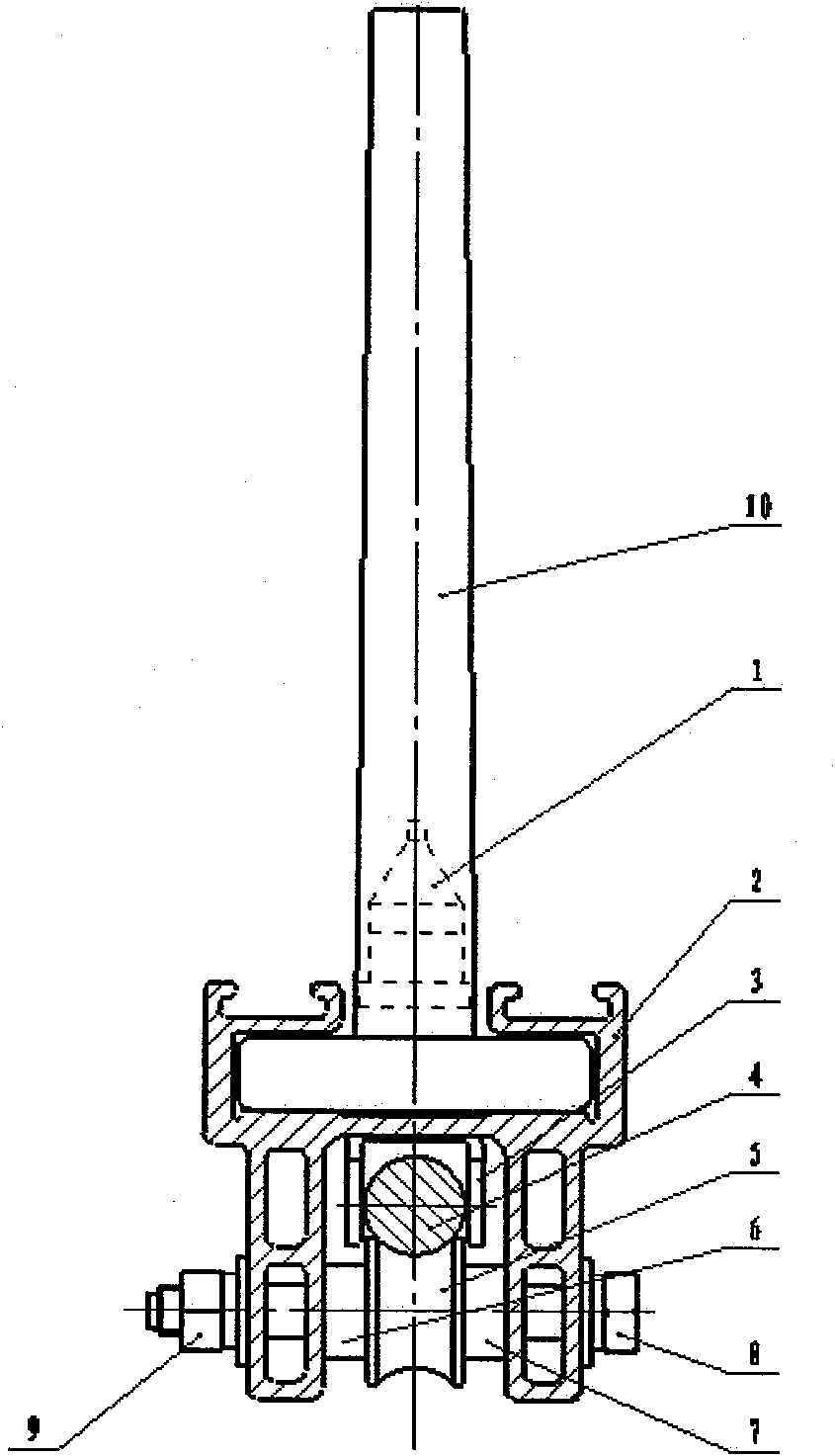

Method for machining deep hole

InactiveCN104625142AEffective tremor controlGuaranteed positioning accuracyDrilling/boring measurement devicesBoring/drilling machinesDrill bushingDeep hole

The invention provides a method for machining a deep hole. The method includes the steps that firstly, a drill bushing hole is machined, wherein the drill bushing hole 3 is machined in the center of the deep hole 5 needing to be machined in a part 4 to be machined; secondly, a drill bushing is inserted, wherein the drill bushing 1 is additionally arranged and installed in the drill bushing hole 3, and the center hole 2 of the drill bushing 1 and the deep hole 5 are the same in diameter; thirdly, the deep hole is drilled, wherein a lengthened drill bit passes the center hole 2 of the drill bushing 1 to drill the deep hole 5 into required depth. By the adoption of the technical scheme, compared with the prior art, the drill bushing generates certain guiding and fixing effects on the drill bit, the phenomenon that the drill bit vibrates is effectively controlled, the requirement for the machining depth is met, the requirements for the location degree and the roundness of the machined hole are met, and the drill bit is prevented from being broken off.

Owner:HARBIN

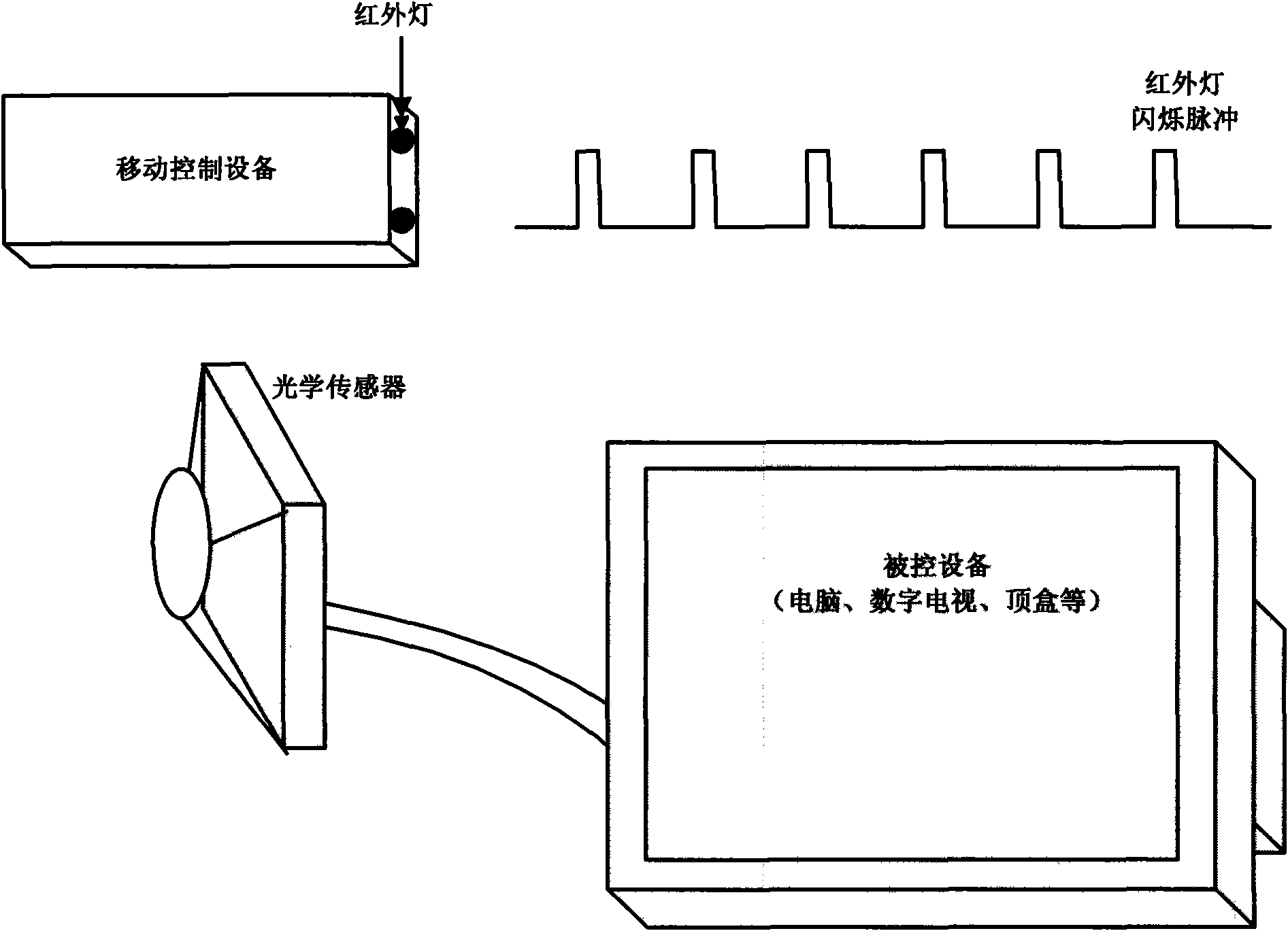

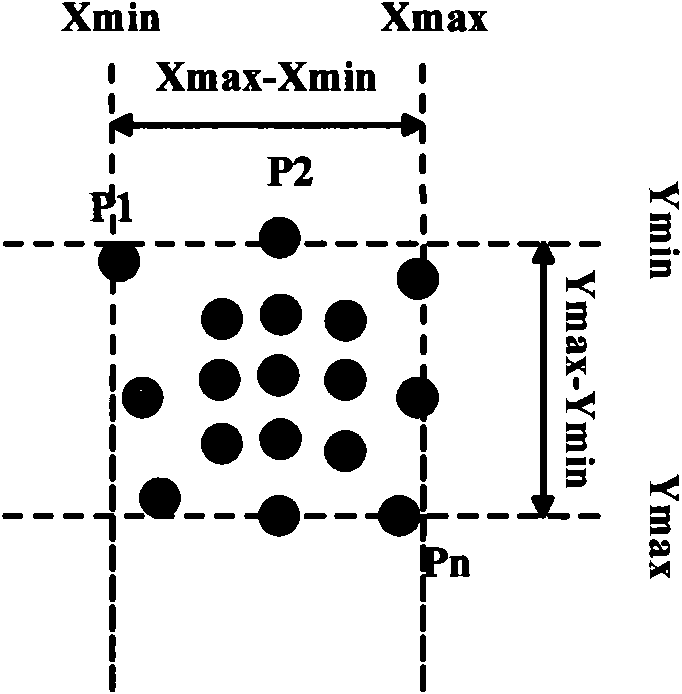

Positioning method based on infrared light spots

InactiveCN101923402AImprove effectivenessImprove stabilityInput/output processes for data processingInformation processingLight spot

The invention discloses a positioning method based on infrared light spots. In the positioning method, by arranging an infrared lamp on mobile control equipment and an optical sensor on a controlled equipment end, the motion of the mobile control equipment enables the infrared light spots of the infrared lamp to move in space, and the optical sensor acquires infrared light spot data and then sends to controlled equipment for processing so as to realize positioning, therefore the information processing amount of a mobile control equipment end is greatly reduced so as to be beneficial to the power consumption control and the cost control of the mobile control equipment; by turning on and turning off the infrared lamp arranged on the mobile control equipment according to certain frequency intermittence, the optical sensor arranged on the controlled equipment end acquires the infrared light spots by adopting scanning frequency matched with the switching frequency of the infrared lamp, therefore the requirements for the positioning can be better ensured, and power consumption generated due to the infrared lamp is reduced.

Owner:鼎亿数码科技(上海)有限公司 +1

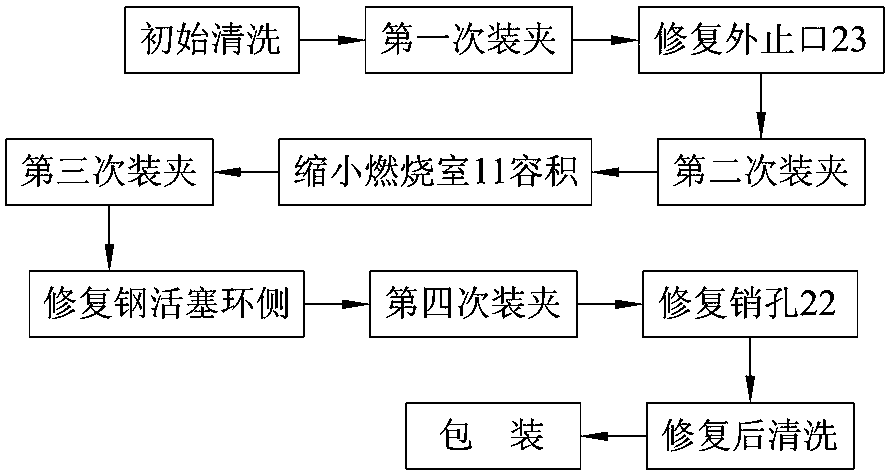

Method for casting butterfly valve body

The invention relates to a method for a casting butterfly valve body, comprising the steps of: 1, manufacturing an inner core: forming an annular inner core structure for later use by utilizing a plurality of fan-shaped inner core boxes; 2, manufacturing an outer core boxes according to the method in the step 1: forming an annular outer core structure for later use by utilizing a plurality of fan-shaped outer core boxes; 3, manufacturing a mould base for later use; 4, concentrically arranging the inner core and the outer core on the mould base; 5, reasonably adjusting the positions of the inner core and the outer core, planishing water-glass sand in the inner core and drying by utilizing carbon dioxide gas for later use; and 6, completing pouring molten steel within 1.5-2.5 minutes through a pouring opening on an sealing cover, holding the temperature for 7 hours and completing the casting. The method has the advantages of simple preparation process, reasonable design and short processing time, the production efficiency increased by more than 50%, guaranteed stability of the molded butterfly valve body, better roundness, no cracks on the surface and greatly enhanced tightness of the valve.

Owner:HENAN YUXING CASTING

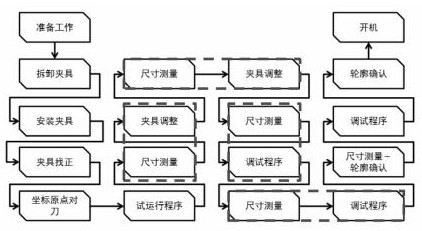

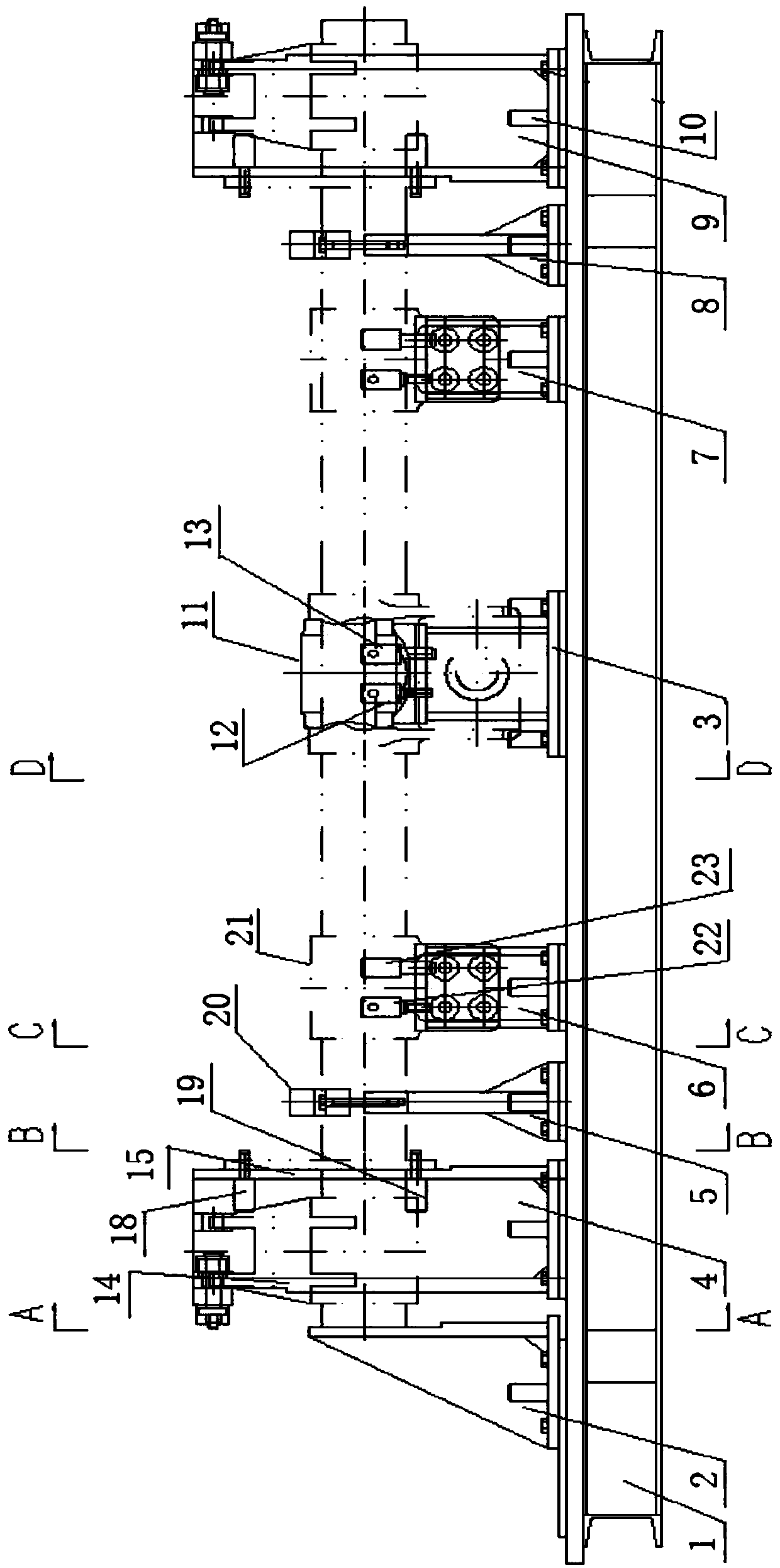

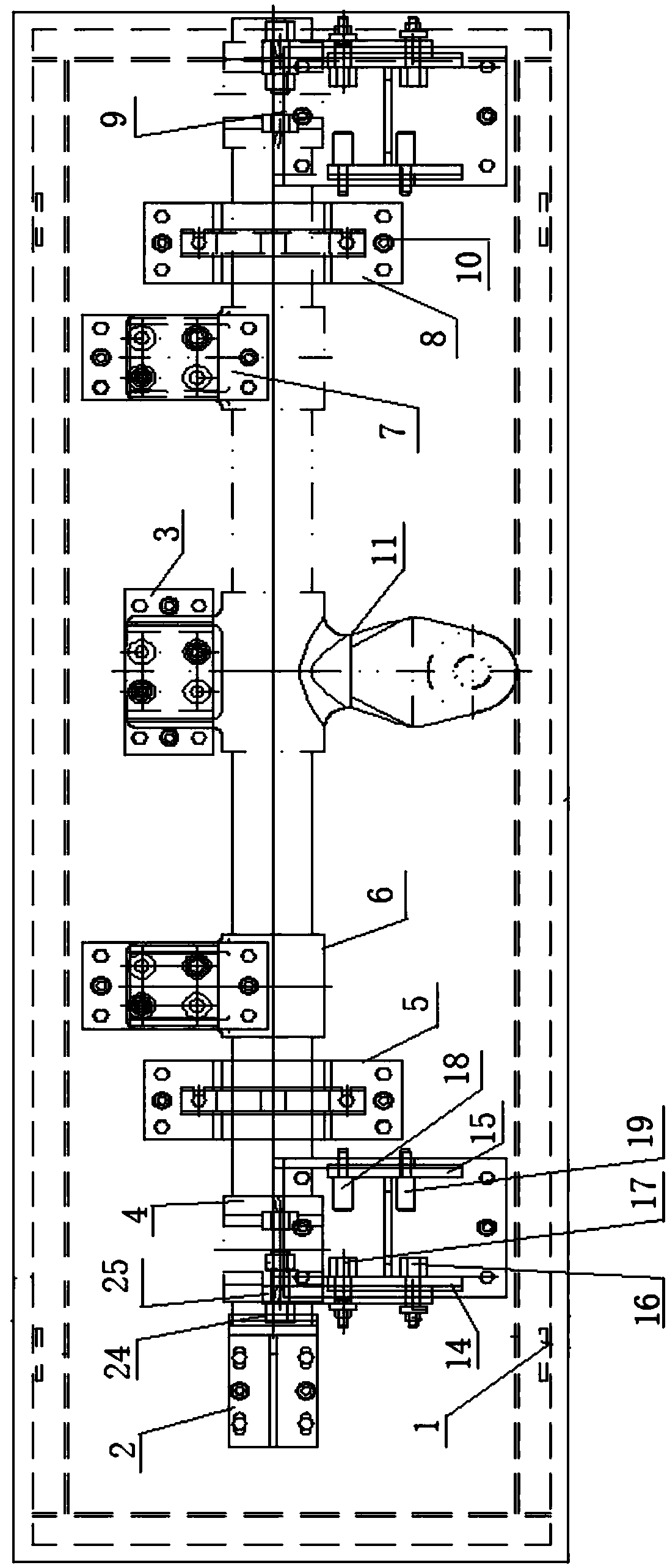

Workpiece machining flexible production line and machining method implemented through same

ActiveCN110227951AGuaranteed sizeEasy clearanceOther manufacturing equipments/toolsMetal working apparatusProduction lineNumerical control

The invention discloses a workpiece machining flexible production line and a machining method implemented through the same. The flexible production line comprises production units used for machining amachine part, and a conveying system connected between the production units; the production units include a rough machining unit, a finish machining unit and a station unit; and the roughing unit comprises a rough grinding unit. By adopting the technical scheme, according to the universal joint retainer flexible production line, three numerical control horizontal grinding machines and an automatic conveyor belt form a window, inner circle and outer circle grinding machining process control automatic line, complicated machining operation is achieved, the dimensional requirements, precision requirements and position requirements are effectively guaranteed, the part machining quality is stable, optimal fit clearances of produced universal joint retainers can be ensured, and impact, noise andvibration generated by universal joint assemblies during usage are reduced.

Owner:温州华义信息技术有限公司

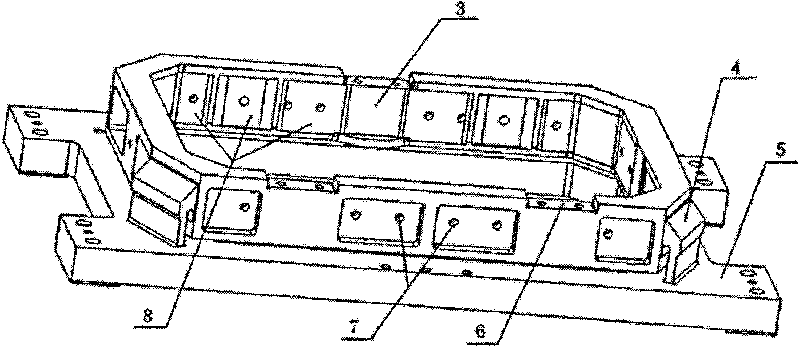

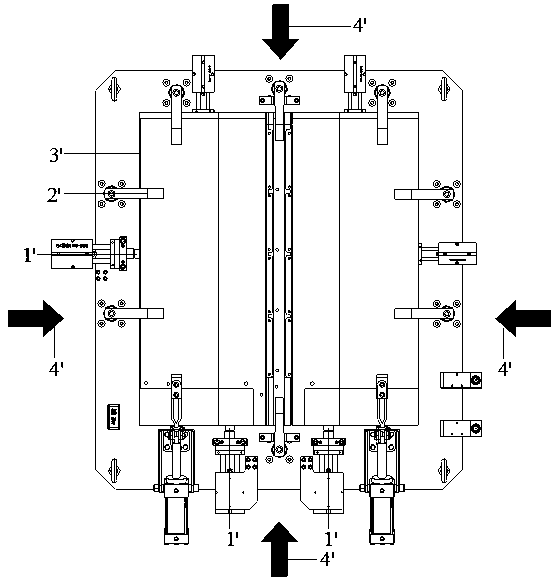

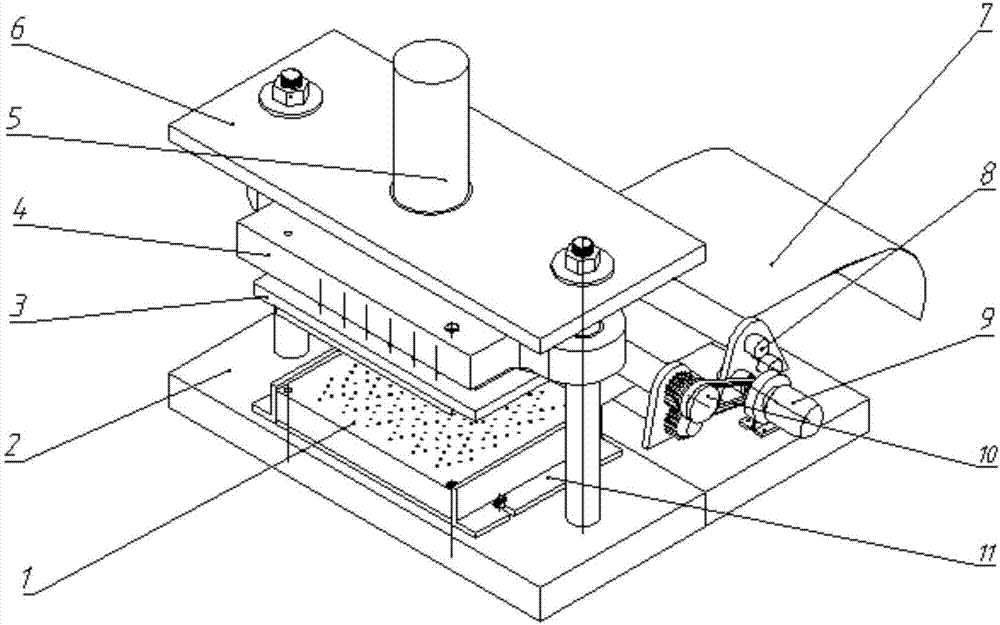

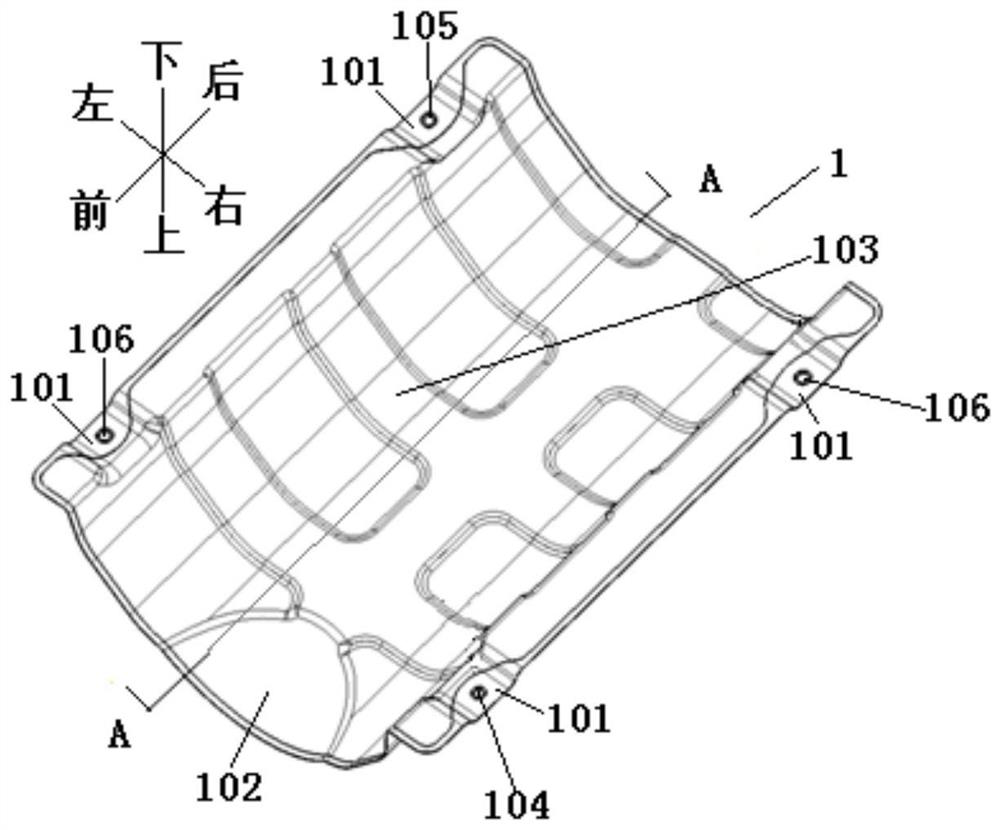

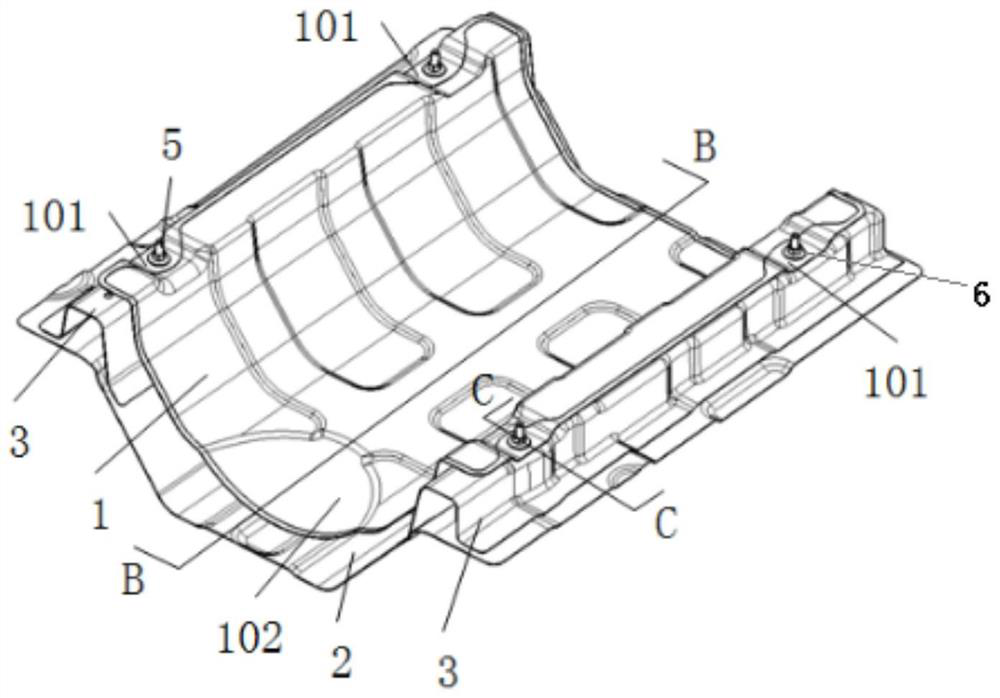

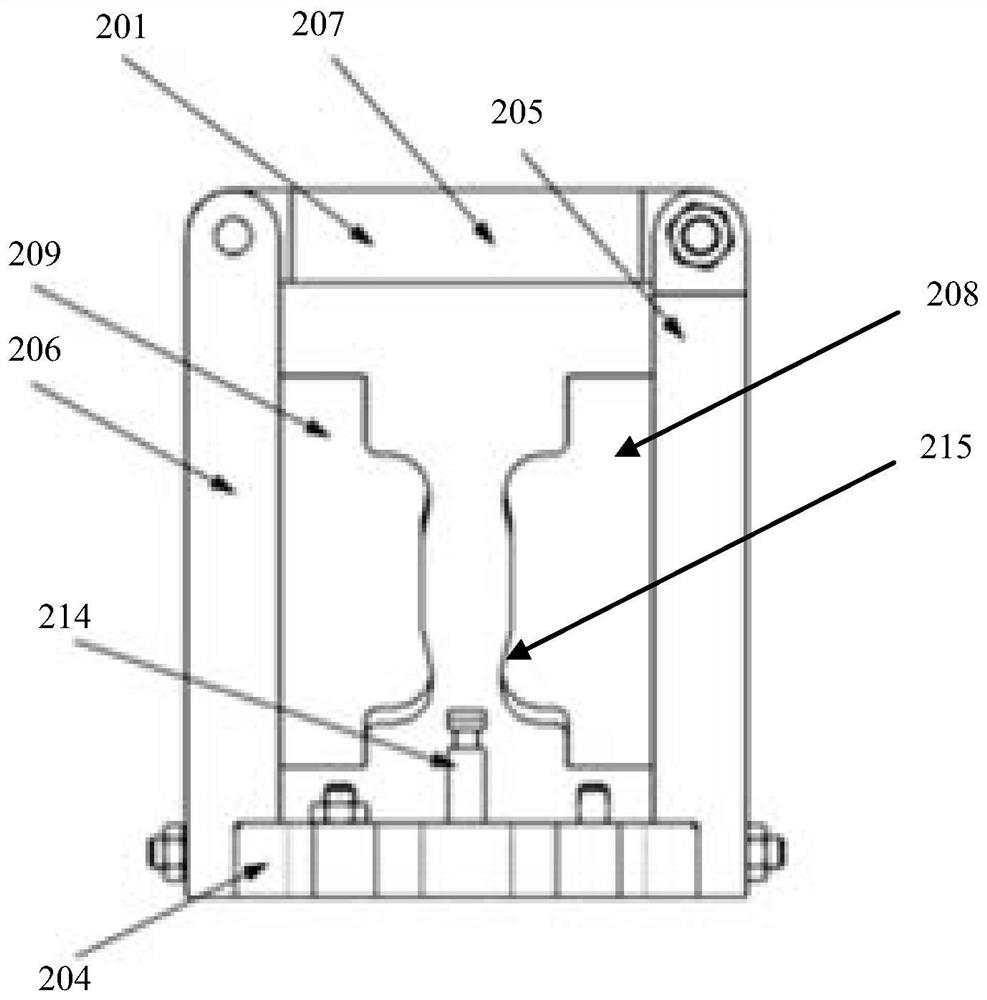

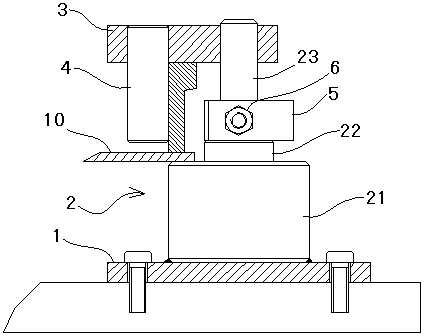

Battery tray bottom plate CNC finish machining fixing tool

PendingCN111283457AGuaranteed positioning requirements in the horizontal directionGuaranteed Position RequirementsWork clamping meansPositioning apparatusElectrical batteryStructural engineering

The invention discloses a battery tray bottom plate CNC finish machining fixing tool. The battery tray bottom plate CNC finish machining fixing tool comprises a tool body, and the tool body comprisesan air pressure structure plate, a horizontal positioning mechanism and a negative pressure acupoint adsorption mechanism; and a to-be-machined product is arranged on the air pressure structure plate,clamped in the horizontal positioning mechanism, positioned in the X and Y directions through the horizontal positioning mechanism, attached to all contact points in the vertical direction of the negative pressure acupoint adsorption mechanism 400 in a floating mode, and adsorbed in the Z direction through the negative pressure acupoint adsorption mechanism. In this way, according to the batterytray bottom plate CNC finish machining fixing tool, positioning requirements of the product in the horizontal direction can be effectively met, it can be guaranteed that all the contact points in thevertical direction are attached to the product in the floating mode through negative pressure acupoints, the periphery and hole positions can be machined at a time, thus multiple times of clamping isavoided, and the machining time is shortened.

Owner:纽维科精密制造江苏有限公司

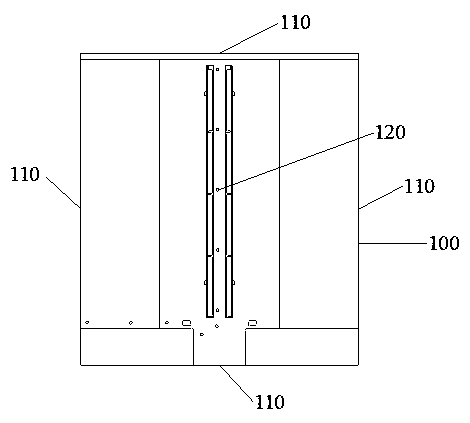

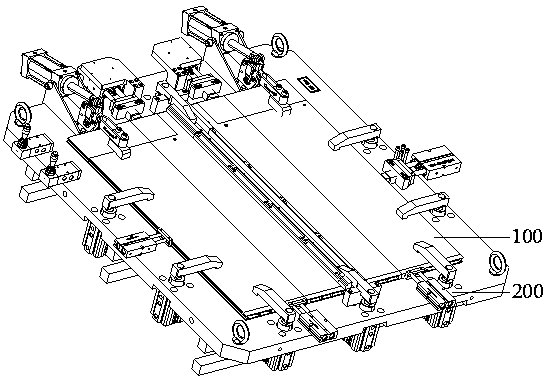

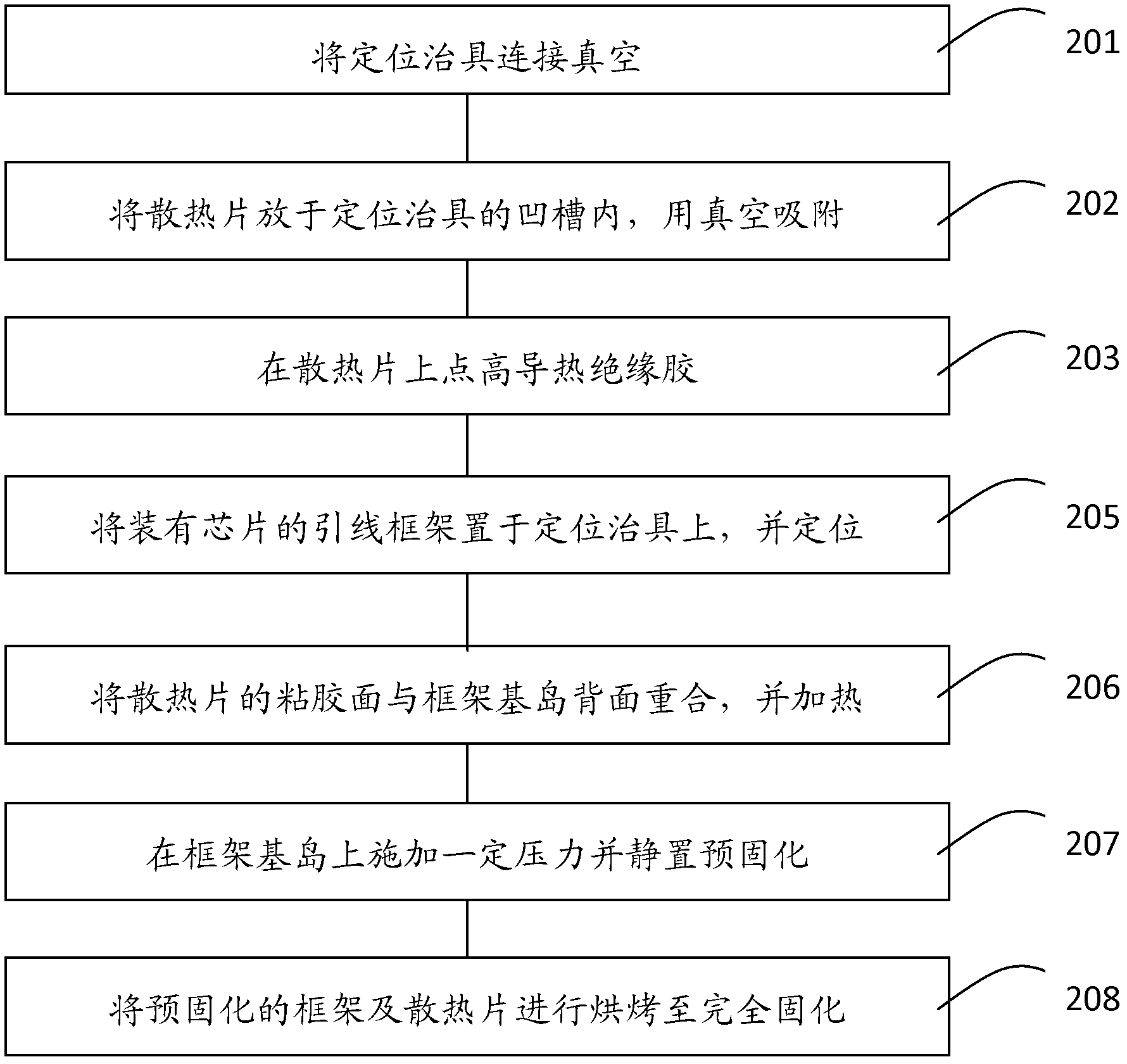

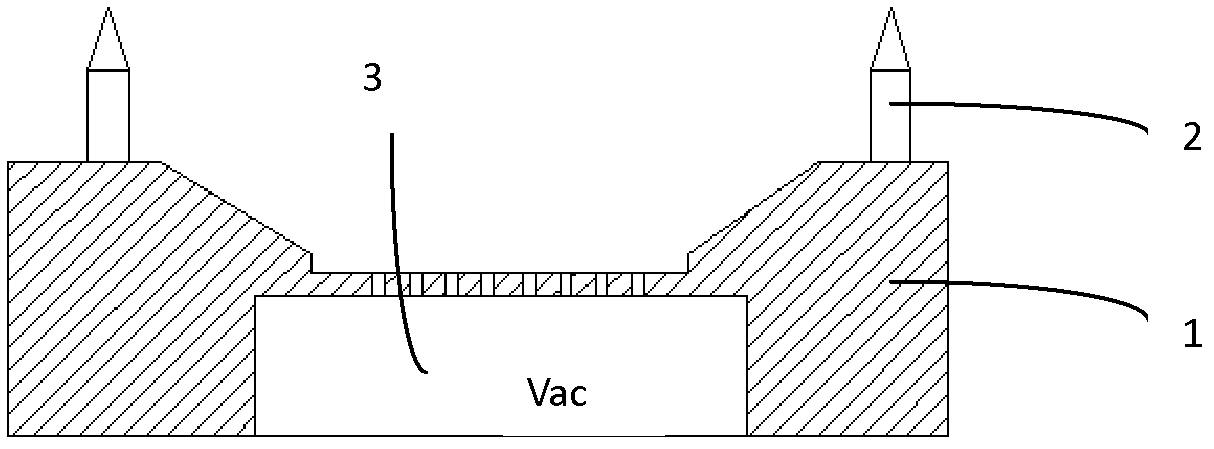

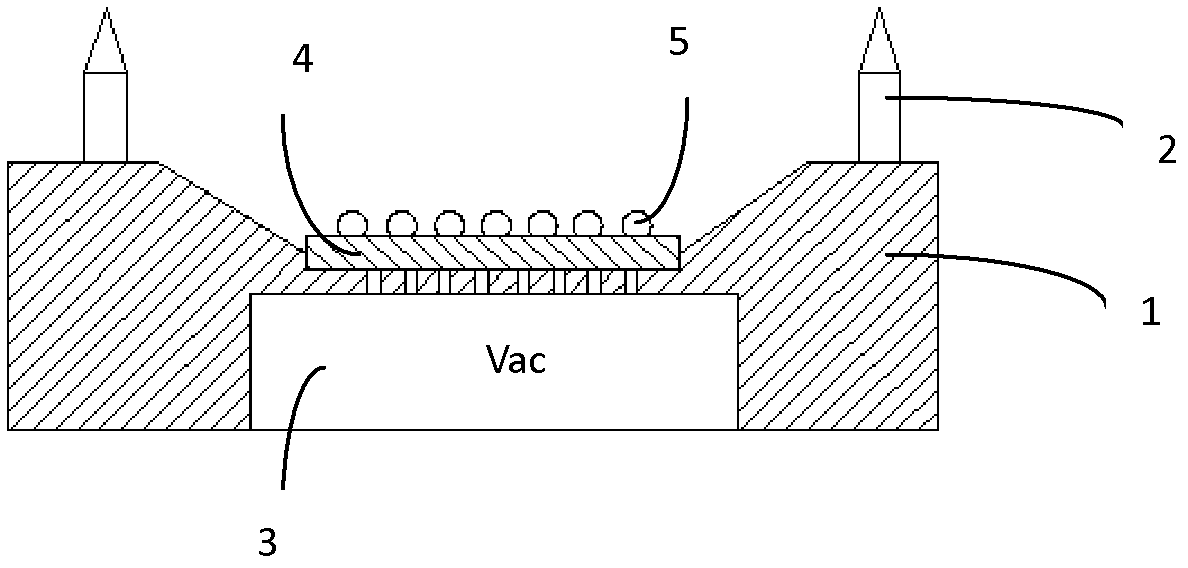

Method for installing cooling fin of high-power module

InactiveCN102522340ANo pollutionEasy to controlSemiconductor/solid-state device manufacturingEngineeringHeat sink

The invention provides a method for installing a cooling fin of a high-power module. An island of a lead frame is adhered to a cooling fin according to the following steps: enabling a positioning jig to be connected with vacuum; placing the cooling fin in a groove of the positioning jig, and utilizing vacuum to adsorb the cooling fin; arranging high heat-conduction insulating cement on the cooling fin; placing the lead frame where a chip is installed above the positioning jig, and using a positioning hole arranged on the lead frame and a positioning pin arranged on the positioning jig to perform positioning; enabling the back surface of the frame island to coincide with a mucilage glue surface of the cooling fin; and jointly baking the lead frame and the positioning jig, and fully solidifying the high heat-conduction insulating cement which enables the cooling fin to be adhered to the frame island. The method has the advantages of being high in reliability, low in cost, good in heat dissipation effect, little in pollution and the like.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

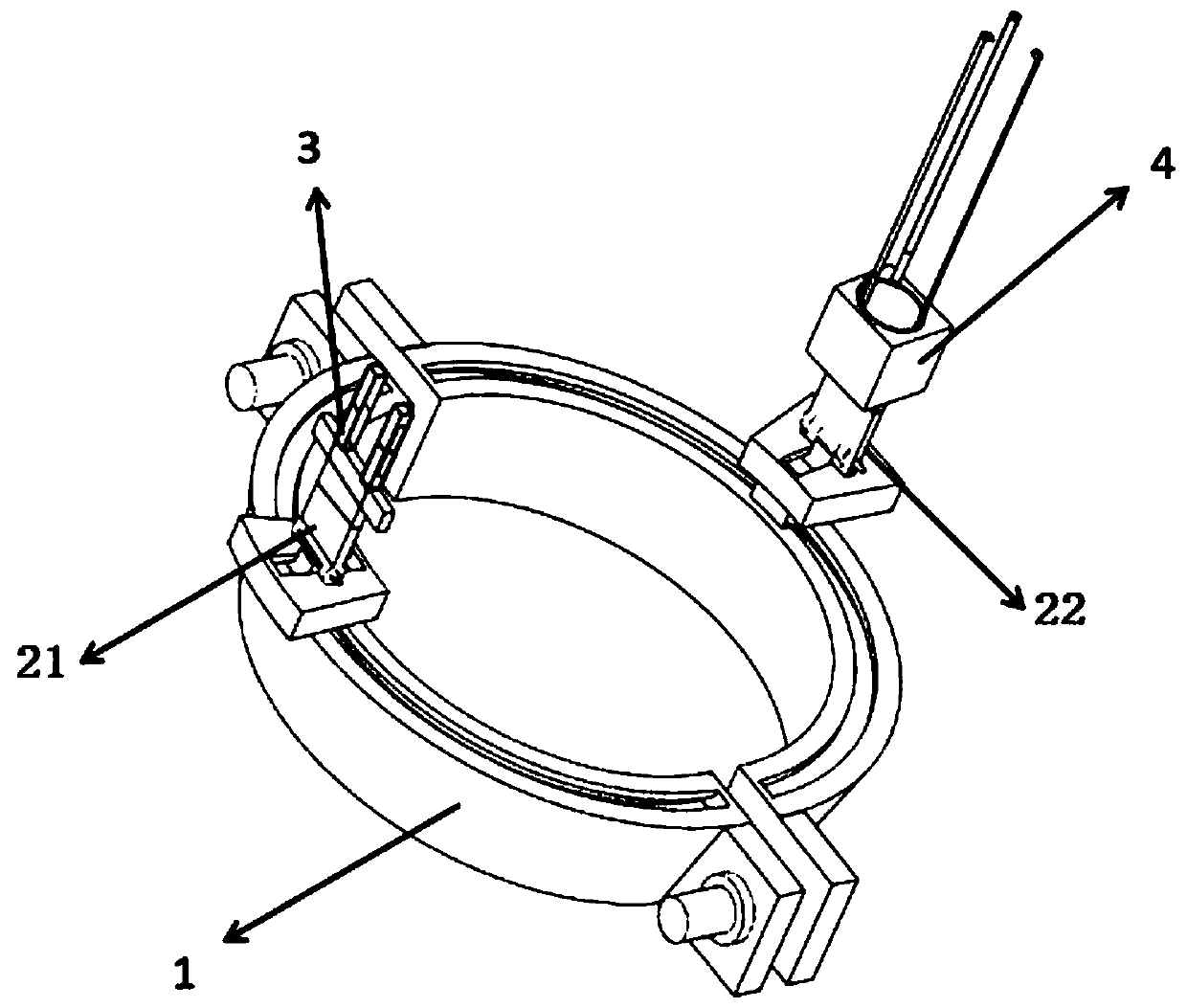

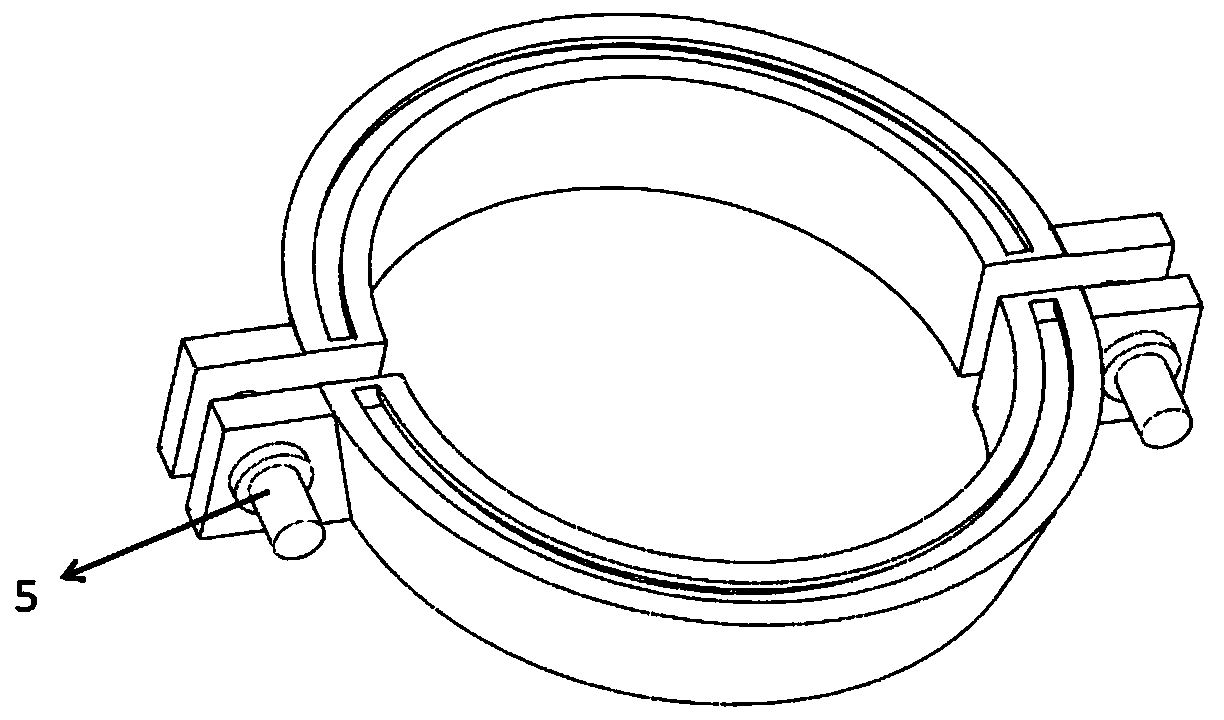

Positioning device for X-ray detection of GIS equipment

ActiveCN110849919AClear imagingGuaranteed multi-angle shootingMaterial analysis by transmitting radiationEngineeringComputational physics

The invention provides a positioning device for X-ray detection of GIS equipment. The system is fixed on the GIS equipment through a base, and an imaging plate fixing frame is used for clamping and fixing an imaging plate; a ray machine fixing claw is used for clamping and fixing a ray machine; a first movable sliding block is used for bearing the imaging plate to move in the circumferential direction and the radial direction of the base, and a second movable sliding block is used for bearing the ray machine to move in the circumferential direction and the radial direction of the base; the imaging plate and the ray machine move in the circumferential direction along the base so that multi-angle shooting of the X-ray machine can be guaranteed; the imaging plate and the ray machine move in the radial direction along the base so that the focal length can be well adjusted, and it is guaranteed that obtained imaging of the GIS equipment is clearer; and the imaging plate fixing frame can guarantee that the imaging plate is vertically placed and can also guarantee that the imaging plate is horizontally placed after rotating by 90 degrees, and the ray machine fixing claw guarantees that the position of the X-ray machine can meet the transillumination requirements of a vertical GIS and a horizontal GIS.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

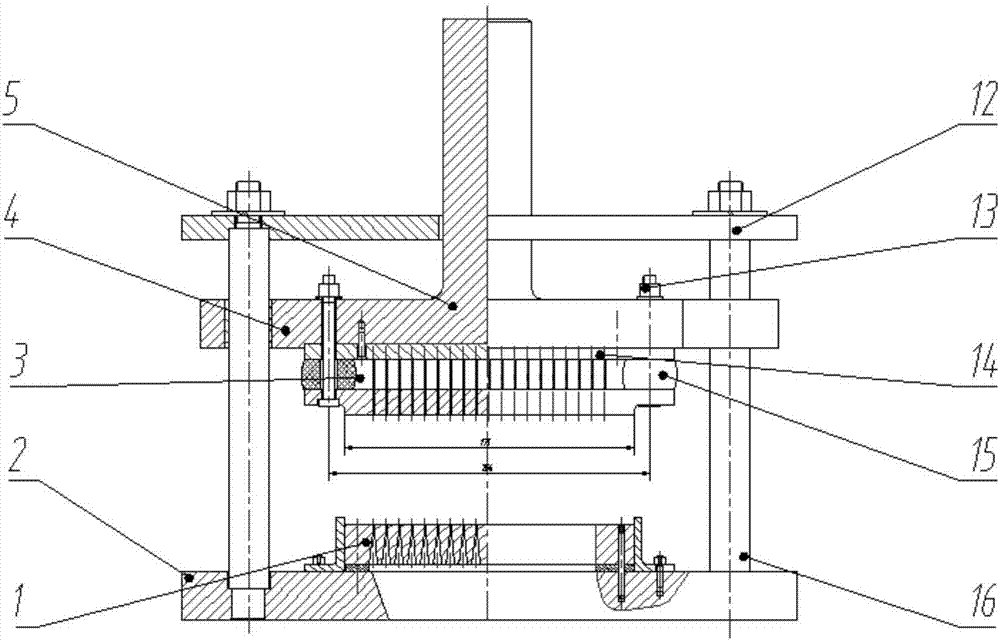

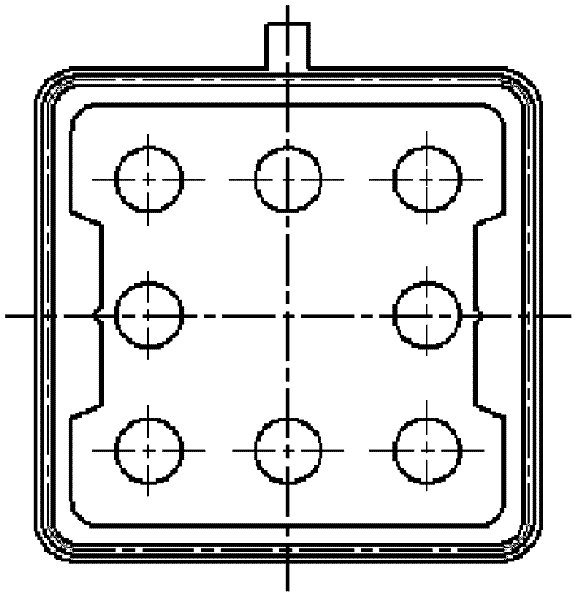

Male and female inlaid mould, mould and system for sol-gel (SG) abrasive material microreplication forming hole

InactiveCN107442640AEasy to manufactureEasy for stampingMetal-working feeding devicesStripping-off devicesSystems designMachining system

The invention discloses a male and female inlaid mould, mould and system for a sol-gel (SG) abrasive material microreplication forming hole. According to the male and female inlaid mould, mould and system for the SG abrasive material microreplication forming hole, distribution conditions of male mould units are adjusted according to the sizes of workpieces, the size of a related cutting-building side value and a manufacturing mode of a related mould, and the number of the male mould units is determined according to the size of blanking force and the size of the cutting-building side value; and a automatically-feeding system designed according to characteristics of a stepper motor is matched with a layout mode mentioned in the invention, and a machining system capable of continuously machining and blanking can be achieved through mutual matching.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

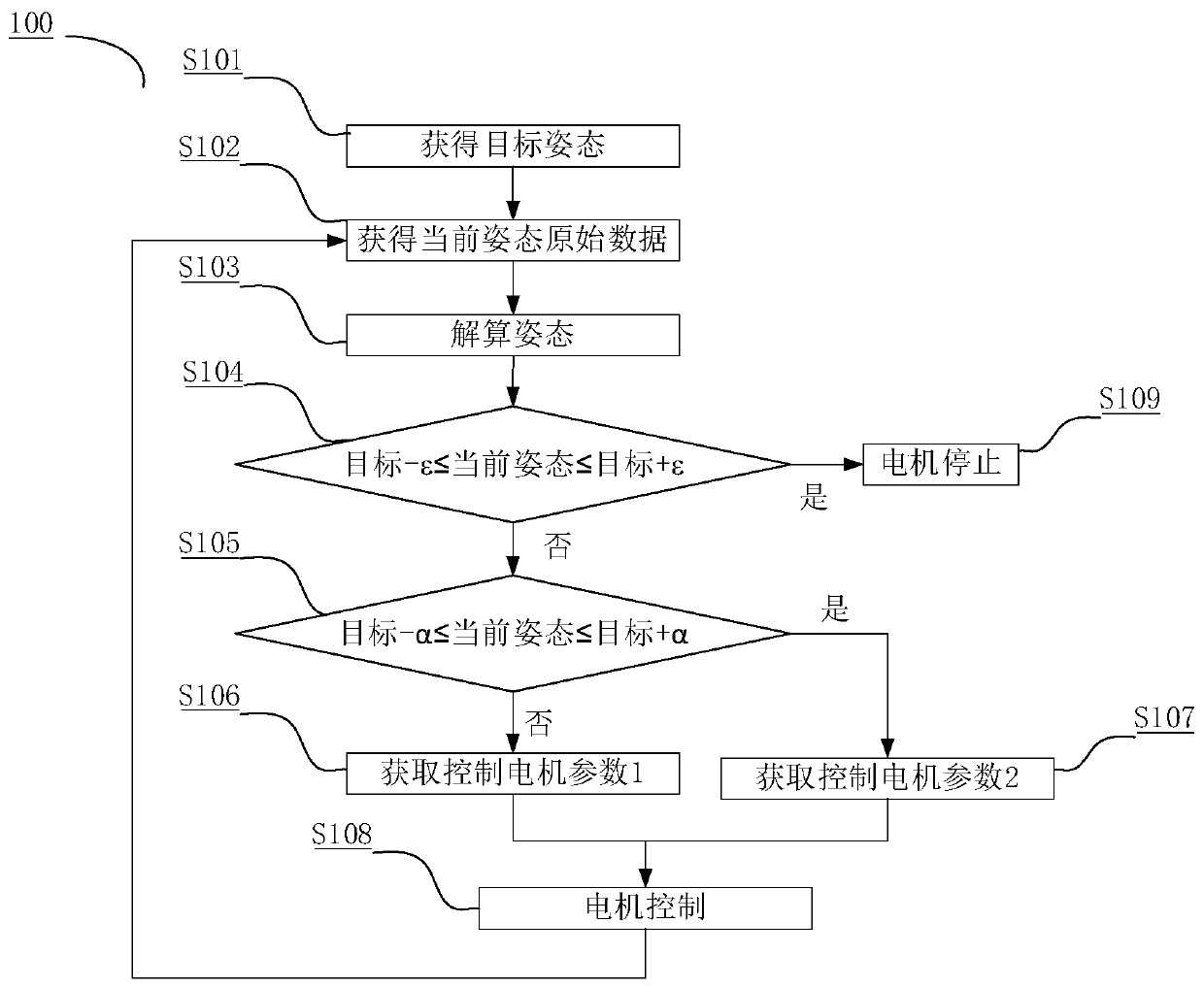

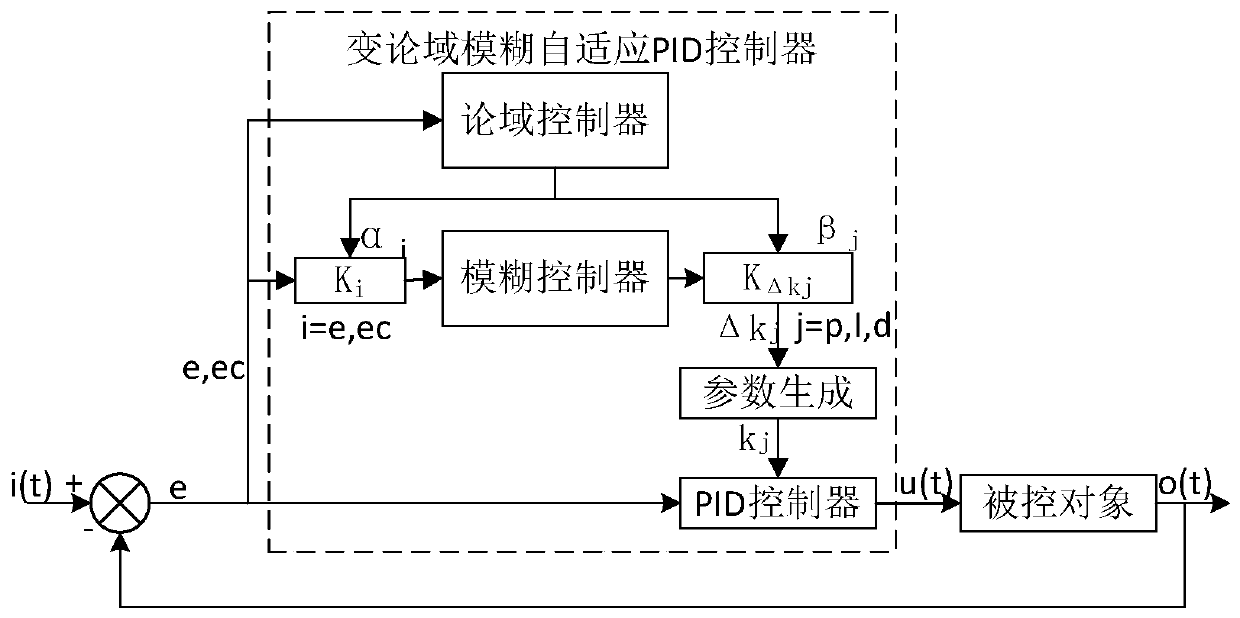

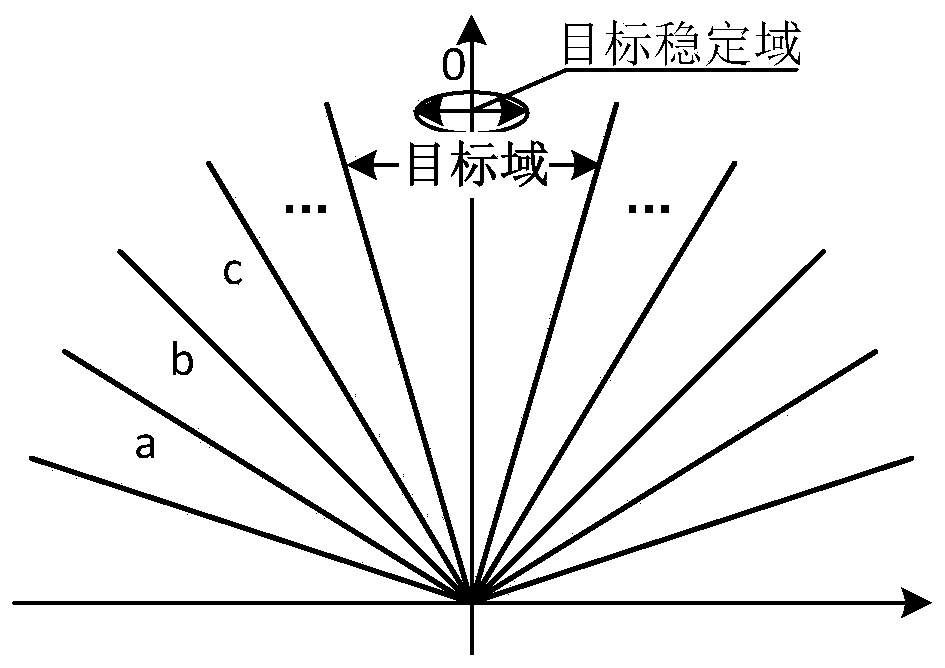

Holder control method and holder

InactiveCN109947138AQuick responseImprove dynamic stabilityControl without using feedbackElectric machineControl engineering

The invention provides a holder control method and a holder. The method comprises the following steps: acquiring a target hold posture to determine a movement target; acquiring the current holder posture to know the current movement state; determining the holder posture to generate different parameters and perform different control strategies; determining the control parameters of a motor runningin a motor control process through at least one of algorithm, lookup and setting default; then controlling the motor to run or stop based on the motor control parameters. With the adoption of the method, the holder responding speed is high; the dynamic stability is high; the requirements on positioning accuracy and loading capacity can be met; the overall performance of the holder can be improved.

Owner:XIAN TECHNOLOGICAL UNIV

Method and fixture for controlling welding deformation of igniter

ActiveCN109352241AGuaranteed Position RequirementsAvoid interferenceWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention discloses a method and fixture for controlling welding deformation of an igniter. A technological threaded hole used for clamping is added in a large joint inner cavity of a boss of theigniter, a hole is designed in the middle part of a traditional positioning bolt, then, the boss is tensioned by employing a screw, so that the boss is fixed onto the bolt, and then, the boss not onlyis positioned but also is clamped; a square hole is formed in a suitable position of a fixture body corresponding to a welding seam, so that a welding gun is prevented from interfering with the fixture body, and an assembly is welded under a rigid constraint state; and a part welding way is changed, i.e., a part is changed into a vertical state from a horizontal state, so that the phenomenon thata welding pool of the welding seam sags due to self gravity to form excrescences making connection unreliable in the inner cavity is avoided.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

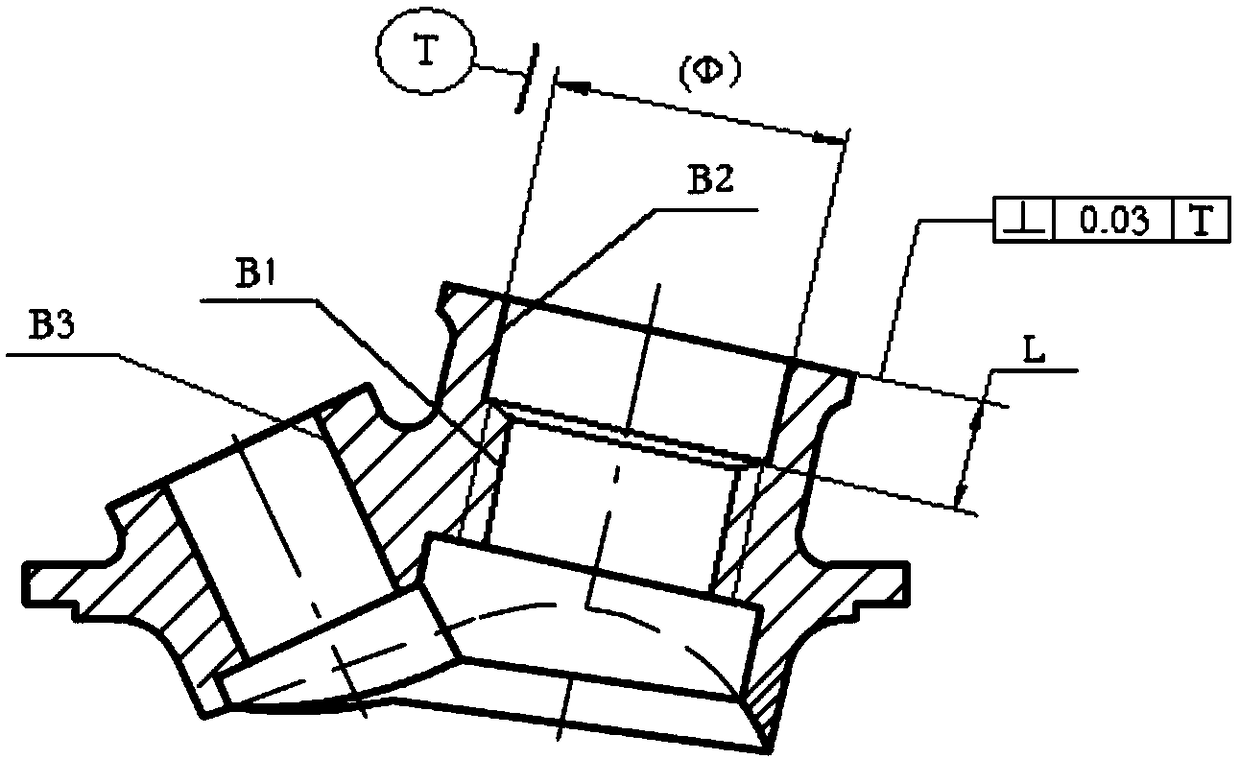

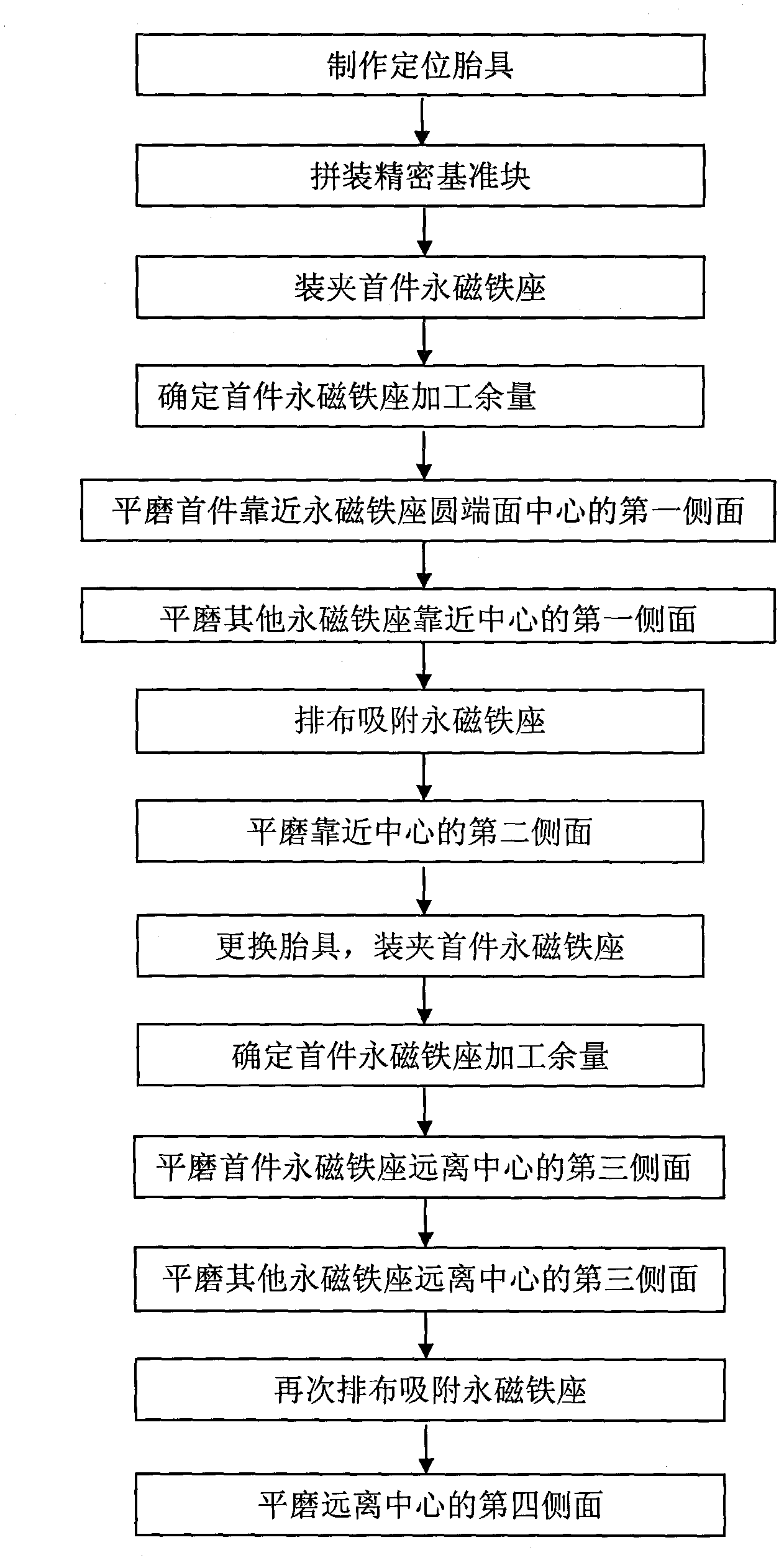

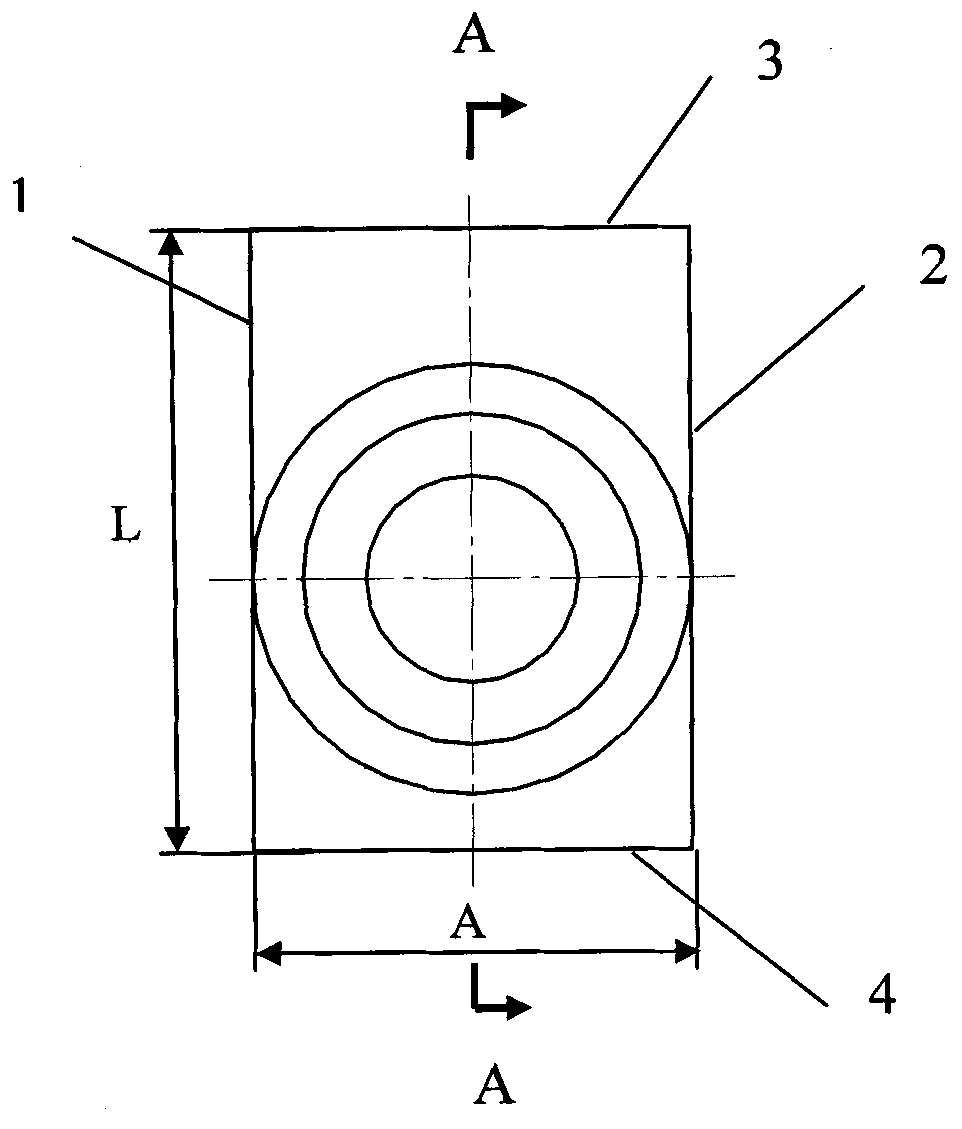

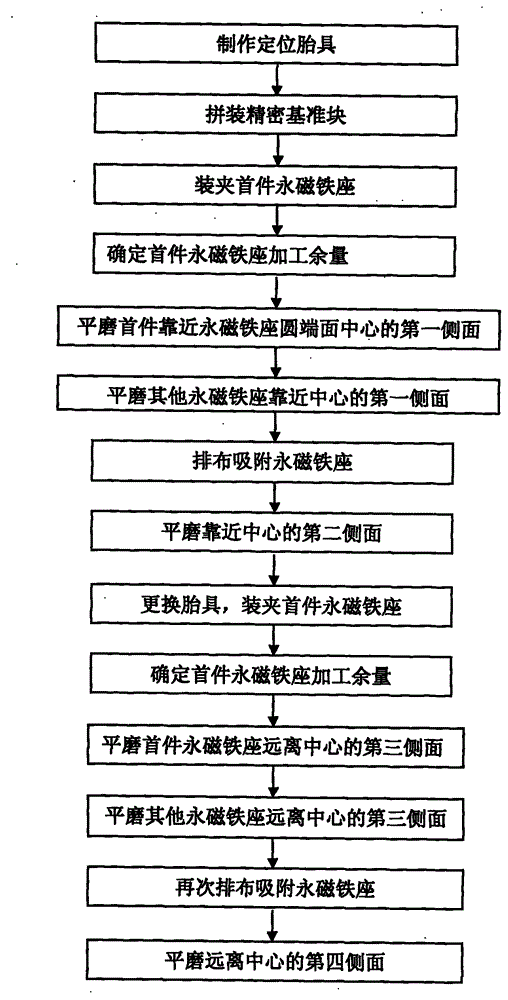

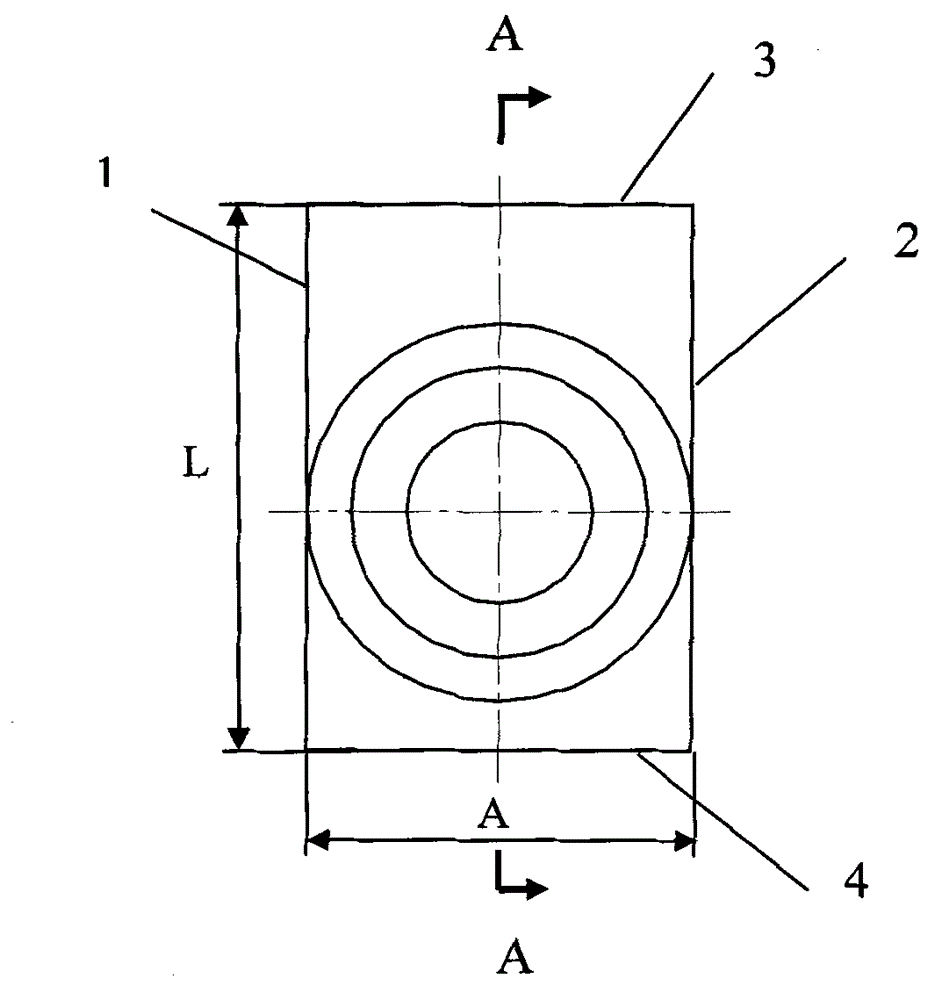

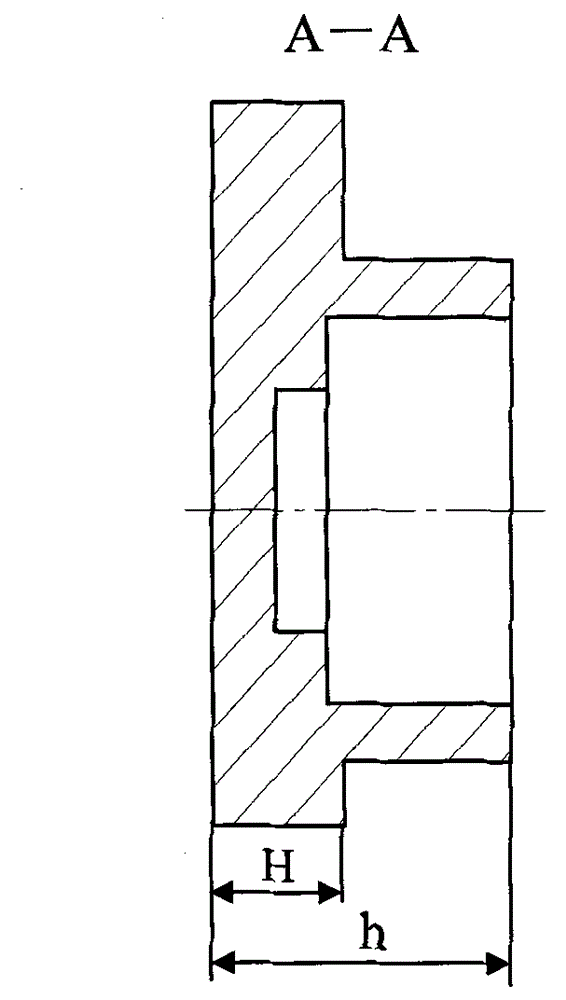

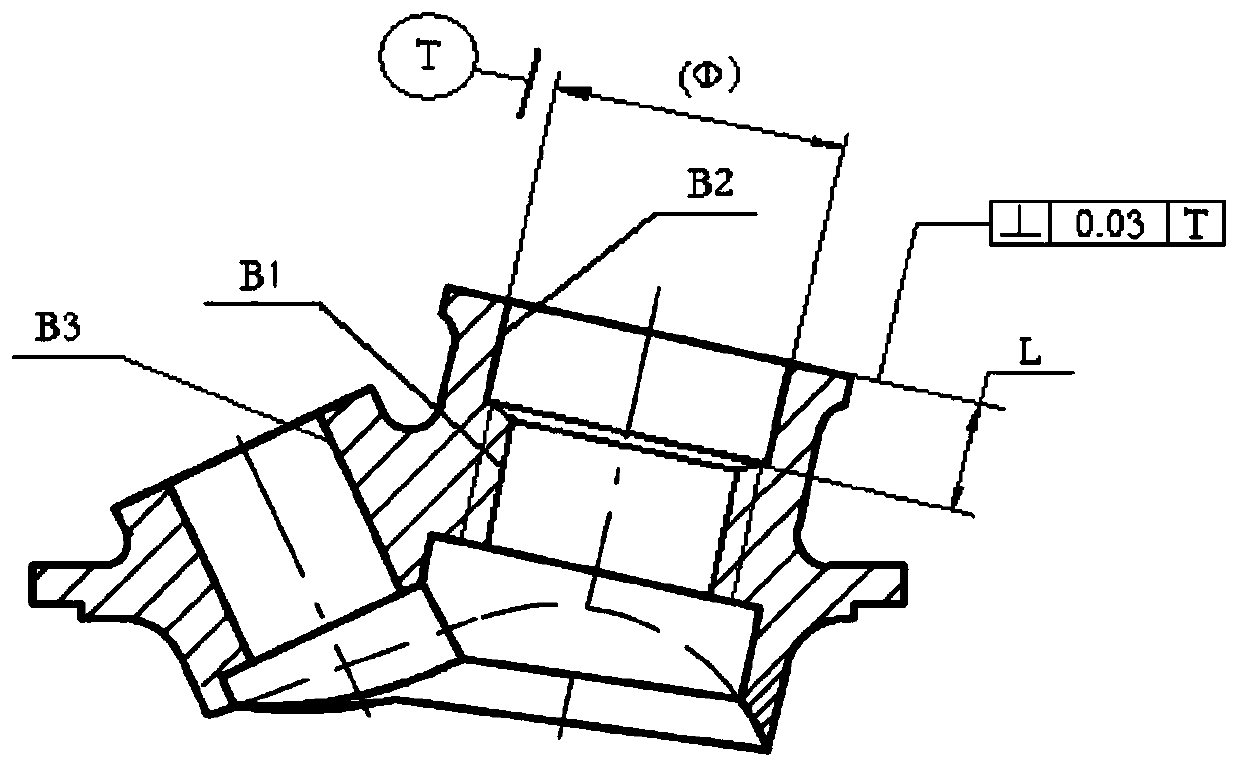

A grinding method of high-precision permanent magnet seat

InactiveCN102284893AFix stability issuesSolve measurement difficultiesSeat surface grinding machinesMagnetCooling methods

The invention belongs to a processing technology for a precision component made of special material, and relates to a processing method for high-precision benchmark conversion of parts made of soft magnetic alloy. An auxiliary positioning tool is arranged, and the problem of mutual verticality of a plurality of surfaces can be solved; a high-precision benchmark block is matched for conversion of measurement benchmarks, and the problem that actual processing dimensions cannot be determined easily can be solved; the tool is adopted for conversion of the processing benchmarks, a processing supply terminal is arranged, and the defects that each part needs to be centered and measured each time when being processed can be overcome; and moreover, magnetic weakening can be avoided through optimizing processing parameters and selecting reasonable sand wheels and cooling methods. Compared with the conventional processing method, the problems of the traditional method that the parts cannot be clamped and positioned easily and need to be clamped and centered multiple times during processing can be solved; high position accuracy and dimensional accuracy of side faces can be guaranteed at the same time; and the processing efficiency can be increased greatly, good dimensional consistency can be maintained, and the processing quality can be stabilized.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

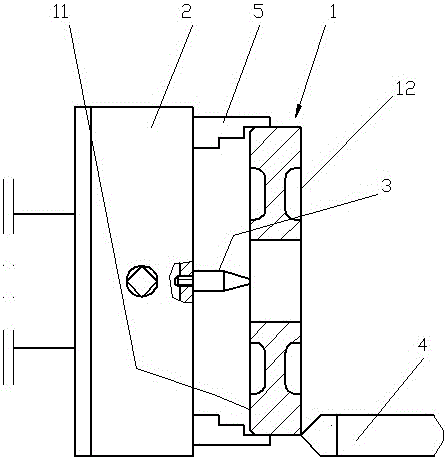

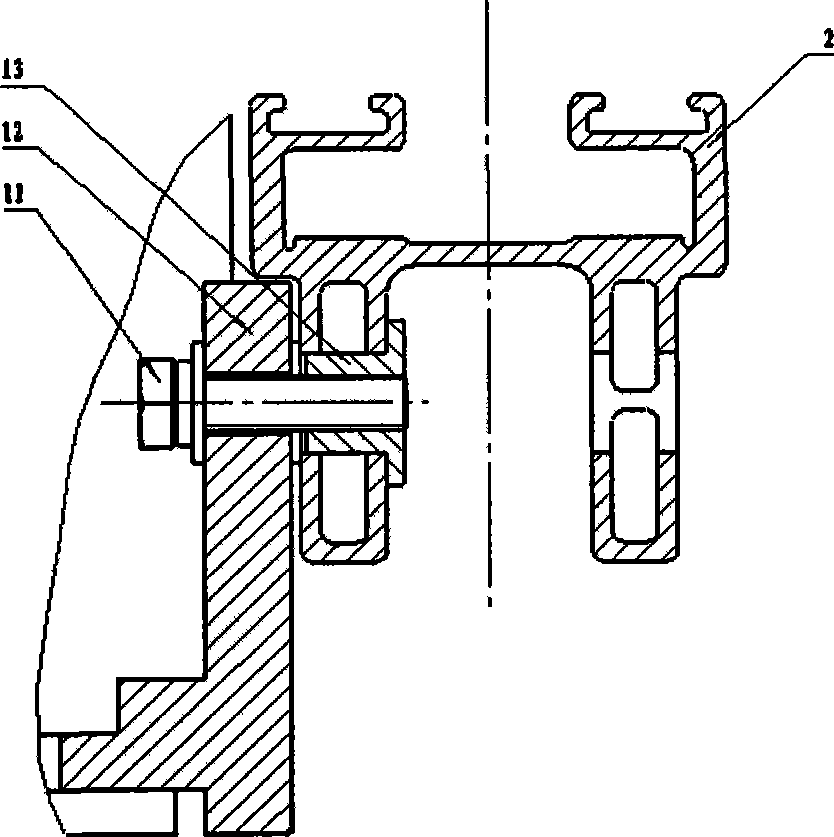

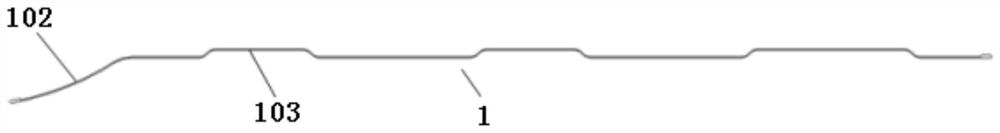

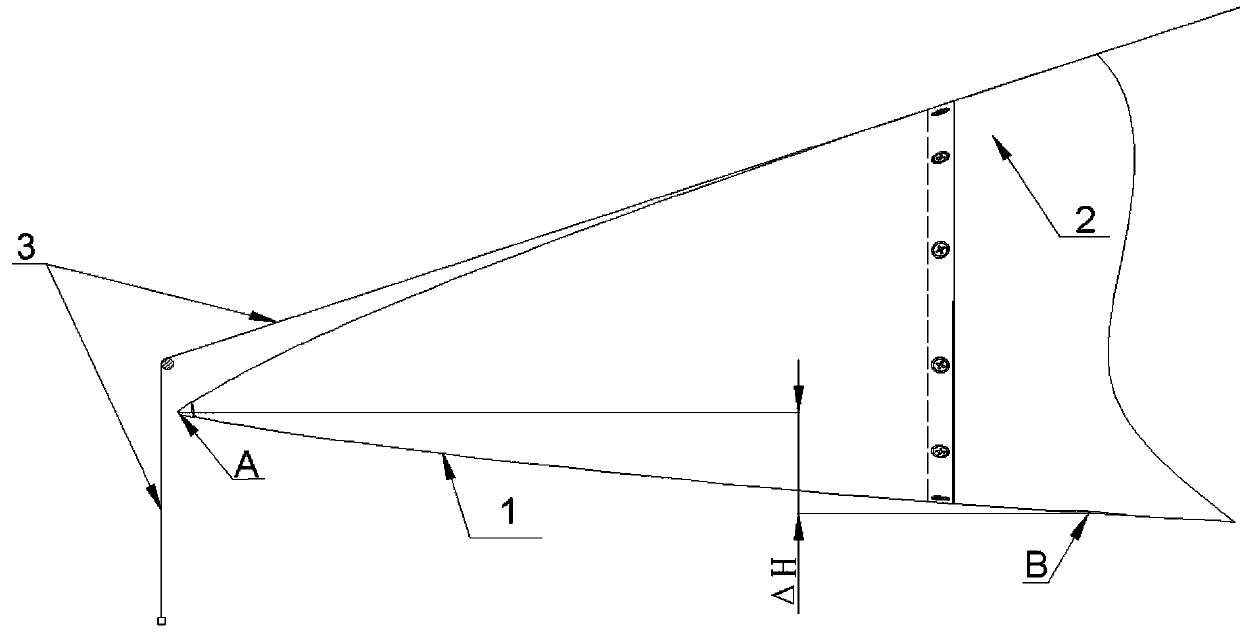

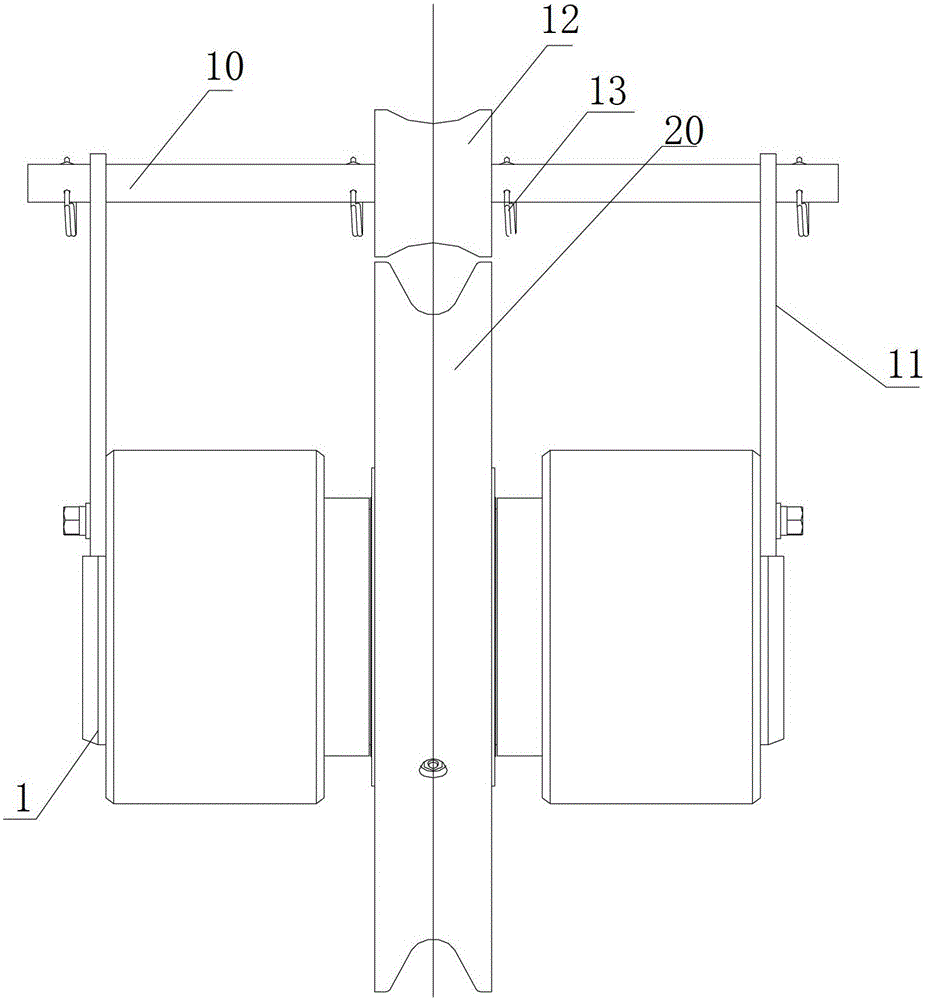

Cam conveying guide rail for doffer of ring spinning frame

The invention relates to a cam conveying guide rail of a ring spinning frame for collectively doffing. The cam conveying guide rail (2) is fixed on a supporting foot (12) through a second bolt (11) and a positioning sleeve (13), a yarn tube (10) is sleeved on a cam (1) which is arranged in an open groove of the cam conveying guide rail (2), a supporting claw (3) is connected with a transmission rod (4) and the cam (1), the transmission rod (4) is connected with a pulley (5), the lower part of the cam conveying guide rail (2) is provided with a first bolt (8), the first bolt (8) is provided with the pulley (5), two sides of the pulley (5) are provided with a first shaft sleeve (6) and a second shaft sleeve (7), and the end head of the first bolt (8) is provided with a nut (9). The cam conveying guide rail (2) is made of aluminum alloy. The shape of the upper part of the cam conveying guide rail (2) is an oblong open groove, and the shape of the lower part of the cam conveying guide rail is two hollow oblong support plates, so the cam conveying guide rail has the advantages of difficult deformation and convenient installation.

Owner:JINGWEI TEXTILE MASCH CO LTD

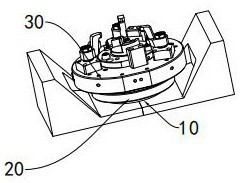

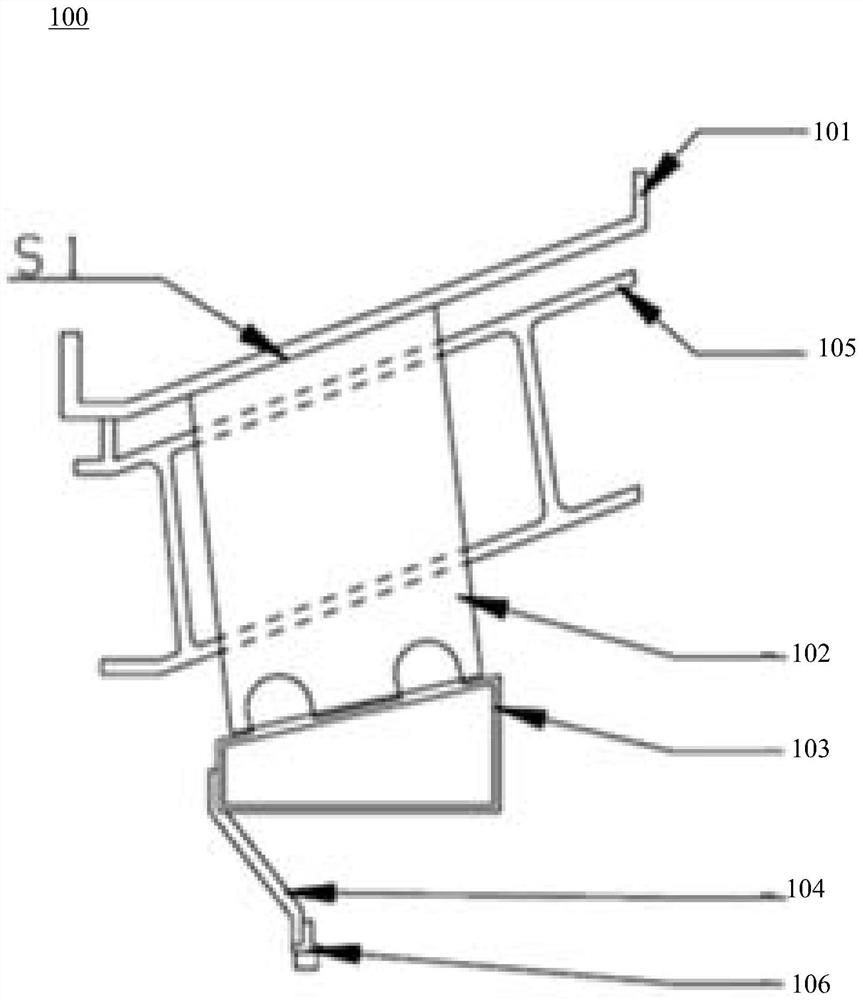

Clamp body positioning mechanism suitable for turning and milling combined machining center

ActiveCN113500432AEasy to assemble and disassembleEliminate radial positioning gapsAutomatic control devicesFeeding apparatusEngineeringMachine tool

The invention discloses a clamp body positioning mechanism suitable for a turning and milling combined machining center. The clamp body positioning mechanism comprises a transition disc fixed to a machine tool working table, a clamp body used for clamping a workpiece and a plurality of positioning assemblies between the transition disc and the clamp body, wherein the positioning assembly comprises a lower positioning sleeve located at the top of the transition disc and an upper positioning piece located at the bottom of the clamp body, the lower positioning sleeve comprises an annular positioning piece with a positioning hole and an elastic piece, and the elastic piece is located below the annular positioning piece; the hole wall of the positioning hole is an annular inner conical surface which is gradually inclined to the center from top to bottom; an arc-shaped inclined surface matched with the annular inner conical surface is arranged on the outer wall of the upper positioning piece; the upper positioning piece extends into the positioning hole of the lower positioning sleeve in a pluggable manner, and the annular inner conical surface and the arc-shaped inclined surface abut against each other to play a positioning role; an elastic force of the elastic piece drives the annular positioning piece to float up and down to change the matching position of the annular inner conical surface and the arc-shaped inclined surface, thereby adjusting the positioning precision.

Owner:IKD CO LTD

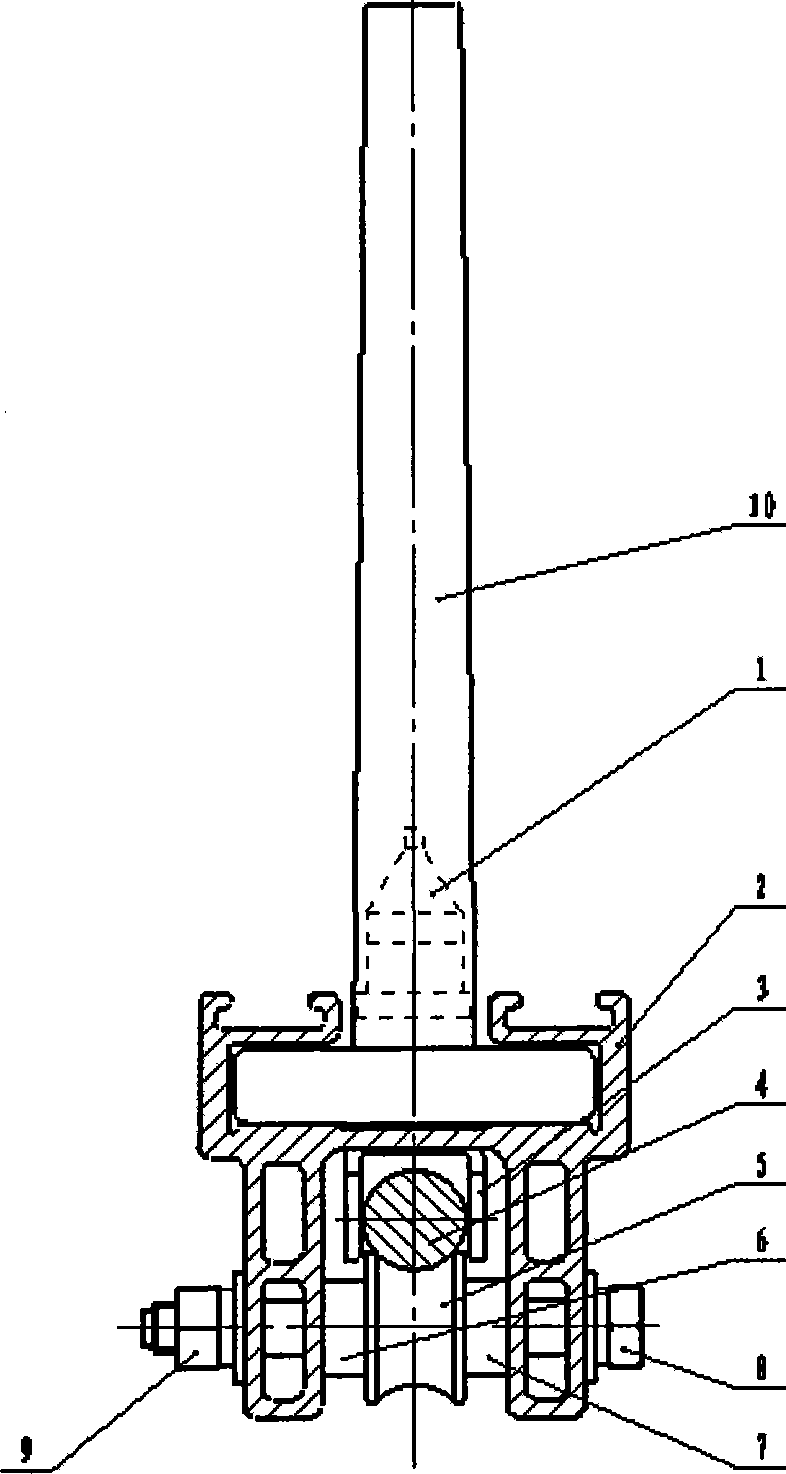

Machining method and device for ultra-long and ultra-thin sleeve parts

PendingCN114700505ASimple processing methodIncrease productivityTurning machinesTotal factory controlNumerical controlForce direction

The invention relates to the technical field of machining and clamps, in particular to a machining method and device for ultra-long and ultra-thin sleeve parts. According to the technical scheme, a turning machining mode is adopted, inner hole final machining is completed on a vertical numerical control lathe, outer circle final machining is completed on a horizontal numerical control lathe, the machining sequence is that the hole is machined first and then the outer circle is machined, a slotted sleeve is adopted for clamping in inner hole machining, and a thin-wall sleeve special device capable of changing the clamping force direction is adopted for outer circle machining. The machining of the ultra-long and ultra-thin sleeve type part is specifically completed through the three procedures of rough turning of an outer circle, turning of an inner hole and finish turning of the outer circle. The special device for the thin-wall sleeve is composed of an installation mandrel, a positioning sleeve, a pressing plate, a gasket and a pressing nut, and the clamping force direction is changed from the radial direction to the axial direction. The special device for the slotted sleeve and the thin-wall sleeve is adopted, so that the requirements for the size, the shape, the position precision and the surface roughness of the inner hole and the outer circle of the ultra-long and ultra-thin sleeve part are met. The method has the beneficial effects that the process method is simple and can be completed in one processing mode, and the production efficiency and the processing quality are high.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

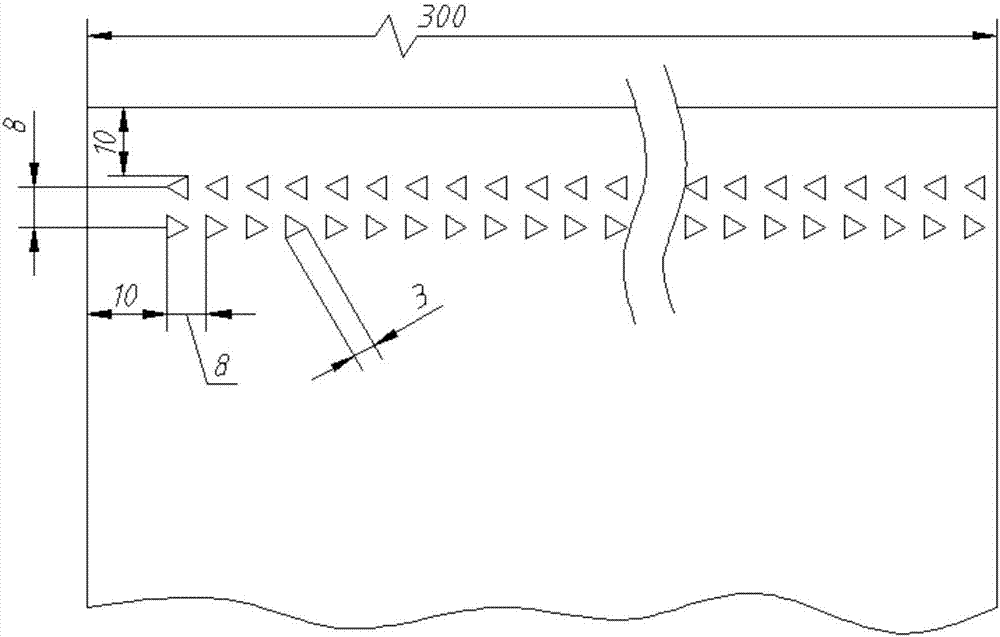

Method for stamping precisely porous bottom plate for sealing

The invention provides a method for stamping a precisely porous bottom plate for sealing. In the method, strips are acted by a press, so that an upper mold and a lower mold of a mold move mutually under the action of the strips, and when the strips are acted by the press, the bottom plate is stamped by the following steps of: 1, punching; 2, guiding; 3, guiding; 4, punching scraps; 5, idling; 6, idling; 7, punching scraps; 8, idling; 9, pre-punching; 10, pre-punching; 11, idling; 12, extruding; 13, idling; 14, extruding ribs; 15, idling; 16, idling; 17, performing fine punching; 18, idling; and 19, blanking. The method has the characteristics of high production efficiency, high dimensional accuracy, high quality consistency and the like, and the requirements of positional precision and surface roughness of bores on the bottom plate can be effectively met.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

Heat insulation plate, heat insulation plate mounting structure and vehicle

ActiveCN114135381AGuaranteed reliabilityImprove reliabilityExhaust apparatusSilencing apparatusEngineeringMechanical engineering

The invention relates to a heat insulation plate, a heat insulation plate mounting structure and a vehicle. The heat insulation plate comprises a heat insulation plate body, mounting parts are arranged on the left side and the right side of the heat insulation plate body, the mounting parts are of a double-layer structure formed by flanging the edge of the heat insulation plate body, and a flow guide part is formed on the front side of the heat insulation plate body and used for conducting flow guide on flowing-through gas and reducing the acting force of the gas on the exterior of the heat insulation plate. The invention further provides a heat insulation plate mounting structure which comprises the heat insulation plate. The invention further provides a vehicle which comprises the heat insulation plate mounting structure. The heat insulation board solves the problems that an existing heat insulation board is poor in reliability of installation points, the installation points are cracked, the strength is not enough, and then the heat insulation board falls off.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

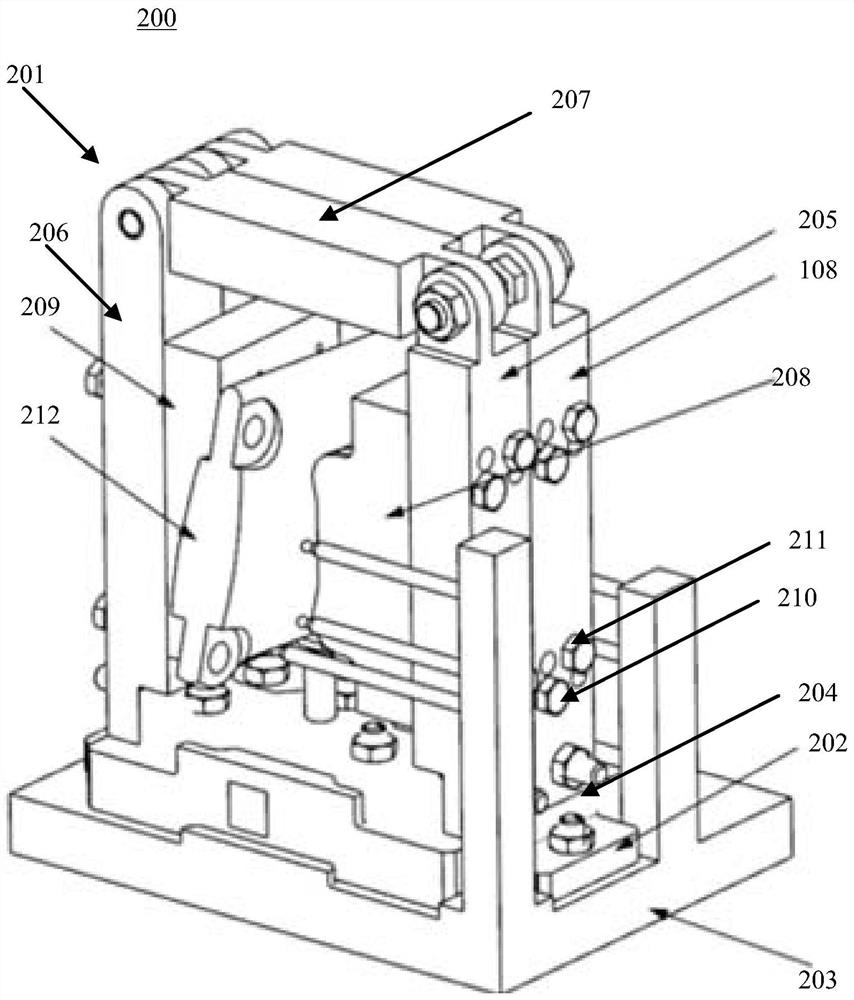

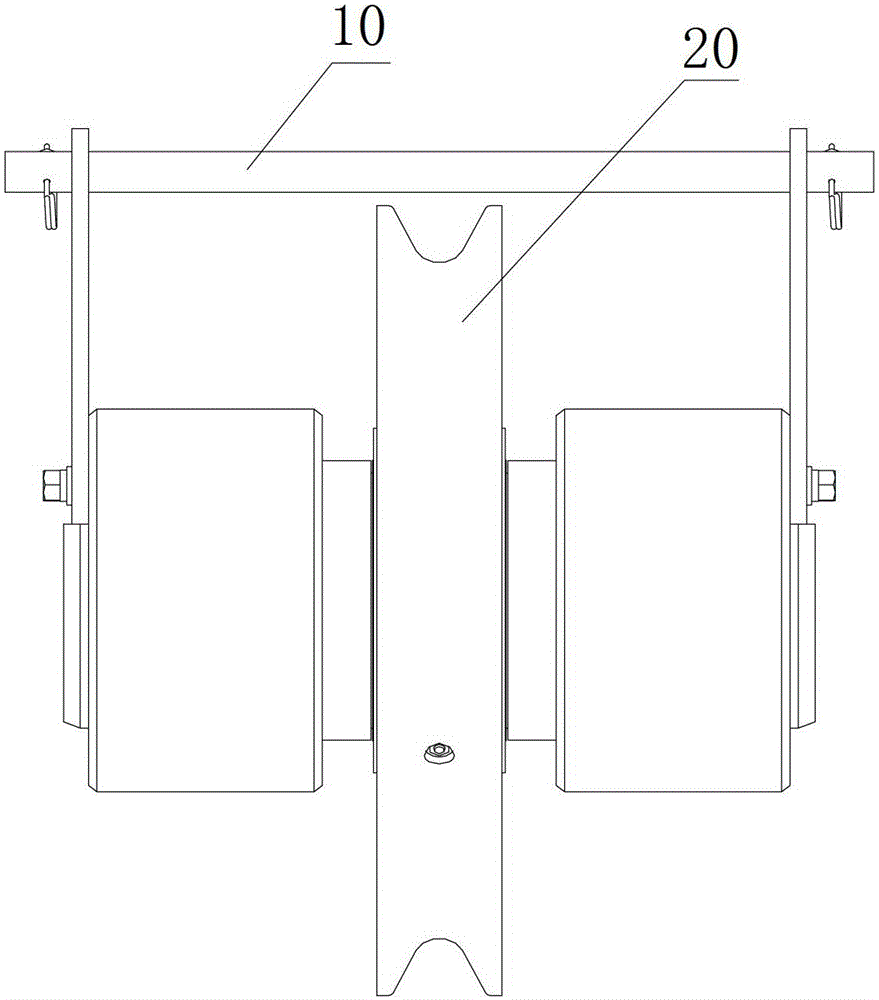

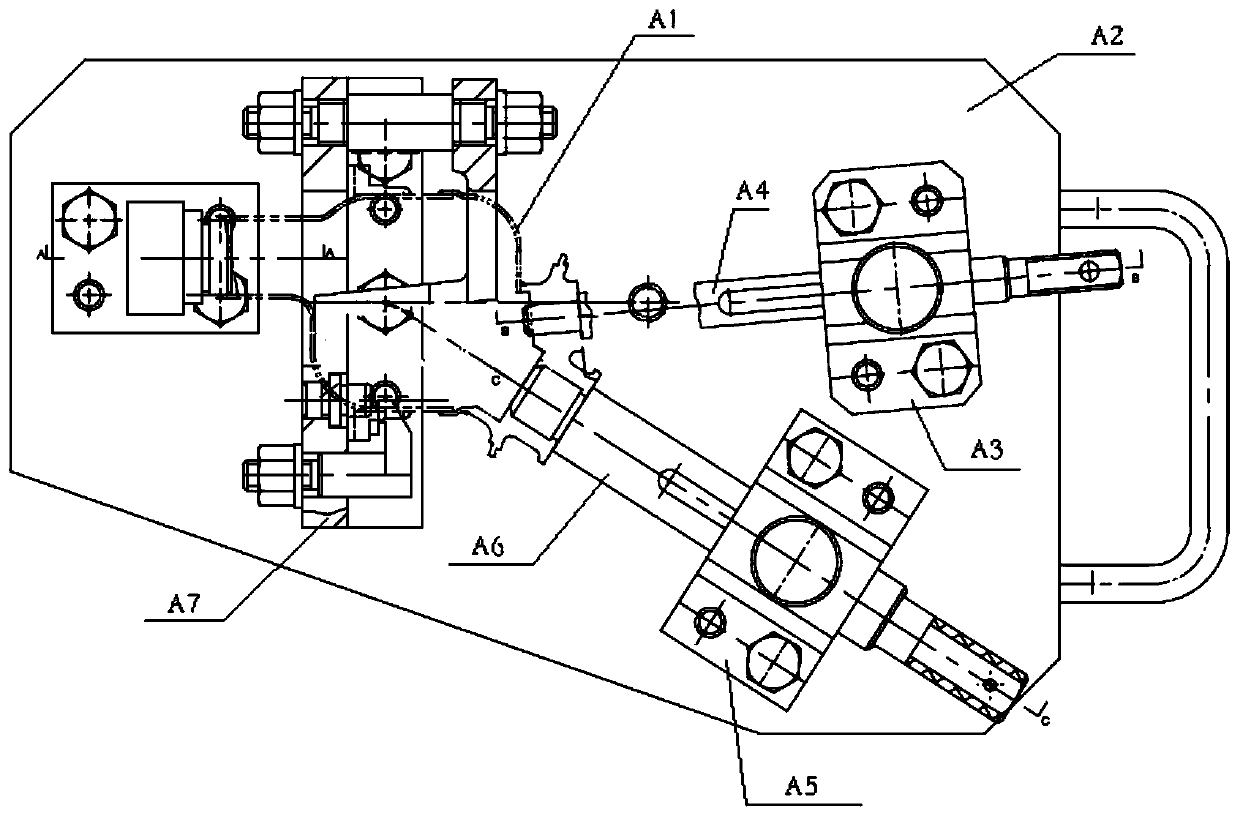

Combined machining tool and combined machining method for force bearing support plate

ActiveCN113770428AReduce the number of toolingImprove processing efficiencyMilling equipment detailsPositioning apparatusMachining processStructural engineering

The invention relates to a combined machining tool and a combined machining method for a force bearing support plate. The combined machining tool comprises at least two sets of clamping tools, wherein each set of clamping tool comprises a base, a first stand column, a second stand column, a cross beam, a first shape follow-up clamping block and a second shape follow-up clamping block; the first stand columns and the second stand columns are vertically and oppositely arranged on the bases; the two ends of the cross beams are fixedly arranged at the tops of the first stand columns and the tops of the second stand columns correspondingly; and the first shape follow-up clamping blocks and the second shape follow-up clamping blocks are oppositely arranged on the inner sides of the first stand columns and the inner sides of the second stand columns and used for clamping the two sides of the force bearing supporting plate. According to the combined machining tool and the combined machining method for the force bearing supporting plate provided by the invention, the positioning requirement and the rigidity requirement of the force bearing supporting plate in the machining process can be met, the number of tools is reduced, and the machining efficiency is improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

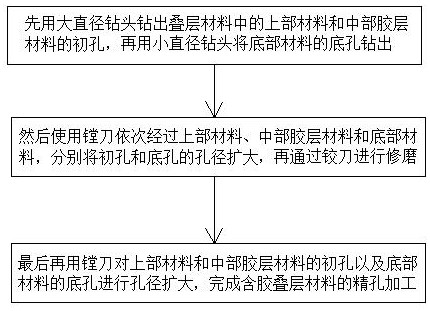

Precise hole machining method for glue-containing laminated material

The invention discloses a precise hole machining method for a glue-containing laminated material, and belongs to the technical field of aerospace part preparation. The precise hole machining method is characterized by comprising the following steps that a, primary holes of an upper material and a middle rubber layer material in the laminated material are drilled by using a large-diameter drill bit, and then a bottom hole of a bottom material is drilled by using a small-diameter drill bit; b, a boring cutter sequentially passes through the upper material, the middle rubber layer material and the bottom material, the hole diameters of the primary holes and the bottom hole are enlarged correspondingly, and then grinding is conducted through a reamer; and c, finally, hole diameter expansion is conducted on the primary holes of the upper material and the middle rubber layer material and the bottom hole of the bottom material through the boring cutter, and fine hole machining of the rubber-containing laminated material is completed. According to the precise hole machining method, through cooperative use of the boring cutter and the reamer, machining correctness and machining efficiency of the holes in the different materials can be guaranteed, and the position precision and aperture precision requirements of the holes are guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

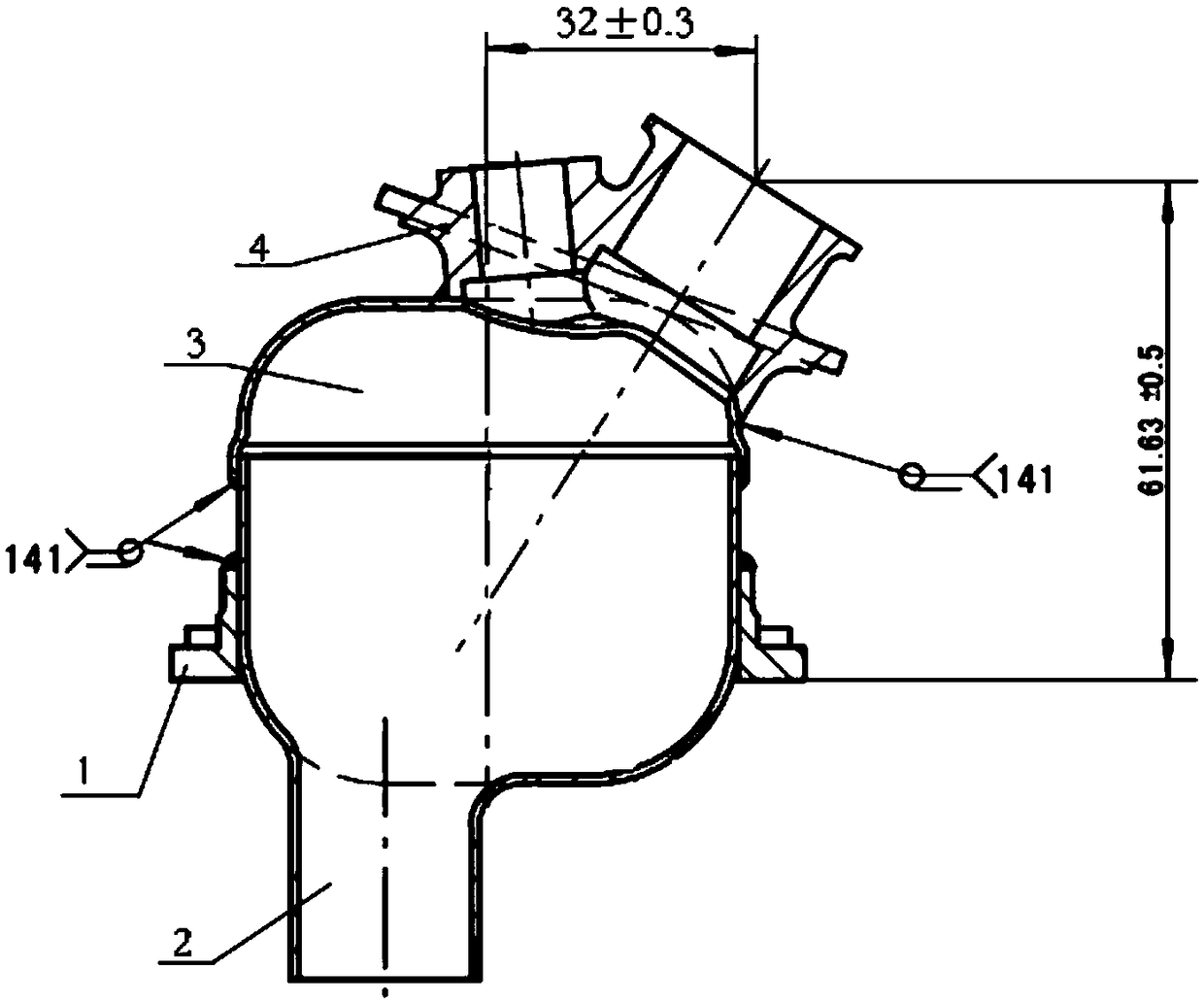

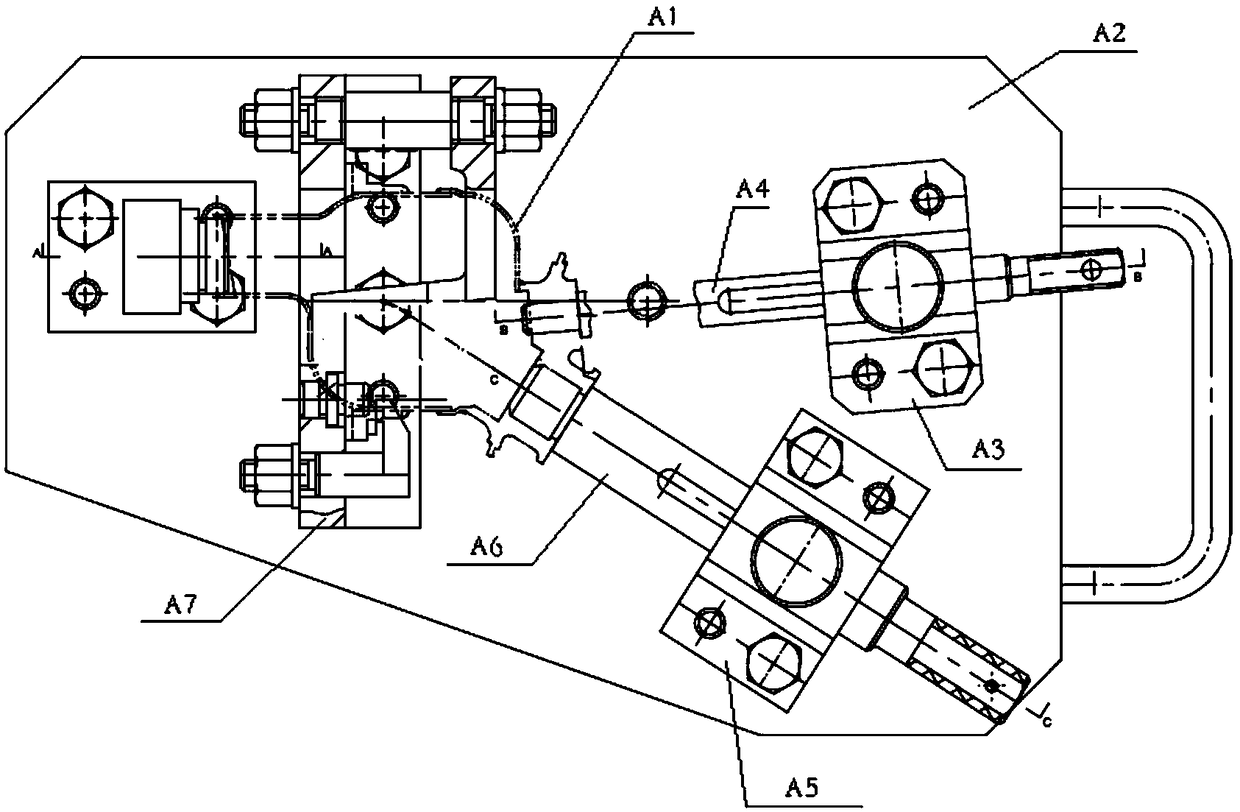

Welding positioning device for vehicle front air storage cylinder assembly

InactiveCN109531010AImprove welding process qualityGuaranteed location sizeWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses a welding positioning device for a vehicle front air storage cylinder assembly. The welding positioning device comprises a base, a first positioning seat, a second positioningseat, a third positioning seat, a fourth positioning seat, a fifth positioning seat, a sixth positioning seat, a seventh positioning seat and an eighth positioning seat; and all the positioning seatsand the base are positioned through mounting positioning pins, then all the positioning seats are connected with the base through bolts and nuts, the first positioning seat is arranged on one side ofthe base, the second positioning seat is arranged in the middle of the base, a first positioning face used for being positioned with the end face of one side of a cylinder body of a front air storagecylinder is arranged on the top face of the first positioning seat, the second positioning seat is connected with an upper plate, the upper plate is connected with a first positioning pin and a secondpositioning pin, and a second positioning face used for positioning the horizontal mounting face of a front tow hook is arranged on the top face of the upper plate. According to the welding positioning device, all parts of the front air storage cylinder assembly can be fixed conveniently, the precision requirements of the position and the size can be met during welding, welding is convenient, andthe time and labor are saved.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

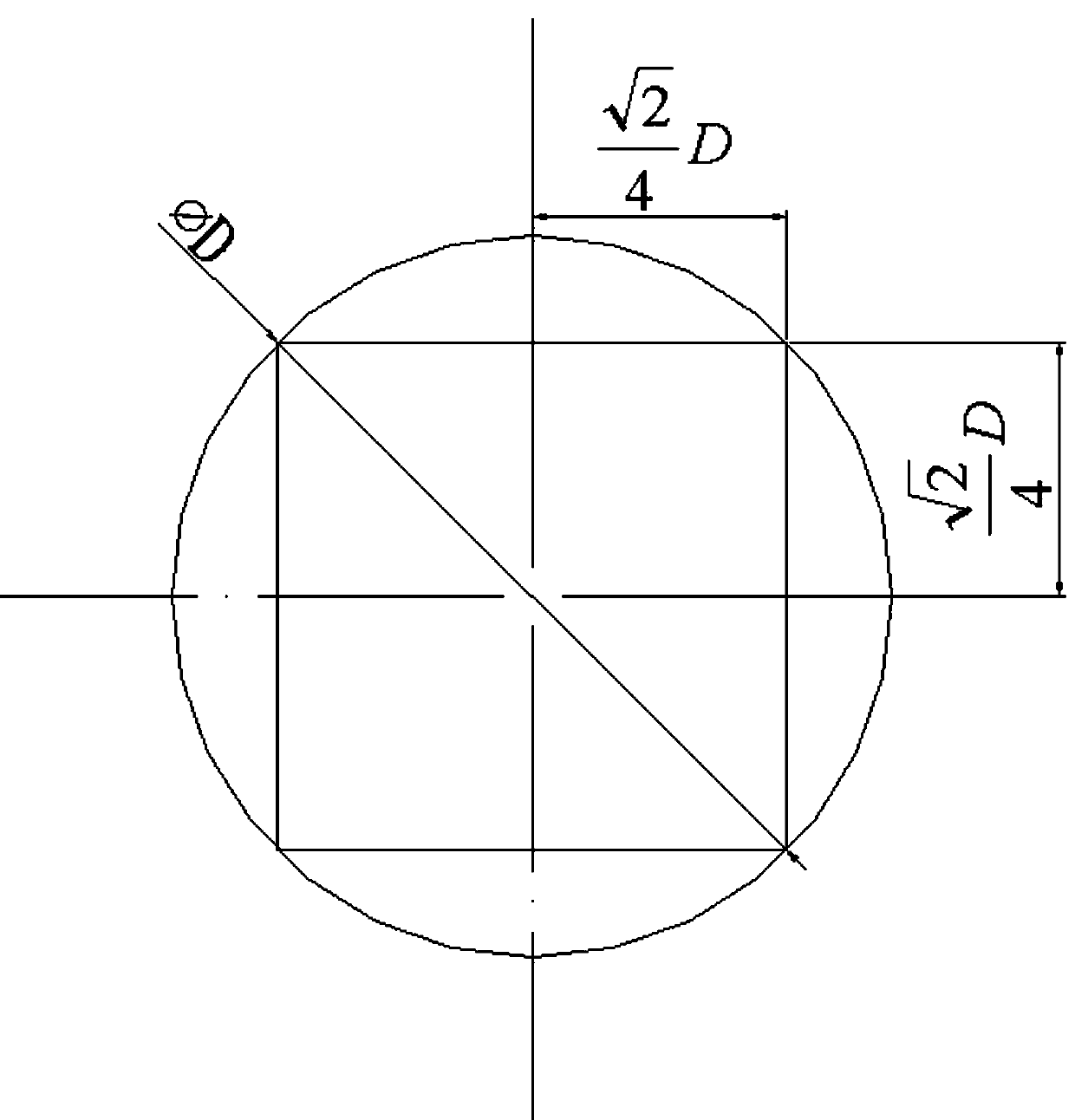

Radar-dome positioning method without special tooling

InactiveCN107917703AGuaranteed Position RequirementsSolve the problem of not being able to use tooling for positioningSurveying instrumentsAircraft assemblySharp pointAirplane

The invention relates to a radar-dome positioning method without a special tooling, and belongs to methods for positioning aircraft radar-domes outside frames. The back of a radar-dome sleeves a frameplate of a body and is fixed relative to the position of an aircraft, and coaxiality of the radar-dome relative to a theoretical axis is only related to deviation of the tip of the radar-dome relative to a theoretical position, so that a sharp point of the radar-dome can meet positioning requirements within a circle taking a theoretical center as a circle center and with the diameter of phi D. The positioning requirements of the radar-dome can be met outside the frames without the special tooling.

Owner:JIANGXI HONGDU AVIATION IND GRP

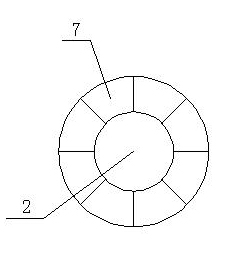

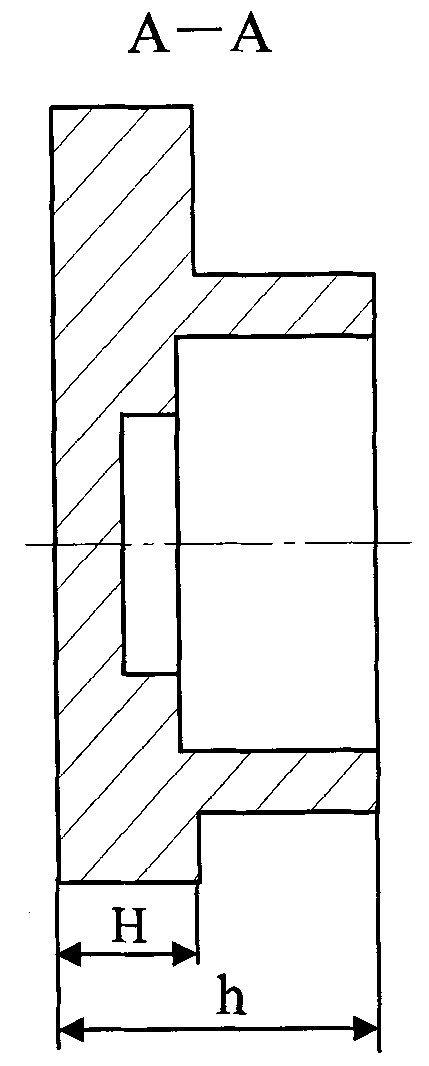

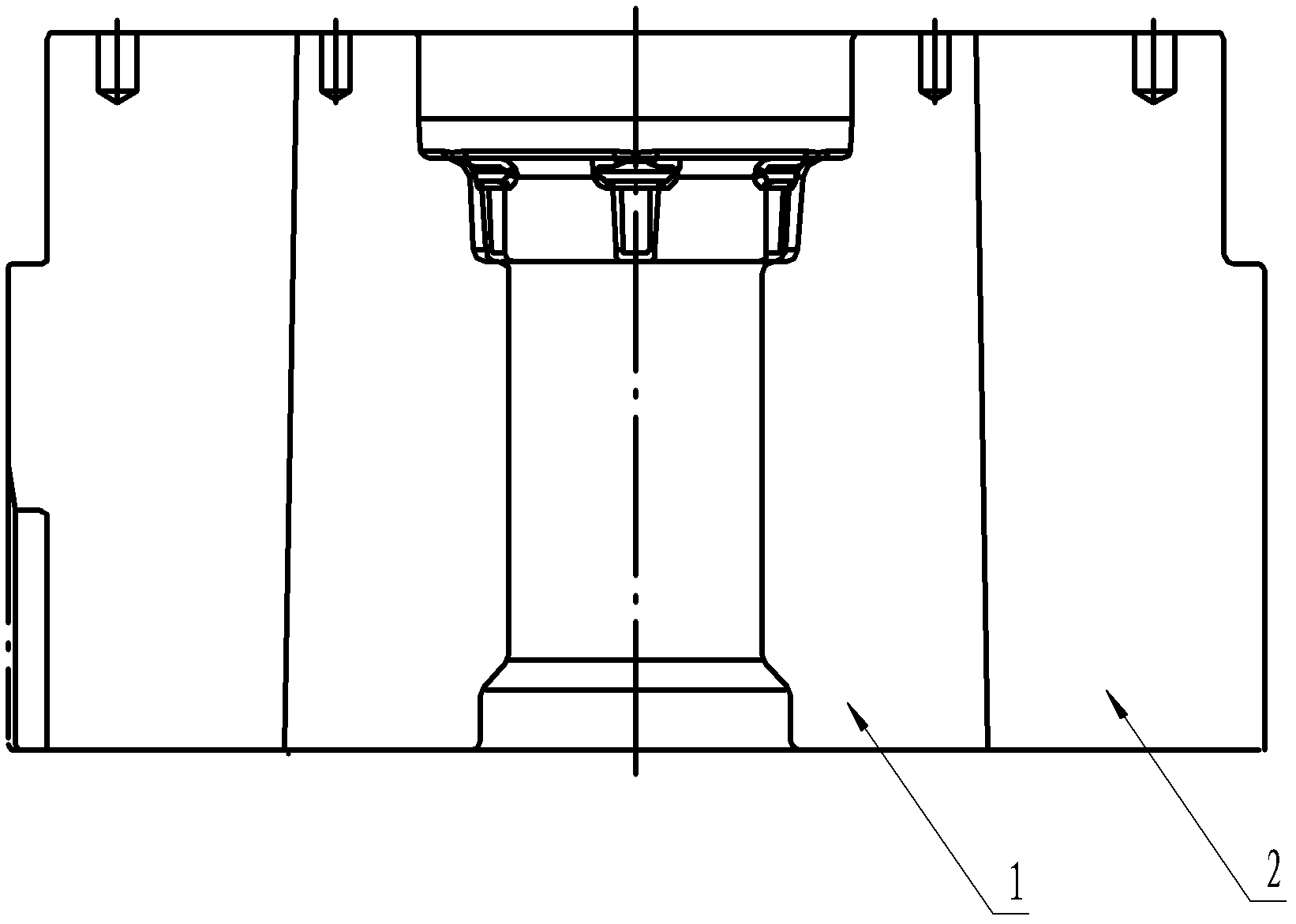

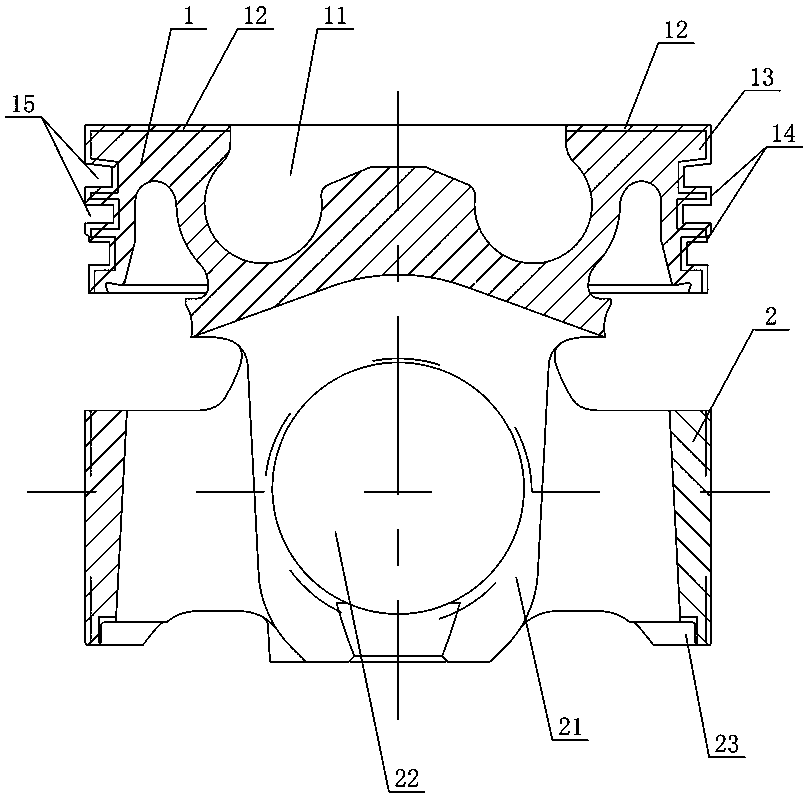

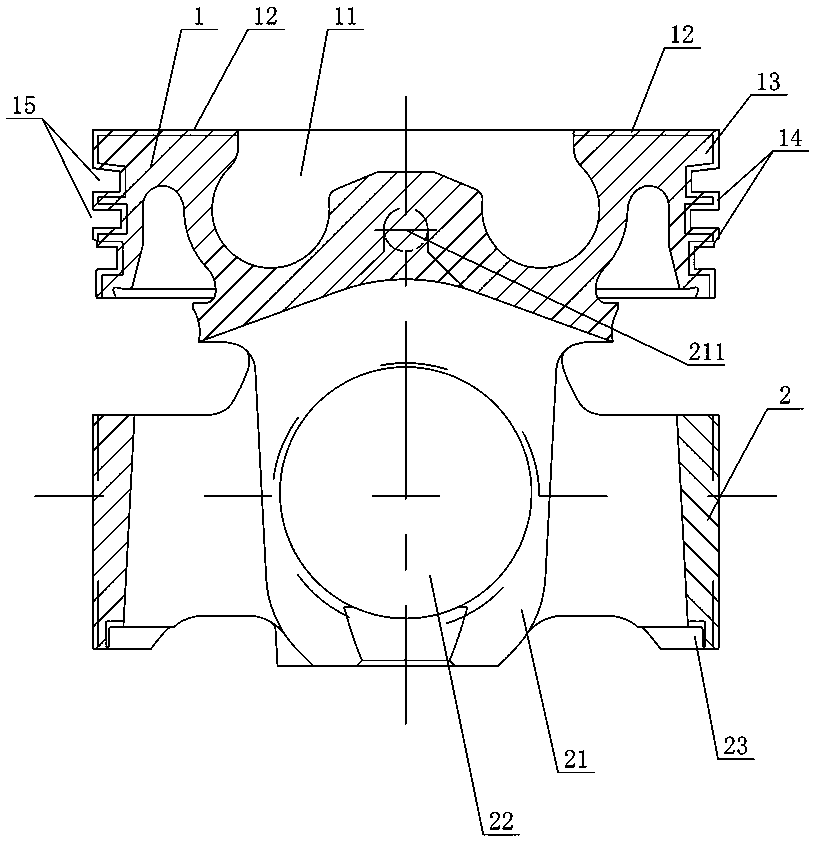

Large-diameter die with requirements on positions of inner ring and outer ring and processing method thereof

ActiveCN102335707BShorten production timeReduce investmentForging/hammering/pressing machinesMetal working apparatusEngineeringProcessing cost

The invention discloses a large-diameter die with the requirements on the positions of an inner ring and an outer ring and a processing method thereof, the die comprises the inner ring, the outer ring and a key slot, wherein the key slot is annularly formed on the periphery of the outer ring, and the die is characterized in that positioning pin holes which are consistent with the requirements on the position degree are respectively increased on the inner ring and the outer ring of the die, the axial lines of the positioning pin holes of the inner ring and the outer ring and the reference are interrelated on the same central plane, and the reference is the central line of the key slot. The processing method of the die comprises the following steps of: processing the outer ring and the inner ring separately, then performing press-fitting, respectively increasing the positioning pin holes which are interrelated with the reference on the inner ring and the outer ring of the die, using a clamp to well set the positions by utilizing the pin holes and further performing the press-fitting, wherein the axial lines of the positioning pin holes of the inner ring and the outer ring and the reference are interrelated on the same central plane and the reference is the central line of the key slot. By adopting the die, the complex shape of an inner cavity and the requirements on the position of the positioning reference of the outer ring can be ensured; simultaneously, the die is low in processing cost and high in processing efficiency, and can overcome the deficiencies in the prior art and meet the requirements of mass production.

Owner:JIANGSU SUNWAY PRECISION FORGING

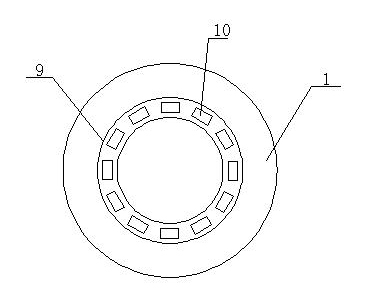

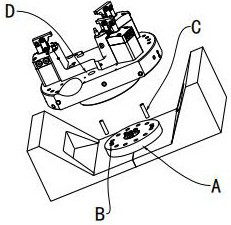

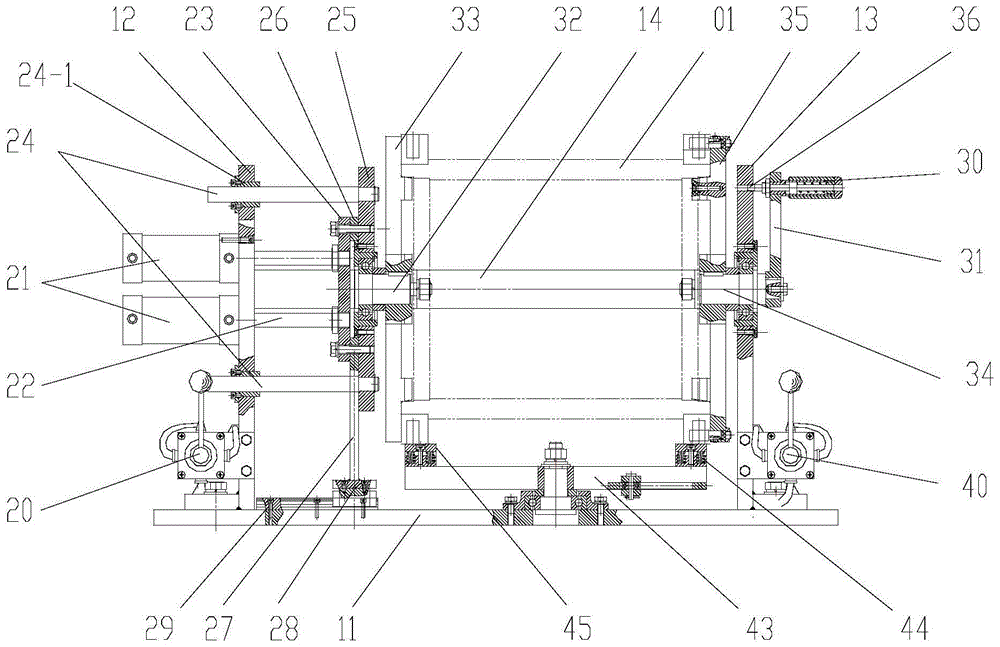

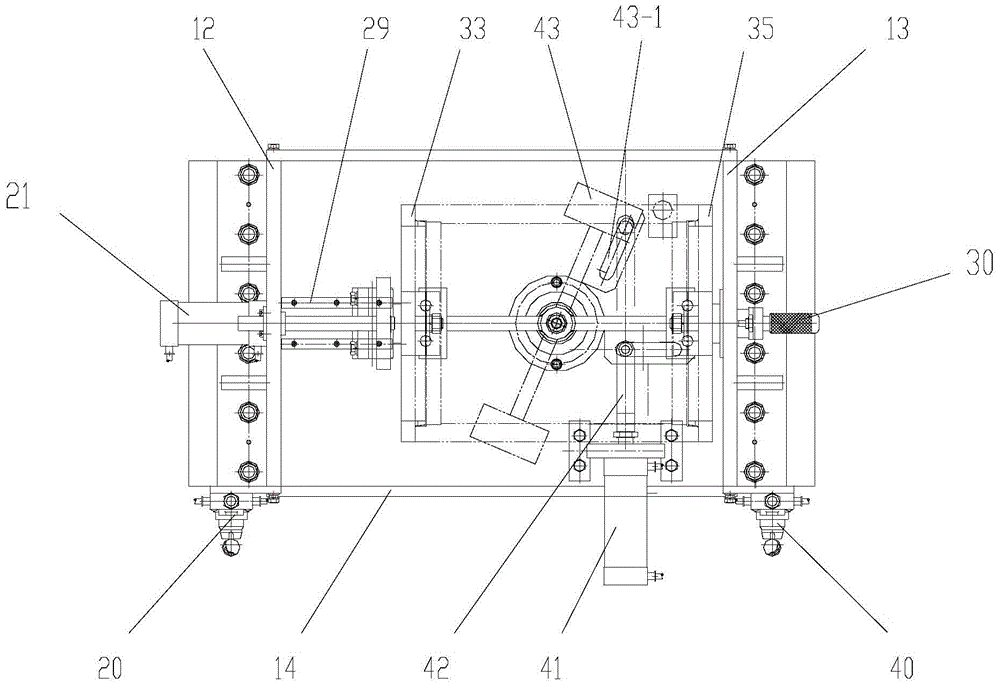

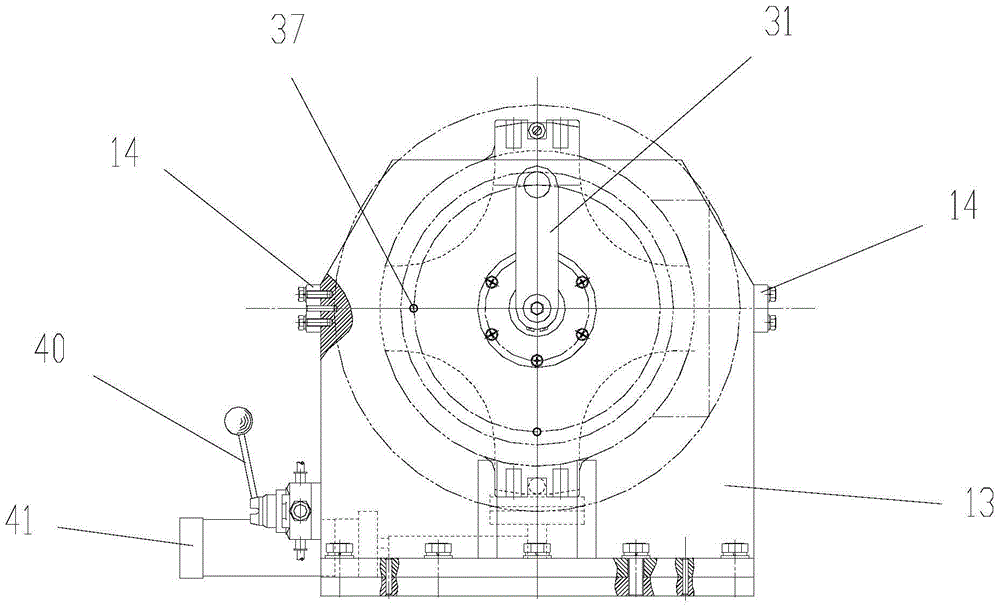

Rotary motor casing processing fixture

ActiveCN105215747BImprove efficiencyHigh precisionWork clamping meansPositioning apparatusEngineeringAlloy

The invention relates to a rotating motor casing machining tool fixture. The rotating motor casing machining tool fixture is characterized by comprising a tool frame mechanism, an axial clamping mechanism, a rotating mechanism and a bottom support mechanism, wherein the axial clamping mechanism and the bottom support mechanism are respectively connected with the tool frame mechanism; the rotating mechanism is connected with the axial clamping mechanism; a left support plate and a right support plate of the tool frame mechanism are fixed through a pull belt; the axial clamping mechanism axially fastens a casing workpiece; left and right rotating shafts of the rotating mechanism are pinned with left and right clamping plates, and are supported on the axial clamping mechanism through bearings; and the bottom support mechanism upwards supports the casing workpiece. The rotating motor casing machining tool fixture has the following beneficial effects: the axial clamping and the vertical support of an aluminum alloy motor casing are both driven by a cylinder, so that the clamping time is shortened; the pressure control is realized through a pressure adjusting valve to prevent the deformation of a clamped aluminum alloy; and the rotating mechanism realizes once clamping of an aluminum alloy motor casing, and can perform the multi-angle surface milling, drilling and tapping machining for the surface of the casing to improve the production efficiency.

Owner:中色创新研究院(天津)有限公司

High-precision permanent magnet seat grinding method

InactiveCN102284893BImplement benchmark conversionImprove consistencySeat surface grinding machinesEngineeringGrinding wheel

The invention belongs to a processing technology for a precision component made of special material, and relates to a processing method for high-precision benchmark conversion of parts made of soft magnetic alloy. An auxiliary positioning tool is arranged, and the problem of mutual verticality of a plurality of surfaces can be solved; a high-precision benchmark block is matched for conversion of measurement benchmarks, and the problem that actual processing dimensions cannot be determined easily can be solved; the tool is adopted for conversion of the processing benchmarks, a processing supply terminal is arranged, and the defects that each part needs to be centered and measured each time when being processed can be overcome; and moreover, magnetic weakening can be avoided through optimizing processing parameters and selecting reasonable sand wheels and cooling methods. Compared with the conventional processing method, the problems of the traditional method that the parts cannot be clamped and positioned easily and need to be clamped and centered multiple times during processing can be solved; high position accuracy and dimensional accuracy of side faces can be guaranteed at the same time; and the processing efficiency can be increased greatly, good dimensional consistency can be maintained, and the processing quality can be stabilized.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

A new type of steel wire rope gear

Owner:XCMG CONSTR MACHINERY

Method and fixture for controlling welding deformation of igniter

ActiveCN109352241BGuaranteed Position RequirementsAvoid interferenceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses a method and fixture for controlling welding deformation of an igniter. A technological threaded hole used for clamping is added in a large joint inner cavity of a boss of theigniter, a hole is designed in the middle part of a traditional positioning bolt, then, the boss is tensioned by employing a screw, so that the boss is fixed onto the bolt, and then, the boss not onlyis positioned but also is clamped; a square hole is formed in a suitable position of a fixture body corresponding to a welding seam, so that a welding gun is prevented from interfering with the fixture body, and an assembly is welded under a rigid constraint state; and a part welding way is changed, i.e., a part is changed into a vertical state from a horizontal state, so that the phenomenon thata welding pool of the welding seam sags due to self gravity to form excrescences making connection unreliable in the inner cavity is avoided.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Cam conveying guide rail for doffer of ring spinning frame

Owner:JINGWEI TEXTILE MASCH CO LTD

Eccentric jacking positioning mechanism

InactiveCN104355212ATo satisfy the market's needsSolve the problem of positioning processingEscalatorsArchitectural engineeringStructural engineering

Owner:SUZHOU XINDA ESCALATOR ACCESSORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com