Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166results about How to "Good lithography performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photoresist composition for deep ultraviolet lithography comprising a mixture of photoactive compounds

InactiveUS6991888B2Reduce edge roughnessAcceptable photosensitivityOrganic chemistryOrganic compound preparationResistUltraviolet

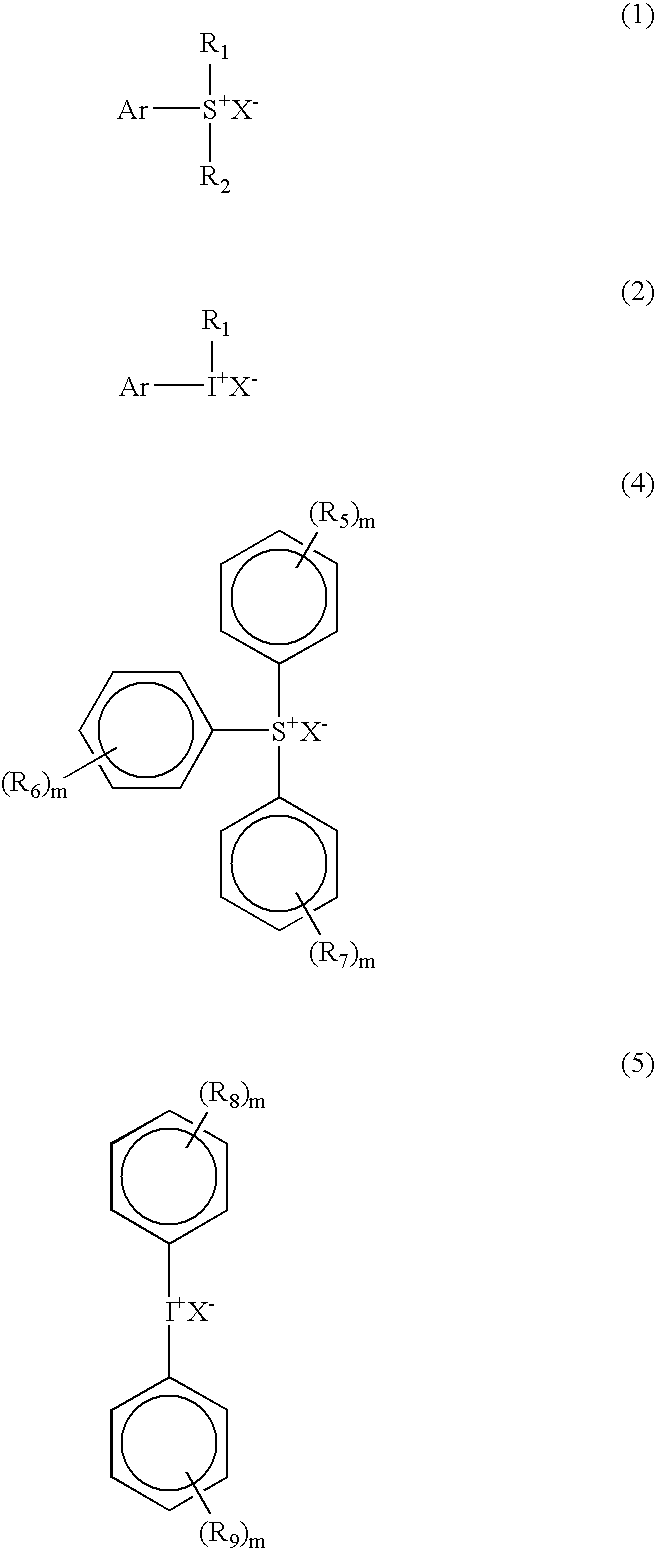

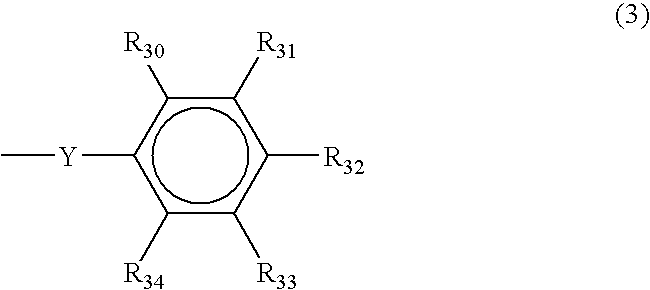

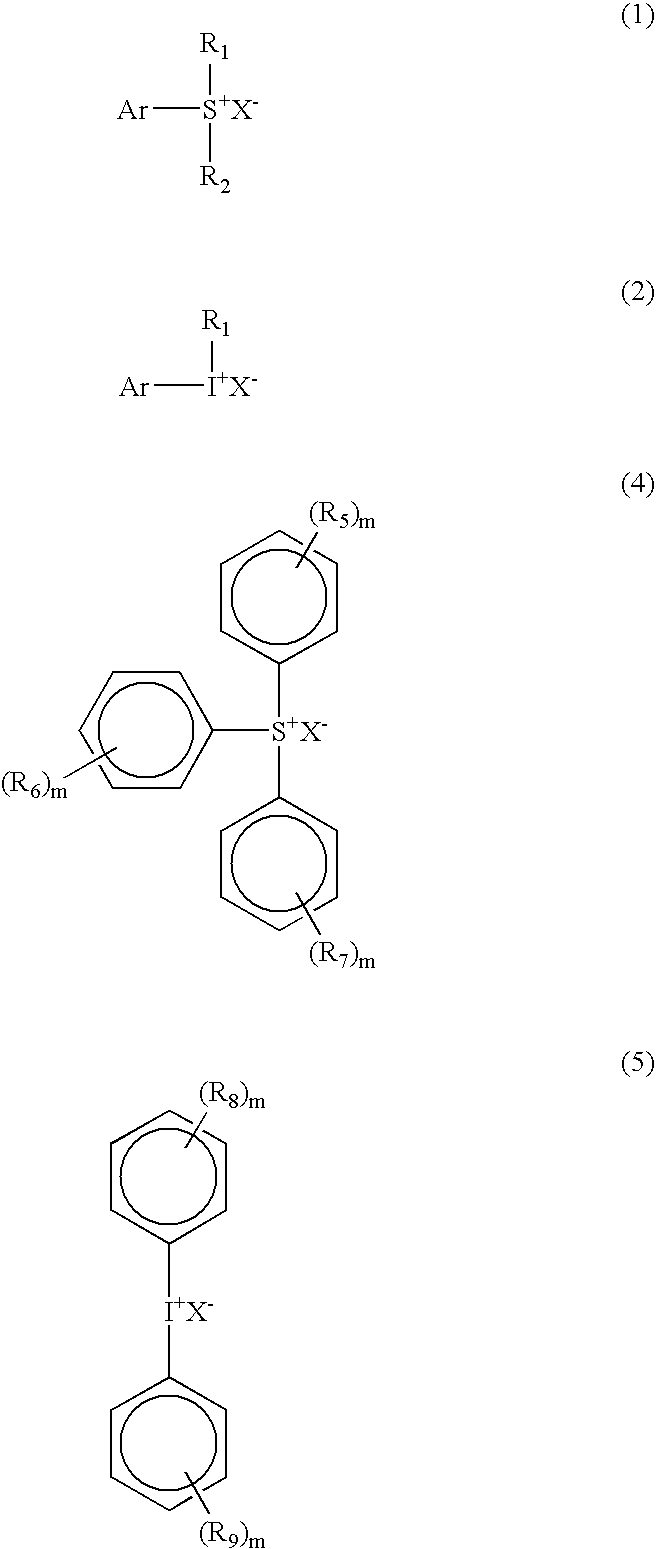

The present invention relates to a novel photoresist composition that can be developed with an aqueous alkaline solution, and is capable of being imaged at exposure wavelengths in the deep ultraviolet. The invention also relates to a process for imaging the novel photoresist as well as novel photoacid generators.The novel photoresist comprises a) a polymer containing an acid labile group, and b) a novel mixture of photoactive compounds, where the mixture comprises a lower absorbing compound selected from structure 1 and 2, and a higher absorbing compound selected from structure 4 and 5, where, R1 and R2 R5, R6, R7, R8, and R9 are defined herein; m=1–5; X− is an anion, and Ar is selected from naphthyl, anthracyl, and structure 3, where R30, R31, R32, R33, and R34 are defined herein.

Owner:MERCK PATENT GMBH

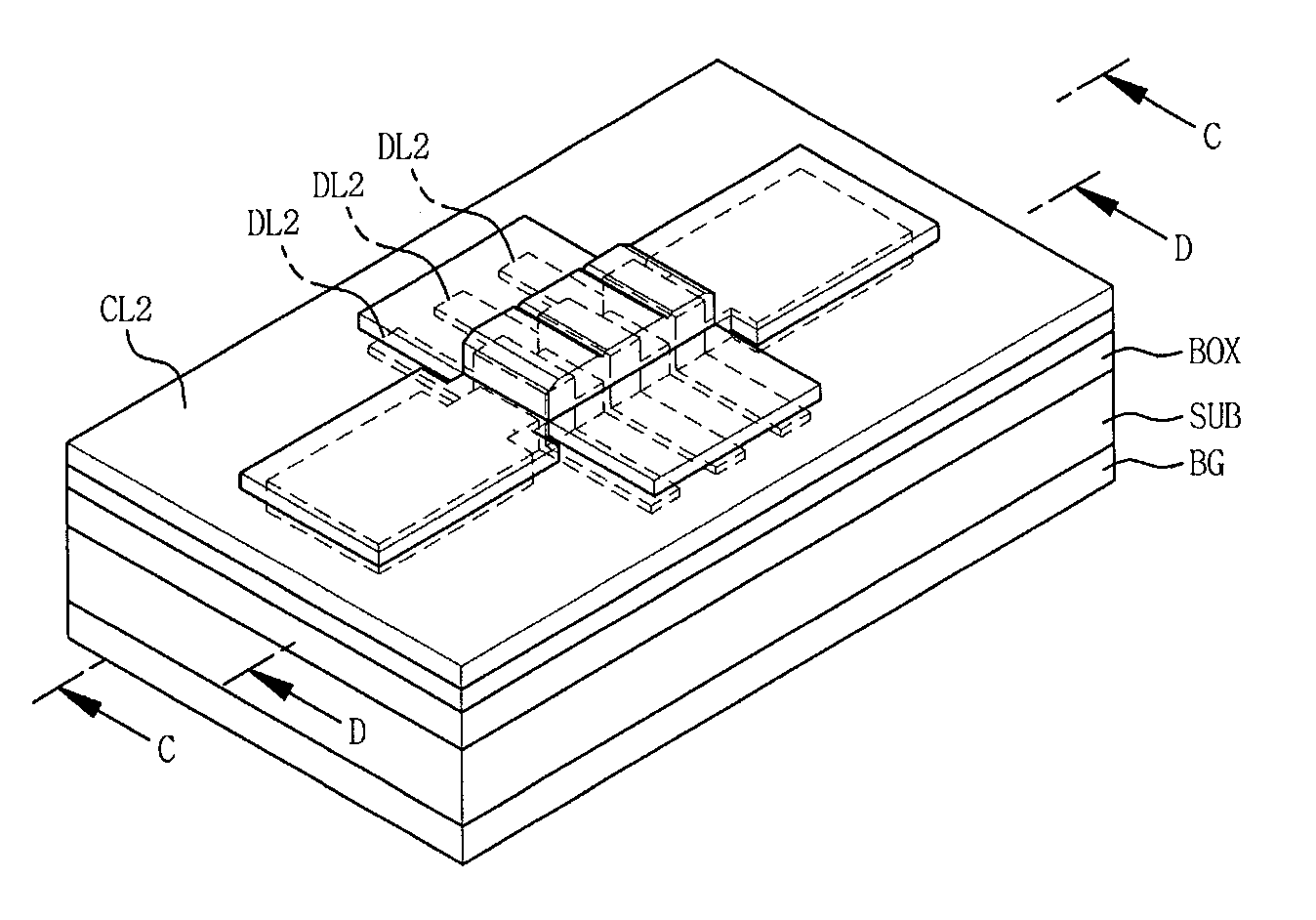

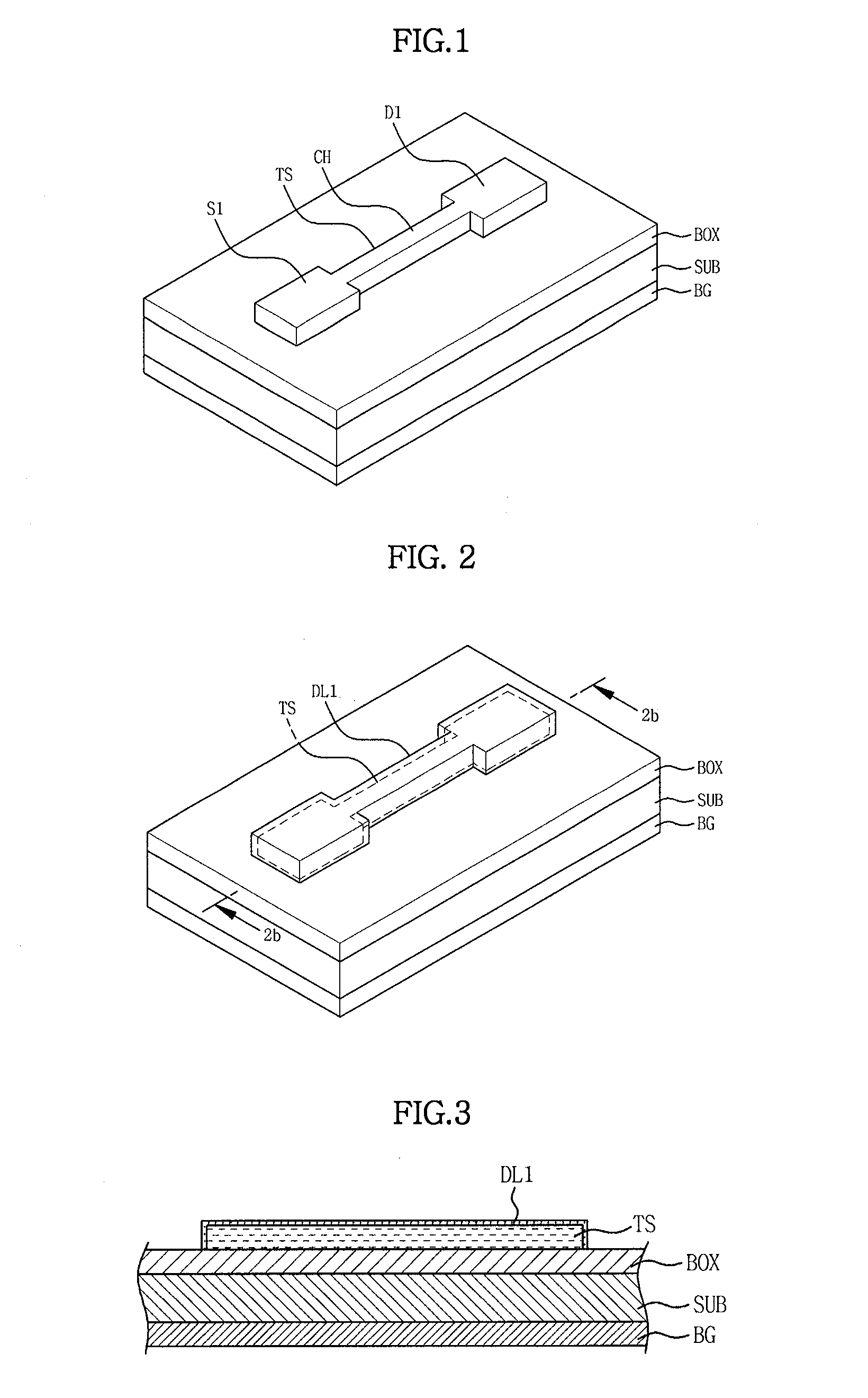

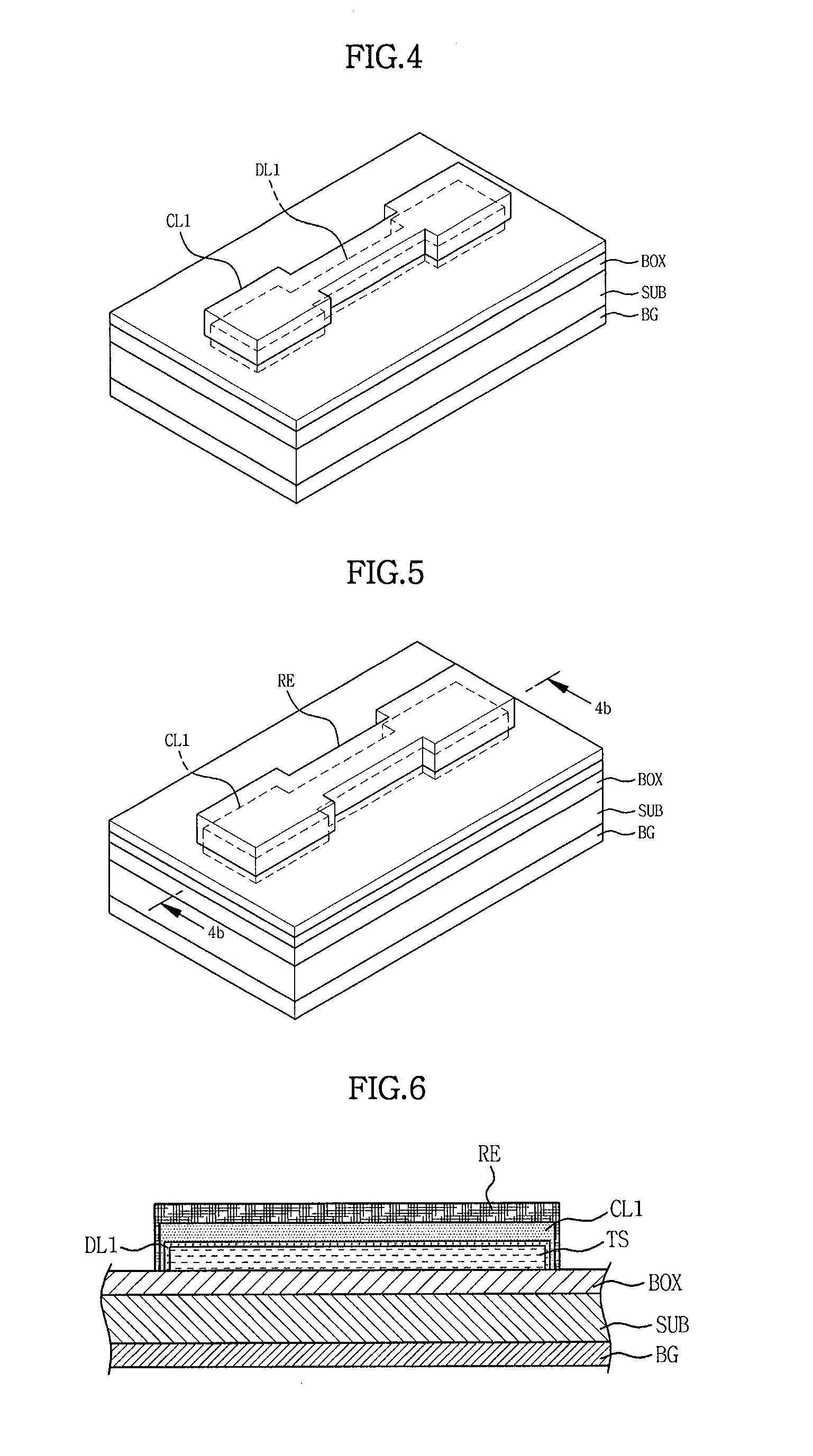

Nanoscale multi-junction quantum dot device and fabrication method thereof

InactiveUS20100006821A1Improve performanceSmall sizeNanoinformaticsSemiconductor/solid-state device manufacturingLine widthQuantum dot

The present invention relates to a method of fabricating a nanoscale multi-junction quantum dot device wherein it can minimize constraints depending on the number or shape of patterns and a line width, and in particular, overcome shortcomings depending on the proximity effect occurring between patterns while employing the advantages of electron beam lithography to the utmost by forming a new conductive layer between the patterns and utilizing it as a new pattern.

Owner:NANOCHIPS

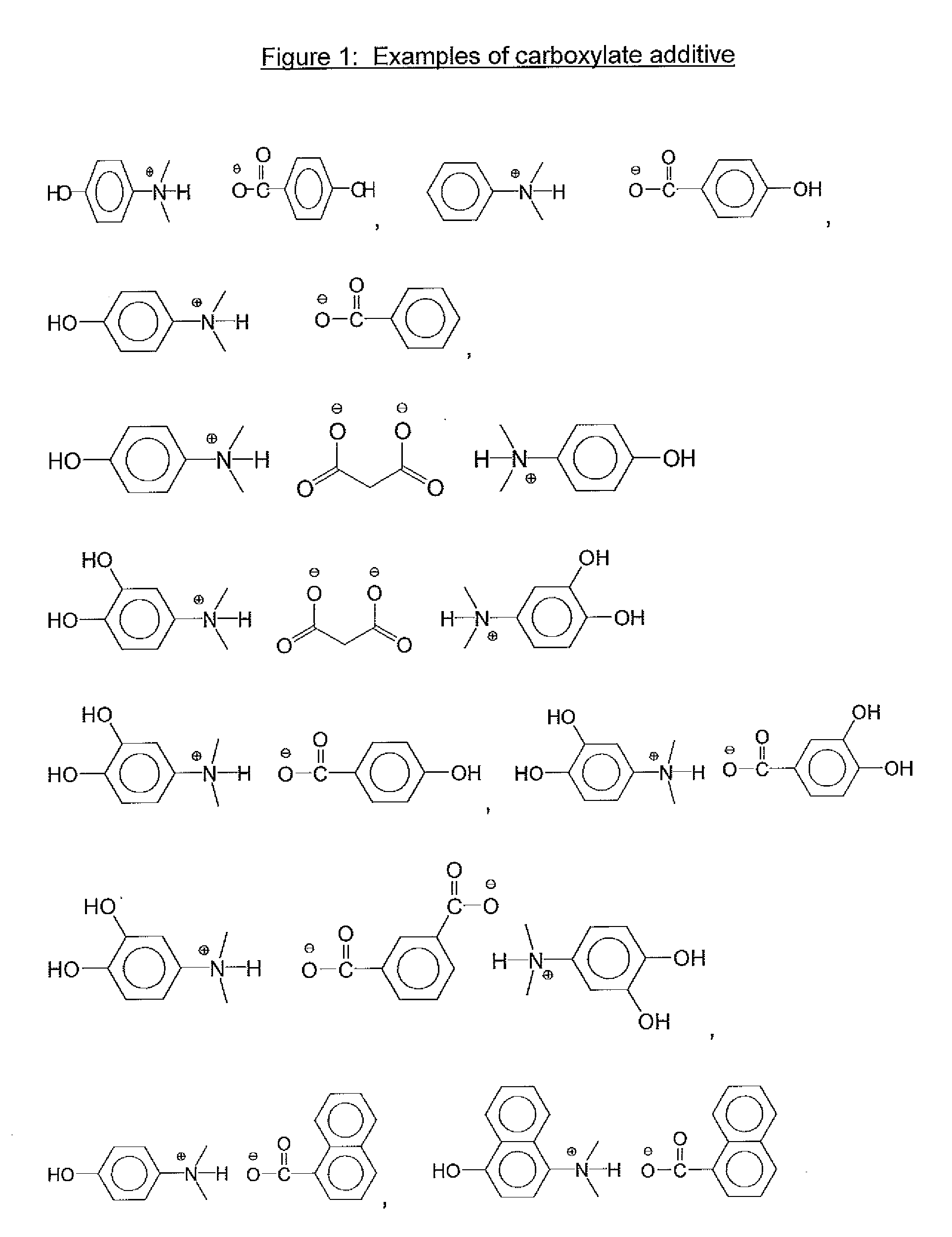

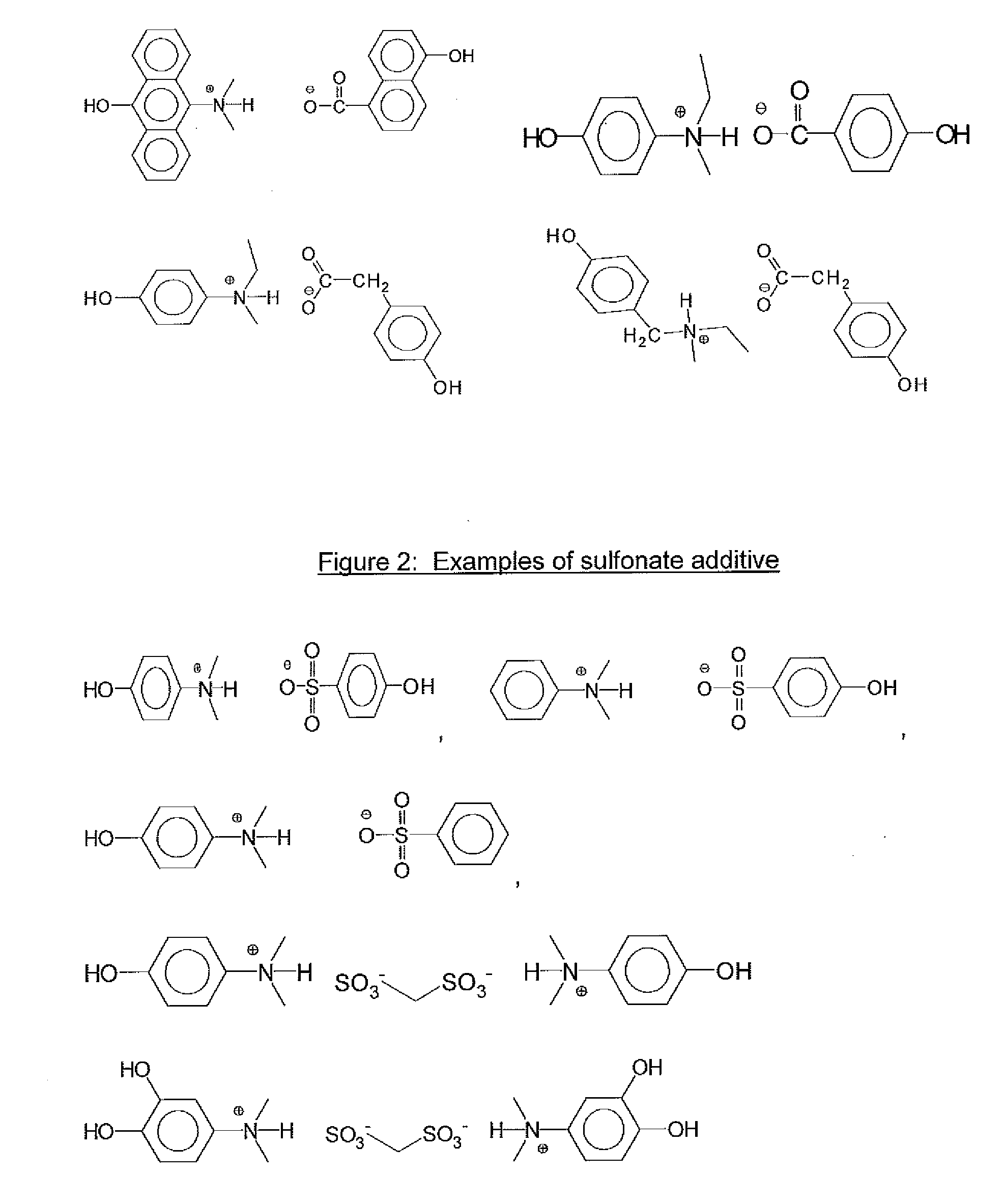

Bottom antireflective coating compositions and processes thereof

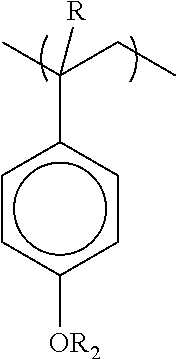

ActiveUS20120308939A1Reduce decreaseIncrease etch rateSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPolymerAryl

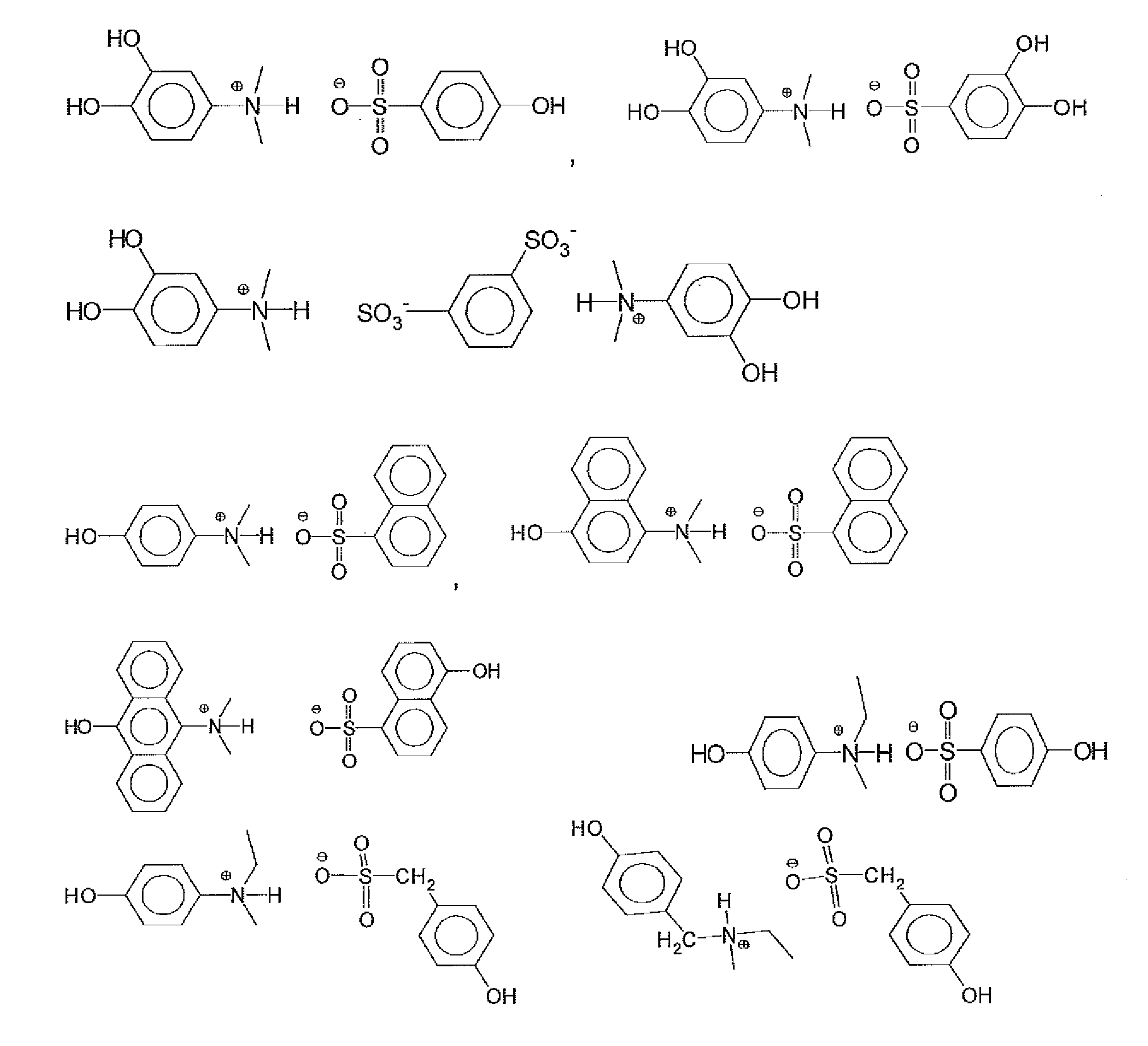

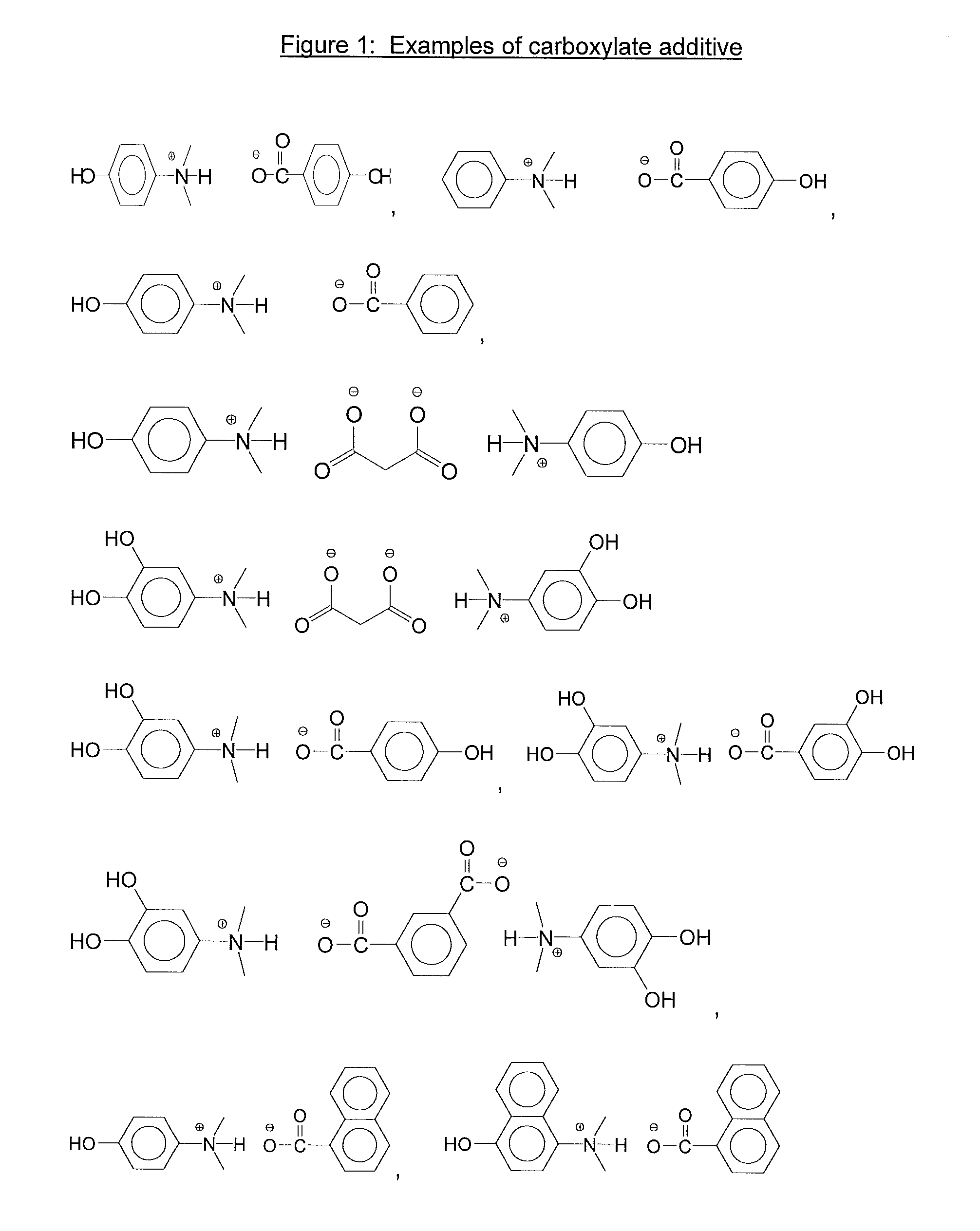

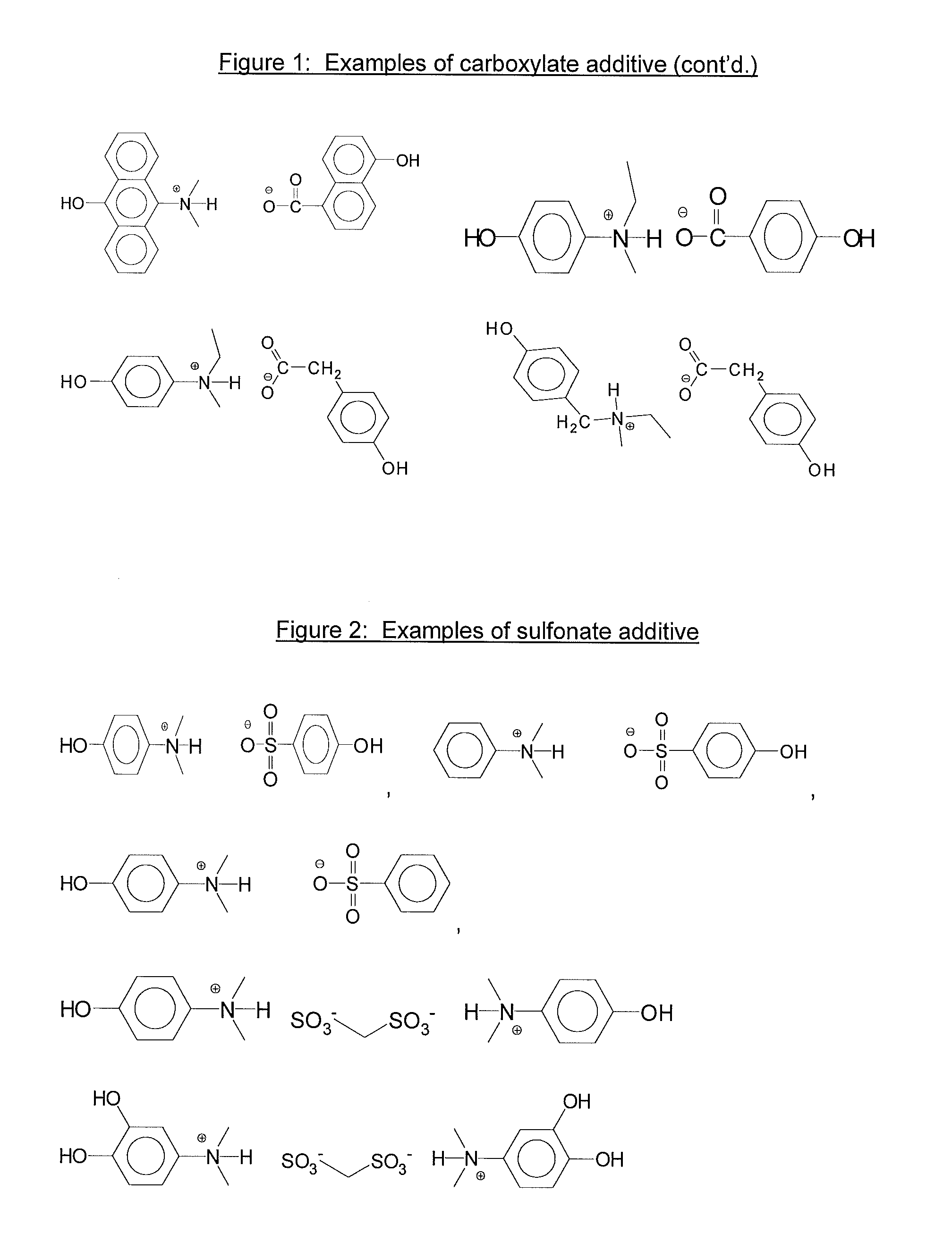

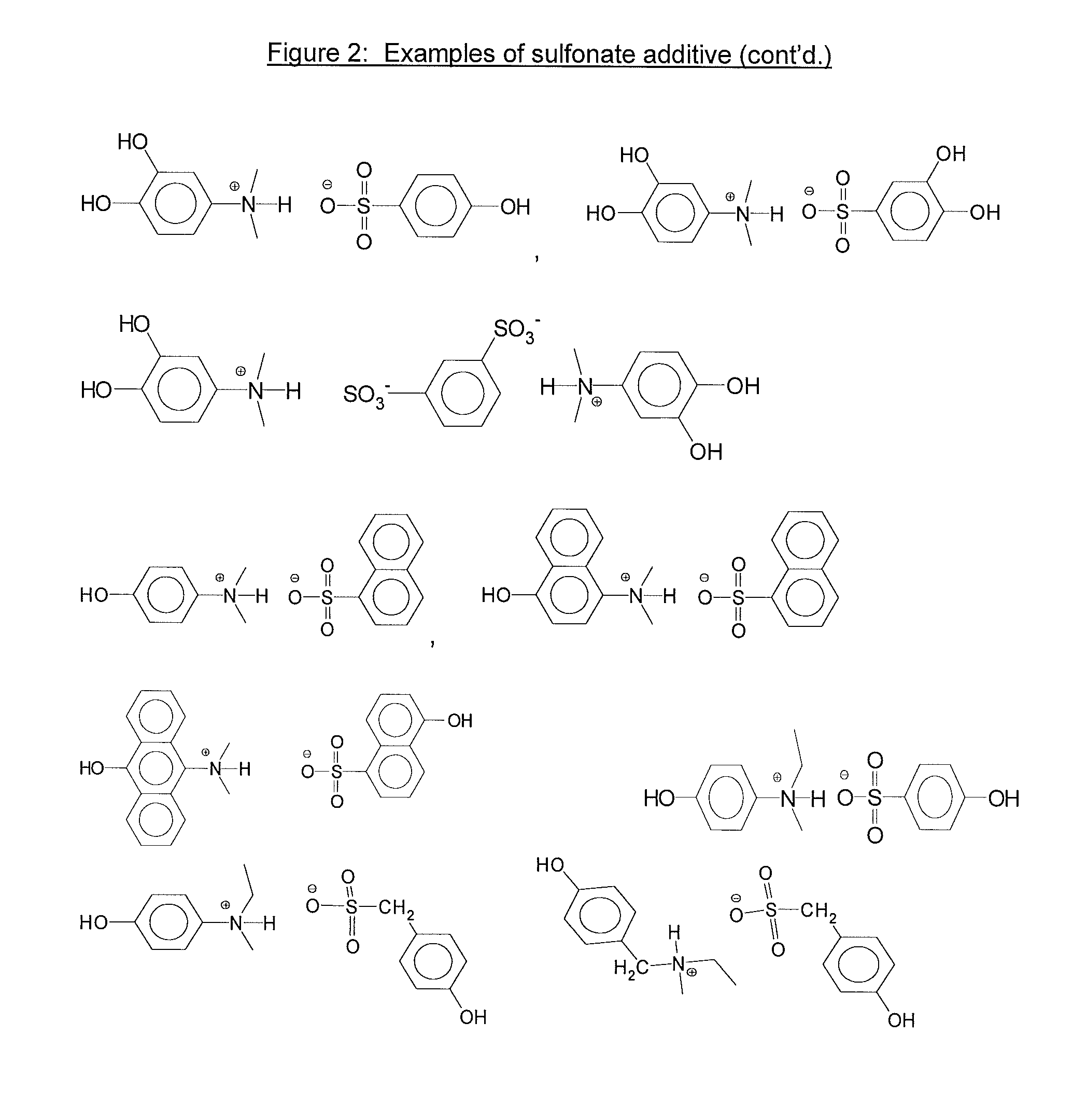

The present invention relates to an antireflective coating composition comprising a crosslinking agent, a polymer comprising at least one chromophore group and at least one hydroxyl and / or a carboxyl group, and an additive, further where the additive has structure 1 and comprises at least one arylene-hydroxyl moiety,where Y is selected from an carboxylate anion or sulfonate anion, R1, R2, and R3 are independently selected from unsubstituted C1-C8 alkyl, substituted C1-C8 alkyl, aryl and arylene-hydroxyl; X1, X2, and X3 are independently selected from direct valence bond and C1-C8 alkylene group, and, n=1, 2 or 3. The invention further relates to a process for using the composition.

Owner:MERCK PATENT GMBH

Nanocomposite positive photosensitive composition and use thereof

InactiveUS20130108956A1Good lithography performanceHigh dry etch resistanceMaterial nanotechnologyPhotosensitive materialsPolymer scienceInorganic particle

The present invention relates to a positive photosensitive composition suitable for image-wise exposure and development as a positive photoresist comprising a positive photoresist composition and an inorganic particle material having an average particle size equal or greater than 10 nanometers, wherein the thickness of the photoresist coating film is less than 5 microns. The positive photoresist composition can be selected from (1) a composition comprising (i) a film-forming resin having acid labile groups, and (ii) a photoacid generator, or (2) a composition comprising (i) a film-forming novolak resin, and (ii) a photoactive compound, or (3) a composition comprising (i) a film-forming resin, (ii) a photoacid generator, and (iii) a dissolution inhibitor. The invention also relates to a process of forming an image using the novel photosensitive composition.

Owner:AZ ELECTRONICS MATERIALS USA CORP

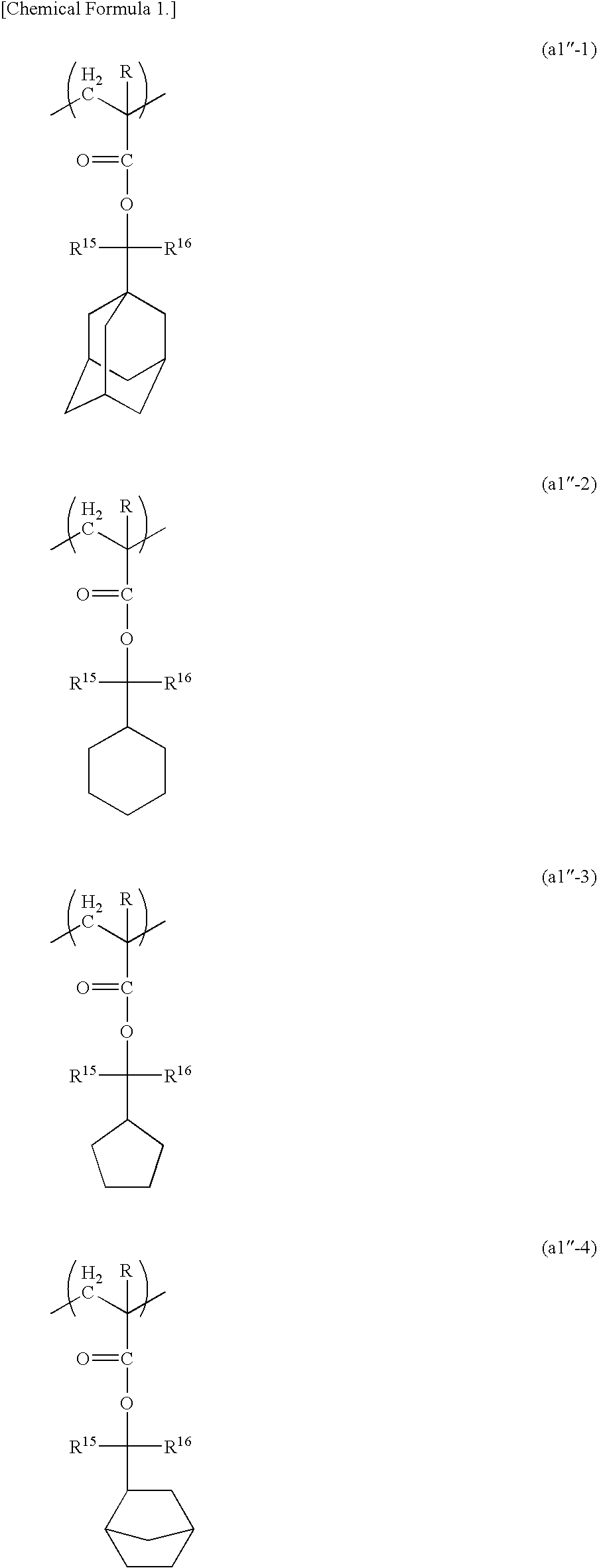

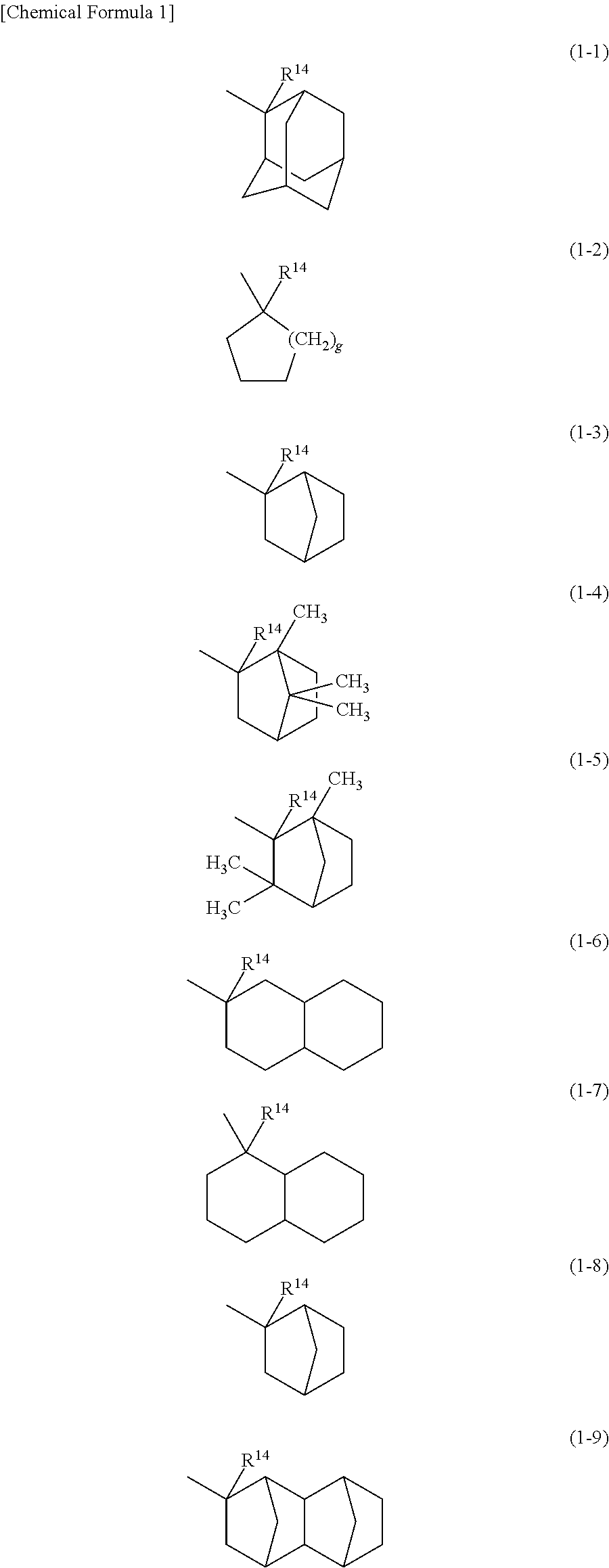

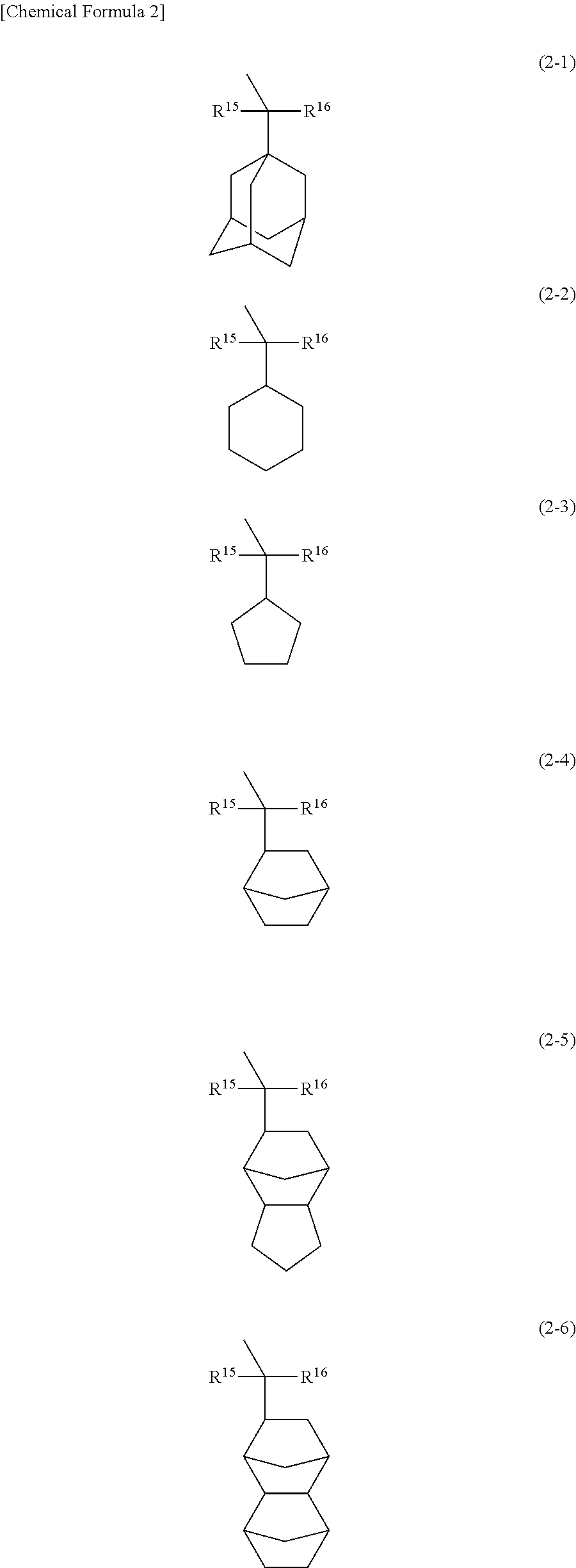

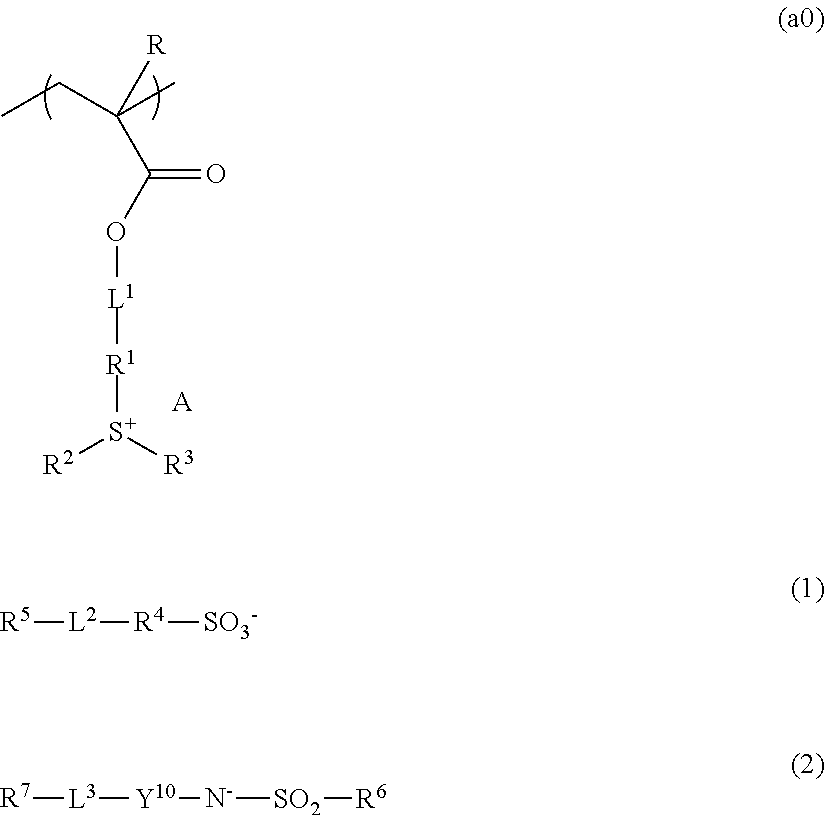

Resist composition, method of forming resist pattern, polymeric compound and compound

ActiveUS9017924B2Good lithography performanceOrganic chemistryPhotosensitive materialsCompound aPolymer science

Owner:TOKYO OHKA KOGYO CO LTD

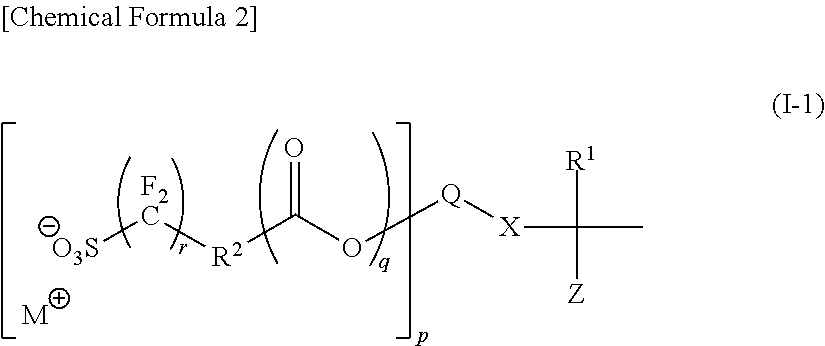

Resist composition and method of forming resist pattern

ActiveUS20120214101A1Excellent lithography propertyGood lithography performancePhotosensitive materialsRadiation applicationsResistSolubility

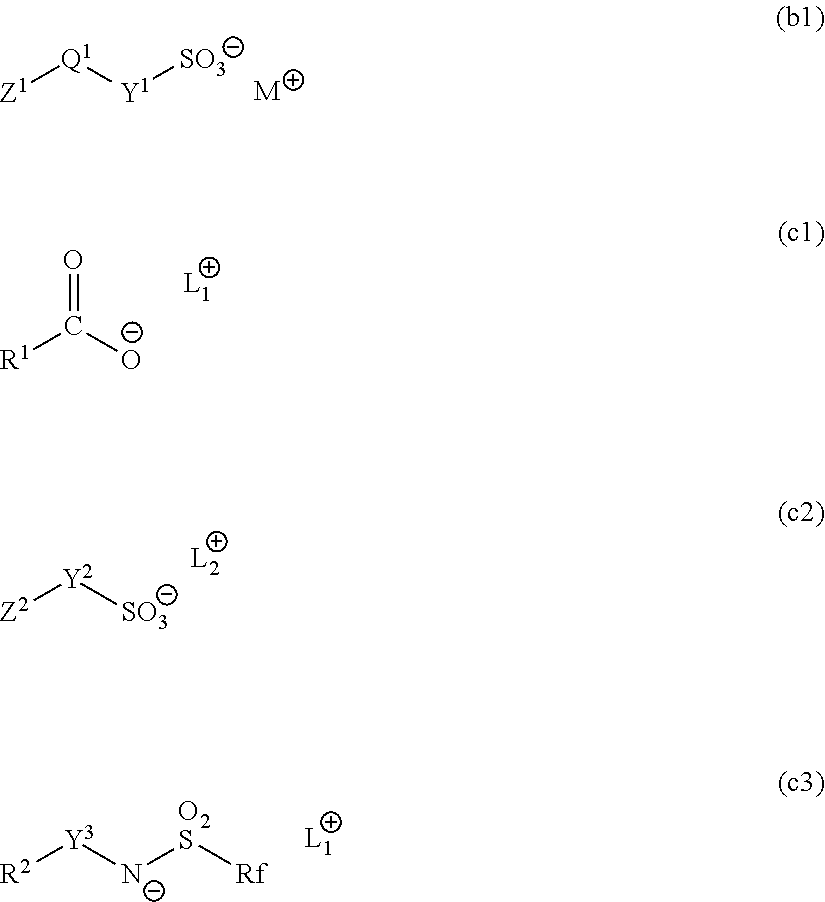

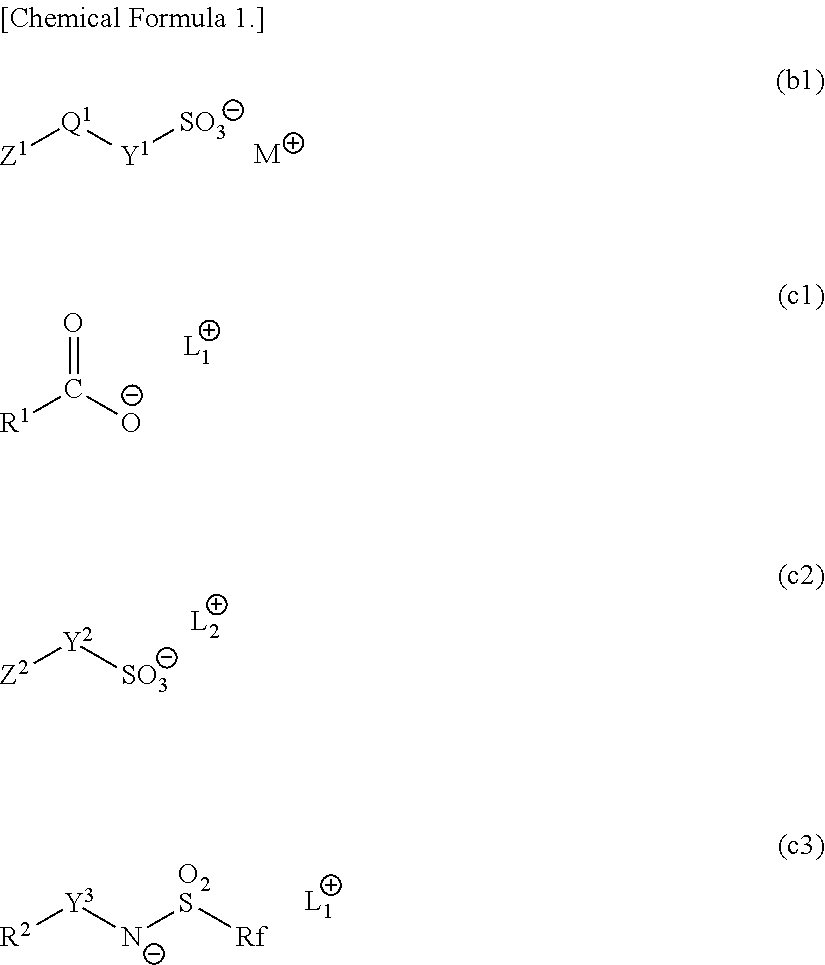

A resist composition including a base component (A) which exhibits changed solubility in a developing solution under action of acid, a basic-compound component (C) and an acid-generator component (B) which generates acid upon exposure, the component (B) including a compound represented by formula (b1), and the component (C) including at least one compound represented by formulas (c1) to (c3) (wherein Z1 represents a ring skeleton-containing hydrocarbon group, Q1 represents a divalent linking group containing oxygen, Y1 represents a fluorinated alkylene group, M+ represents an organic cation, R1 represents a fluorinated alkyl group or a hydrocarbon group, L1+ and L2+ represents a sulfonium or an iodonium, Z2 represents a hydrogen atom or a hydrocarbon group, Y2 represents a single bond or a divalent linking group containing no fluorine, R2 represents an organic group, Y3 represents an alkylene group or an arylene group; and Rf represents a fluorine-containing hydrocarbon group).

Owner:TOKYO OHKA KOGYO CO LTD

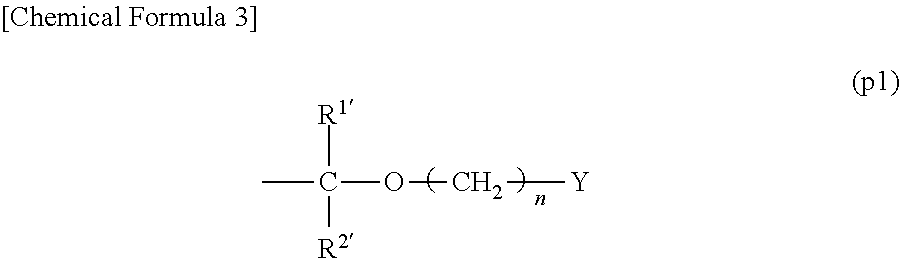

Method of producing polymeric compound, resist composition, and method of forming resist pattern

ActiveUS20120328993A1Good lithography performanceImprove distributionPhotomechanical exposure apparatusMicrolithography exposure apparatusPolymer sciencePrecursor polymer

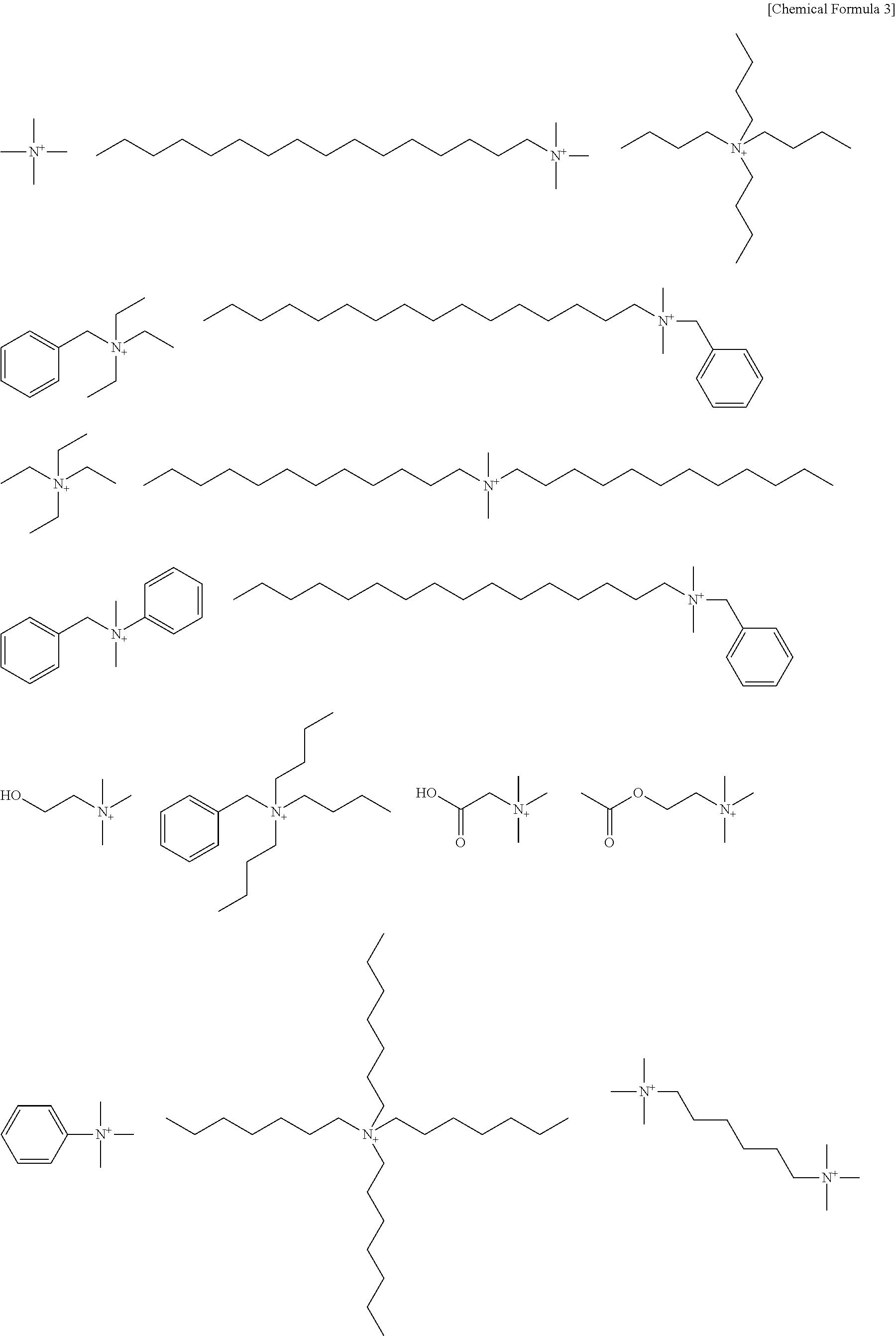

A method of producing a polymeric compound containing a structural unit that decomposes upon exposure to generate an acid, the method including: synthesizing a precursor polymer by polymerizing a water-soluble monomer having an anionic group, washing the precursor polymer with water, and subsequently subjecting the precursor polymer to a salt exchange with an organic cation. Also, a polymeric compound produced using the method of producing a polymeric compound, and a method of forming a resist pattern using the resist composition.

Owner:TOKYO OHKA KOGYO CO LTD

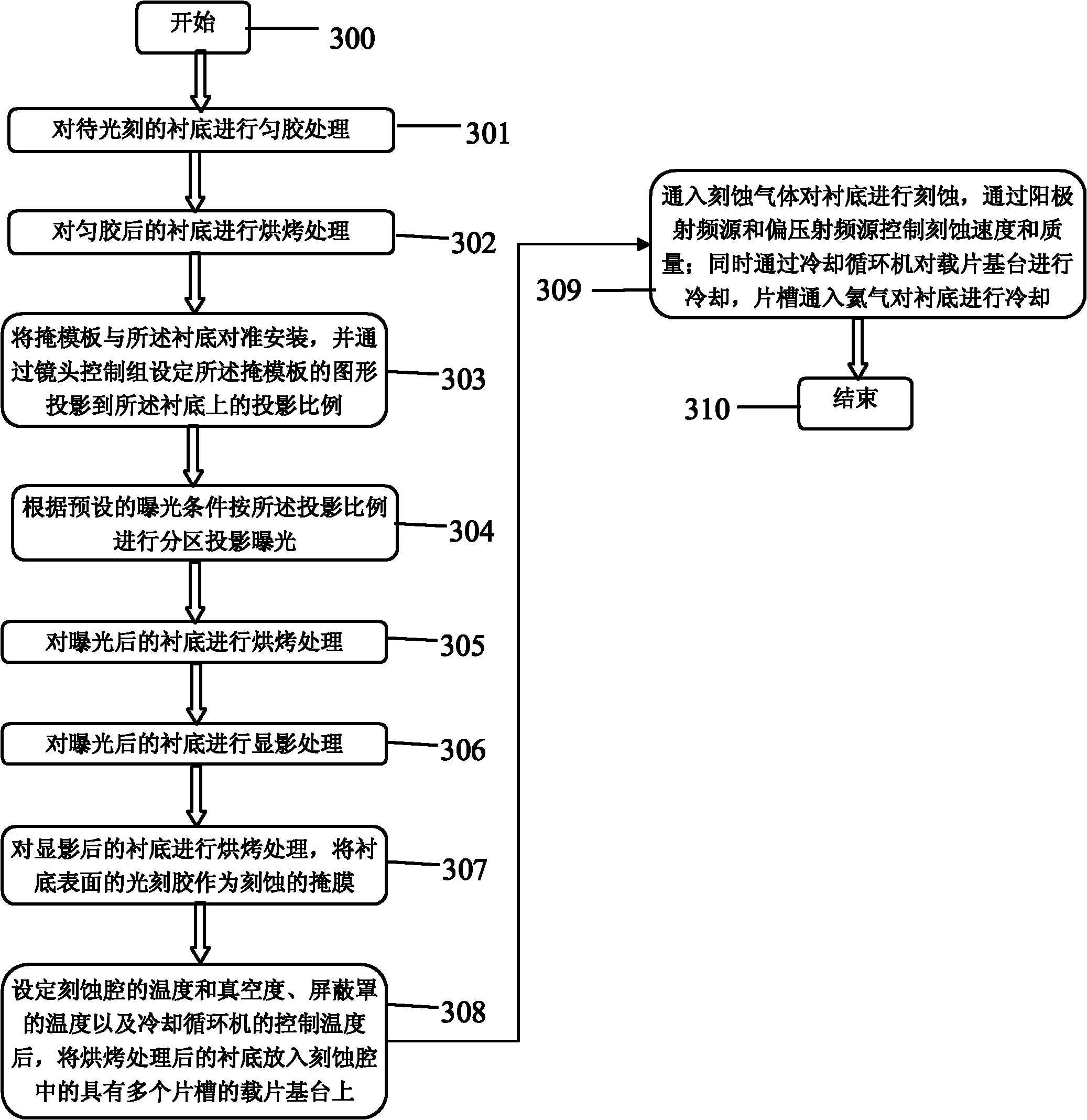

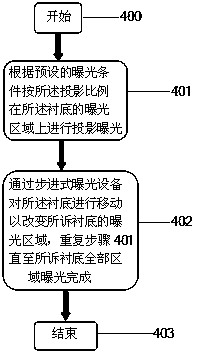

Method for manufacturing graphical sapphire substrate

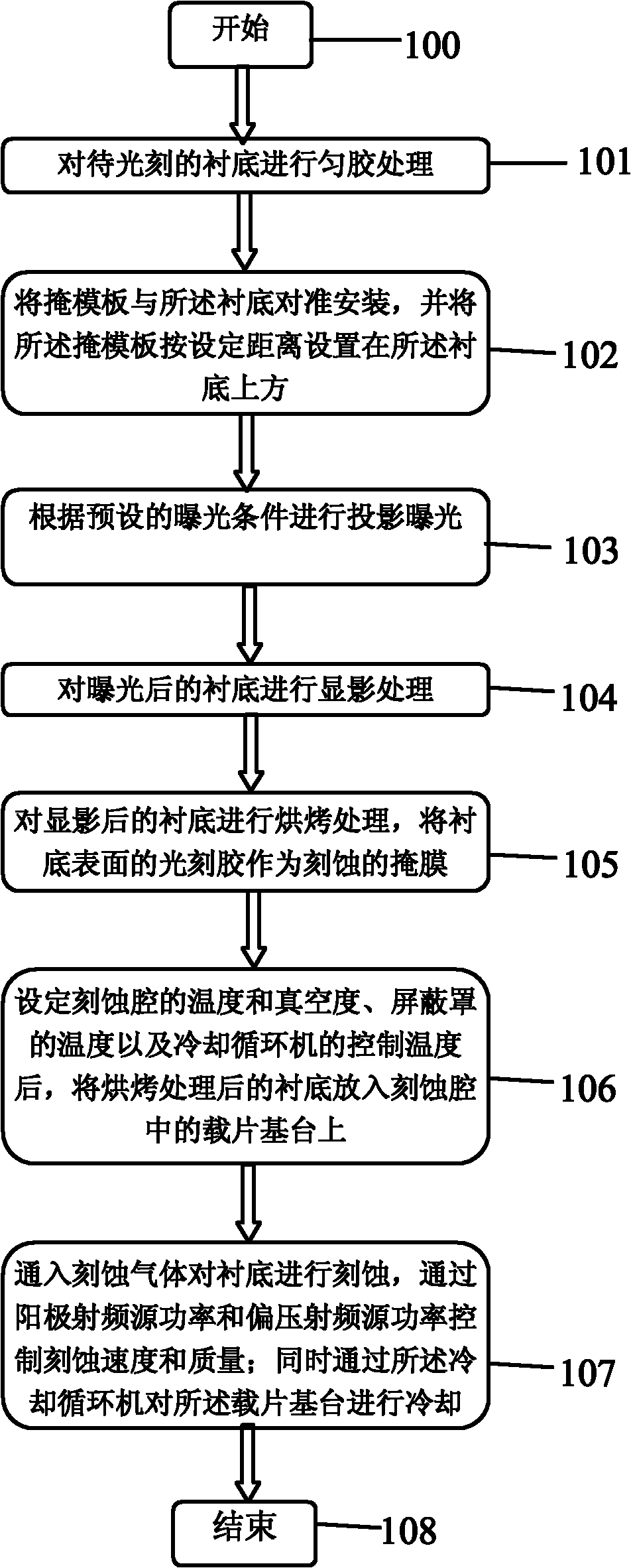

InactiveCN102157629AAvoid damageSolve photoresist carbonizationPhotomechanical exposure apparatusPhotosensitive material processingProduction rateRadio frequency

The invention relates to a method for manufacturing a graphical sapphire substrate. The method comprises the following steps of: performing spin-coating treatment on a substrate to be photoetched; aligning and installing a mask plate and the substrate and installing the mask plate above the substrate according to set distance; performing projection exposure according to preset exposure conditions; performing developing treatment on the exposed substrate; performing roasting treatment on the developed substrate, and taking photoresist on the surface of the substrate as an etching mask; after setting the temperature and the vacuum degree of an etching cavity, the temperature of a shield cover and the control temperature of a cooling circulation mechanism, placing the roasted substrate on a slide glass base station in the etching cavity; introducing an etching gas for etching the substrate; controlling etching speed and quality by anode radio frequency source power and bias radio frequency source power; and simultaneously, cooling the slide glass base station by using the cooling circulation mechanism. By the method, the graphical substrate production efficiency is high and the luminous efficiency of a chip produced by using the substrate is high and stable.

Owner:长治虹源科技晶体有限公司

Polymer, resist composition and method of forming resist pattern

InactiveUS20130022911A1Excellent lithography propertyGood lithography performancePhotosensitive materialsPhotomechanical exposure apparatusPolymer scienceBackbone chain

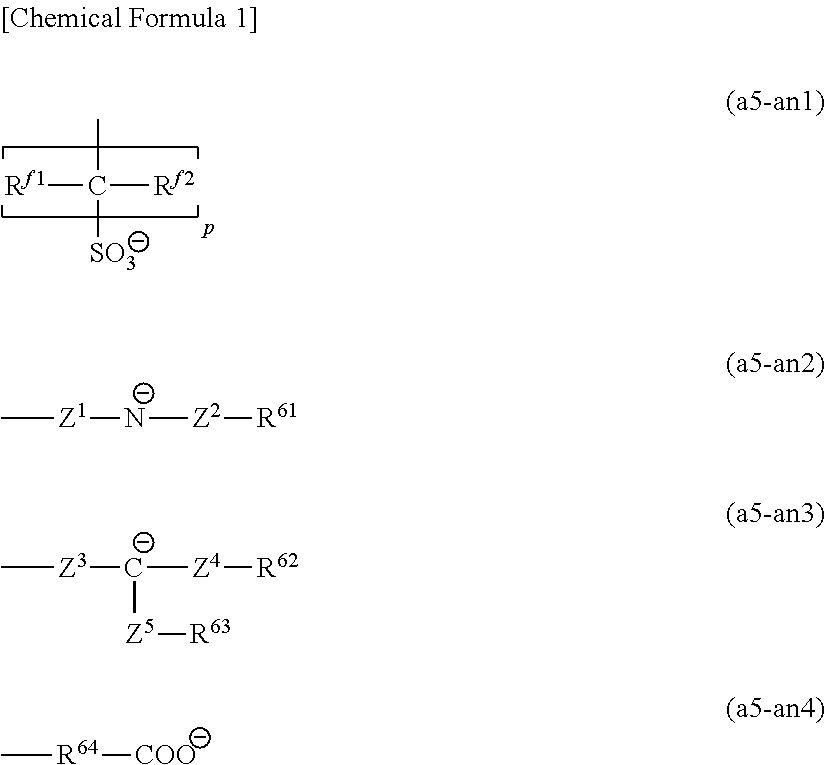

A polymer containing an anion part which generates acid upon exposure on at least one terminal of the main chain, and at least one structural unit selected from the group consisting of a structural unit (a0) containing a —SO2-containing cyclic group, a structural unit (a3) containing at least one group selected from the group consisting of —OH, —COOH, —CN, —SO2NH2 and —CONH2 and a structural unit (a5) which generates acid upon exposure.

Owner:TOKYO OHKA KOGYO CO LTD

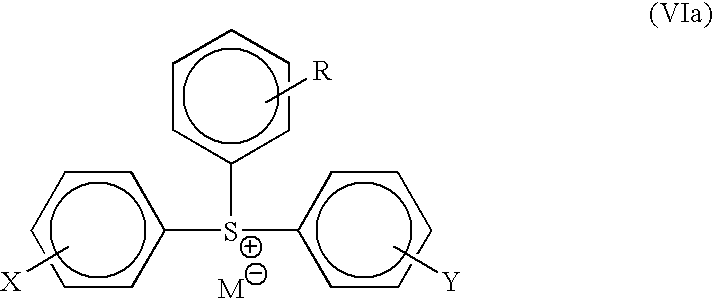

Photoresist compositions and methods and articles of manufacture comprising same

InactiveUS7704668B1Good lithography performanceGood storage stabilityPhotosensitive materialsRadiation applicationsSolubilitySulfonate

The invention provides positive-acting chemically-amplified photoresist compositions that can provide excellent lithographic performance as well as significantly enhanced storage stability. In one aspect, photoresist compositions are provided that comprise a solvent that is free of hydroxy groups (i.e. non-hydroxylic solvent), a resin binder and a photoactive compound that exhibits enhanced and long-term solubility in the solvent. In a further aspect, resists are provided that are formulated in a hydroxyl-containing solvent such as ethyl lactate and that contains a sulfonium salt photoactive compound that includes a sulfonate counter anion that can provide enhanced storage stability for the resist.

Owner:SHIPLEY CO LLC

Resist composition and method of forming resist pattern

ActiveUS20090197197A1Excellent lithography propertyGood lithography performancePhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundResist

A resist composition comprising a base component (A) which exhibits changed solubility in an alkali developing solution under action of acid, an acid-generator component (B) which generates acid upon exposure, and a nitrogen-containing organic compound (D), the nitrogen-containing organic compound (D) including a nitrogen-containing polymeric compound (D1) having a structural unit (d0) containing a nitrogen atom in the side chain thereof.

Owner:TOKYO OHKA KOGYO CO LTD

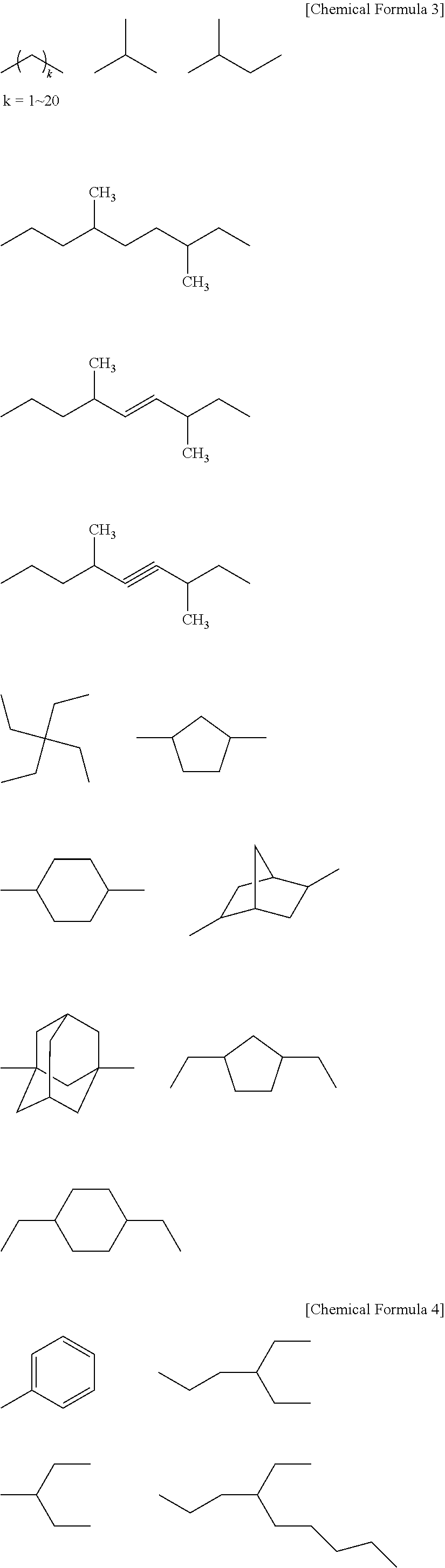

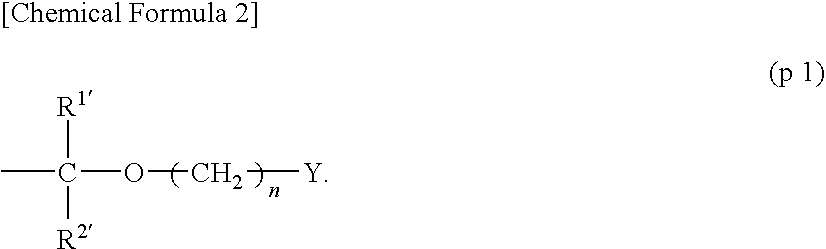

Resist composition, method of forming resist pattern, novel compound, and acid generator

ActiveUS20110287362A1Maintain good propertiesReduce roughnessOrganic chemistryPhotosensitive materialsSolubilityChemical compound

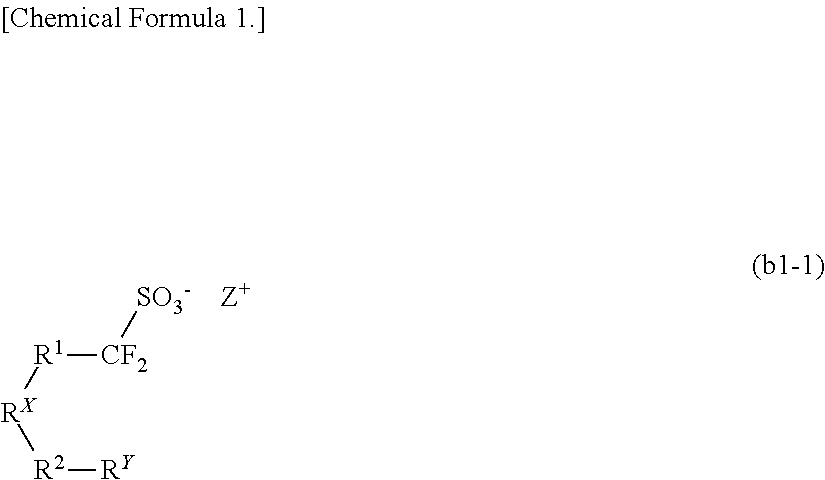

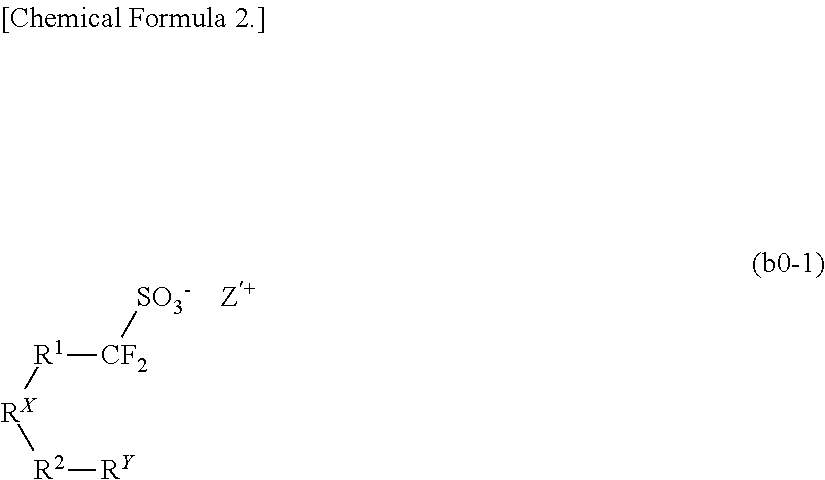

A resist composition including a base component (A) which exhibits changed solubility in an alkali developing solution under action of acid and an acid-generator component (B) which generates acid upon exposure, the acid-generator component (B) including an acid generator (B1) represented by general formula (b1-1) shown below (in the formula, RX represents a divalent aliphatic group of 3 to 20 carbon atoms; RY represents a monovalent aliphatic group of 3 to 20 carbon atoms having —C(═O)—O— or —S(═O)2—; each of R1 and R2 independently represents a divalent linking group; and Z+ represents a monovalent organic cation).

Owner:TOKYO OHKA KOGYO CO LTD

Bottom antireflective coating compositions and processes thereof

ActiveUS8623589B2Reduce decreaseIncrease etch ratePhotosensitive materialsSemiconductor/solid-state device manufacturingPolymerArylene

The present invention relates to an antireflective coating composition comprising a crosslinking agent, a polymer comprising at least one chromophore group and at least one hydroxyl and / or a carboxyl group, and an additive, further where the additive has structure 1 and comprises at least one arylene-hydroxyl moiety,where Y is selected from an carboxylate anion or sulfonate anion, R1, R2, and R3 are independently selected from unsubstituted C1-C8 alkyl, substituted C1-C8 alkyl, aryl and arylene-hydroxyl; X1, X2, and X3 are independently selected from direct valence bond and C1-C8 alkylene group, and, n=1, 2 or 3. The invention further relates to a process for using the composition.

Owner:MERCK PATENT GMBH

Compound, polymeric compound, acid generator, resist composition, and method of forming resist pattern

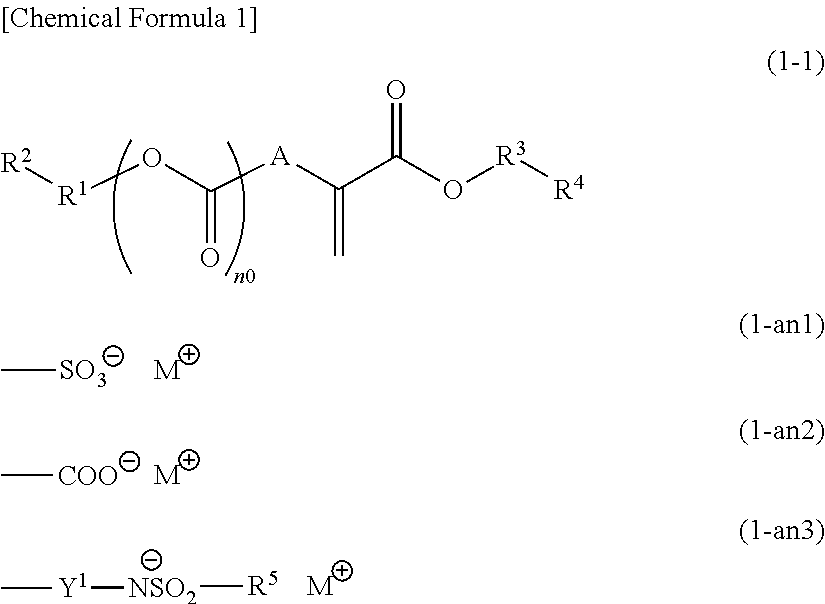

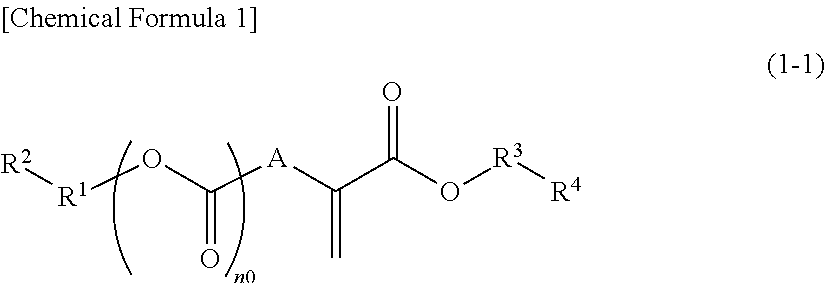

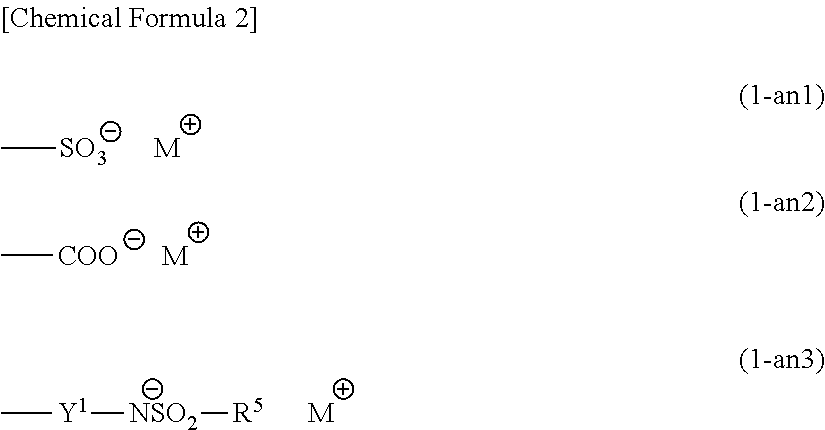

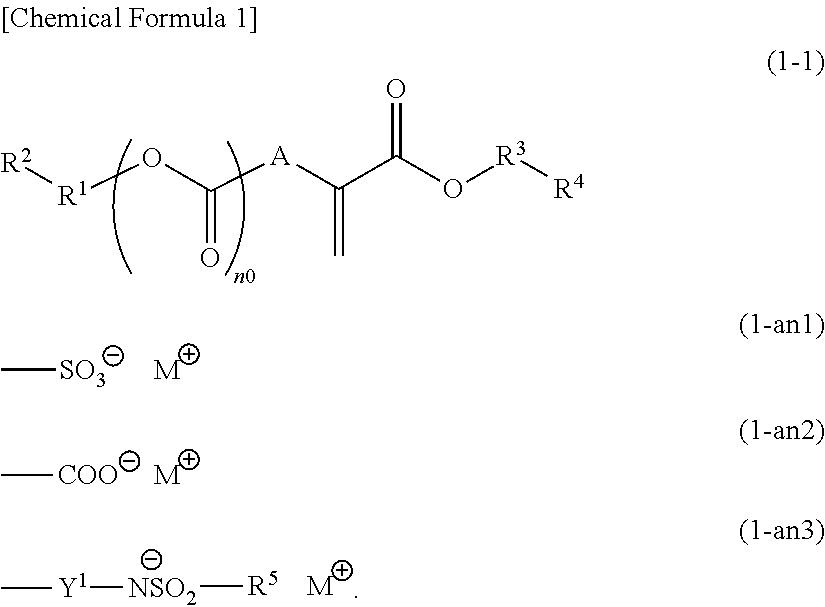

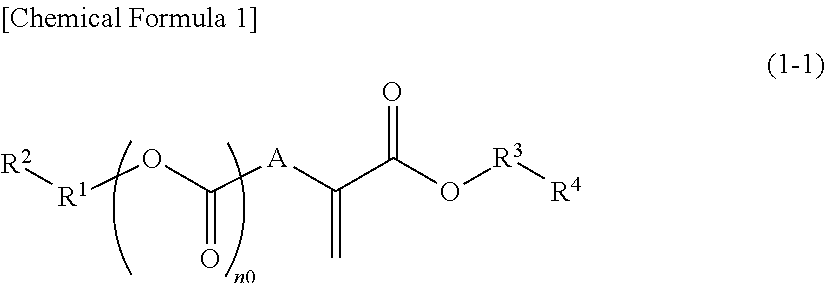

ActiveUS20120270155A1Good lithography performanceOrganic chemistryPhotosensitive materialsChemical compoundHydroxy group

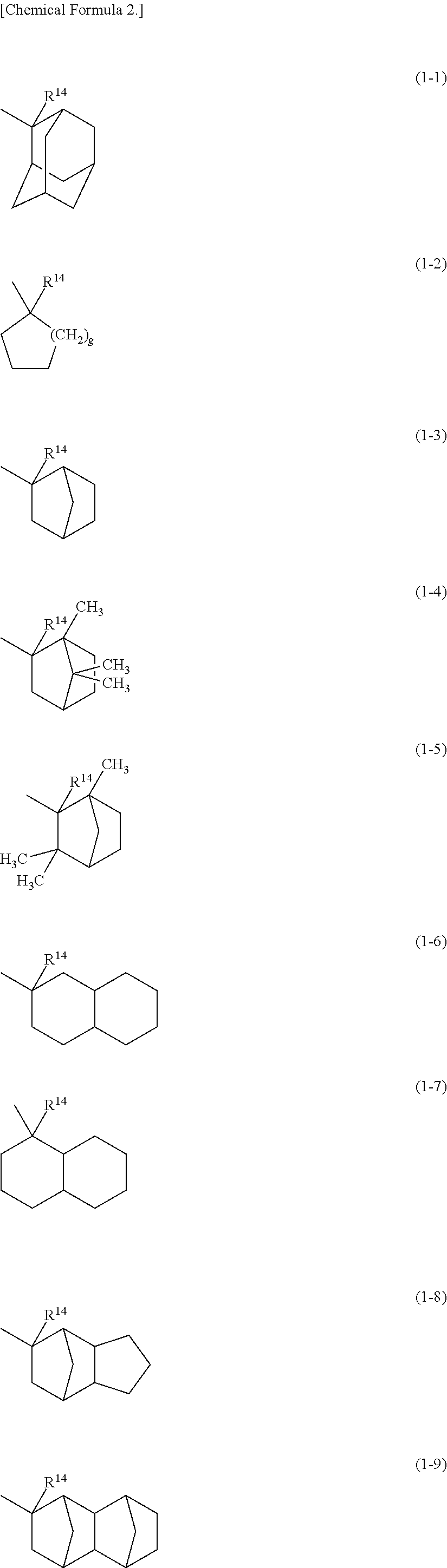

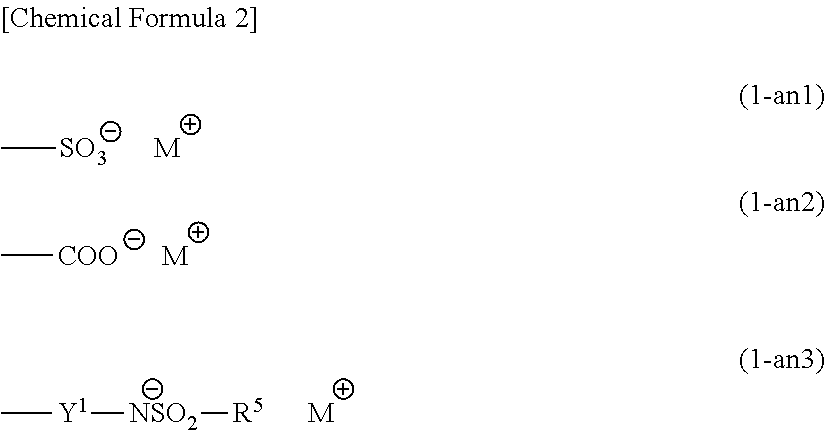

There are provided a novel compound, a polymeric compound, a resist composition, an acid generator and a method of forming a resist patternthe compound represented by general formula (1-1):wherein each of R1 and R3 independently represents a single bond or a divalent linking group; A represents a divalent linking group; each of R2 and R4 independently represents a hydroxyl group, a hydrocarbon group which may have a substituent, or a group represented by general formula (1-an1), (1-an2) or (1-an3), provided that at least one of R2 and R4 represents a group represented by general formula (1-an1), (1-an2) or (1-an3); and n0 is preferably 0 or 1, andwherein Y1 represents a single bond or —SO2—; R5 represents a linear or branched monovalent hydrocarbon group of 1 to 10 carbon atoms, cyclic monovalent hydrocarbon group of 3 to 20 carbon atoms or monovalent hydrocarbon group of 3 to 20 carbon atoms having a cyclic partial structure which may be substituted with a fluorine atom; and M+ represents an organic cation or a metal cation,

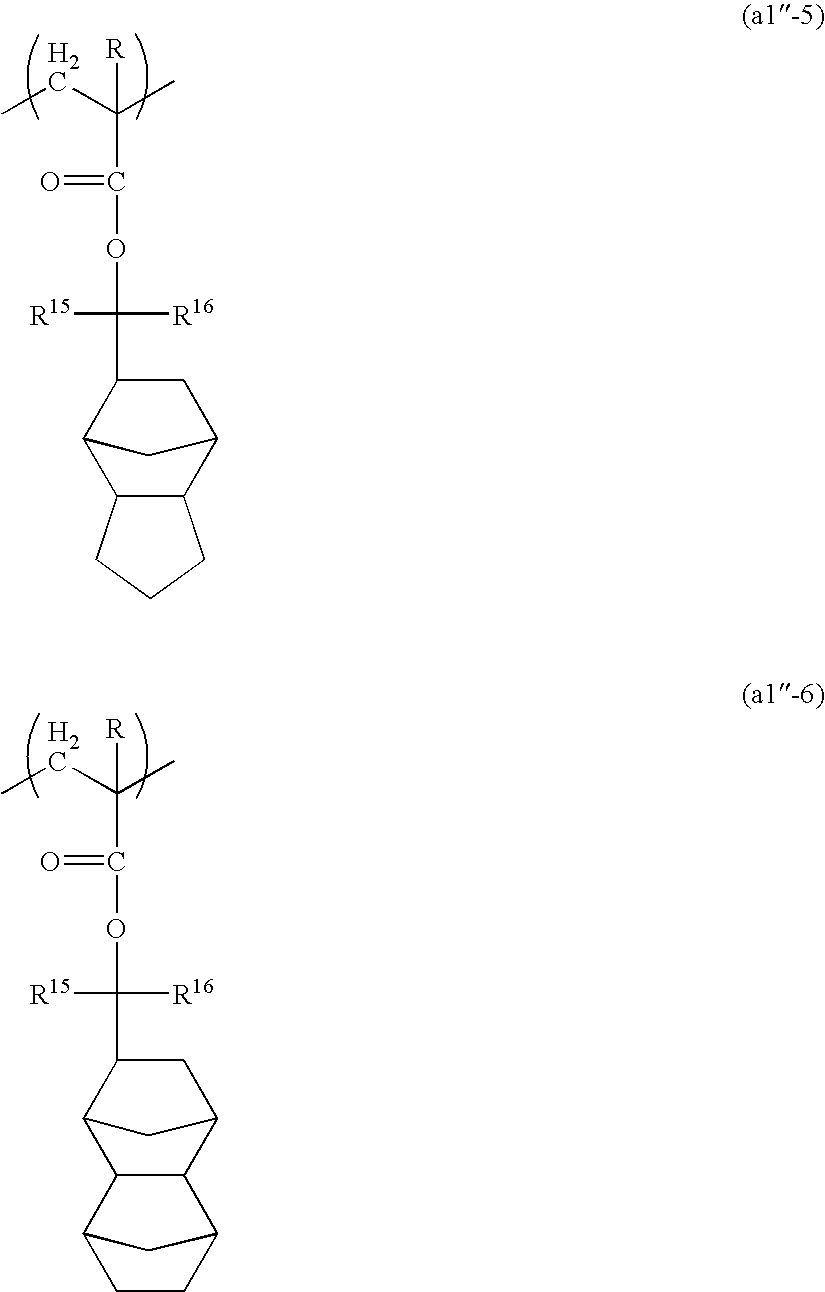

Resist composition and method of forming resist pattern

ActiveUS20130189619A1Good lithography propertyGood storage stabilityPhotosensitive materialsPhotomechanical exposure apparatusResistSolubility

A resist composition containing a base component (A) that exhibits changed solubility in a developing solution under action of acid, a photoreactive quencher (C), and an acid generator component (B) that generates acid upon exposure, and further containing an acid (G) having a pKa of 4 or less.

Owner:TOKYO OHKA KOGYO CO LTD

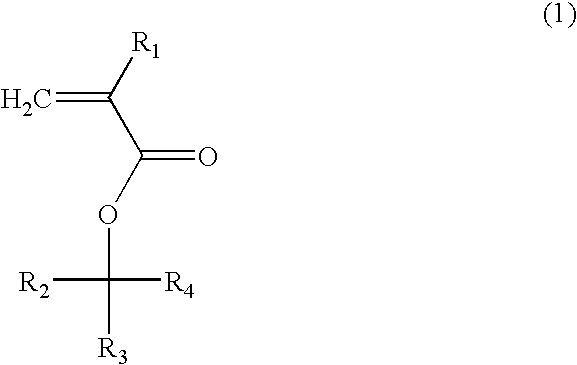

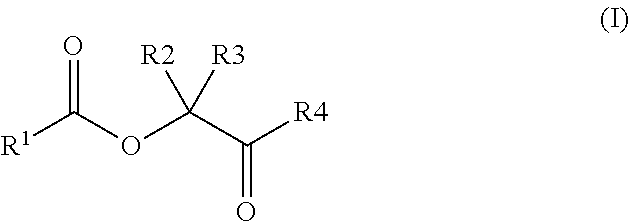

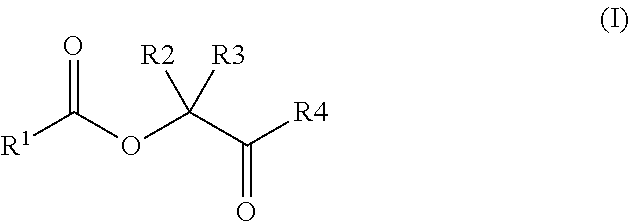

(Meth)acrylate compound, photosensitive polymer, and resist composition including the same

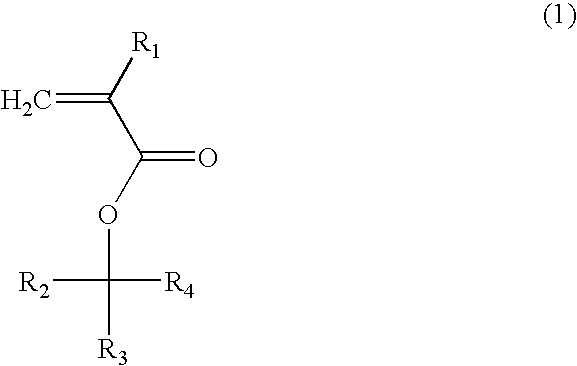

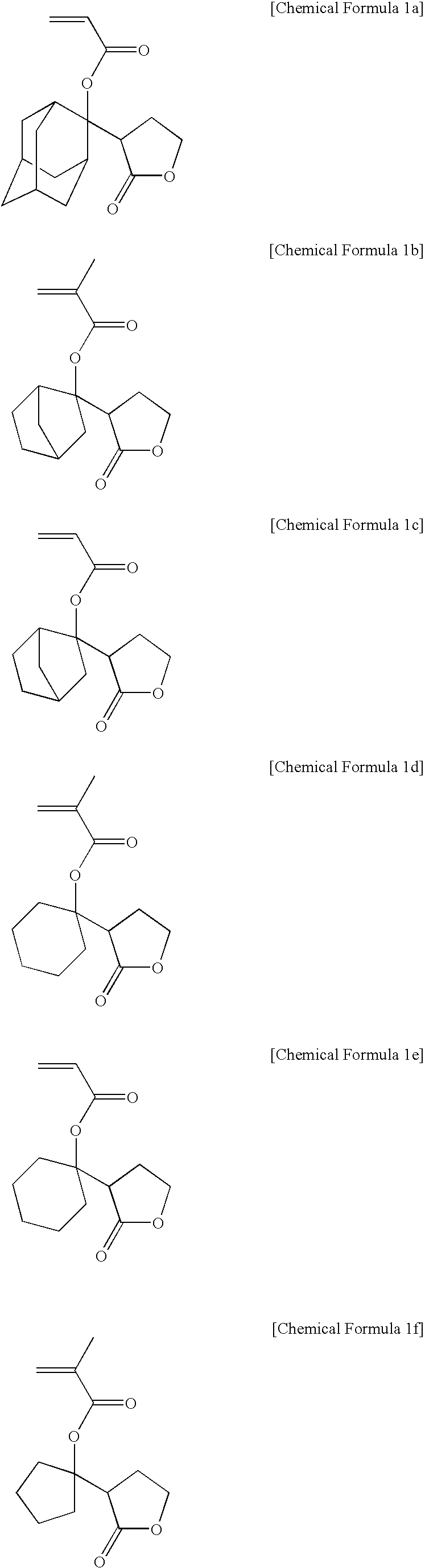

InactiveUS20100167200A1Low costExcellent resistance to dry etchingOrganic chemistryPhotosensitive materialsResistMeth-

A (meth)acrylate compound having an acid-labile ester group, a photosensitive polymer, and a resist composition including the same, the (meth)acrylate compound being represented by the following Chemical Formula 1wherein, R1 is hydrogen or methyl, R2 and R3 are each independently a substituted or unsubstituted linear alkyl, a substituted or unsubstituted cyclic alkyl, or linked each other to form a monocyclic ring or a fused-ring, and R4 is a linear ester or cyclic ester group.

Owner:CHEIL IND INC

Compound, polymeric compound, acid generator, resist composition, and method of forming resist pattern

ActiveUS9005874B2Good lithography performanceOrganic chemistryOrganic compound preparationChemical compoundHydroxy group

There are provided a novel compound, a polymeric compound, a resist composition, an acid generator and a method of forming a resist patternthe compound represented by general formula (1-1):wherein each of R1 and R3 independently represents a single bond or a divalent linking group; A represents a divalent linking group; each of R2 and R4 independently represents a hydroxyl group, a hydrocarbon group which may have a substituent, or a group represented by general formula (1-an1), (1-an2) or (1-an3), provided that at least one of R2 and R4 represents a group represented by general formula (1-an1), (1-an2) or (1-an3); and n0 is preferably 0 or 1, andwherein Y1 represents a single bond or —SO2—; R5 represents a linear or branched monovalent hydrocarbon group of 1 to 10 carbon atoms, cyclic monovalent hydrocarbon group of 3 to 20 carbon atoms or monovalent hydrocarbon group of 3 to 20 carbon atoms having a cyclic partial structure which may be substituted with a fluorine atom; and M+ represents an organic cation or a metal cation,

Owner:TOKYO OHKA KOGYO CO LTD

Lithographic printing plate precusor

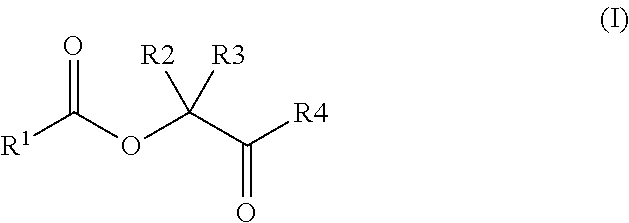

ActiveUS20150168837A1Good lithography performanceEnhance the imagePhotosensitive materialsSemiconductor/solid-state device manufacturingInter layerChemical compound

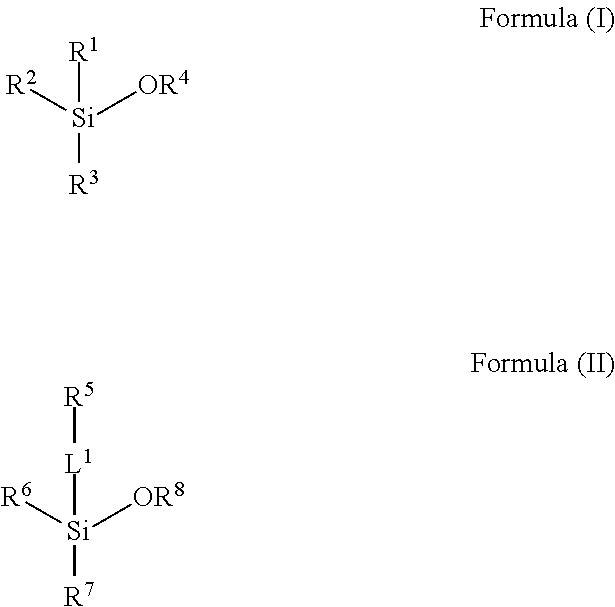

A negative-working lithographic printing plate precursor includes a coating containing a photopolymerizable layer and optionally an intermediate layer between the photopolymerizable layer and the support, wherein the coating further includes a polysiloxane, the polysiloxane being present in the photopolymerizable layer and / or in the optional intermediate layer, and the polysiloxane is obtained by reacting at least one organosilicon compound represented by the general Formula (I) and at least one organosilicon compound represented by the general Formula (II):

Owner:AGFA OFFSET BV

Heat-sensitive imaging material for making lithographic printing plates requiring no processing

InactiveUS6132934AImprove photolithographic effectGood lithography performanceDiffusion transfer processesRadiation applicationsEngineeringHeat sensitive

According to the present invention there is provided a heat-sensitive imaging material for making lithographic printing plates which require no processing. The heat-sensitive imaging element comprises on a lithographic base having a hydrophilic surface a metallic or metal oxide layer and on top thereof an oleophobic polymeric layer having a thickness of less than 5 mu m and comprising a polymer containing phenolic groups.

Owner:AGFA GEVAERT AG

Resist composition and method of forming resist pattern

ActiveUS7960091B2Good lithography performancePhotosensitive materialsSemiconductor/solid-state device manufacturingSimple Organic CompoundsResist

Owner:TOKYO OHKA KOGYO CO LTD

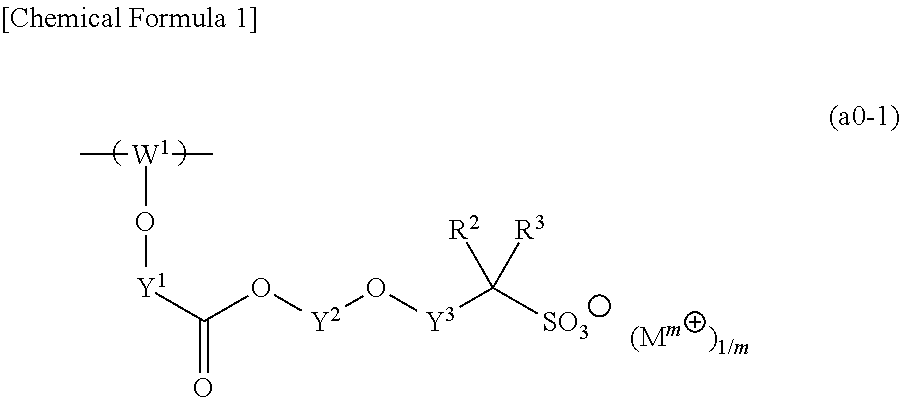

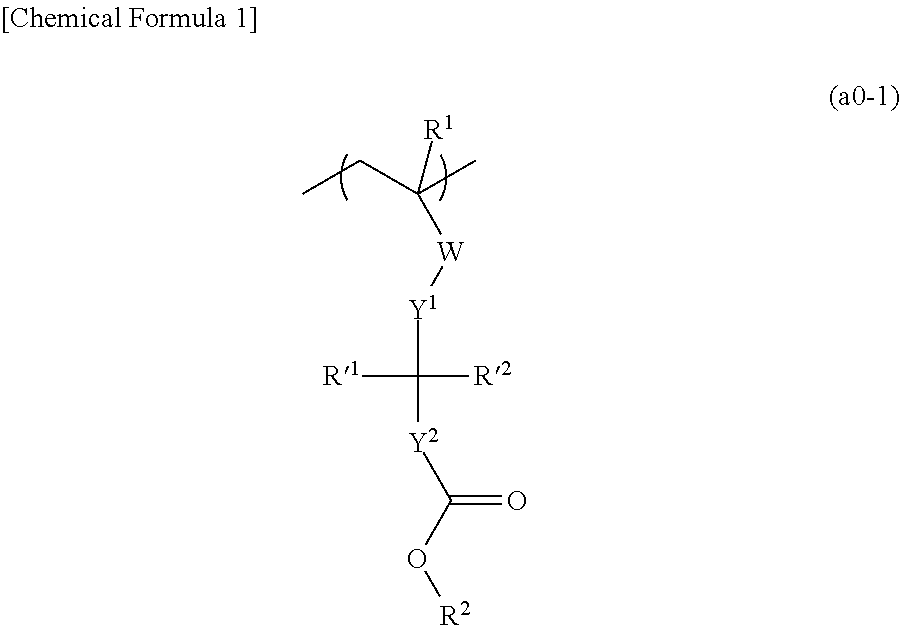

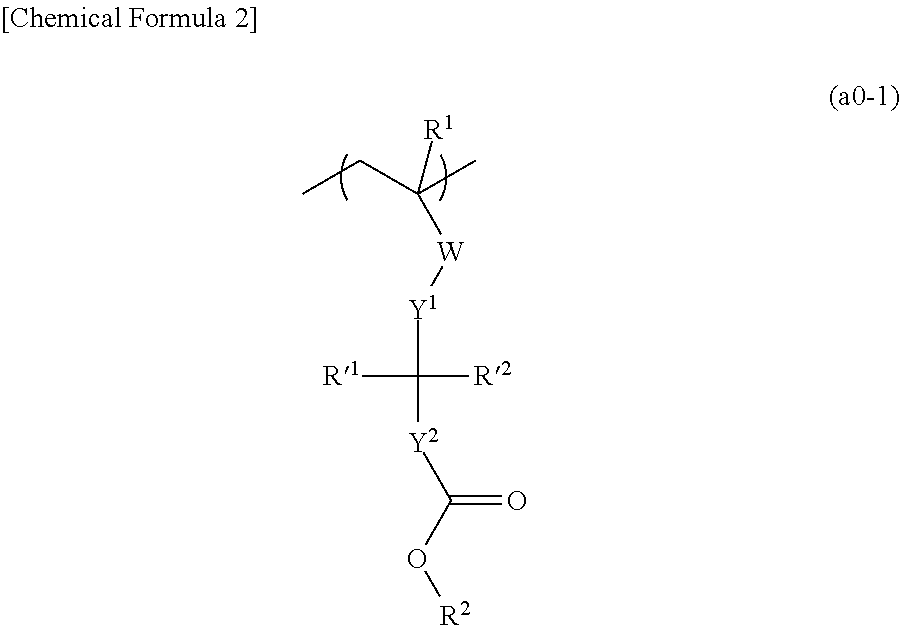

Resist composition, method of forming resist pattern and polymeric compound

ActiveUS8795948B2Good lithography performanceOrganic chemistryPhotosensitive materialsCompound aPolymer science

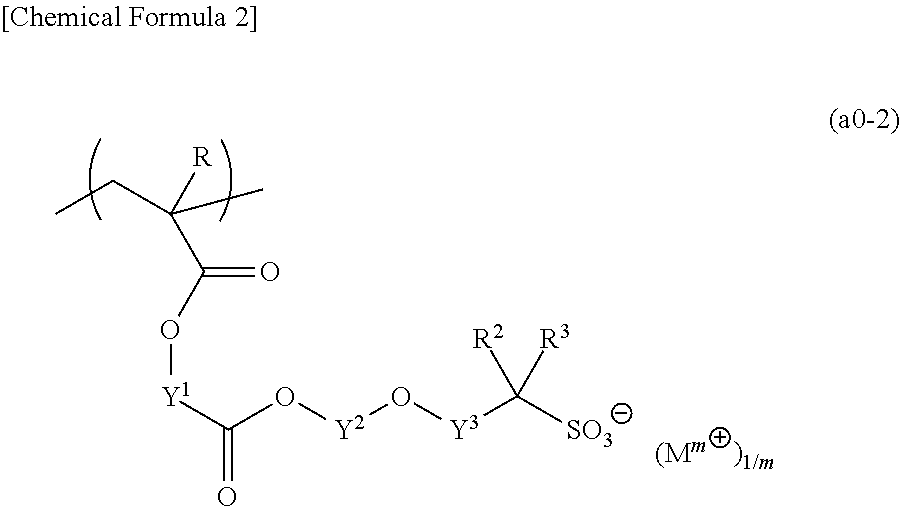

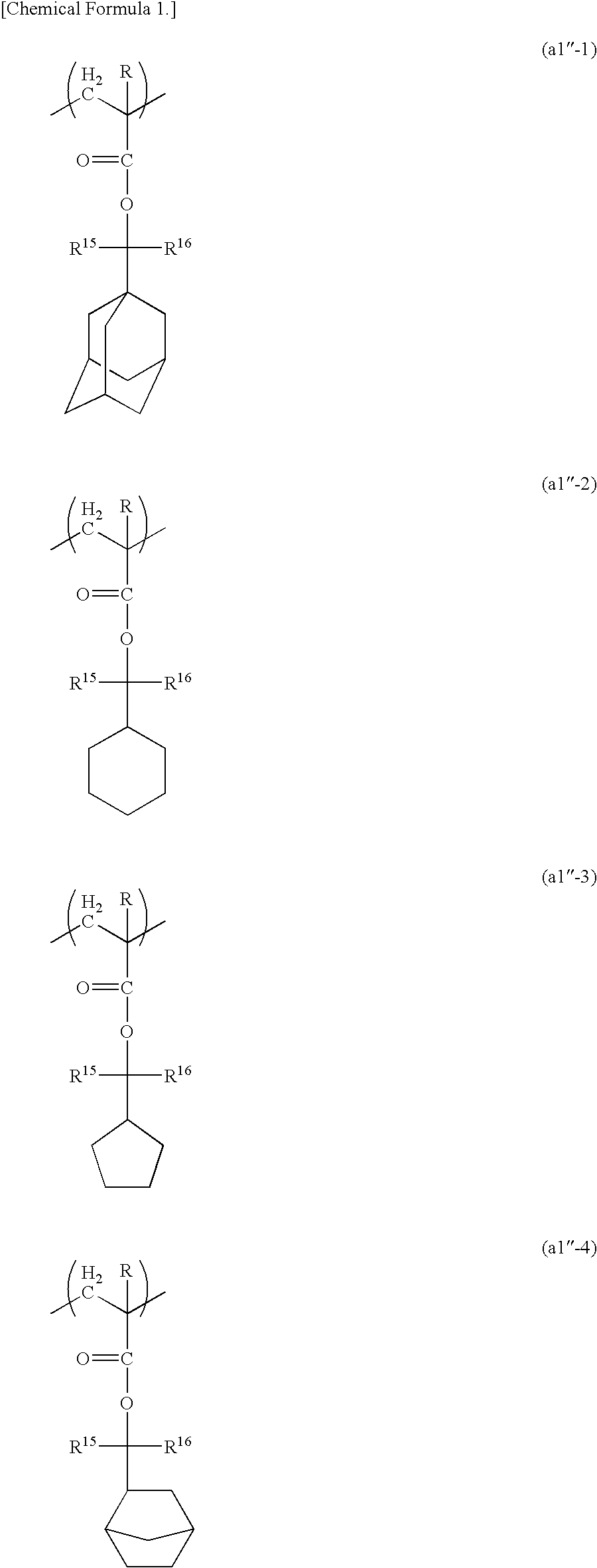

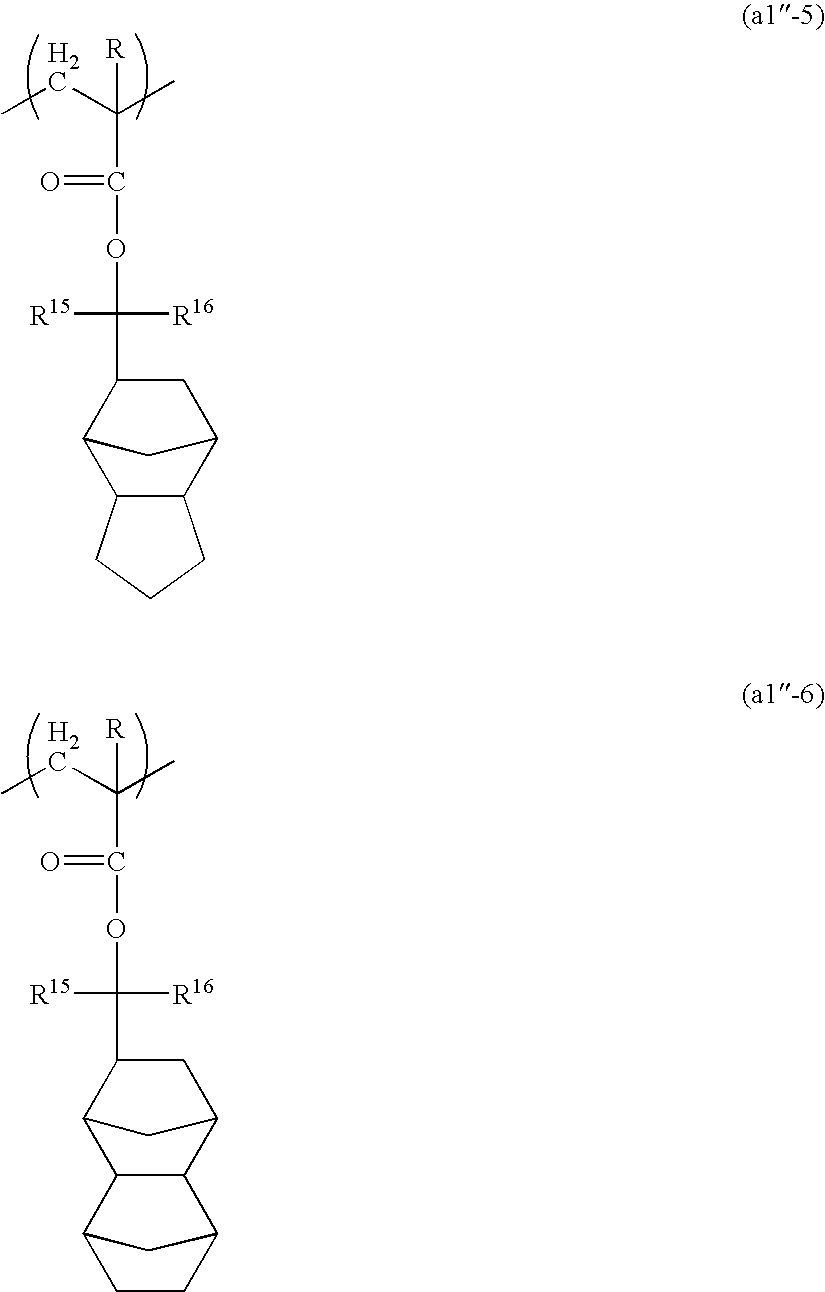

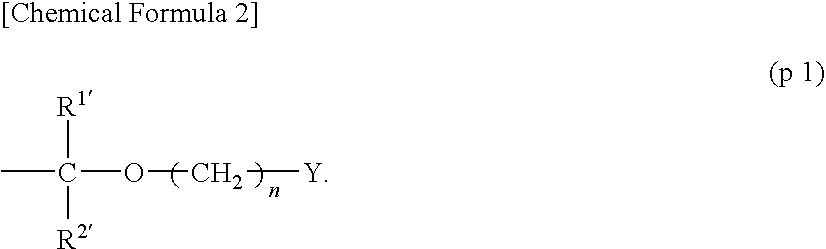

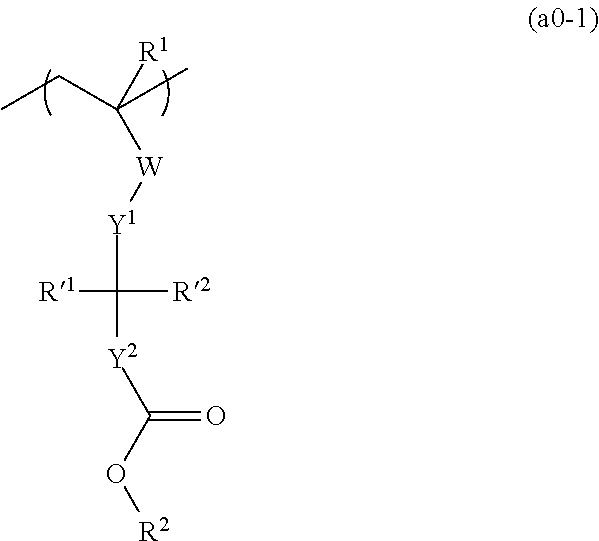

A resist composition including a base component (A) which generates acid upon exposure and exhibits changed solubility in a developing solution under the action of acid, the base component (A) containing a polymeric compound (A1) including a structural unit (a0) represented by general formula (a0-1) shown below, a structural unit (a1) containing an acid decomposable group which exhibits increased polarity by the action of acid and a structural unit (a6) which generates acid upon exposure (wherein R1 represents a hydrogen atom, an alkyl group or a halogenated alkyl group; W represents —COO—, —CONH— or a divalent aromatic hydrocarbon group; Y1 and Y2 represents a divalent linking group or a single bond; R′1 represents a hydrogen atom or an alkyl group of 1 to 6 carbon atoms; R′2 represents a monovalent aliphatic hydrocarbon group; and R2 represents an —SO2— containing cyclic group).

Owner:TOKYO OHKA KOGYO CO LTD

Norbornene, hexafluoropropylene and acrylonitrile ternary polymerization catalyst and ternary polymerization method

ActiveCN105693928AHigh yieldImprove corrosion resistancePentamethylcyclopentadieneHexafluoropropylene

The invention relates to a norbornene, hexafluoropropylene and acrylonitrile ternary polymerization catalyst. The preparation method of the catalyst comprises the steps that (pentamethyl cyclopentadiene) cerium chloride and a ligand are dissolved into a first solvent in a dry three-mouth flask in the inertia atmosphere, titanium tetrachloride is dropped into the solution while stirring is performed, stirring is performed at the constant temperature of 30-60 DEG C for 30-60 min after dropping is performed, and a cerium-titanium complex catalyst is obtained. The polymerization method comprises the steps that a norbornene monomer, a hexafluoropropylene monomer and an acrylonitrile monomer are taken and added into a reaction kettle where repeated vacuumizing and nitrogen charging are performed, and a second solvent is added for dissolution; then, the cerium-titanium complex catalyst is added, a reaction is performed under the certain temperature and pressure, and the product is washed to obtain the terpolymer. Catalyst raw materials are low in price and easy to obtain, catalytic activity can be generated at low temperature, norbornene, hexafluoropropylene and acrylonitrile ternary polymerization is catalyzed, the reaction temperature is low, the catalysis efficiency is high, the copolymer yield is high, and the terpolymer is good in photoetching performance.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

New Alkali Soluble Resin

InactiveUS20110247516A1Good lithographic propertyImprove photolithography qualityPhotosensitive materialsSemiconductor/solid-state device manufacturingArylHydrogen

An alkali soluble resin is disclosed comprising a first monomeric unit including at least one sulfonamide group and a second monomeric unit derived from the monomer according to the following structure (I) wherein R1 represents a structural moiety comprising an ethylenically unsaturated polymerisable group; R2, R3 and R4 independently represent hydrogen, an optionally substituted alkyl, alkenyl, alkynyl, alkaryl, aralkyl, aryl or heteroaryl group or, the necessary atoms to form a five to eight membered ring.

Owner:AGFA OFFSET BV

Resist composition and method of forming resist pattern

InactiveUS20130337387A1Excellent lithography propertyHigh resolutionPhotosensitive material processingOriginals for photomechanical treatmentResistHydrogen atom

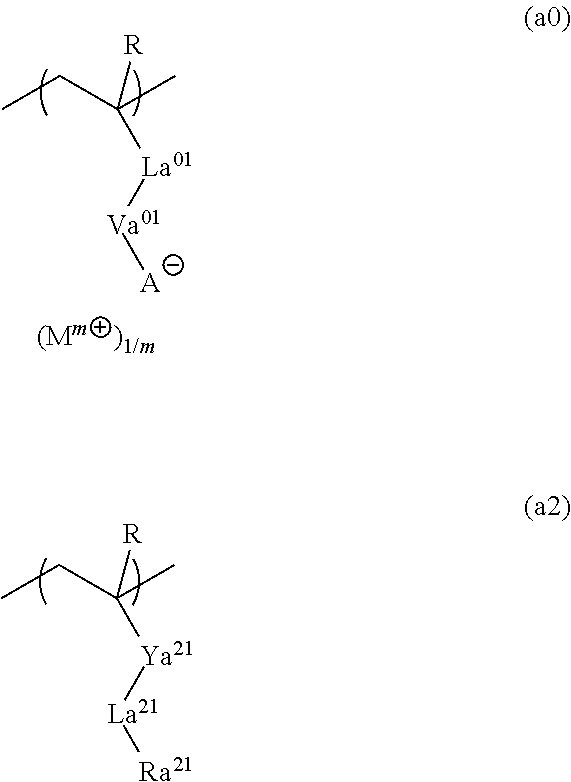

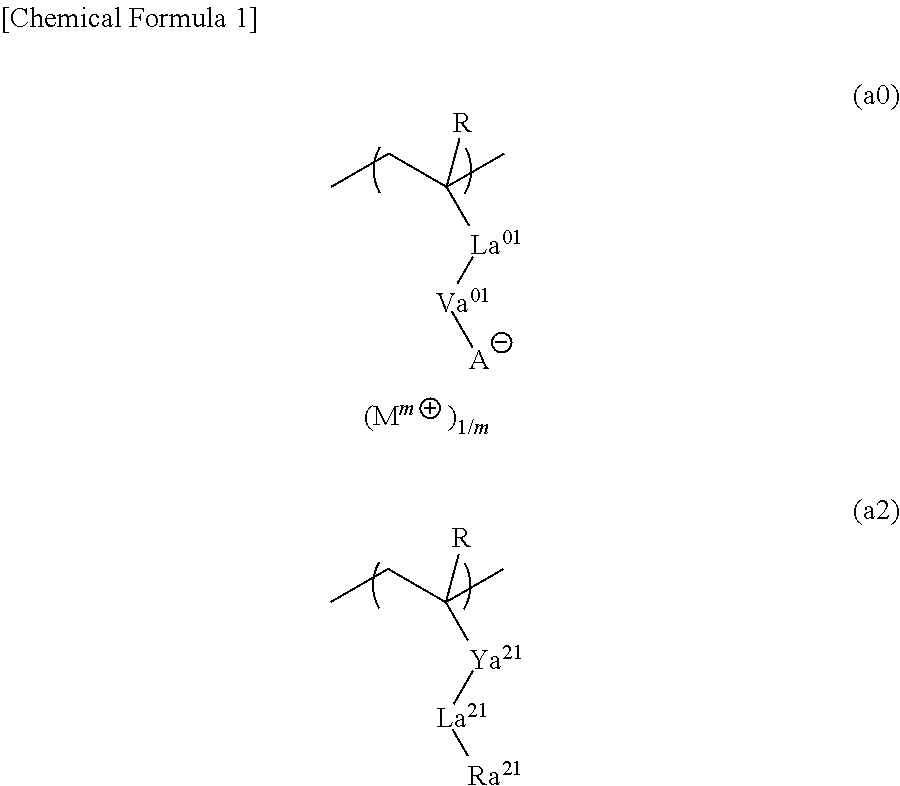

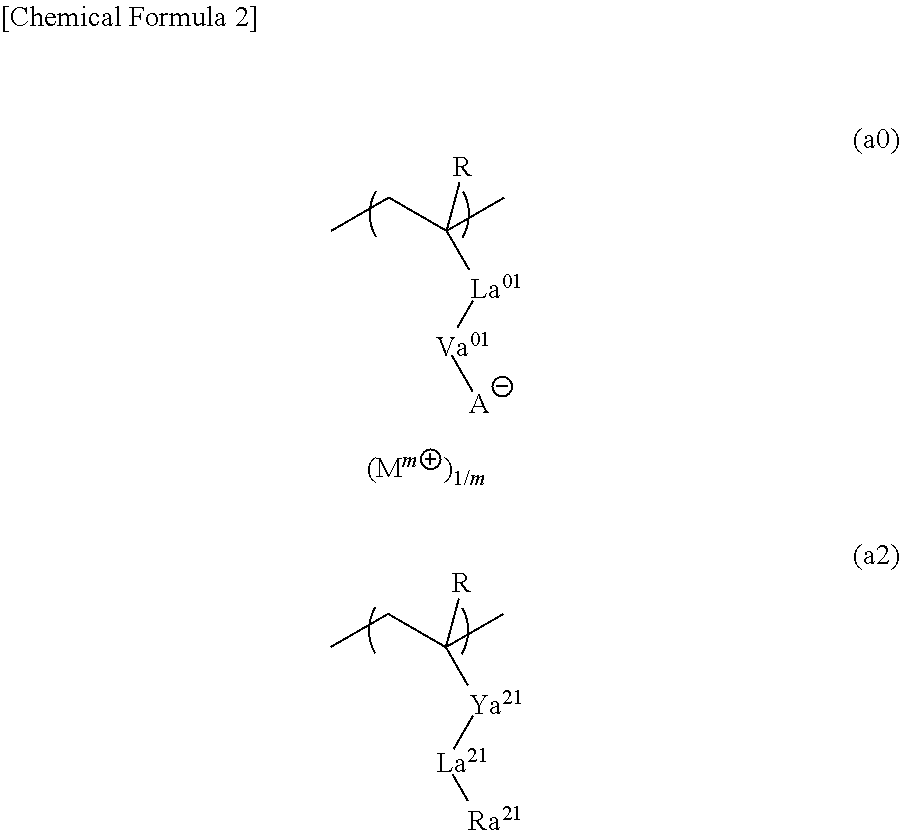

A resist composition including a base component (A) which generates acid upon exposure and exhibits changed solubility in a developing solution by the action of acid, (A) including (A1) including (a0) and (a2), and the resist composition having a Tf temperature of lower than 170° C. (└La01 represents —COO—, —CON(R′)— or a divalent aromatic group, R′ represents a hydrogen atom or a methyl group, Va01 represents a linear alkylene group of at least 3 carbon atoms, A− represents an anion-containing group, Mm+ represents an organic cation, Ya21 represents a single bond or divalent linking group, La21 represents —O—, —COO—, —CON(R′)— or —OCO—, R′ represents a hydrogen atom or a methyl group, and Ra21 represents a lactone-containing group, a carbonate containing group or an —SO2— containing group.

Owner:TOKYO OHKA KOGYO CO LTD

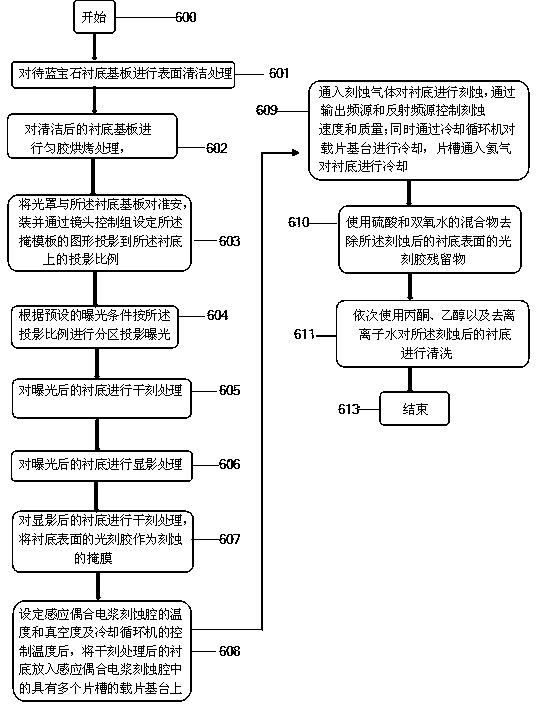

Process for manufacturing patterning sapphire substrate

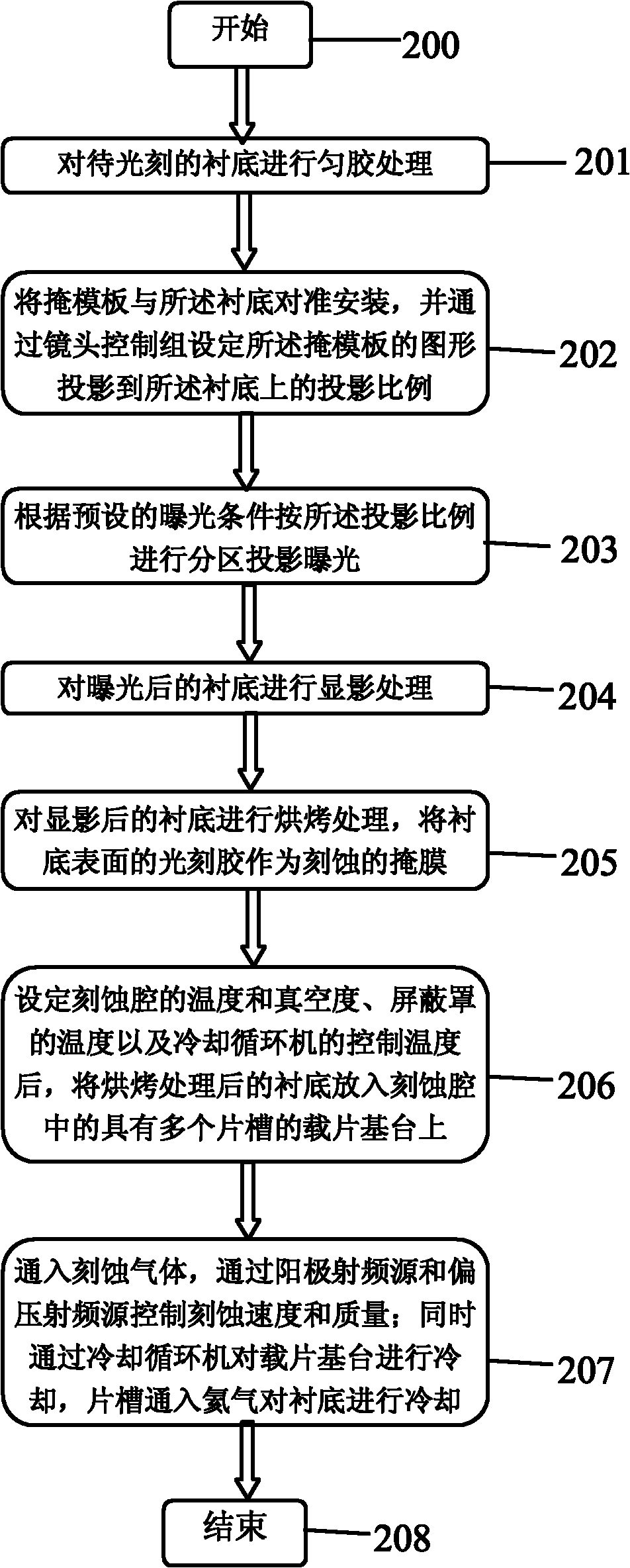

InactiveCN103426980AImprove productivityImprove graphics consistencyPhotomechanical exposure apparatusMicrolithography exposure apparatusProduction rateEngineering

The invention relates to a method for manufacturing a patterning inductive coupling plasma sapphire substrate. The process for manufacturing the patterning inductive coupling plasma sapphire substrate comprises the following steps: conducting cleaning processing on the sapphire substrate; conducting alignment installation on sapphire and the substrate, arranging uniform glue on the front face according to the set distance, and coating the uniform glue on the substrate; 1.3, conducting projection exposure according to the preset exposure condition; conducting developing processing on the substrate after the exposure, conducting dry-etching processing on the substrate after developing, and using photoresist on the surface of the substrate as an etching mask; setting the temperature and the vacuum degree of an inductive coupling plasma etching cavity, and the control temperature of a cooling circulation machine, and then placing the substrate after the dry-etching processing into a slide glass base station in the etching cavity; etching the substrate by filling inductive coupling plasma etching gas into the substrate, and controlling the speed and quality of etching by outputting frequency source power and refraction frequency source power; meanwhile, cooling the slide glass base station through the cooling circulation machine. According to the method for manufacturing the inductive coupling plasma sapphire substrate, the productivity and the graphical consistency are greatly improved, the rate of finished products is high, and the process is stable.

Owner:吉林省九洲光电科技股份有限公司

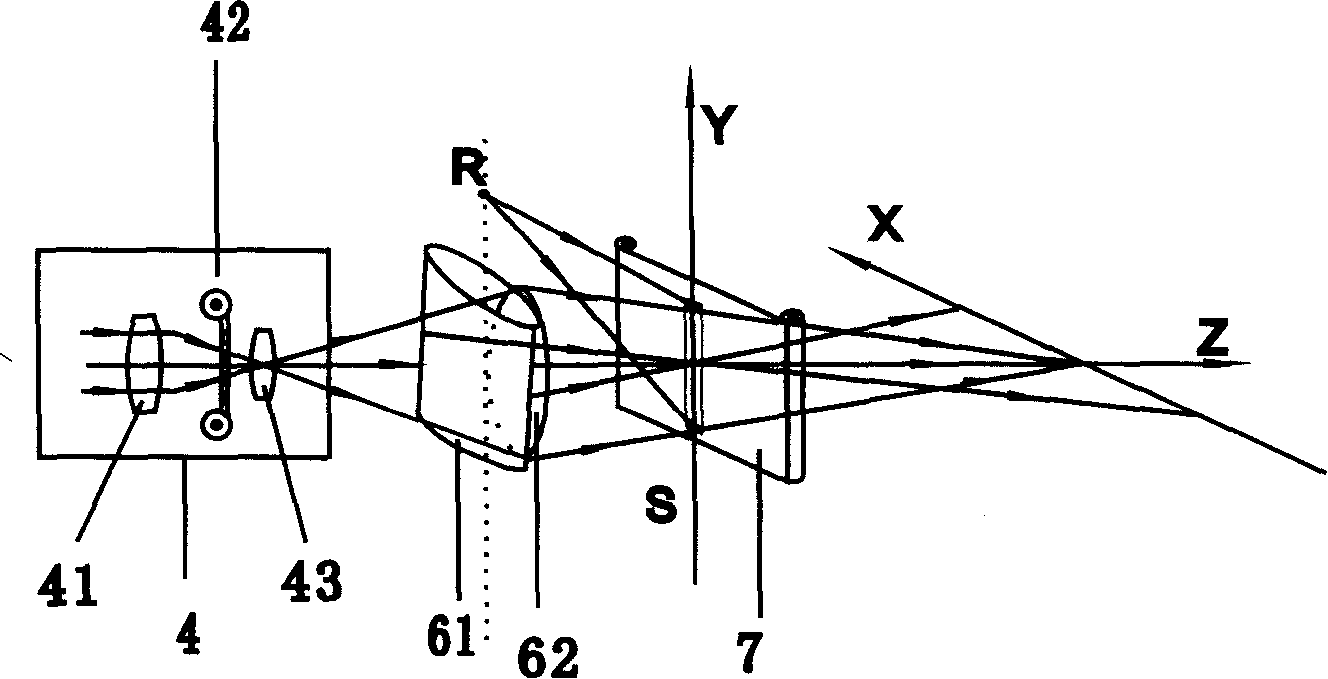

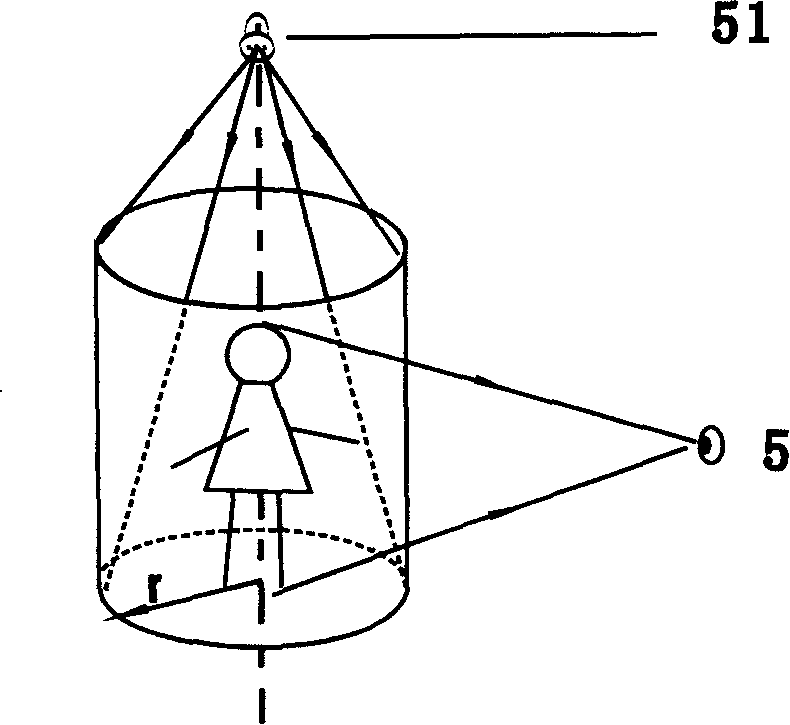

Cylinder type hologram manufacture method, manufacture device and manufactured hologram

The invention discloses a making method for a cylindrical hologram, a making device and a made hologram thereby. The making method comprises following steps: encoding each line information after dividing a plurality of digital images with different visual angles into a plurality of line information; reading the encoded line information by a projection system, condensing the read line information by laser permeating the projection system at a corresponding point of the holographic recording material; recording each line information of each gram spot by spot until a unit hologram is recorded; recording each unit hologram row by row until unit holograms of all view angles are all recorded on the corresponding holographic recording material. The invented method divides and encodes an image into a plurality of line information, records the line information spot by spot on the holographic recording material disposed on the focus of the imaging lens, and the line information is packed recorded by an imaging lens, so that the radius of the final cylindrical hologram is adjusted by adjusting the object distance.

Owner:AFC TECH

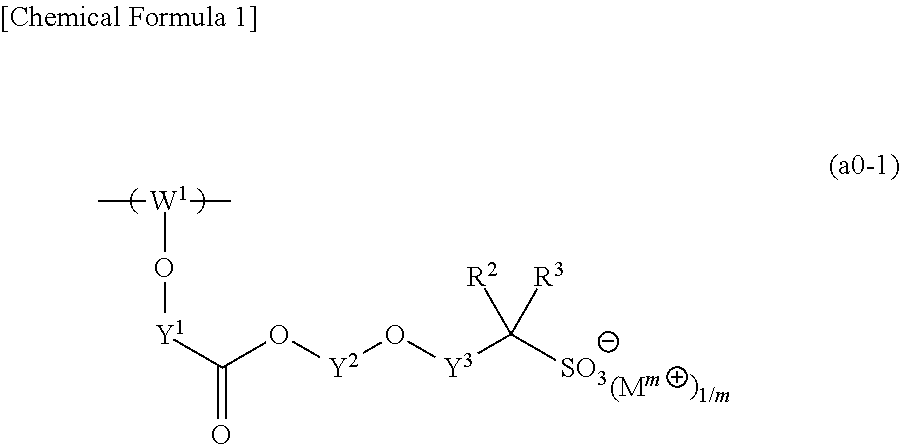

Resist composition, method of forming resist pattern, polymeric compound, and compound

ActiveUS20190107779A1High sensitivityMaintain good propertiesOrganic chemistryPhotomechanical coating apparatusCompound aPolymer science

A resist composition including a resin component having a structural unit derived from a compound represented by formula (a0-1), in which W represents a polymerizable group-containing group; Ra01 represents an alkyl group or an aromatic heterocyclic group containing an oxygen atom or a sulfur atom; in the case where Ra01 is an aromatic heterocyclic group containing an oxygen atom or a sulfur atom, Ra02 is a group which forms an aliphatic cyclic group containing an electron-withdrawing group, together with the tertiary carbon atom (*C) to which Ra01 is bonded; and when Ra01 is an alkyl group, Ra02 is a group in which an aliphatic cyclic group containing an electron-withdrawing group forms a condensed ring together with an aromatic heterocyclic group containing an oxygen atom or a sulfur atom.

Owner:TOKYO OHKA KOGYO CO LTD

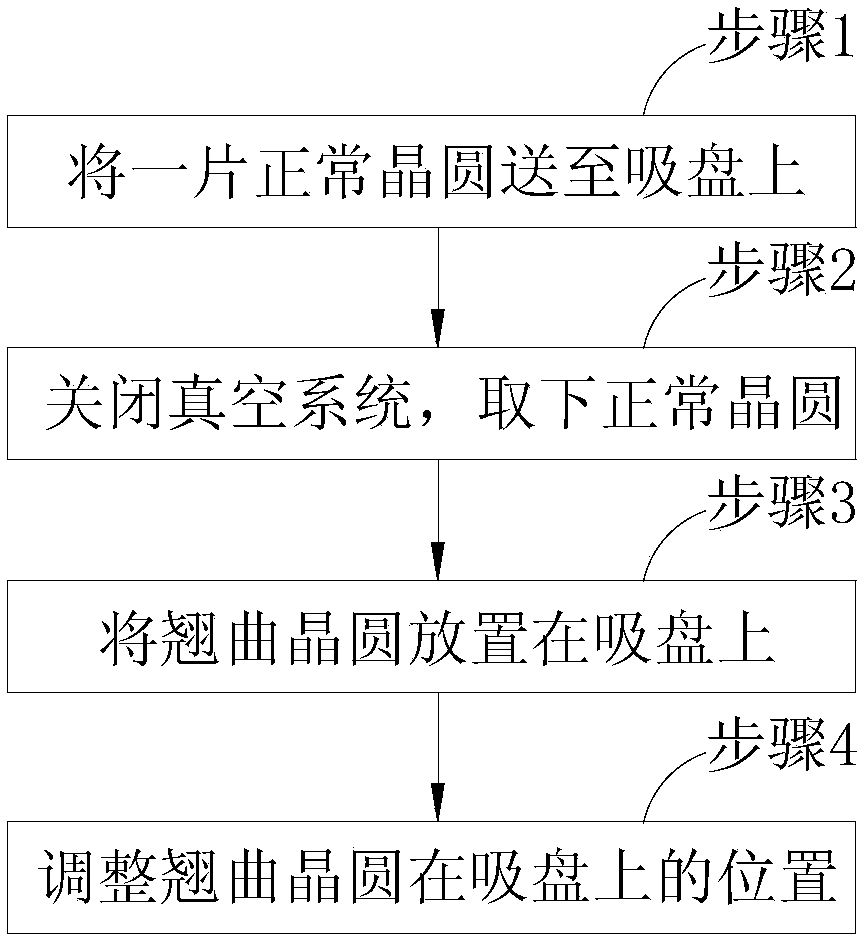

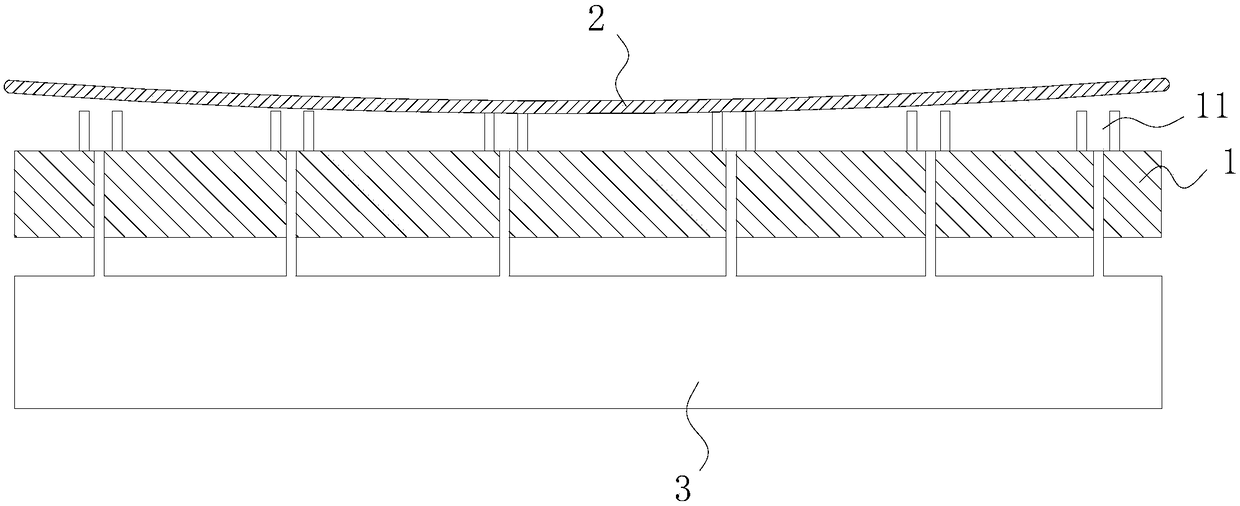

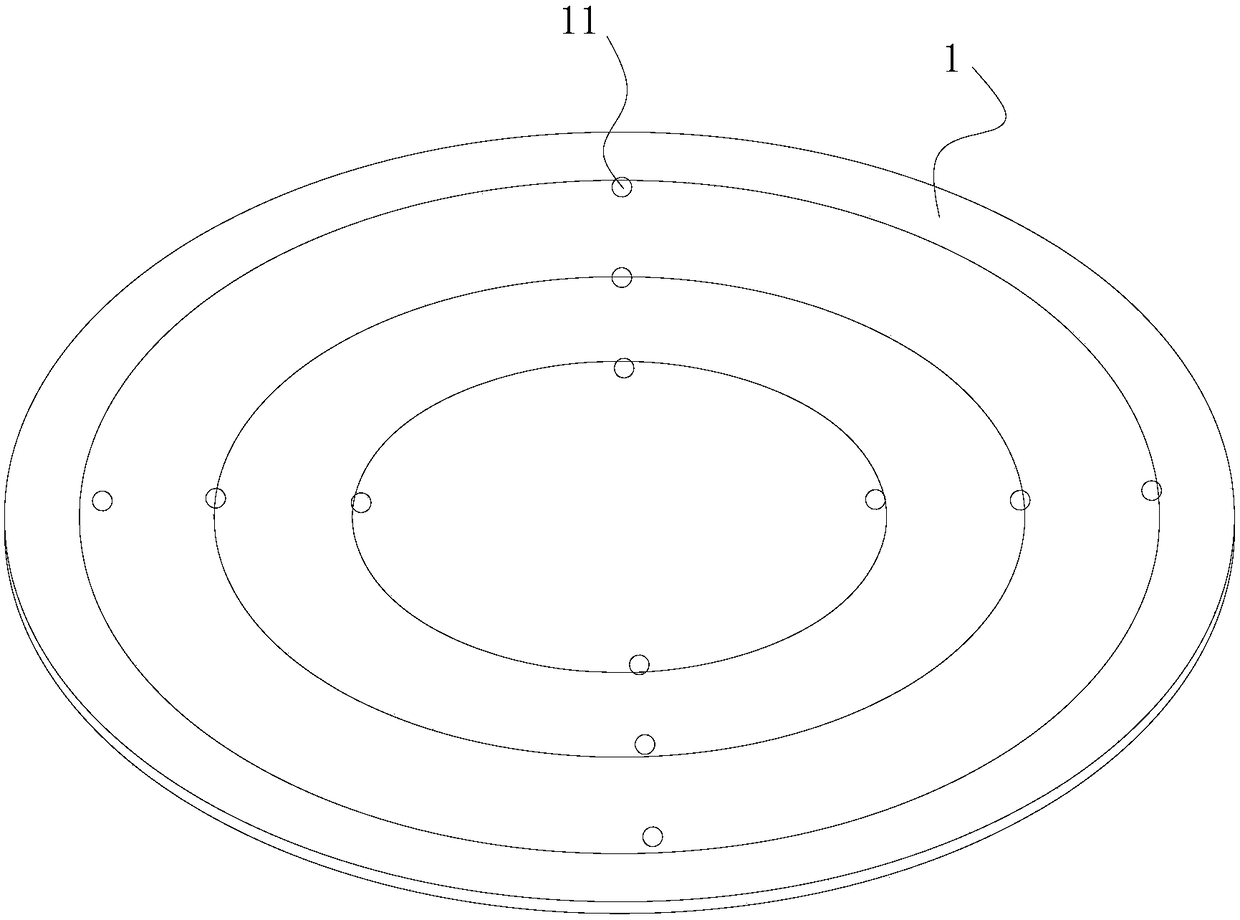

Absorption method of warped wafer and device using absorption method

ActiveCN108206144AGuaranteed Sustained ReleaseImprove adsorption capacitySemiconductor/solid-state device manufacturingEngineeringControl switch

The invention discloses an absorption method of a warped wafer and a device using the absorption method, belongs to the technical field of semiconductors, and is designed for solving the problem thatabsorption for an existing warped wafer is impossible. The method includes the steps of using a normal wafer to form an absorption normal state on a sucker, using a warped wafer to replace the normalwafer; horizontally adjusting and / or rotationally adjusting the position of the warped wafer on the sucker until the warped wafer is absorbed on the sucker. The device comprises the sucker connected to a vacuum system, a plurality of suction holes formed in the sucker, and a control switch arranged on the vacuum system. According to the method for absorbing warped wafers, the wafers are not abandoned because of warping, so that as many wafers as possible can be successfully cut into chips. The rate of finished products is improved, and the cost is reduced. The device disclosed by the inventioncan be used for photoetching the warped wafer by using the absorption method, so that the wafers are prevented from being abandoned, and the photoetching effect is good.

Owner:DYNAX SEMICON

Positive photosensitive resin composition

ActiveUS7674566B2Good lithography performanceElectric discharge tubesSemiconductor/solid-state device detailsLithographic artistImage resolution

Owner:ASAHI KASEI ELECTRONICS CO LTD

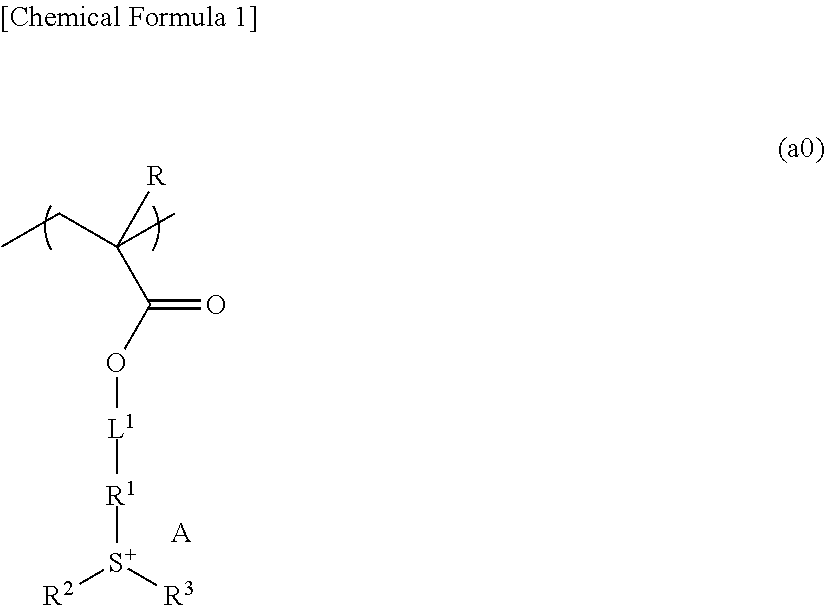

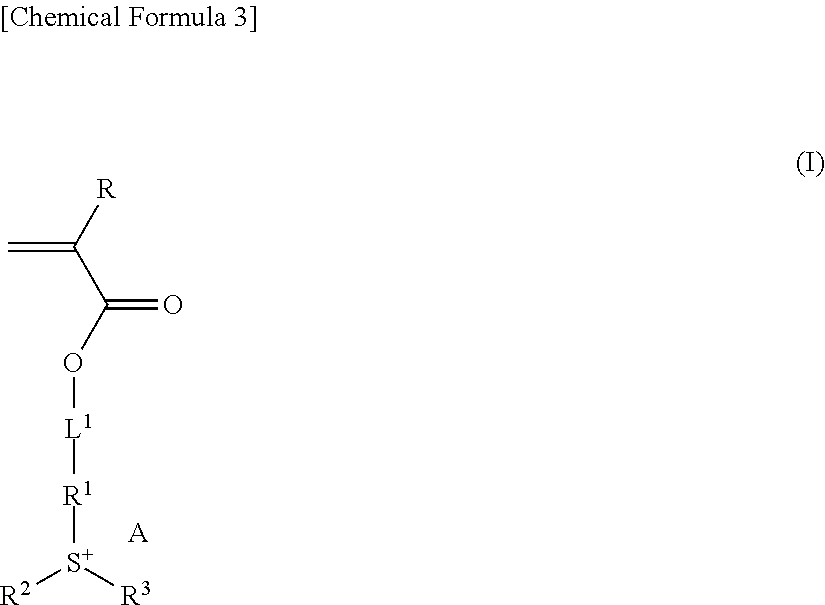

Resist composition, method of forming resist pattern, polymeric compound, and compound

ActiveUS9023581B2Good lithography performanceOrganic chemistryOrganic compound preparationCompound aResist

A resist composition which can form a very fine resist pattern with excellent lithography properties, a new polymeric compound useful for the resist composition, and a compound useful as a monomer for the polymeric compound. The resist composition contains a polymeric compound containing a structural unit (a0) represented by general formula (a0) shown below. In the formula (a0), A is an anion represented by the general formula (1) or (2).

Owner:TOKYO OHKA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com