Method for machining deep hole

A deep hole and processing drilling technology, which is applied in the direction of metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of deep hole position deviation, uneven size, drill bit vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

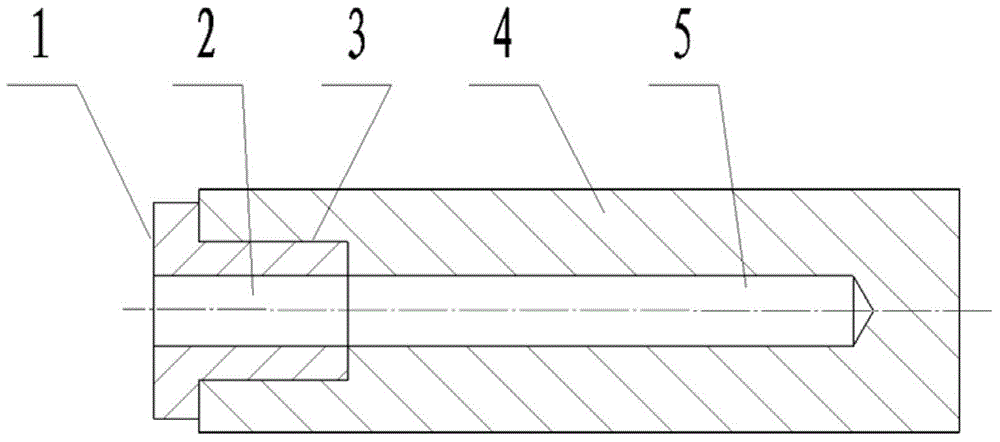

[0011] See attached figure 1 As shown, the method for processing deep holes is characterized in that: the steps of the method are:

[0012] The first step is to process the drill sleeve hole, and the drill sleeve hole 3 is processed at the center position of the part 4 to be processed where the deep hole 5 needs to be processed;

[0013] The second step is to insert a drill sleeve, add a drill sleeve 1 and install it in the drill sleeve hole 3, the diameter of the central hole 2 of the drill sleeve 1 is the same as that of the deep hole 5;

[0014] The 3rd step, drill deep hole, drill deep hole 5 to required depth by the center hole 2 of drill bushing 1 with the extension drill bit.

[0015] Compared with the prior art, the technical solution of the present invention has a certain guide and fixation effect on the drill bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com