Male and female inlaid mould, mould and system for sol-gel (SG) abrasive material microreplication forming hole

A technology of micro-replication and forming holes, which is applied in the field of pressure processing, can solve the problems of reducing the radius of the inner fillet of the processing hole and poor accuracy retention, and achieve the effects of reducing processing costs, reducing deformation, and simple and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

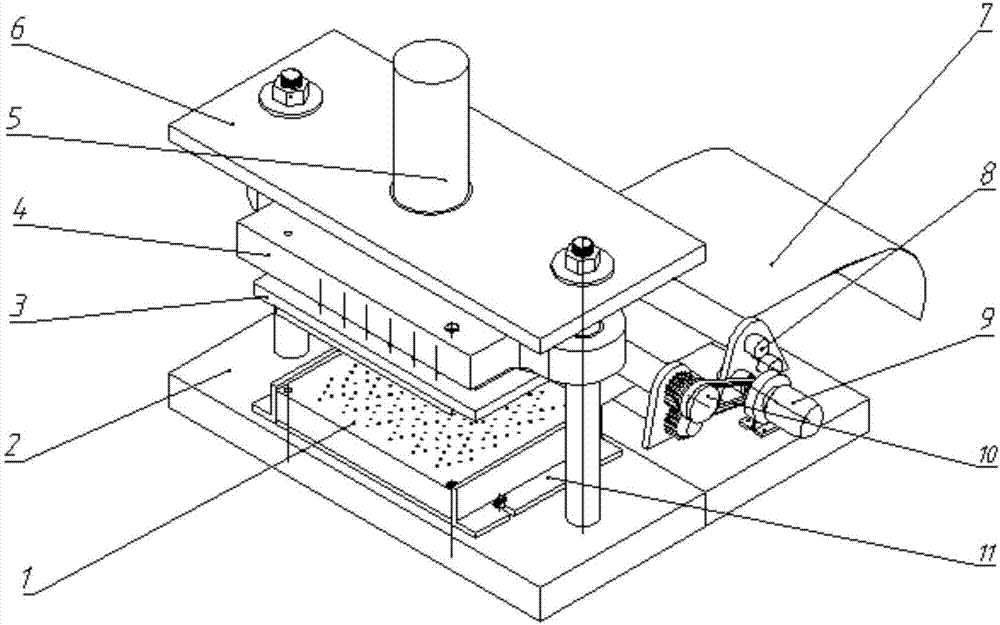

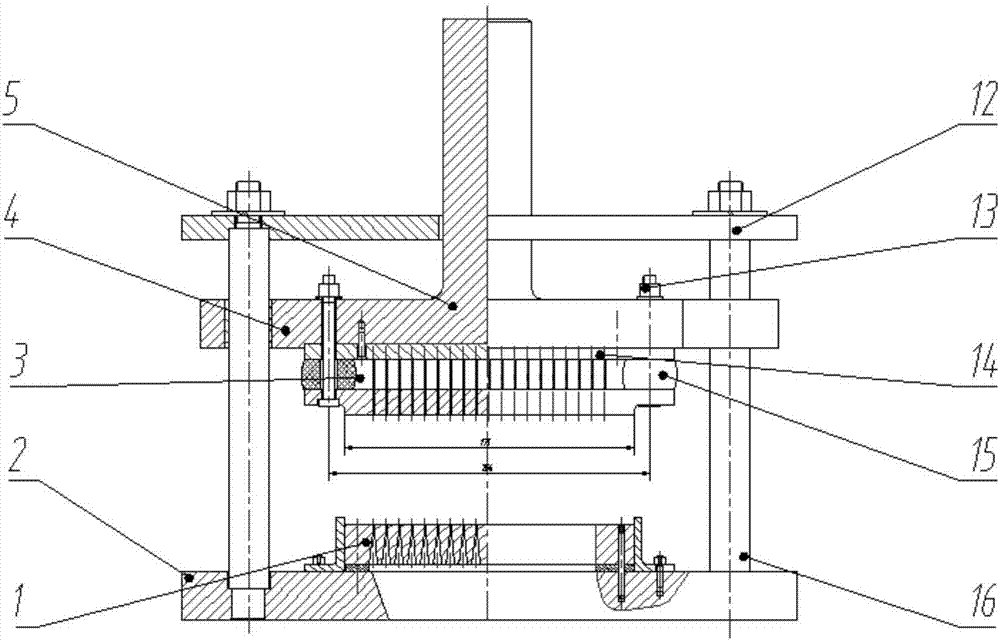

[0050] According to the characteristics of large production batches of blanking parts, high requirements for material utilization, and high requirements for shape accuracy of blanking parts, it can be seen from the "Stamping Die Practical Manual" that the edge value of processing stainless steel 304 is ≥ 2.8mm. If the layout overlap value does not meet the requirements, it will easily lead to material deformation and damage, and the problem of punch processing and manufacturing should be considered in the design.

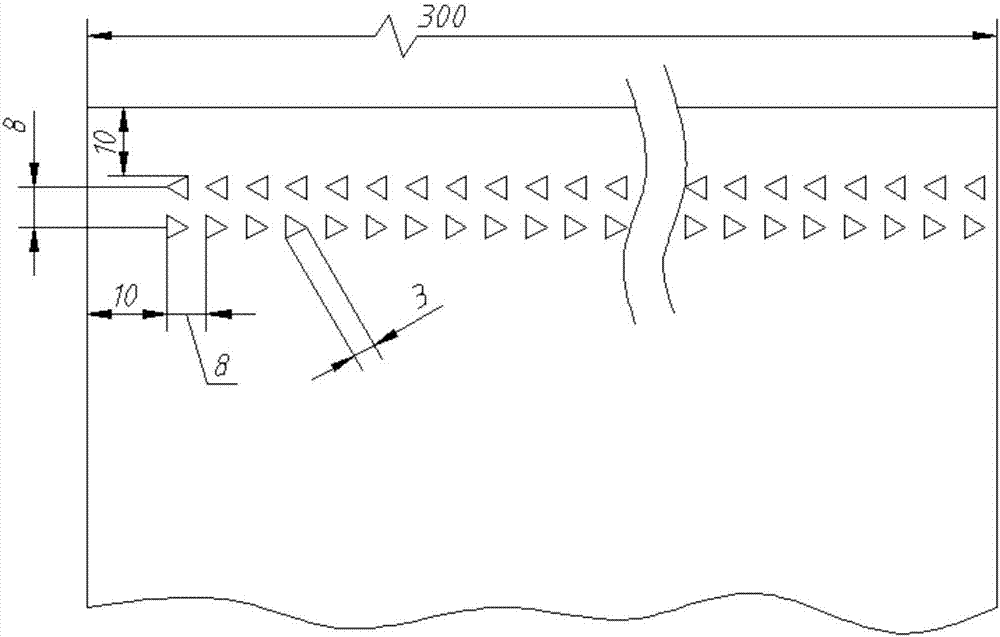

[0051] Due to the small size of the punch, the stripper has the function of protecting the punch and guiding at the same time. In order to facilitate replacement, the punch is designed as an insert structure, and the material is cold work die steel (C r 12MoV), fixed by screws and positioned by positioning pins. The width of the plate is 300mm, the thickness is 0.5mm, and the material is 304 stainless steel. The chamfer produced by stamping is required to be as sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com