Method for casting butterfly valve body

A technology of butterfly valve and inner core, which is applied in the casting field of butterfly valve body, which can solve the problems of difficulty in guaranteeing the shrinkage ratio of molten steel, lower valve sealing performance, poor corrosion resistance and poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

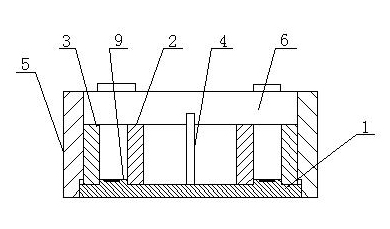

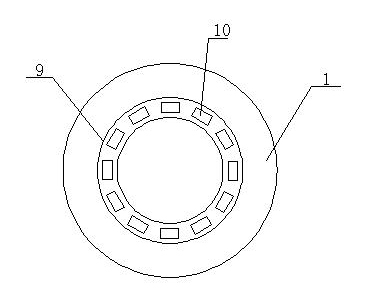

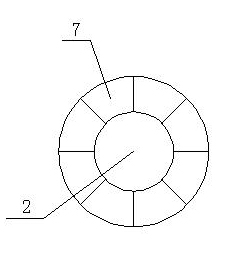

[0034] Step 1. Make the inner core structure: the annular inner core is composed of multiple fan-shaped inner core boxes,

[0035] The inner core box uses sodium silicate sand as raw material. After the mold for making the inner core box is fixed, a plurality of cold irons are evenly arranged in the mold groove. The number of cold irons is reasonably determined according to the working area of the inner core box. Fill the mold groove with glass sand. After the surface is flattened, insert the nozzle with carbon dioxide gas into the mold groove. After 2 minutes, the carbon dioxide gas and water glass sand fully react and the water glass sand hardens. Remove the mold and the sand blank is completed. For future use; apply zircon powder coating on the working surface of the molded sand blank with a thickness of 1.5 mm, and ignite it at room temperature until it goes out naturally; finally use a liquefied gas spray gun to bake the working surface of the sand blank at a temperature...

Embodiment 2

[0042] Embodiment two: the casting method of butterfly valve valve body, it is characterized in that: concrete steps are as follows:

[0043] Step 1. Making the inner core: After fixing the mold for making the inner core box, set the cold iron evenly in the mold groove, then fill the mold groove with water glass sand, level the surface of the water glass sand, and insert the vent pipe into the mold groove , inject carbon dioxide gas, stop the ventilation after 3 minutes, remove the mold, and prepare the sand blank for use; apply zircon powder coating on the working surface of the sand blank, and the thickness of the coating is 2.5 mm, and ignite the sand blank at room temperature until it is naturally Extinguished; finally use a spray gun to bake the working surface of the sand blank, the baking temperature is 1200 ℃, and the baking time is 3 minutes; repeat the process of applying paint, lighting and baking in this step twice, and make a single inner core box After completion...

Embodiment 3

[0049] Embodiment three: the casting method of butterfly valve valve body, it is characterized in that: specific steps are as follows:

[0050] Step 1. Making the inner core: After fixing the mold for making the inner core box, set the cold iron evenly in the mold groove, then fill the mold groove with water glass sand, level the surface of the water glass sand, and insert the vent pipe into the mold groove , inject carbon dioxide gas, stop the ventilation after 2.5 minutes, remove the mold, and prepare the sand blank for use; apply zircon powder coating on the working surface of the sand blank, and the coating thickness is 2 mm, and ignite the sand blank at room temperature until it is naturally Extinguished; finally use a spray gun to bake the working surface of the sand blank, the baking temperature is 1000 ℃, and the baking time is 3 minutes; repeat the process of applying paint, lighting, and baking 3 times in this step, and make a single inner core box After completion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com