Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Fast demolition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing reinforced concrete chimney

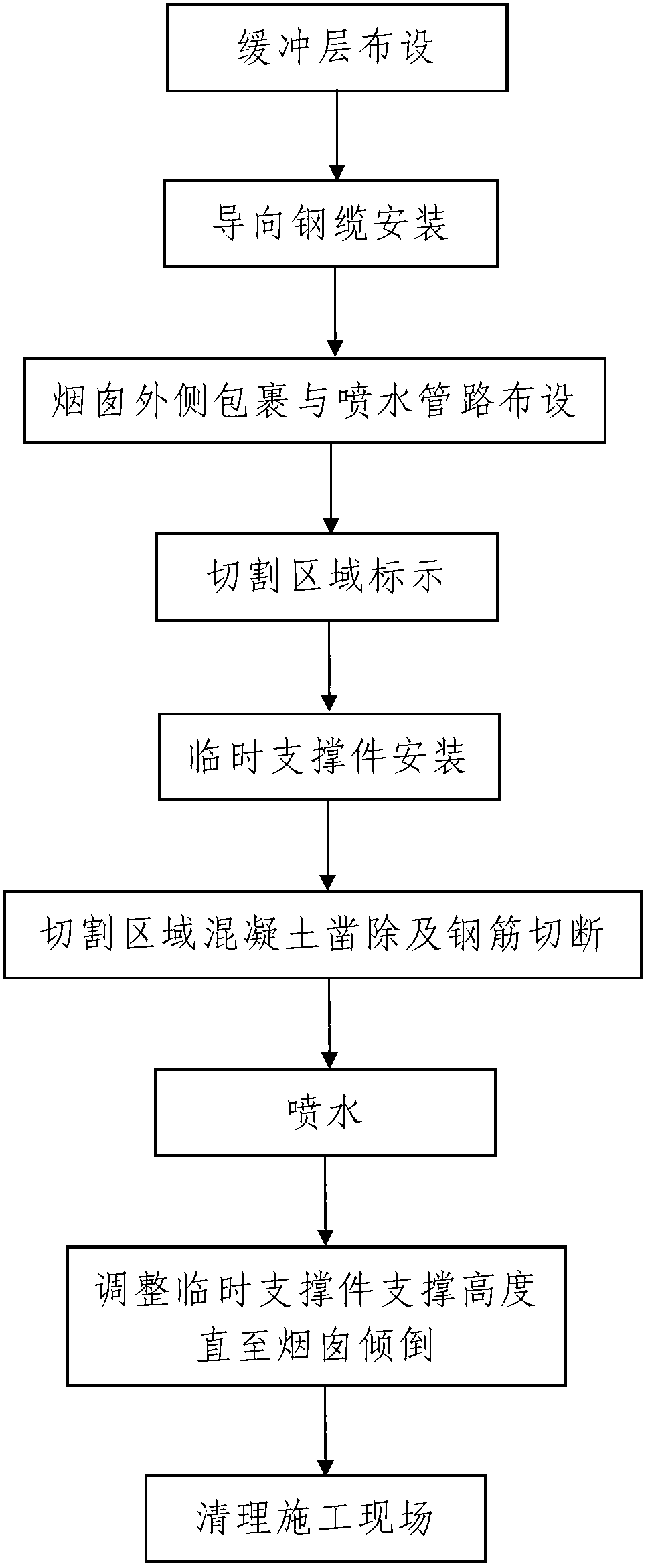

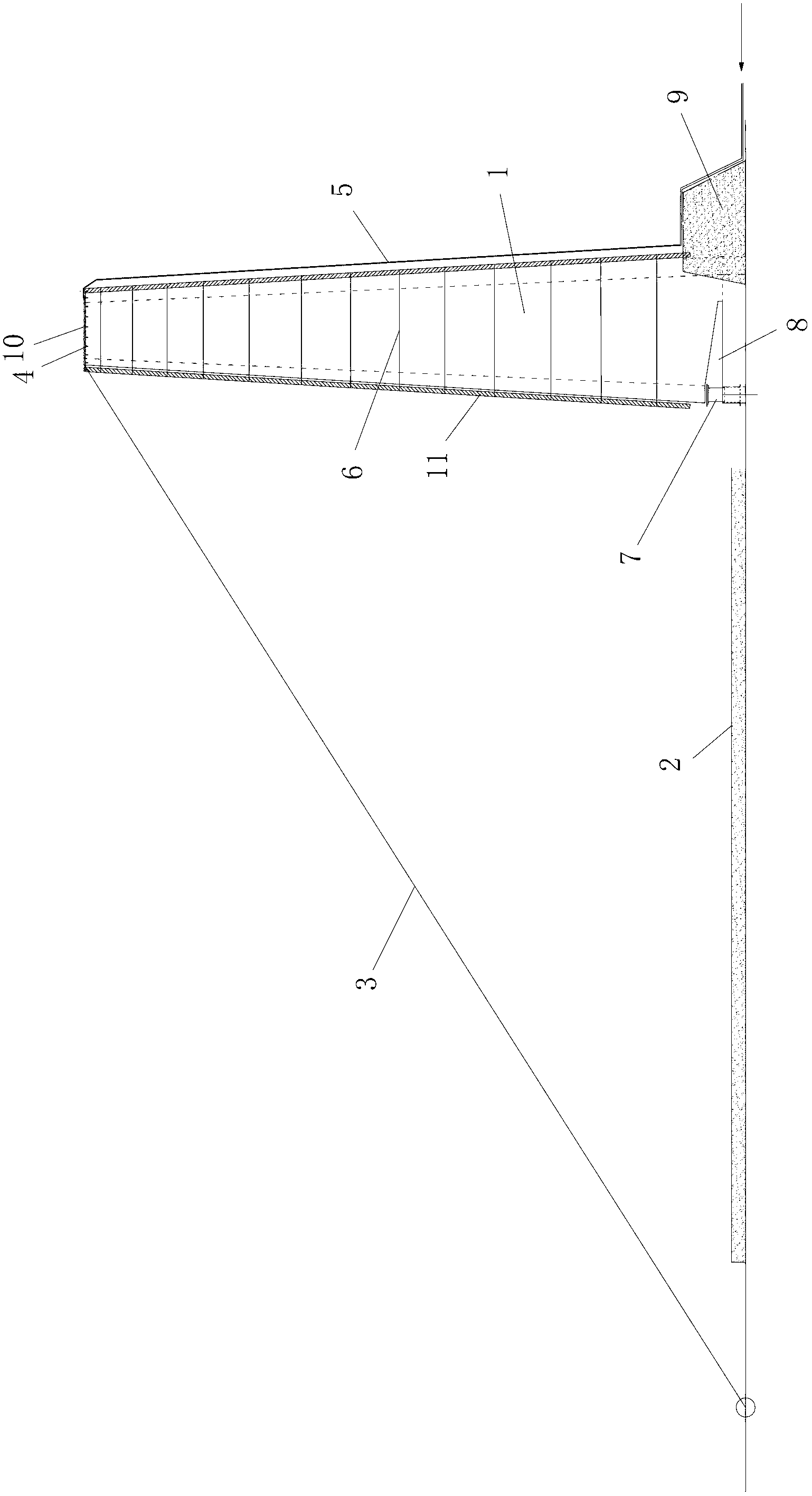

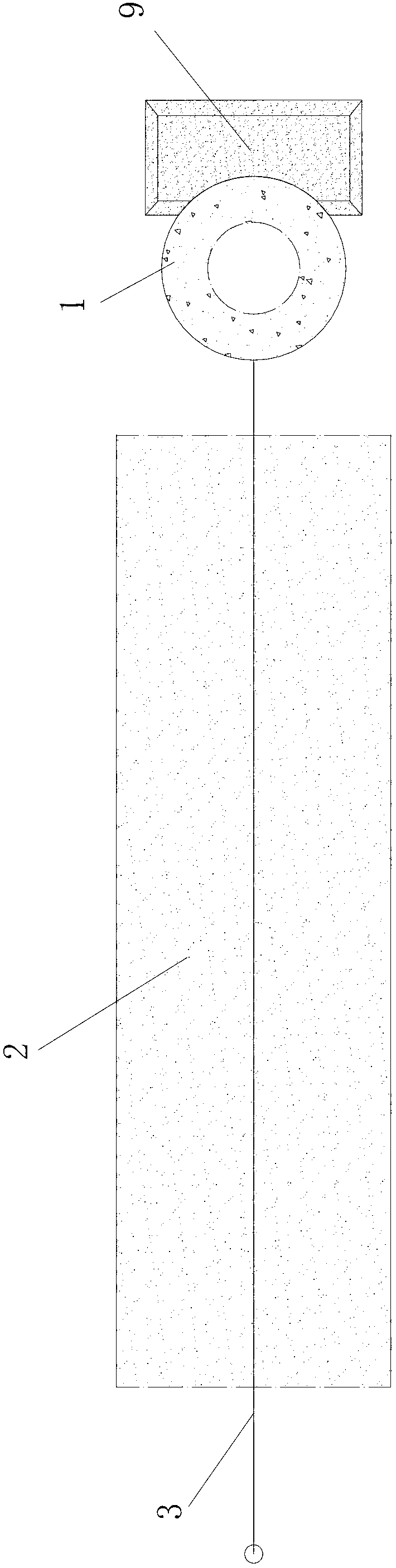

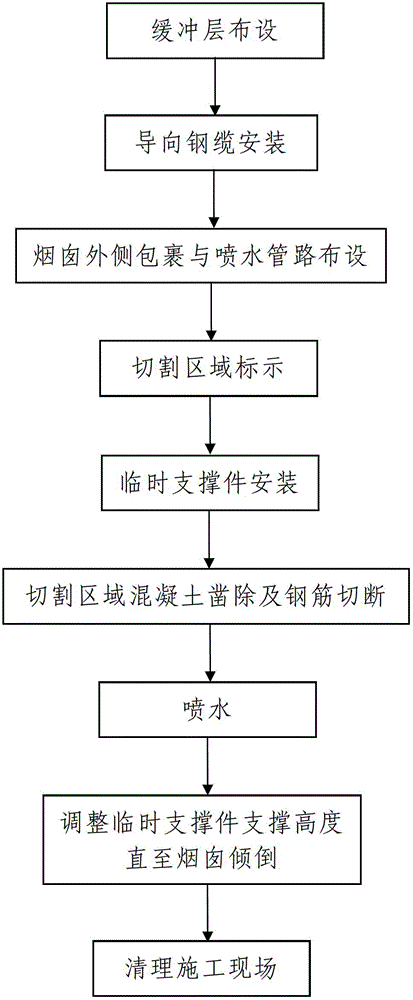

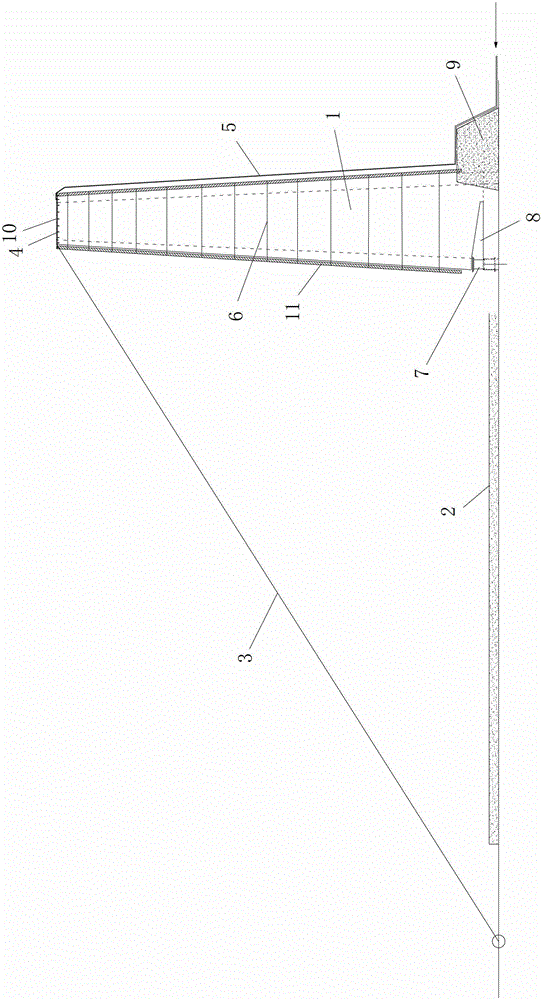

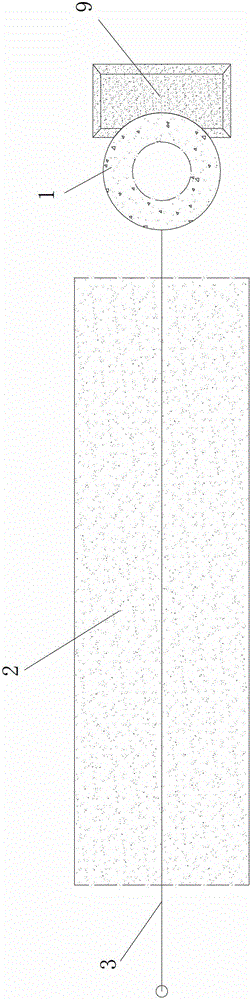

The invention discloses a method for removing a reinforced concrete chimney. The method for removing the reinforced concrete chimney comprises the following steps of: I, performing buffer layer laying: laying a buffer layer at the toppling position of the reinforced concrete chimney; II, performing guide steel cable installation: laying a guide steel cable for guiding the chimney during a toppling process; III, performing chimney outer side packaging and water spray pipeline laying; IV, performing cutting area marking; V, performing temporary support member installation; VI, performing cutting area concrete chiseling away and steel bar cutting off; VII, performing water spraying; VIII, performing adjustment on the support height of a temporary support member until the chimney is toppled: gradually adjusting the support height of the temporary support member downwards until the chimney is unstable under the effect of the gravity of the chimney and is toppled onto the buffer layer; and IX, clearing a construction site. The method disclosed by the invention is simple in step, reasonable in design, convenient in implementation, high in removal speed and good in using effect. The chimney is entirely, slowly and directionally toppled by utilizing the temporary support effect of the support member, and the construction problem that the reinforced concrete chimney is entirely and rapidly removed under a non-blasting operation condition is solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD

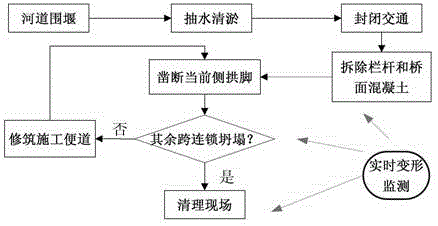

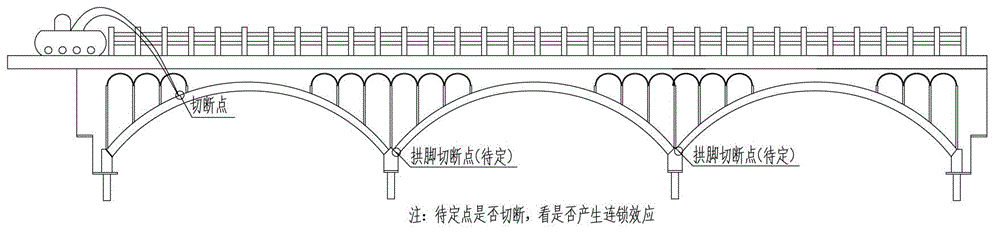

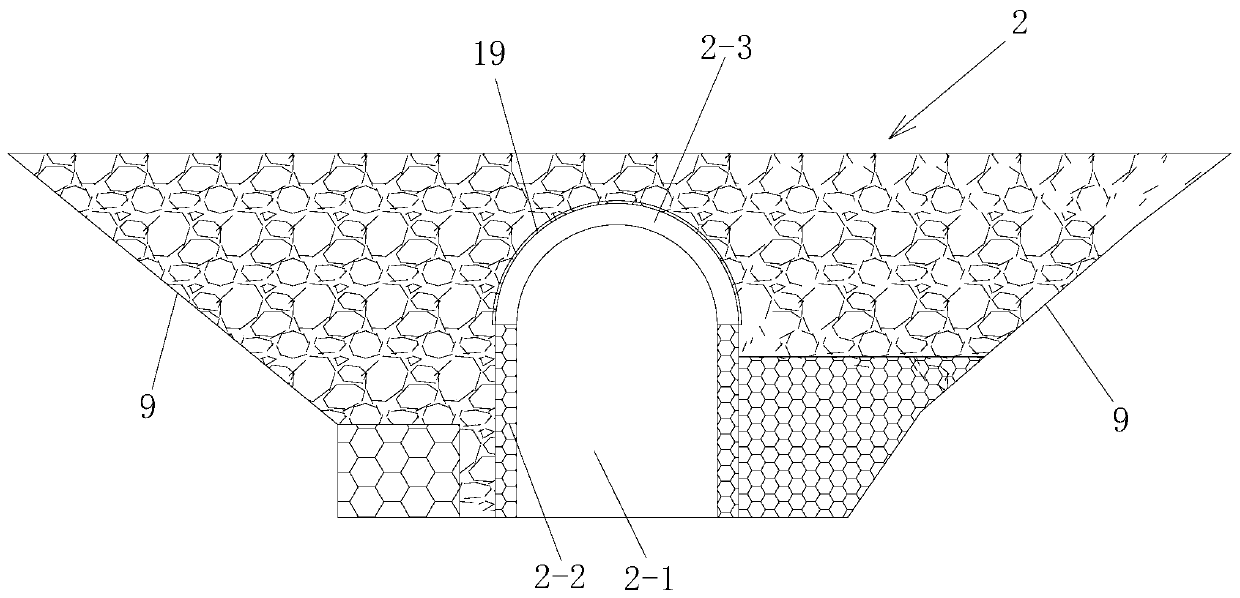

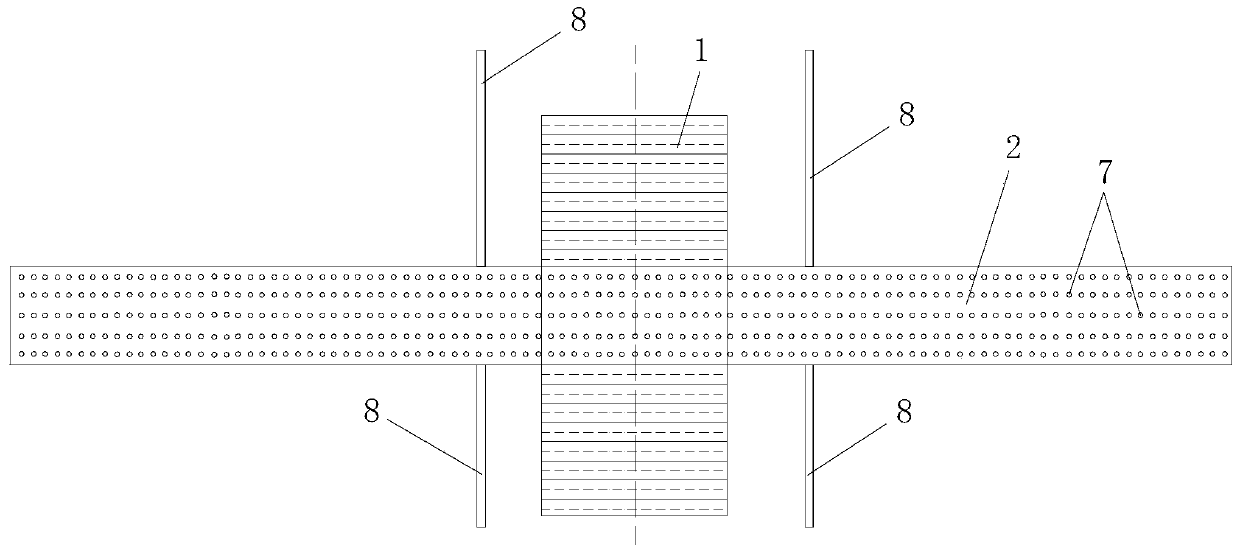

Quick dismantling method for multi-span continuous double arch bridge causing connected arch effect

The invention discloses a quick dismantling method for a multi-span continuous double arch bridge causing a connected arch effect. The quick dismantling method comprises the following steps of: (1) coffering a river channel and ensuring that fragments and residues during bridge dismantling can be cleaned in time; (2) pumping water and dredging to leave a construction site; (3) closing a navigable river and ensuring the safety of navigable vessels; (4) dismantling the railing and bridge surface concrete and reducing objects falling on the bridge surface; (5) sequentially chiseling off the arch ribs from the middle of an arch springing toward two sides; (6) enabling the bridge to continuously collapse by using the connected arch effect; and (7) treating wastes. According to the quick dismantling method disclosed by the invention, the construction period can be effectively shortened and the construction safety is improved; and the phenomenon that the river channel is blocked in the dismantling process is avoided by dredging a cofferdam, so that the construction cost is greatly reduced.

Owner:ZHEJIANG UNIV OF TECH

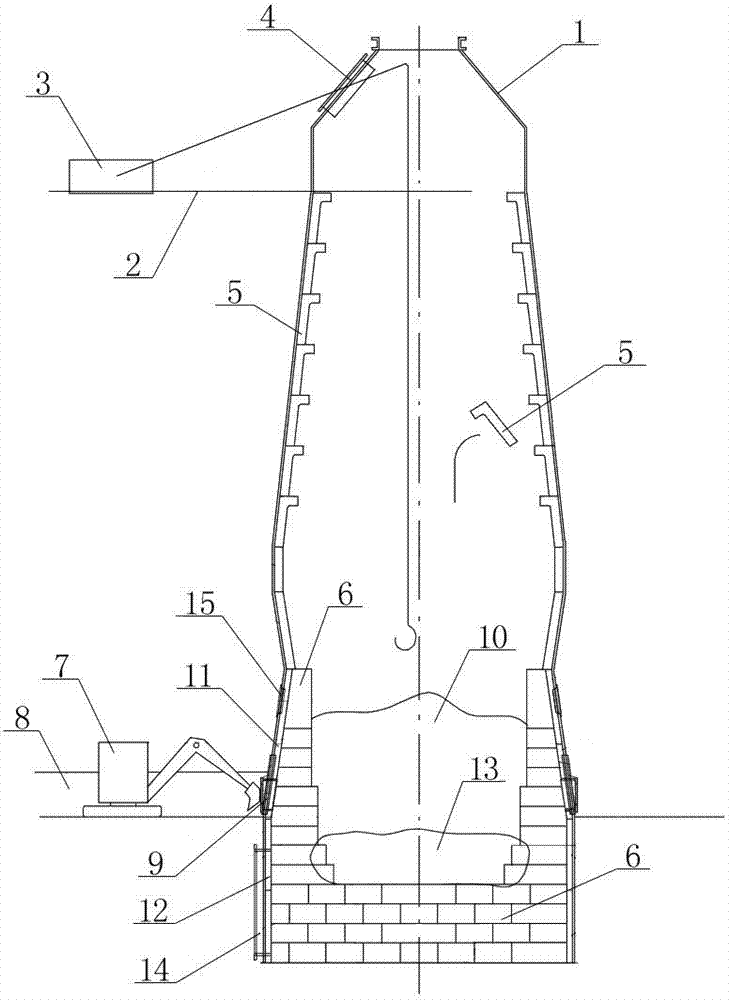

Method for quickly eliminating waste materials and remaining iron in a furnace during blast furnace overhaul

ActiveCN104726625AFast cleaningImprove securityBlast furnace componentsBlast furnace detailsBrickExcavator

The invention relates to a method for quickly eliminating waste materials and remaining iron in a furnace during blast furnace overhaul. The method is a quickly eliminating method for mechanically detaching waste materials and carbon bricks in a furnace on the premise that a blast furnace shell is locally changed, particularly for mechanically detaching and cleaning furnace materials and carbon brick refractory materials on the premise that the blast furnace shell is locally changed, and moreover synchronously knocking and crushing remaining iron clots in the furnace by means of detaching and falling of the upper cooling wall, and removing both remaining iron clots and waste materials out of the furnace by virtue of a grab excavator. The method has the characteristics of use of few labors, high detaching speed, convenience in operation, quick construction, safe construction and the like, and can be used for increasing the speed for cleaning waste materials in the furnace in the process of blast furnace overhaul. Compared with traditional manual detaching and cleaning mode, the method has the advantages that the speed for cleaning waste materials and remaining iron in the furnace during blast furnace overhaul can be increased and the safety factor of the process of constructing in the blast furnace can be improved.

Owner:河北二十冶建设有限公司

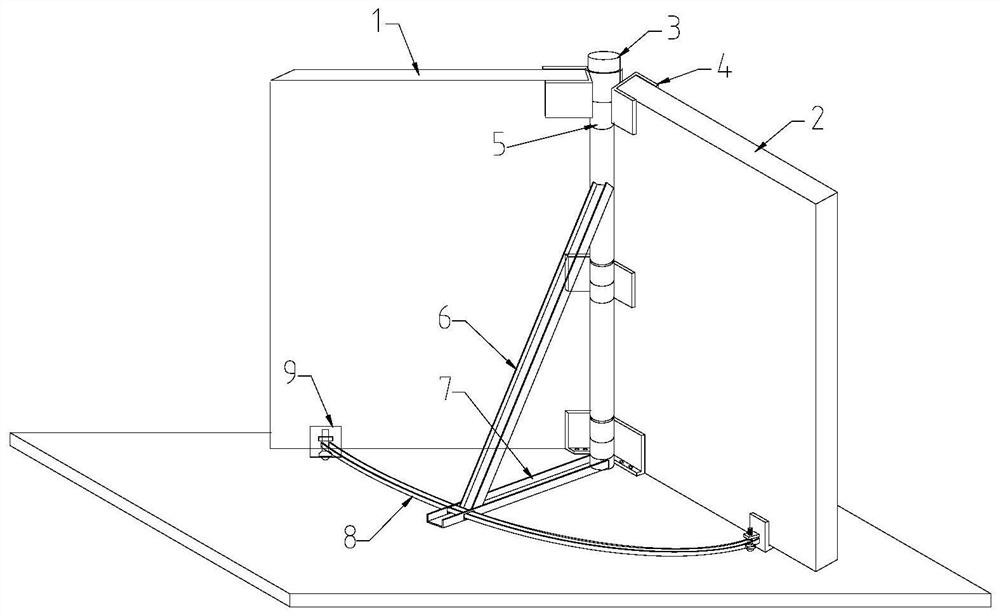

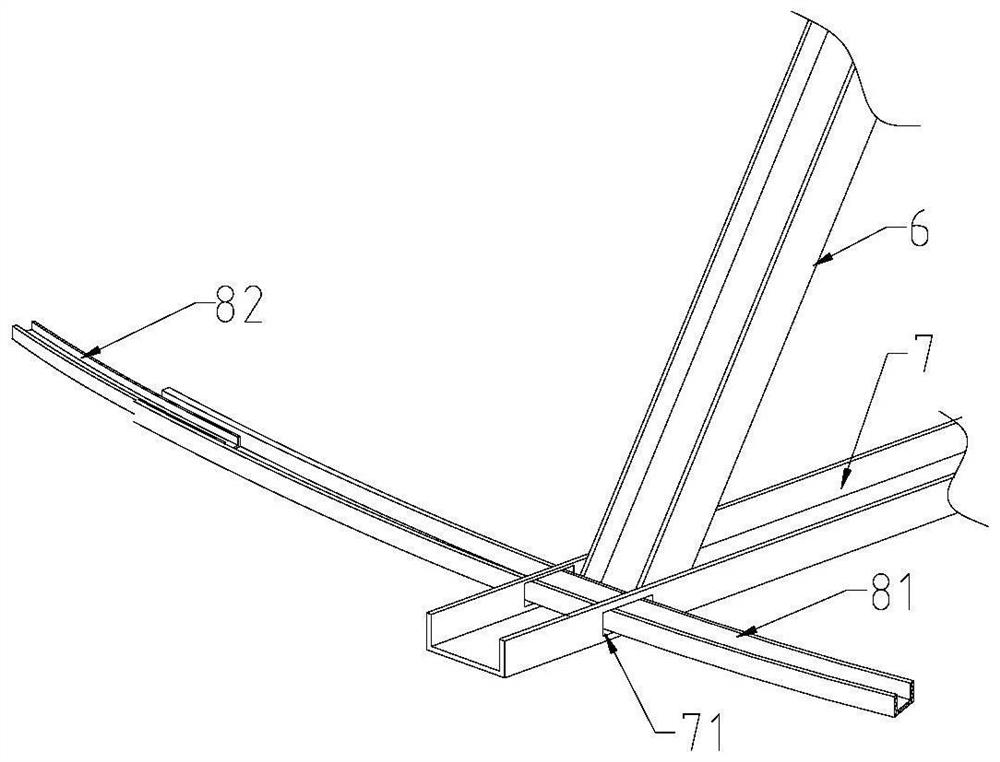

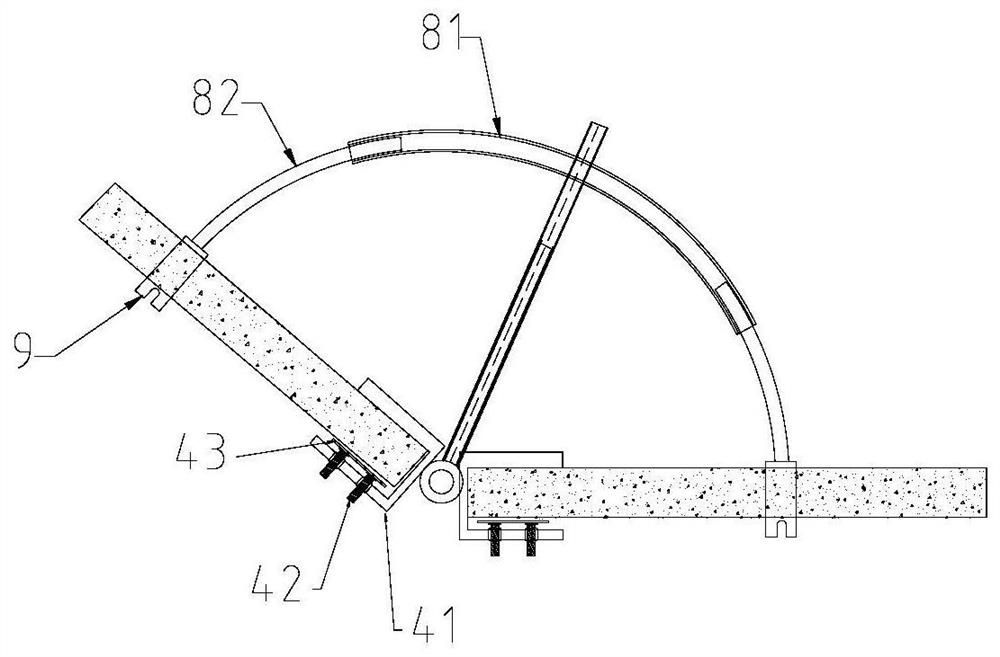

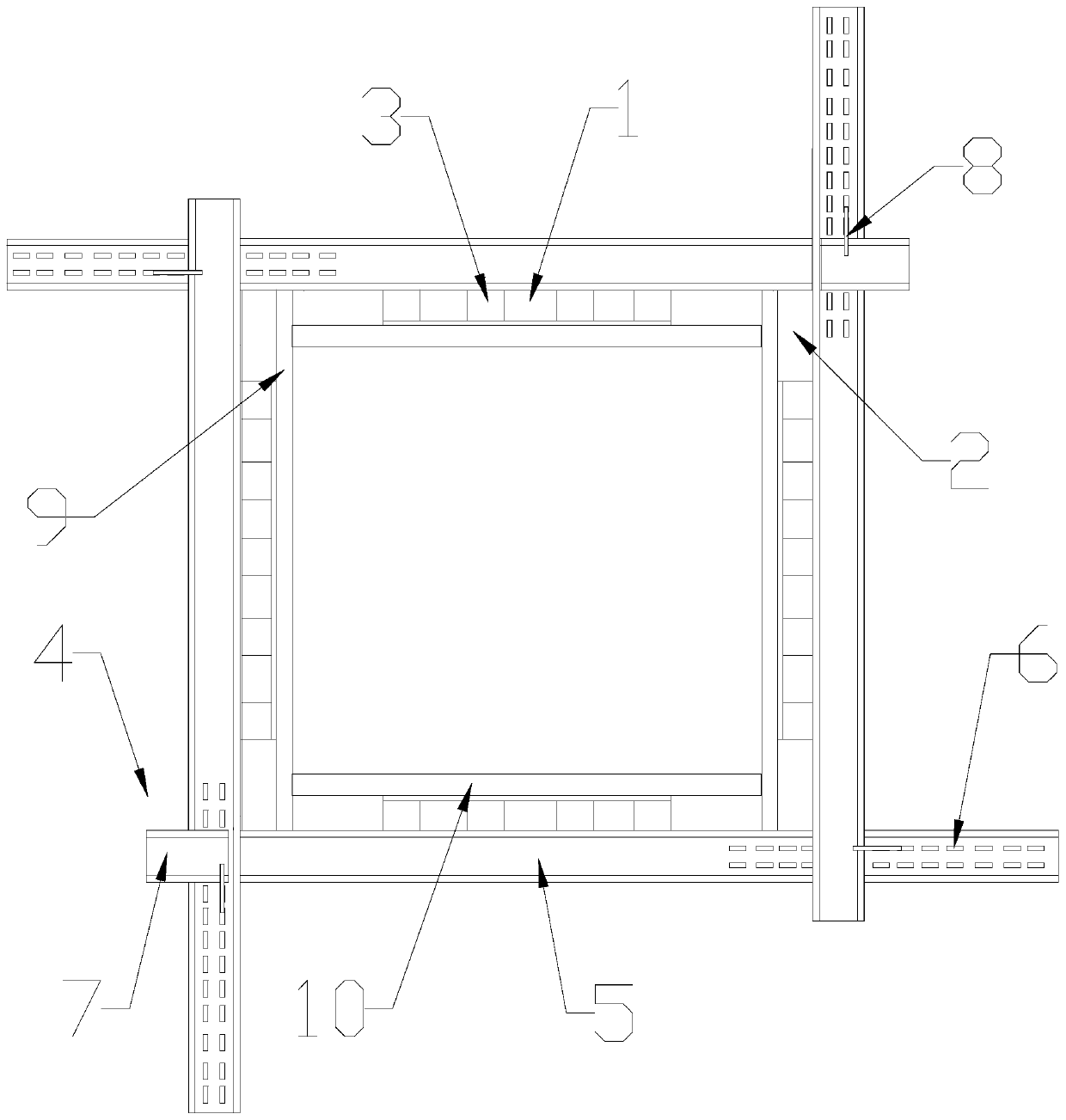

Fabricated wall body included angle adjusting device and construction method thereof

PendingCN111962887AGuaranteed verticalityGuaranteed vertical installationBuilding material handlingLeft wallStructure support

The invention relates to a fabricated wall body included angle adjusting device which comprises a shaft rod erected at an included angle of wall bodies, and the shaft rod, a bottom beam and an obliquebeam form a triangular supporting structure. A through hole is formed in the outer end of the bottom beam, an arc-shaped telescopic beam is installed in the through hole, sliders are arranged at thetwo ends of the arc-shaped telescopic beam, the slider at one end of the arc-shaped telescopic beam is arranged at the bottom of the left wall body, and the slider at the other end is arranged at thebottom of the right wall body; a construction method of the fabricated wall body included angle adjusting device comprises the steps of sleeving the shaft rod with a wall fixator, and connecting the left wall body firstly; connecting the right wall body; pulling telescopic rods out of a guide groove, and inserting L-shaped supporting plates of the sliders at the ends of the two telescopic rods into the bottoms of the wall bodies separately; rotating supporting lead screws of universal wheels to enable the universal wheels to touch the ground, and continuing screwing the supporting lead screwsof the universal wheels to enable the L-shaped supporting plates to slightly lift the wall bodies; adjusting the included angle, and then fixing the free ends of the wall bodies; and fixing a lockingassembly at the included angle. According to the fabricated wall included angle adjusting device, the adjustment of the wall body is labor-saving, the installation precision of the wall body is high,and the speed is high.

Owner:CHINA 22MCC GROUP CORP

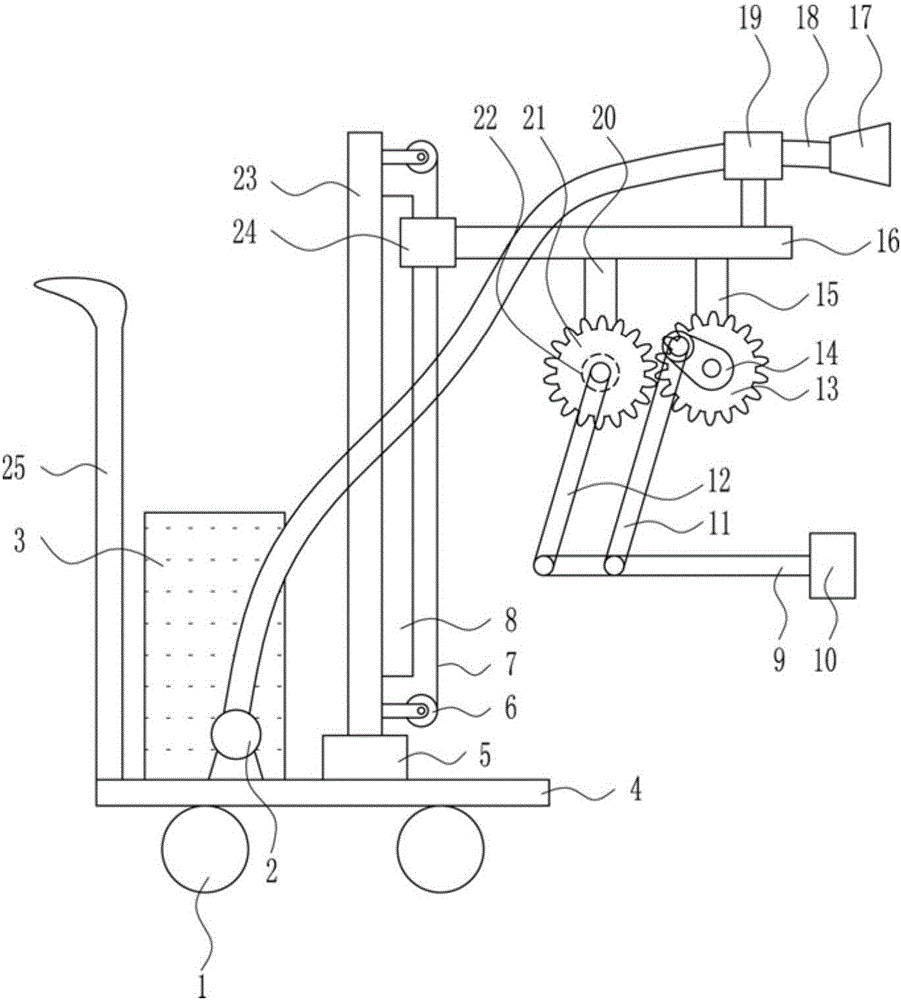

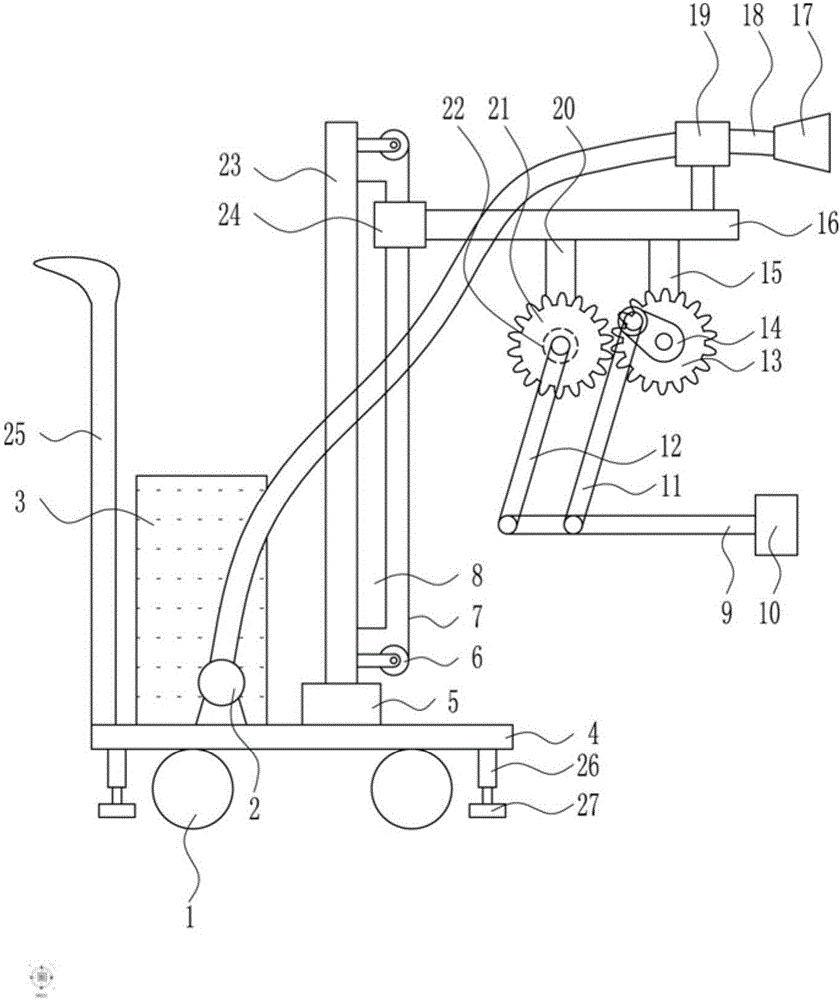

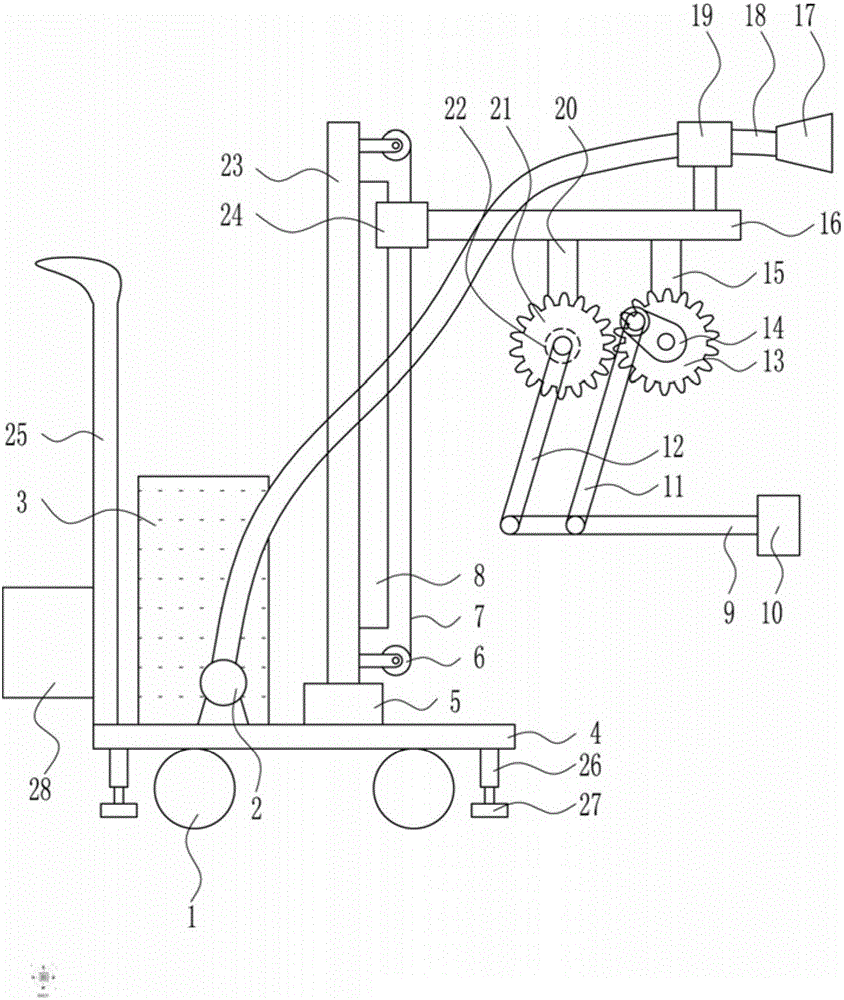

Safety type fast wall dismantling device for decoration

The invention relates to a wall dismantling device, in particular to a safety type fast wall dismantling device for decoration. The safety type fast wall dismantling device for decoration is high in dismantling speed and convenient to operate. The safety type fast wall dismantling device for decoration comprises wheels, a water pump, a water tank, a bottom plate, a first motor, electric reels, a stay wire, a slide rail, a first connecting rod, a collision block, a second connecting rod, a third connecting rod, a first gear, a crank, a first supporting rod, a movable plate, a sprayer, a water tube, a fixing sleeve, a second supporting rod, a second gear, a second motor, a support, a slide block and a push handle. The wheels are symmetrically arranged at the bottom of the bottom plate. The push handle, the water tank and the first motor are sequentially arranged at the top of the bottom plate from left to right. The water pump is arranged on the right side of the bottom inside the water tank. The water tube is arranged on the water pump. According to the safety type fast wall dismantling device for decoration, the effects of high dismantling speed and convenient operation are achieved.

Owner:广州市航通水电设备有限公司

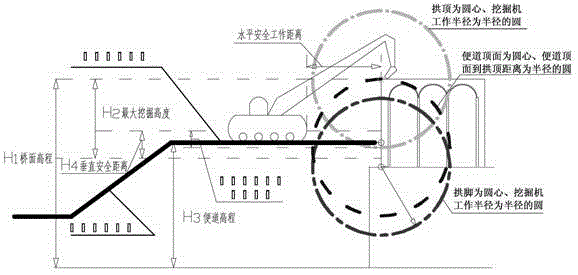

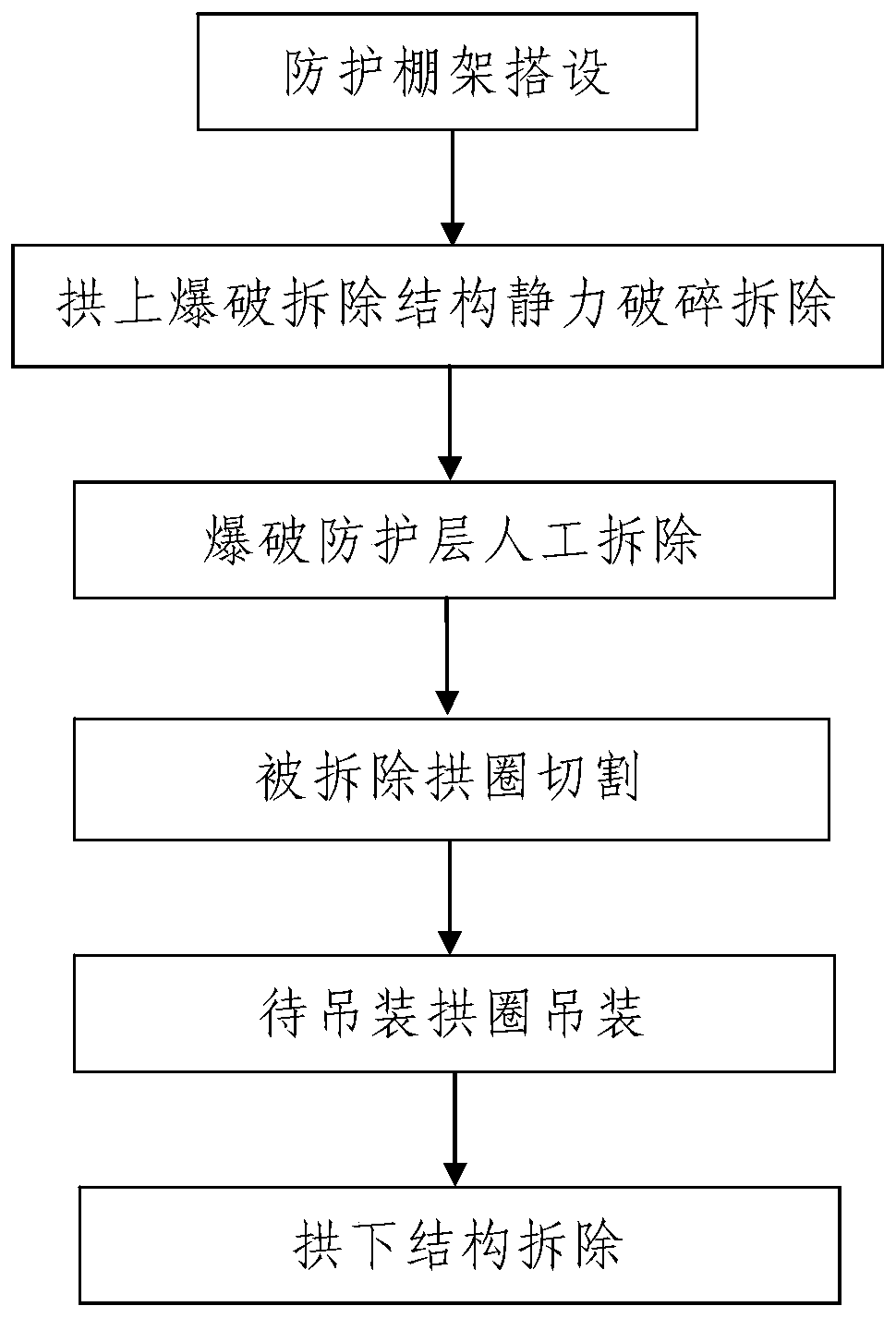

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

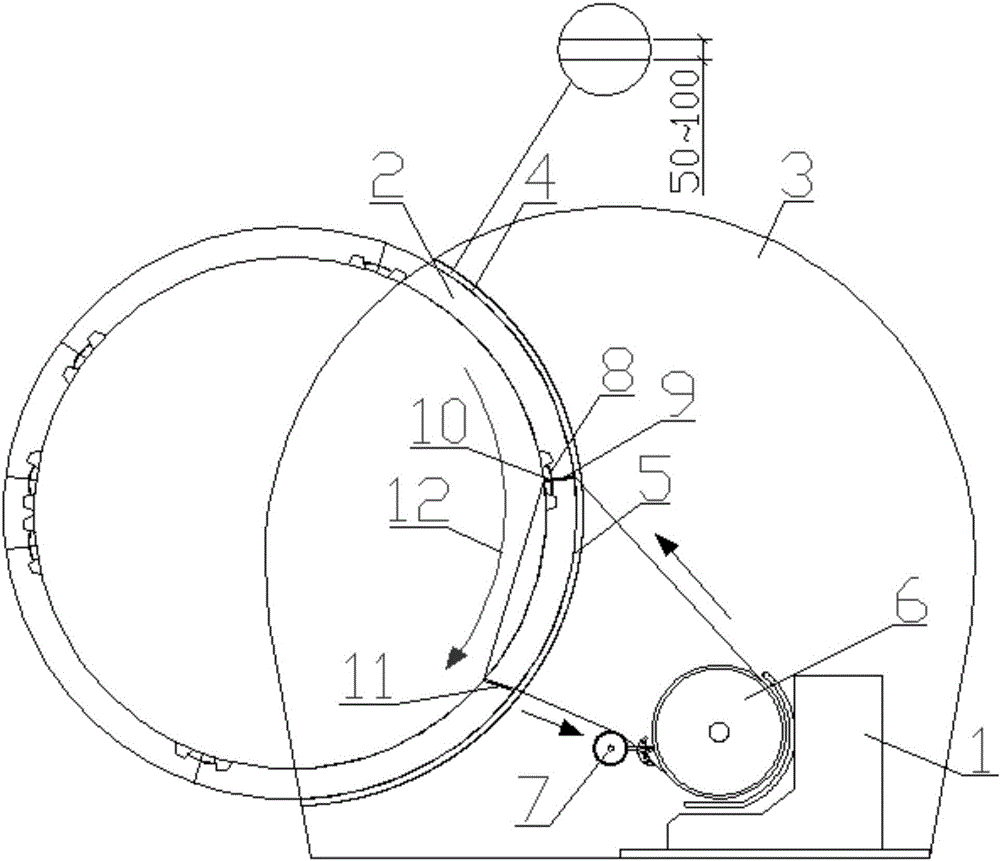

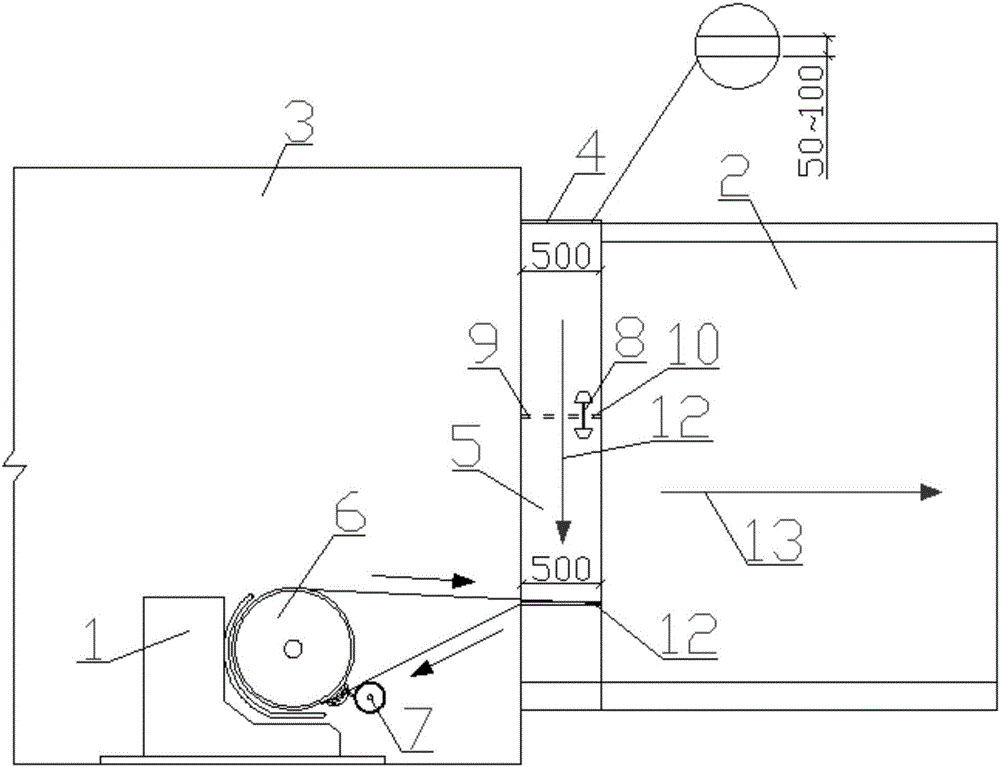

Dismounting method for metro section segments intruding into tunnel gauge

InactiveCN106014425AEasy to operateFast progressUnderground chambersTunnel liningDrive wheelWater cooling

The invention discloses a dismounting method for metro section segments intruding into a tunnel gauge. The method is characterized by comprising the following steps: 1) the back of one segment is hollowed out, and a cavity gap is formed between the segment and surrounding rock; 2) bolts in a circumferential direction of the segment are dismounted, a first hole is drilled by water grinding drill along the longitudinal joint, and a second hole is drilled in the same circumferential section with the first hole along the whole segment; 3) a cutting wire saw penetrates the first hole and the second hole and winds around a driving wheel and an assisting wheel, a wire saw cutting machine is started, the wire saw operates around a cutting surface and grinds the segment to complete circumferential cutting, the wire saw operating in the cutting process is cooled with water, and grinding debris is carried away; 4) the cutting direction is adjusted after the circumferential cutting is completed, the segment is cut in the longitudinal direction of the second hole, longitudinal cutting is completed, the wire saw cutting machine is removed, and accordingly, one segment is dismounted, and dismounting of the next segment is performed. According to the method, construction is easy to operate, the progress is fast, the efficiency is high, the accident rate is low, and only manual cleaning is required after construction is completed.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

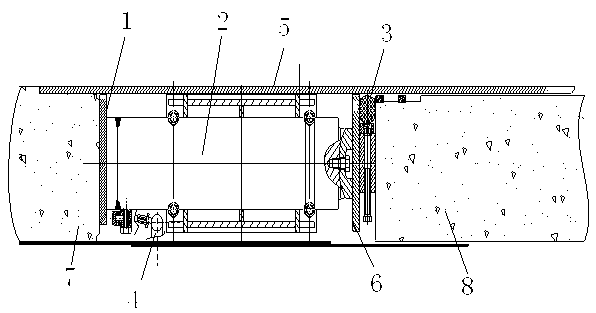

Assembled jacking pipe relaying intermediate

InactiveCN102996898AEvenly distributedEasy to removePipe laying and repairEngineeringMechanical engineering

The invention relates to an assembled jacking pipe relaying intermediate. According to the assembled jacking pipe relaying intermediate, bottom plates and oil cylinder activating and locating boxes are mounted at the middle of an outer shell body of the relaying intermediate, the two ends of the oil cylinder activating and locating boxes are respectively in contact connection with a front bottom plate and a rear bottom plate, the front bottom plate and a concrete pipe section are connected together in a contact manner so as to support relay oil cylinders and provide counter force for the relay oil cylinders; the rear bottom plate and a concrete pipe section are in contact connection with each other; and the relay oil cylinders are mounted in the activating and locating boxes. Due to the oil cylinder activating and locating boxes, after a jacking pipe runs through, the dismounting of the relay oil cylinders is facilitated, the intra-pipe cutting is avoided, the generation of a lot of smoke and dust is avoided, the operation is safe and fireproof, and the dismounted relay oil cylinders can be reutilized. Compared with the existing traditional jacking pipe relaying intermediate, the assembled jacking pipe relaying intermediate is different in structure and mainly formed in a manner that the activating and locating boxes are assembled, relay rings are manufactured by directly using the prolongation of steel bushings of the concrete pipe sections, no other additional components exist, each oil cylinder corresponds to each activating and locating box, a sealing device can be replaced online, the cost is low, the performance is reliable, and the mounting / dismounting is convenient.

Owner:SHANGHAI FOUND ENG GRP +1

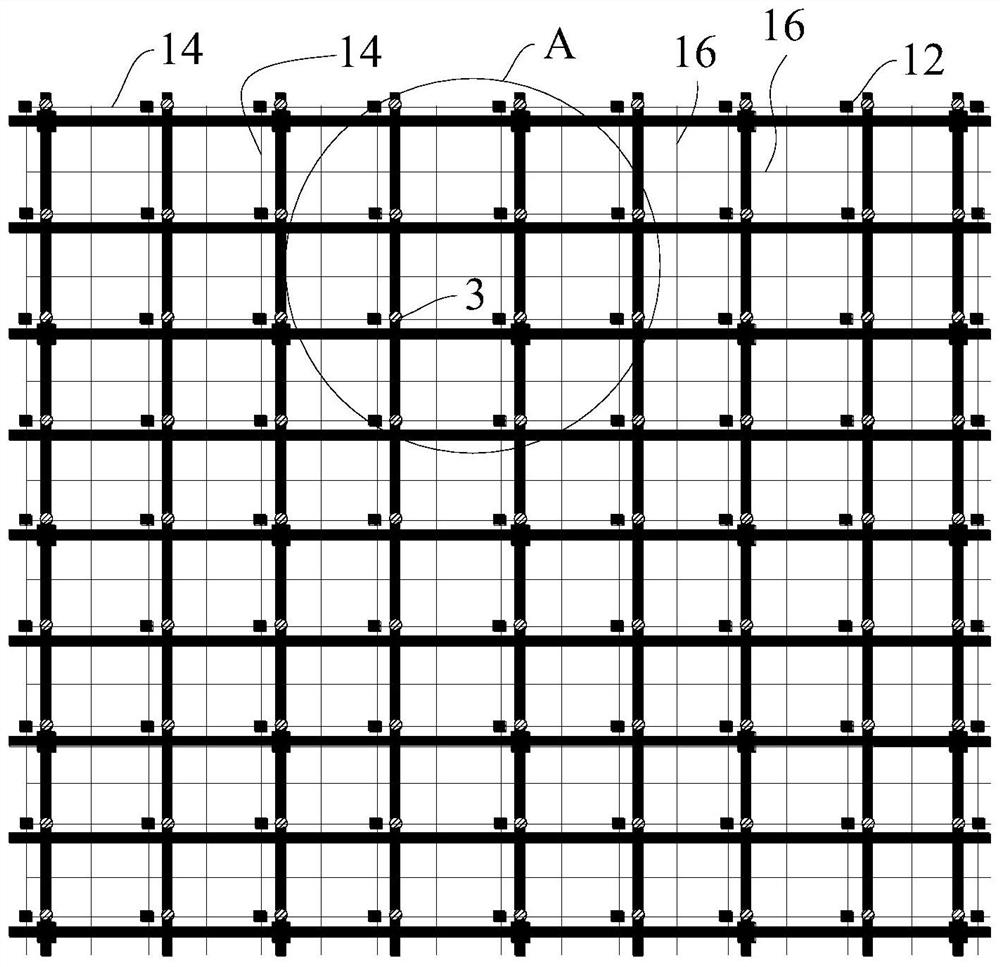

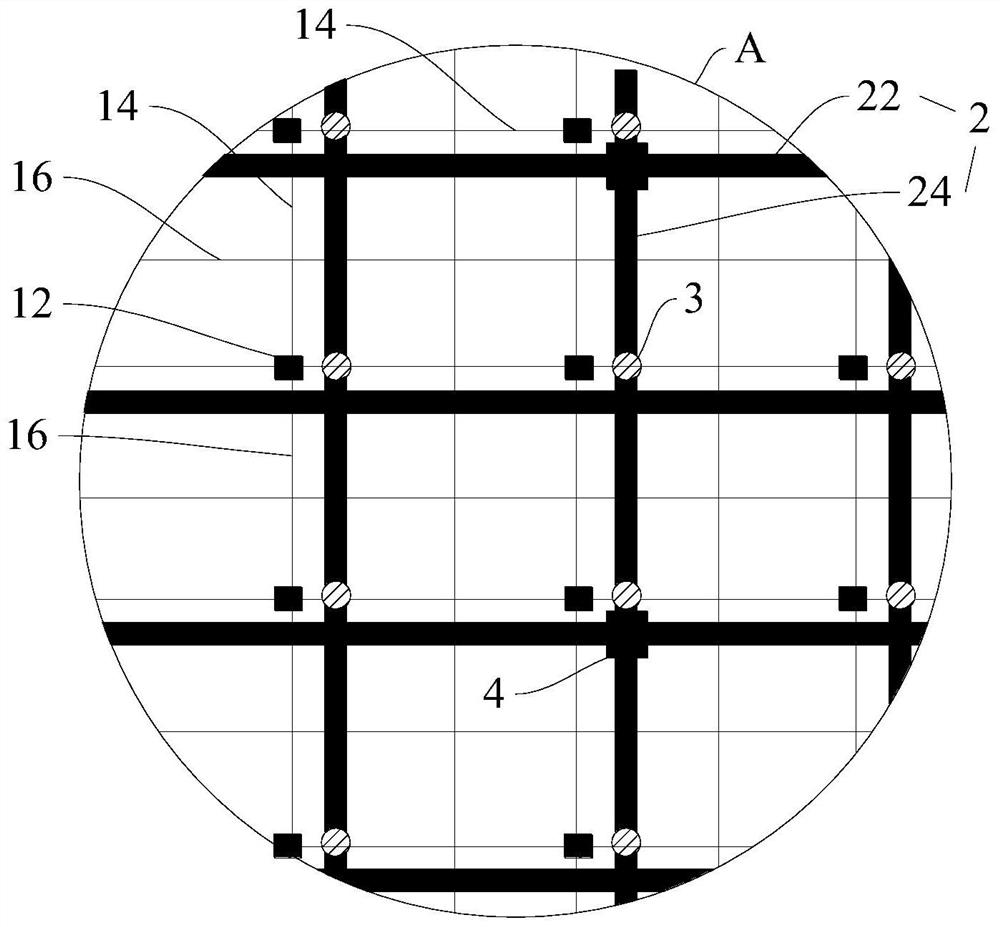

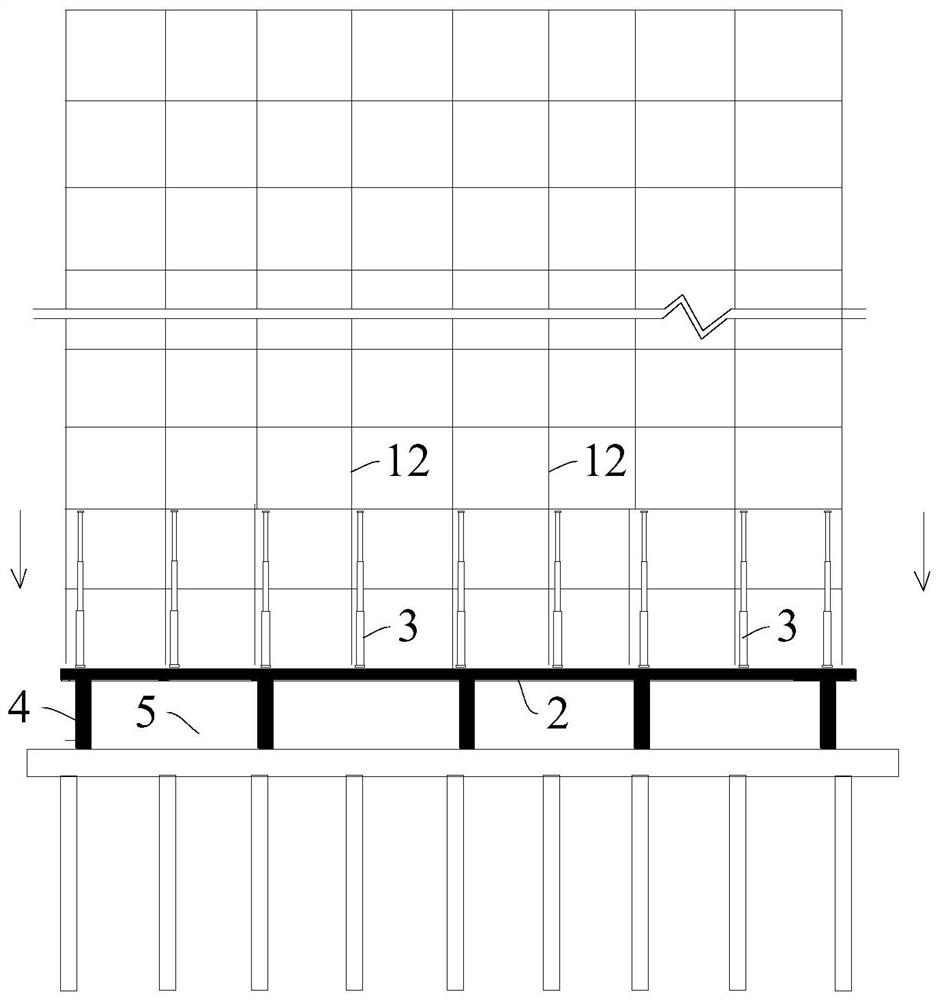

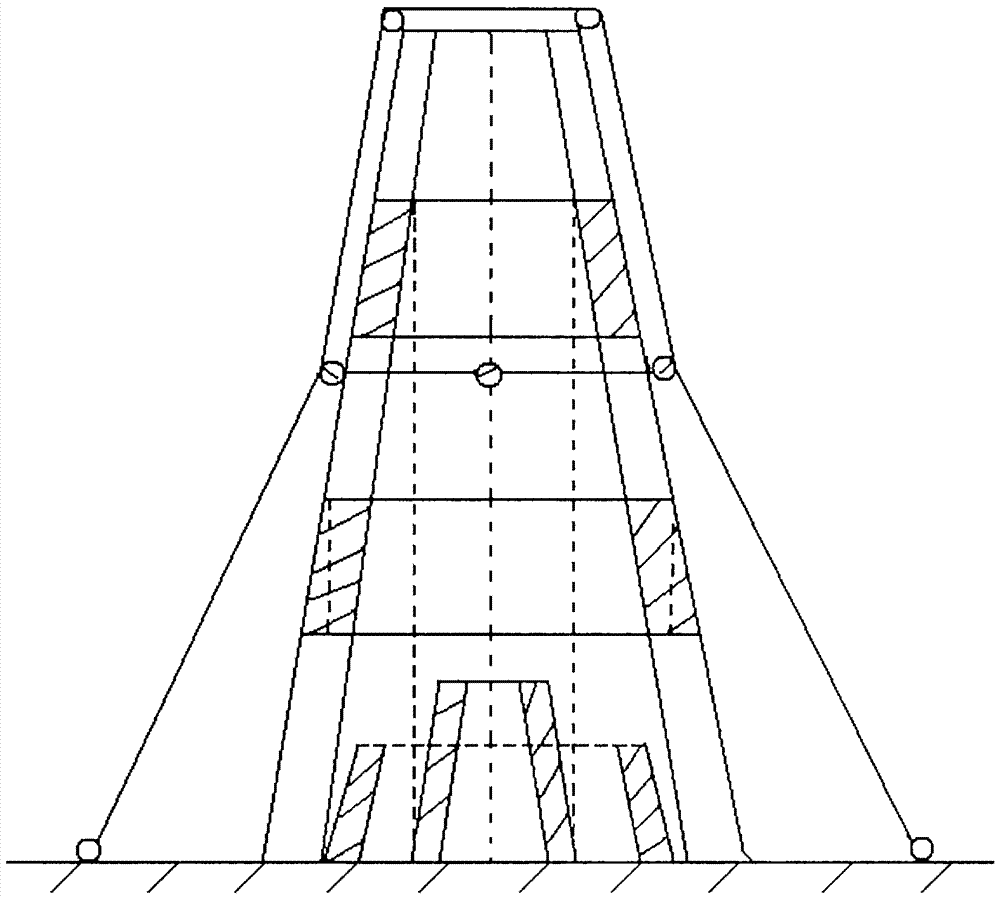

Combined supporting system for foundation pit central island basin type excavation and construction method thereof

The invention provides a combined supporting system for a foundation pit central island basin type excavation and a construction method thereof. A grid type double-shaft cement-soil mixing pile gravity type enclosure wall is added to replace a soil body to slope, steel inclined struts are arranged after overall pouring of a tower bottom plate is completed, and follow-up construction work is carried out. The double-shaft cement-soil mixing pile gravity type enclosure wall is used for replacing the soil body slope, so that the length of the steel inclined struts can be properly shortened, and the influence of the steel inclined struts on foundation pit deformation is reduced; a foundation bottom plate of a tower extends to the position, close to the edge side of a foundation pit, of part ofa foundation bottom plate of a basement to be constructed, the problem of tower bottom plate cutting caused by central island basin type earth excavation is solved, the foundation bottom plate of thetower can be integrally poured, integrity and continuity of the tower structure are guaranteed, and other quality problems such as water leakage caused by improper later construction joint treatment are avoided.

Owner:SHANGHAI CONSTRUCTION GROUP

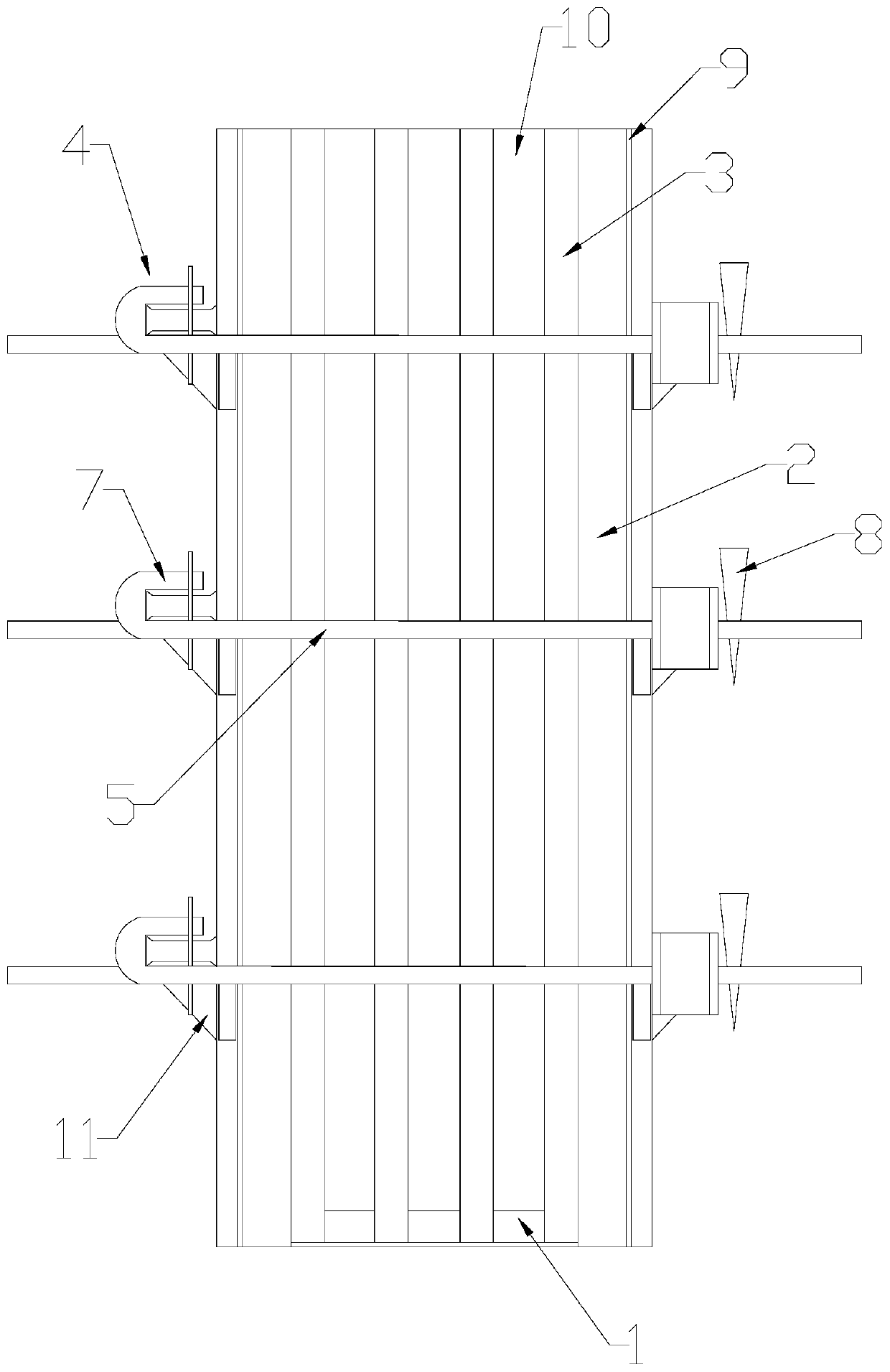

Building frame structure square column reinforcing member formwork and construction method thereof

The invention provides a building frame structure square column reinforcing member formwork and a construction method thereof. The building frame structure square column reinforcing member formwork comprises a frame column formwork assembly, strip-shaped steel angles are arranged at the lower end of the outer wall of the frame column formwork assembly, vertical square timber is arranged on the positions, at the two ends of the strip-shaped steel angles, of the outer wall of the frame column formwork assembly, the vertical side walls of the strip-shaped steel angles are closely attached to theouter wall of the frame column formwork assembly, the horizontal side walls of the strip-shaped steel angles are vertically arranged at the lower ends of the sides, away from the frame column formworkassembly, of the vertical side walls, vertical secondary keels are arranged at the upper ends of the horizontal side walls of the strip-shaped steel angles at intervals, the secondary keels at the ends of the strip-shaped steel angles and the ends of the horizontal side walls of the strip-shaped steel angles are all closely attached to the square timber, and transverse square column reinforcing member main keels are arranged on the same horizontal plane of the outer sides of the secondary keels. The process is simple and convenient, operating by workers is convenient and rapid, the construction speed is high, the assembling efficiency is high, the later dismantling speed is high, and the construction period is saved; and the strip-shaped steel angles are arranged at the lower ends of theframe column formwork assembly and matched with the secondary keels and the square column reinforcing member main keels, and formwork expanding and mortar leakage of the frame column formwork assemblyare avoided.

Owner:河南科建建设工程有限公司

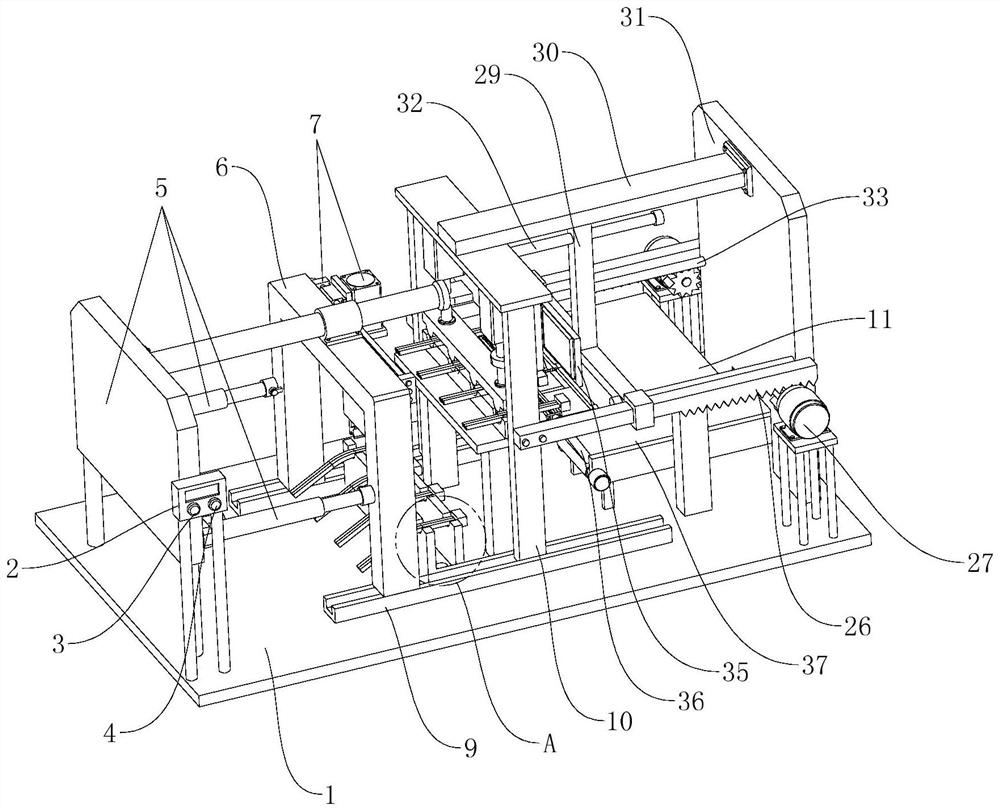

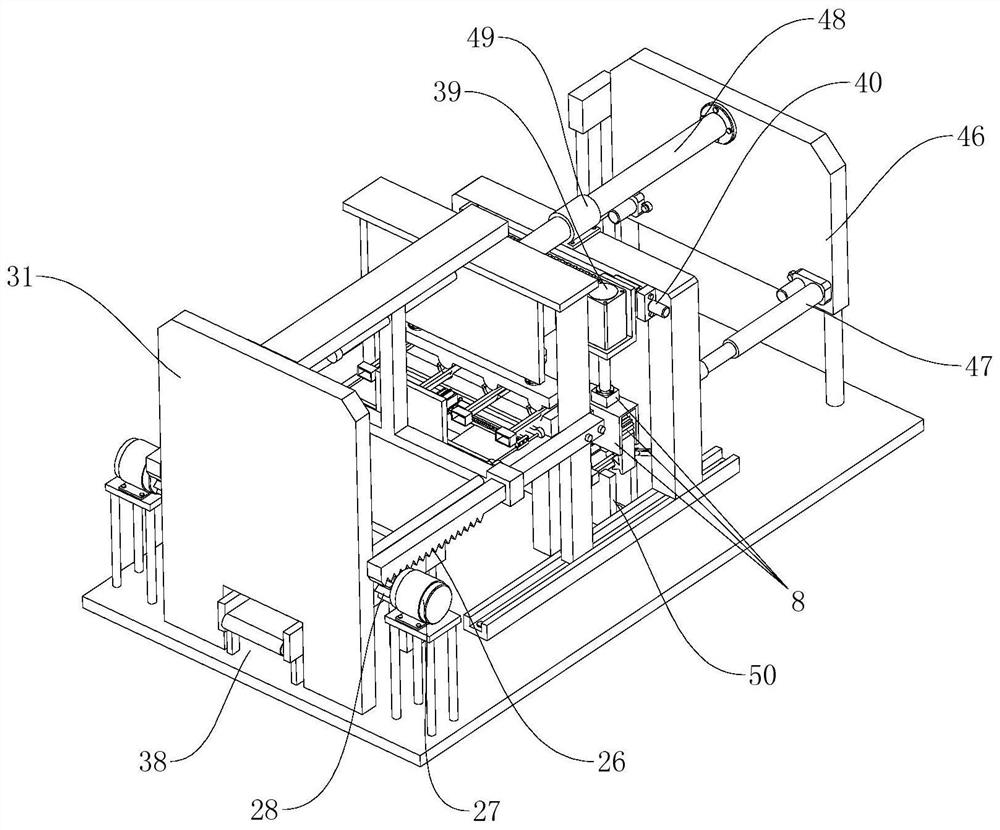

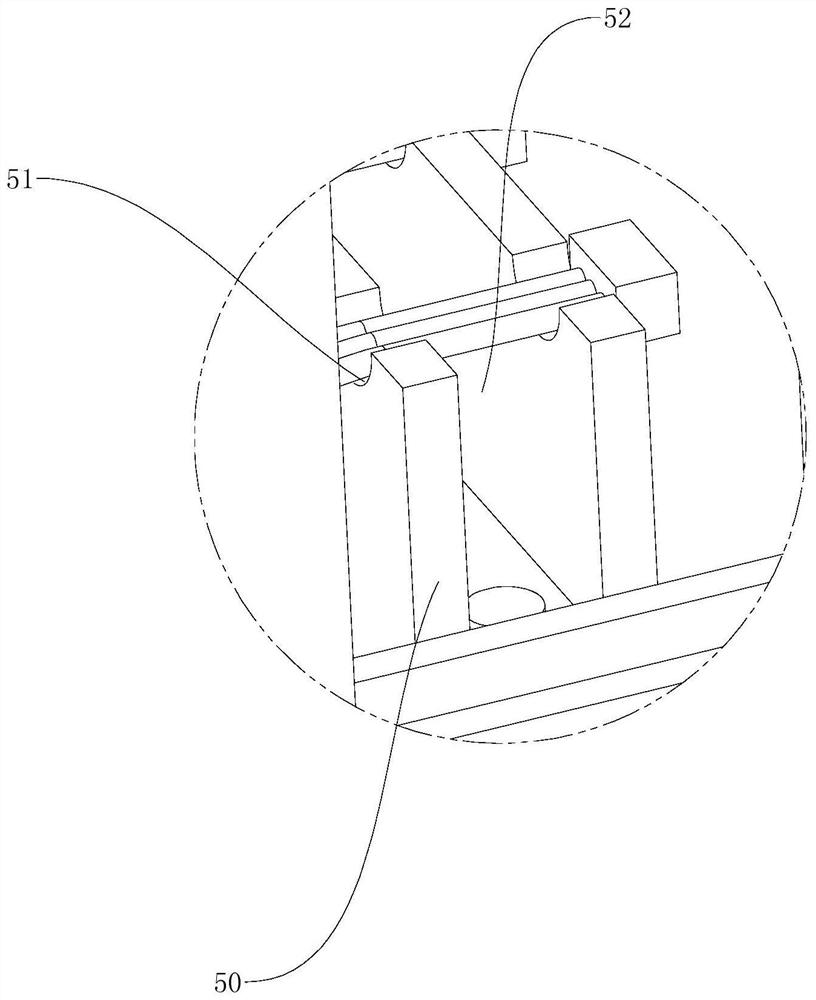

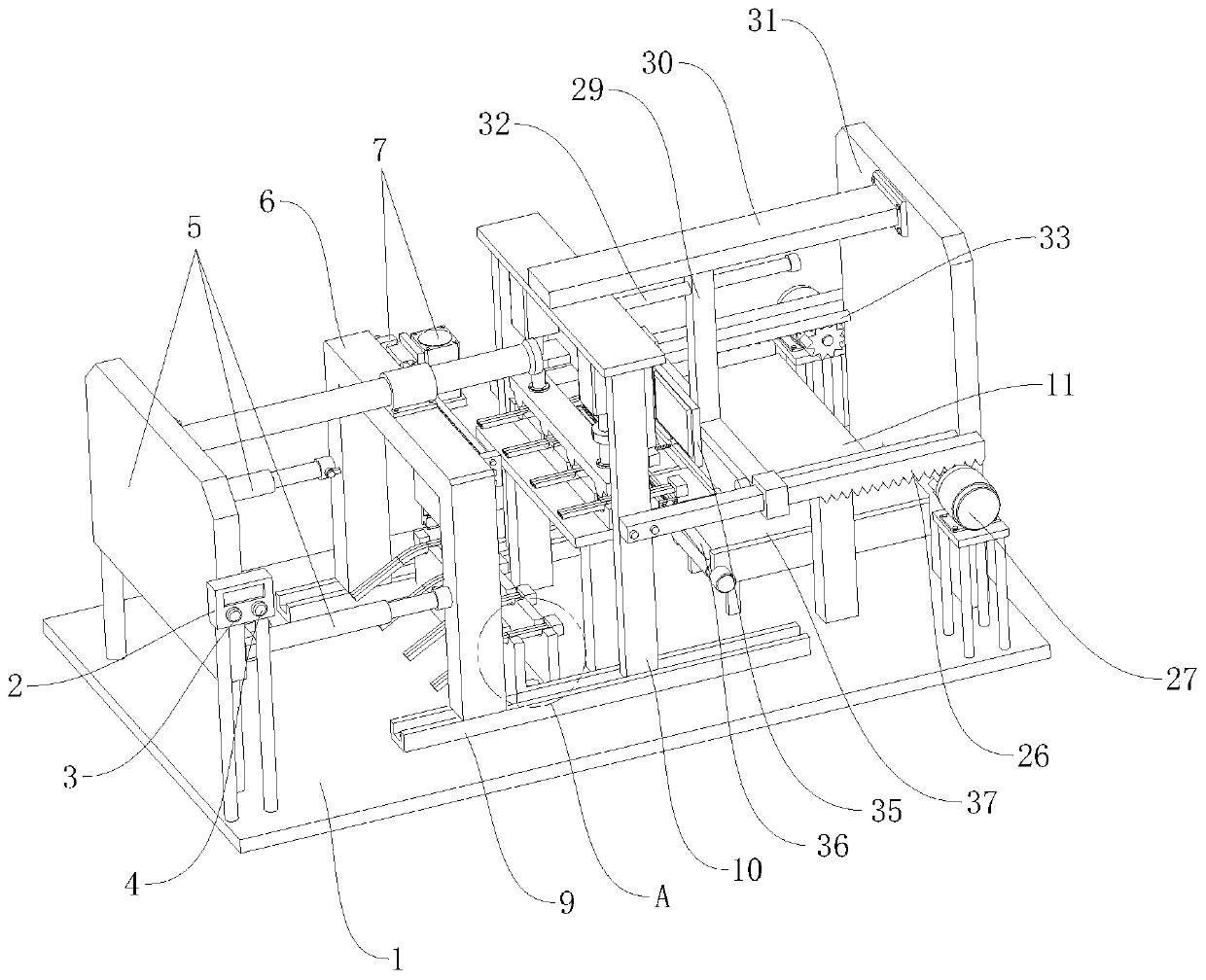

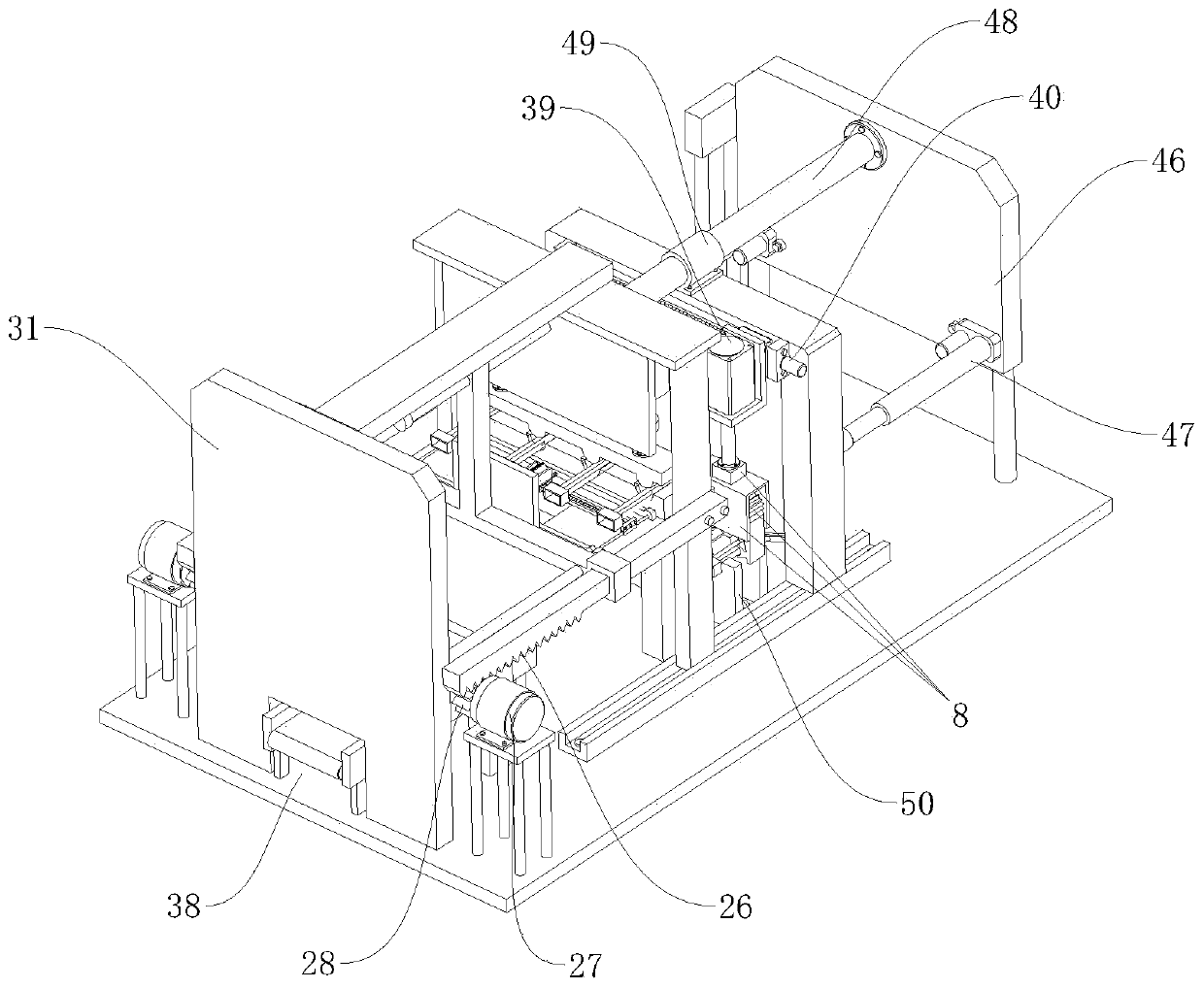

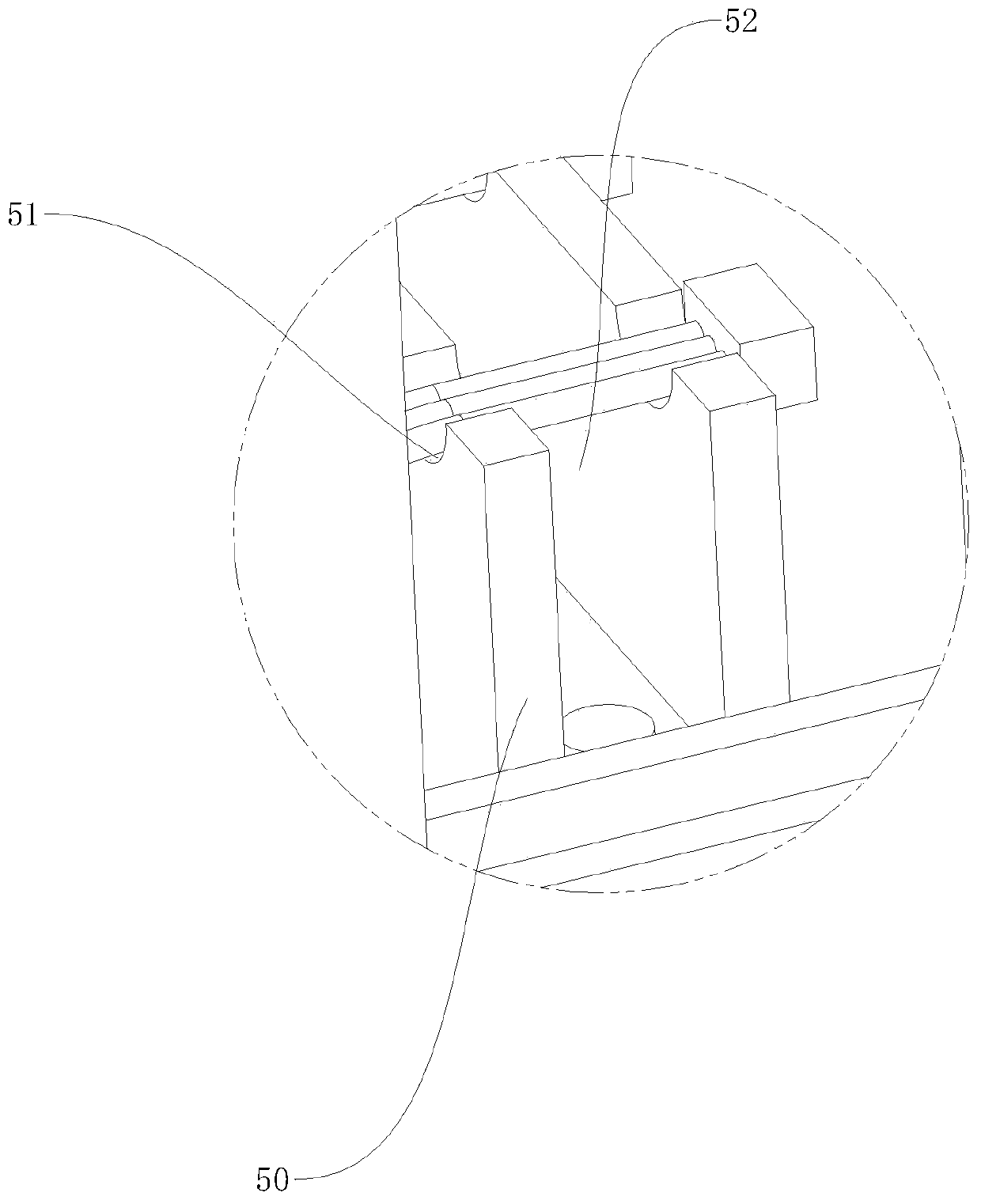

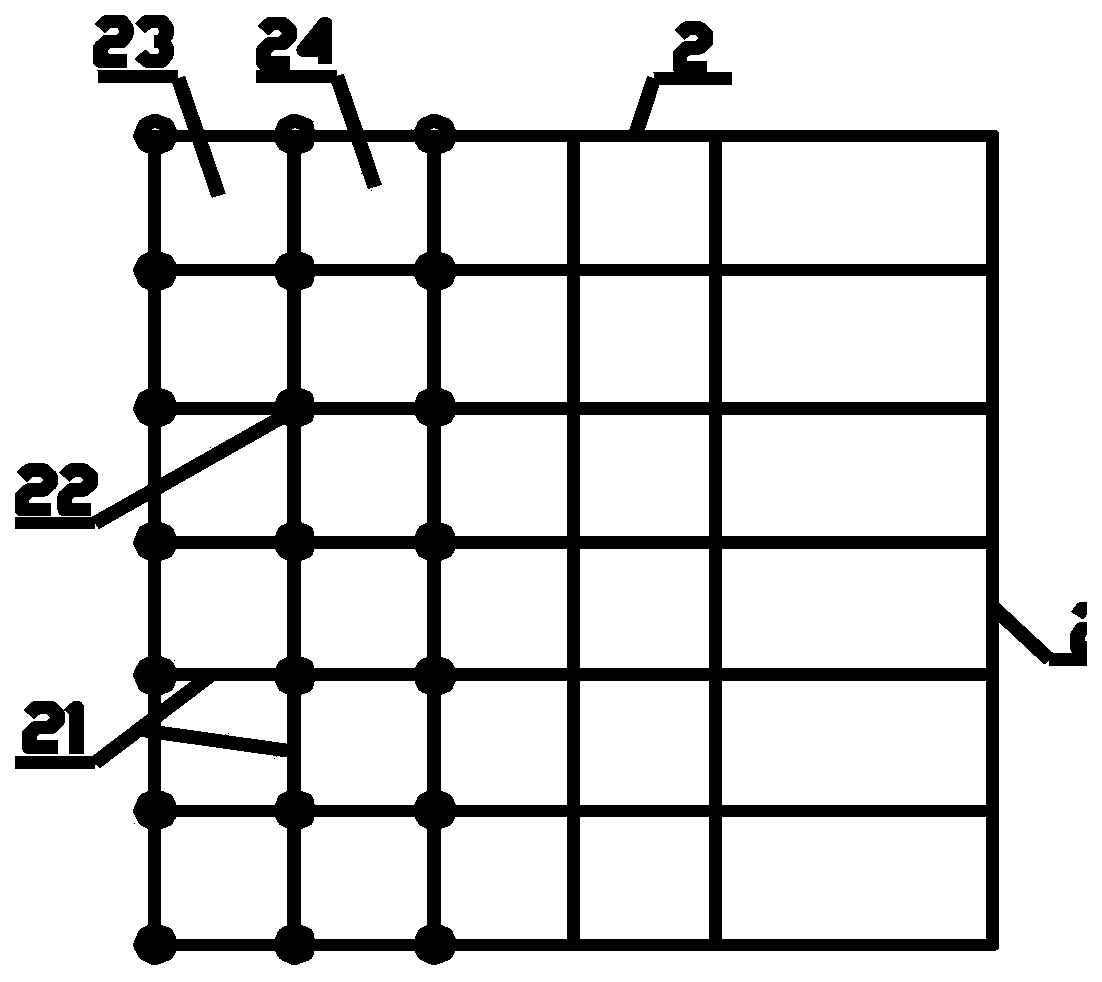

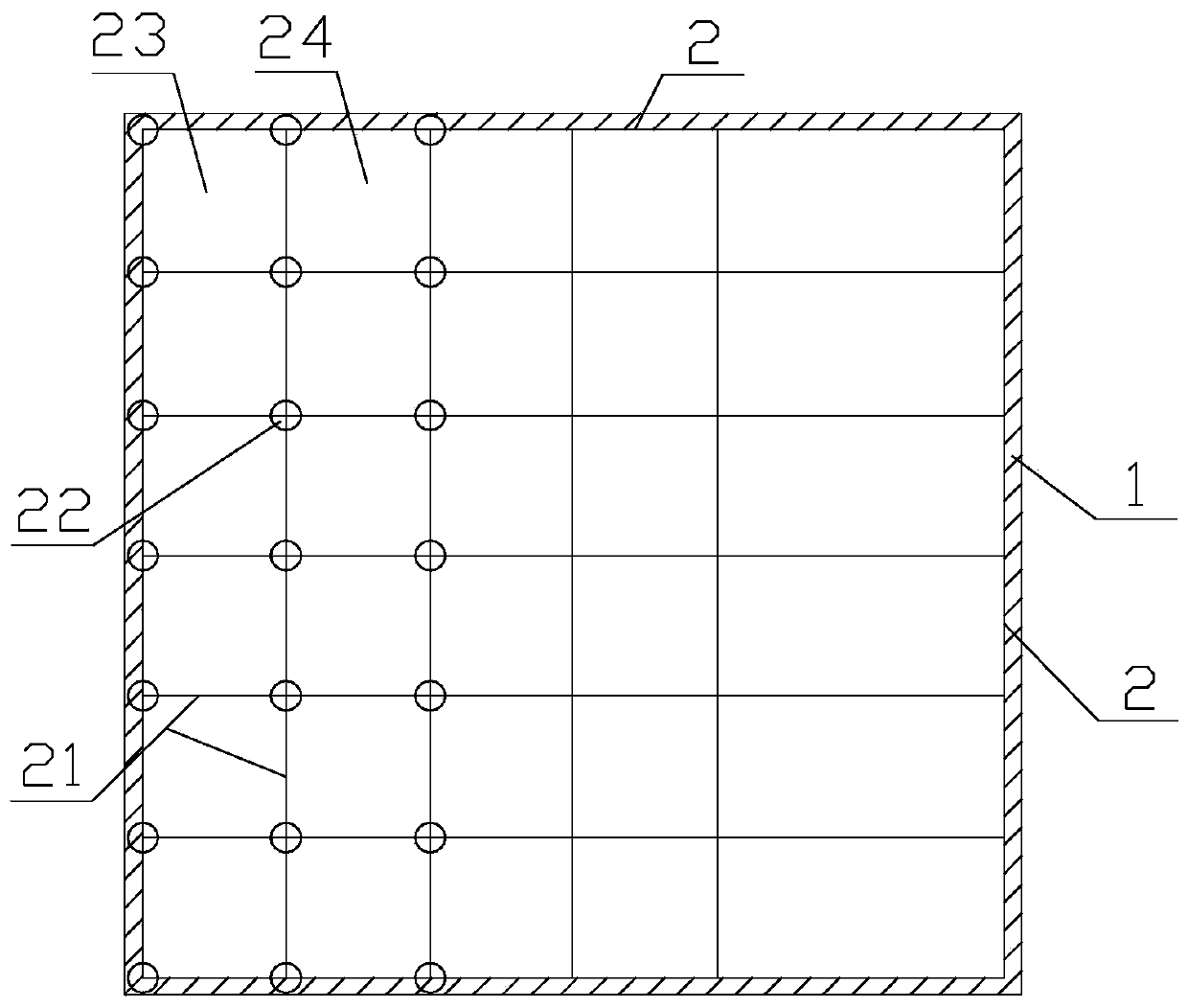

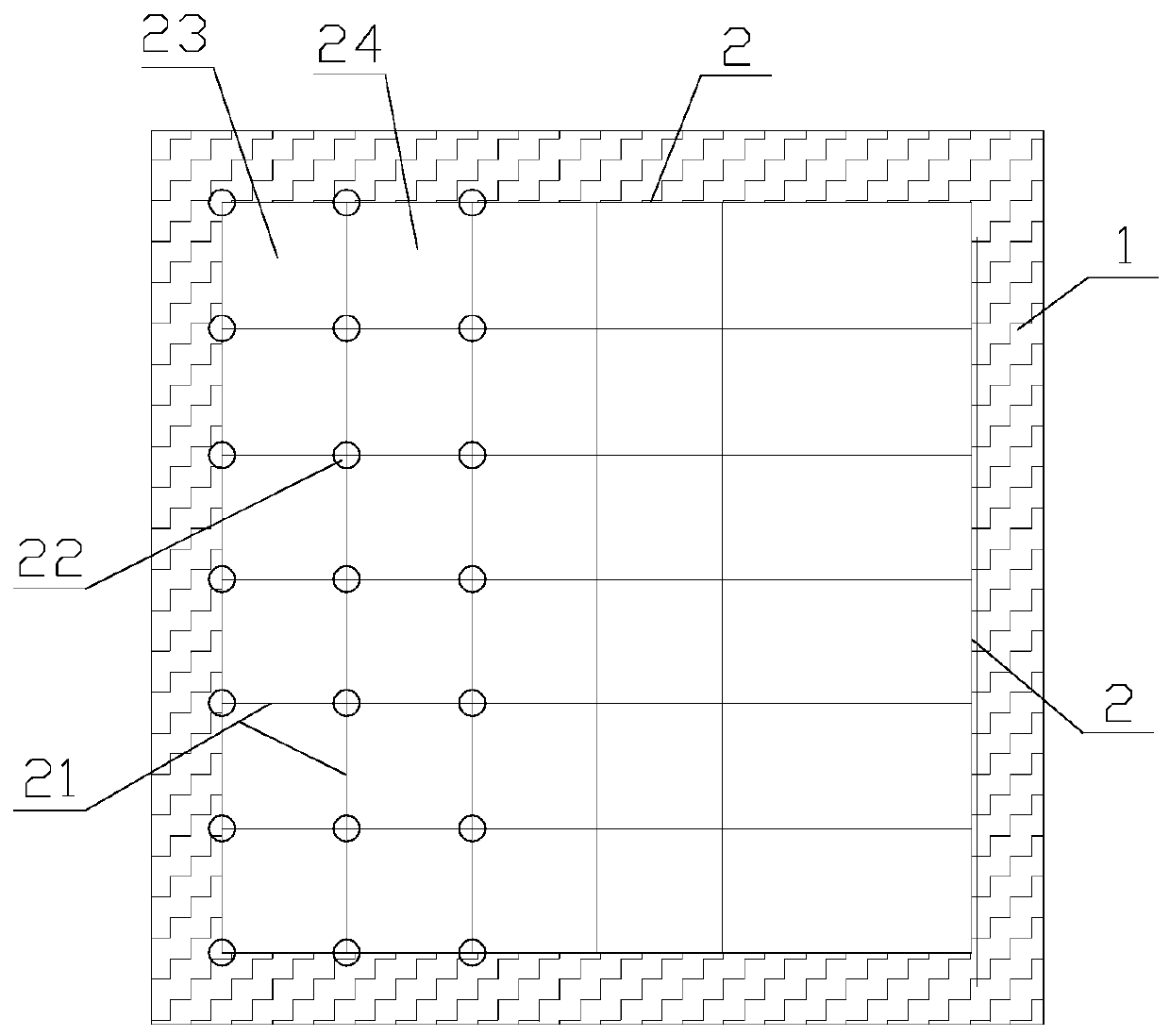

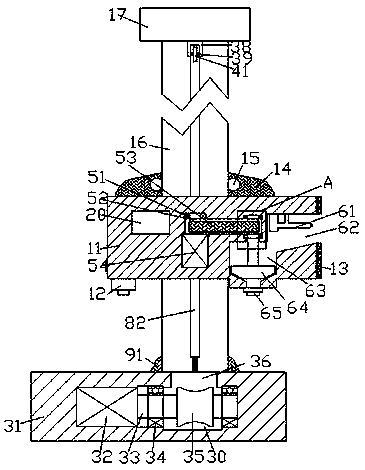

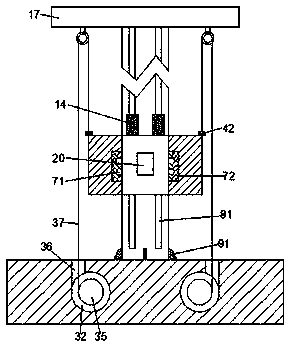

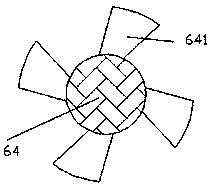

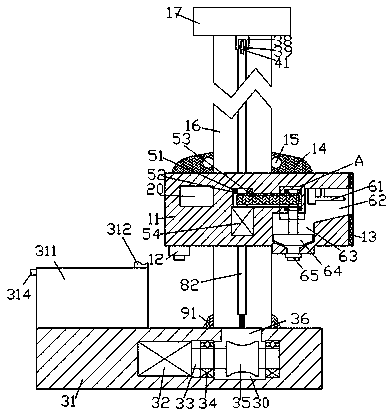

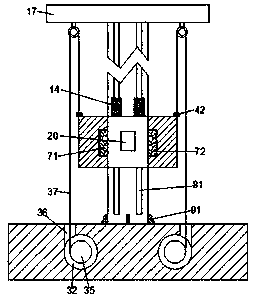

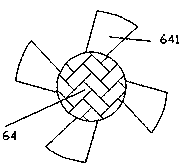

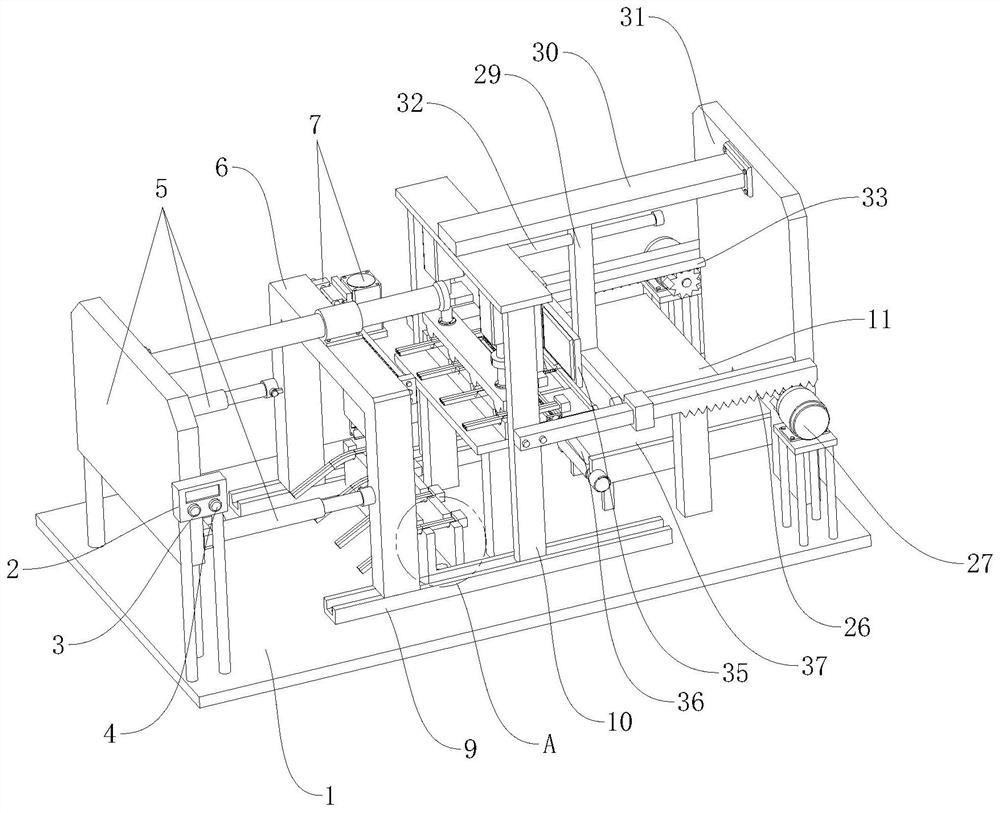

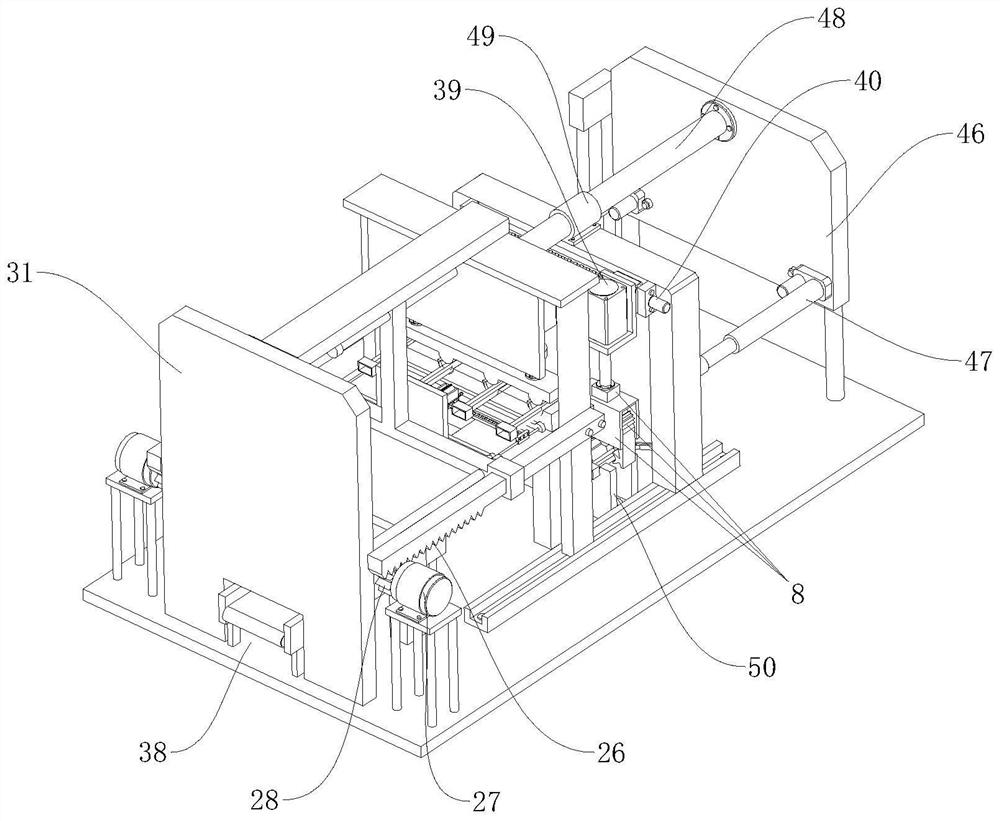

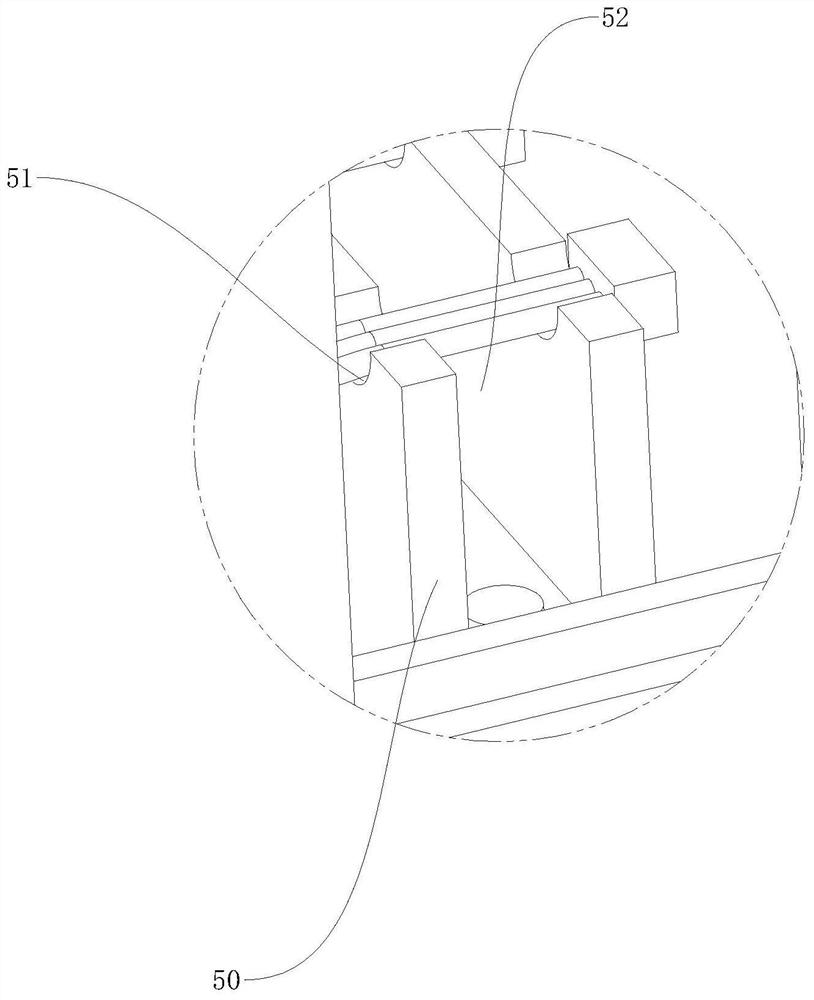

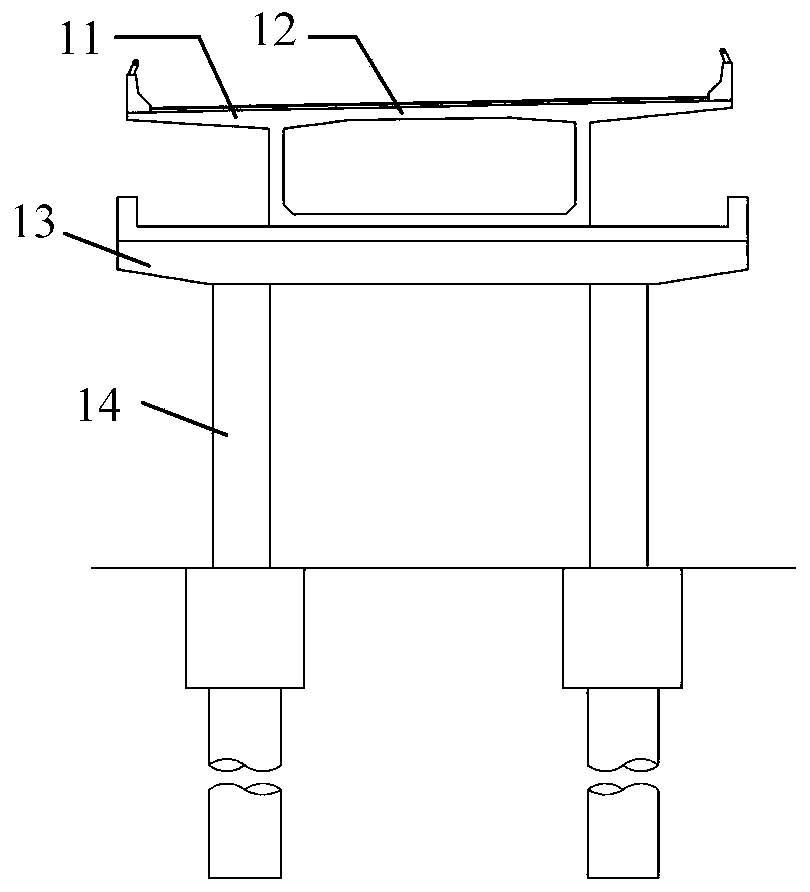

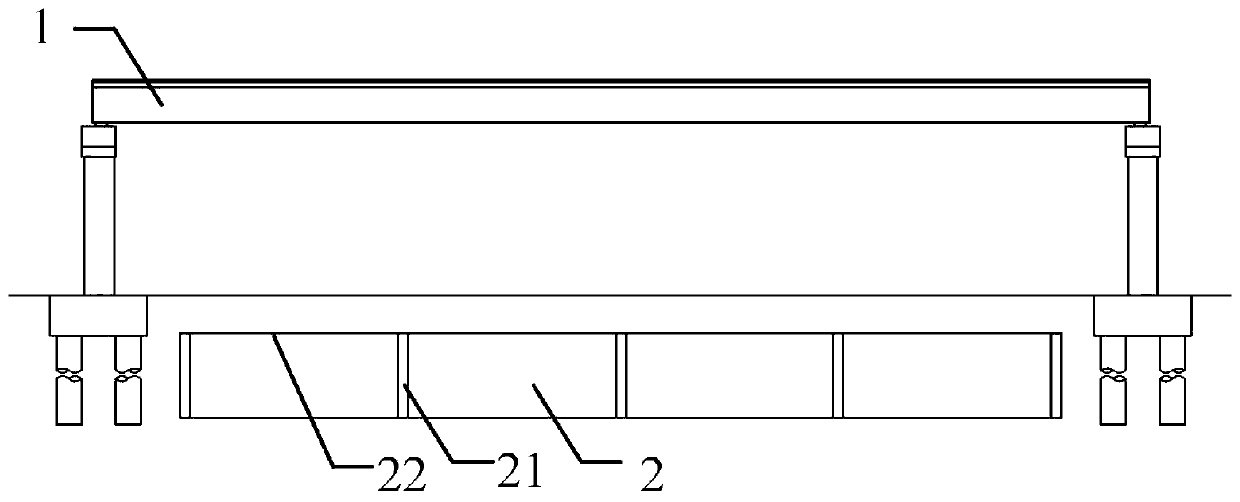

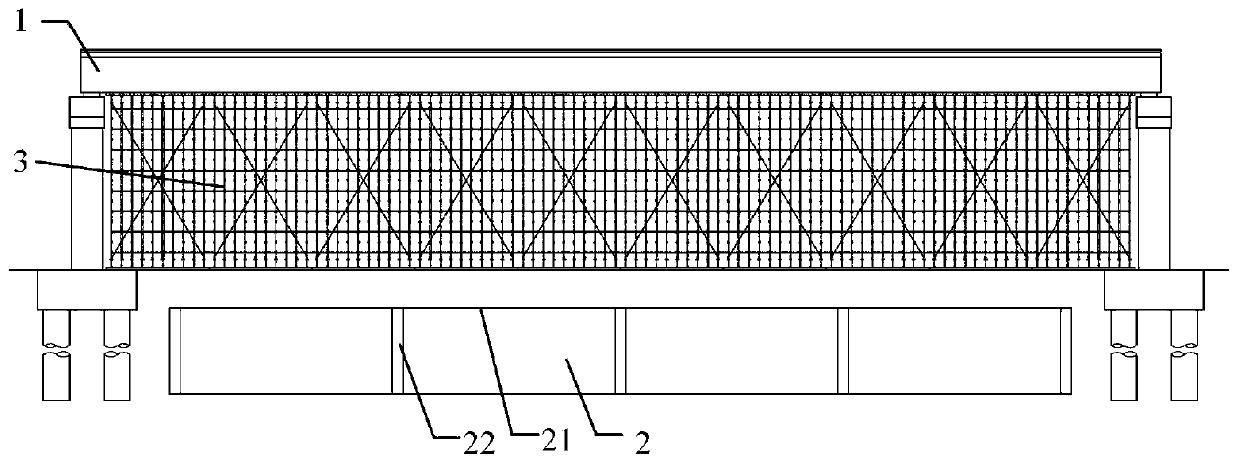

Manufacturing equipment and manufacturing method for pre-cast shear wall

ActiveCN106217637AEasy to operateFast constructionConstruction materialCeramic shaping apparatusDrive wheelMotor control

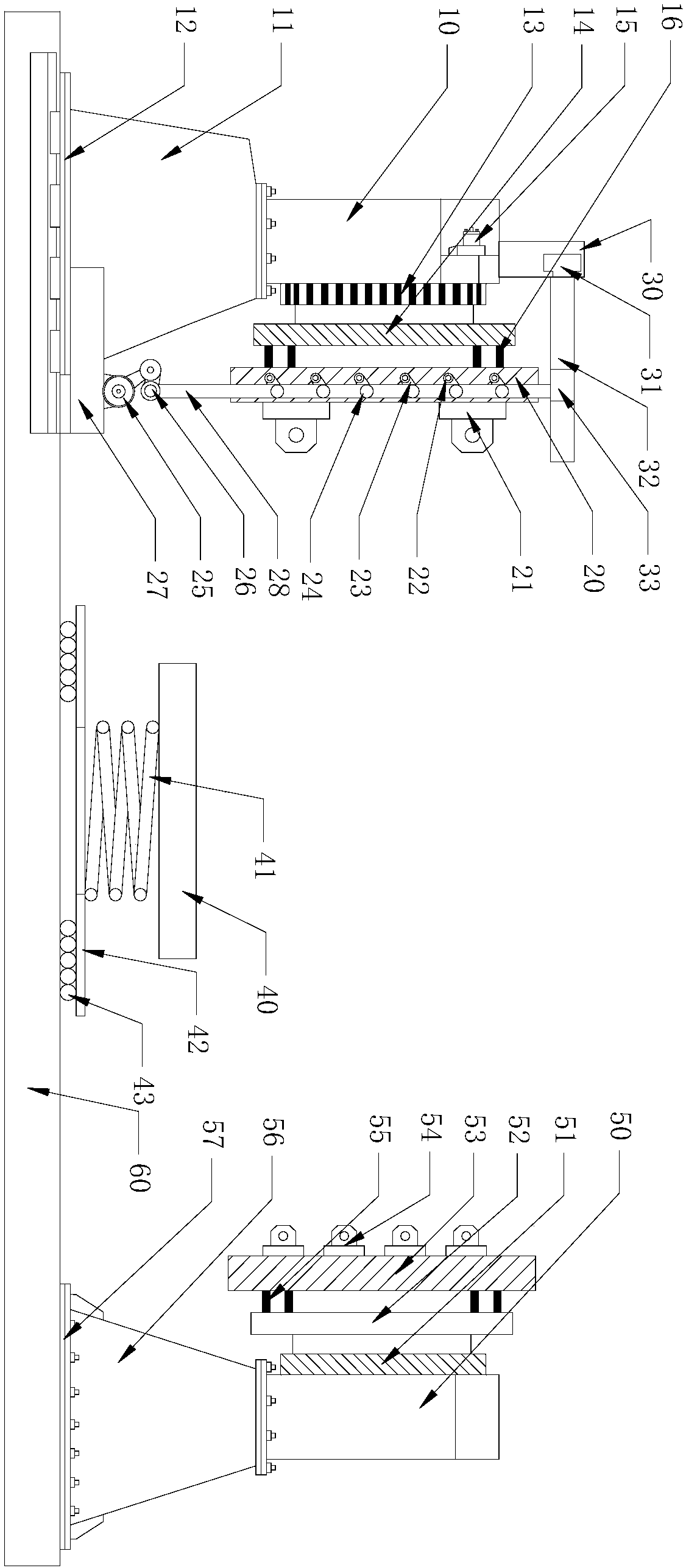

The invention provides manufacturing equipment for a pre-cast shear wall. The manufacturing equipment comprises a master console and a slave console which are arranged on a horizontal base plate, wherein a first operation panel and a second operation panel which are oppositely arranged are arranged on the master console and the slave console; and the first operation panel is arranged on the master console through a gear disc, a control motor controls the rotation of the gear disc, the first operation panel and a pre-casting operation table are driven to rotate through the rotation of the gear disc, the second operation panel is arranged on the slave console through a driven wheel, and the pre-cast shear wall, a slave operation table, the second operation panel and the driven wheel are driven to rotate through the rotation of the gear disc after the pre-cast shear wall is fixed on the pre-casting operation table and the slave operation table. The manufacturing equipment and the manufacturing method for the pre-cast shear wall, which are provided by the invention, have the following advantages: the large shear wall can be operated, a rotation angle of the shear wall during a construction installation process can be randomly adjusted through the master console and the slave console which are oppositely arranged, and the advantages of simple operation, fast construction speed and the like are achieved.

Owner:JIANGSU SUZHONG CONSTR GROUP

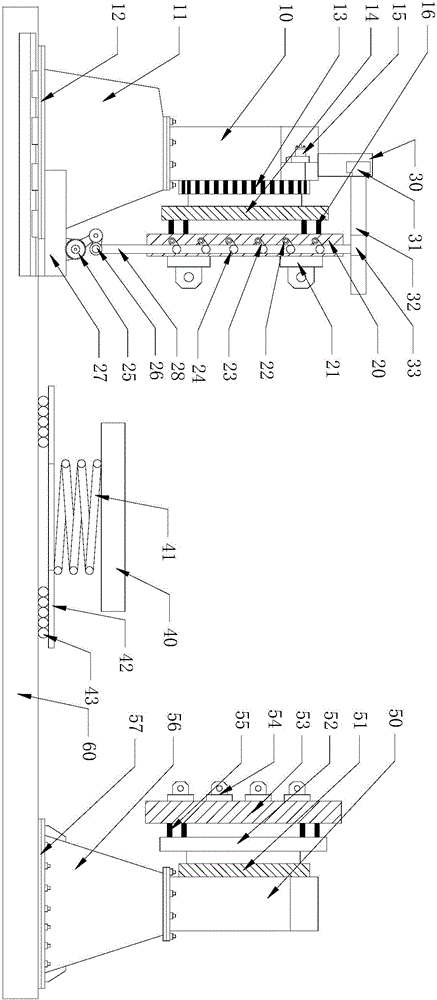

Terminal dismounting device for automobile wire harness recovery

InactiveCN111653912AReduce laborSave loading timeVehicle connectorsLine/current collector detailsCable harnessElectrical and Electronics engineering

The invention relates to the field of dismantling equipment, and specifically relates to a terminal dismounting device for automobile wire harness recovery. The device comprises a base and a controller. The device further comprises a feeding mechanism, a stripping mechanism and a discharging mechanism. The feeding mechanism is arranged at one end of the top of the base so as to feed the automobilewire harness to the stripping mechanism. The stripping mechanism is arranged beside the feeding mechanism so as to strip the terminals of the automobile wire harness fed by the feeding mechanism. Thedischarging mechanism is arranged below the stripping mechanism so as to discharge the automobile wire harness of which the terminal is removed. The feeding mechanism comprises a pushing assembly, aninverted-U-shaped supporting rod, a driving assembly and a clamping assembly. The stripping mechanism comprises an inverted-U-shaped supporting frame, a supporting table, a pressing assembly and a sliding assembly. According to the terminal dismounting device for automobile wire harness recovery, manual dismounting is replaced with automatic equipment, automobile wire harness terminals can be dismounted in batches, meanwhile, the terminal dismounting device has the discharging function, convenience and practicability are achieved, the dismounting time is saved, and the production cost of enterprises and factories is saved.

Owner:叶连波

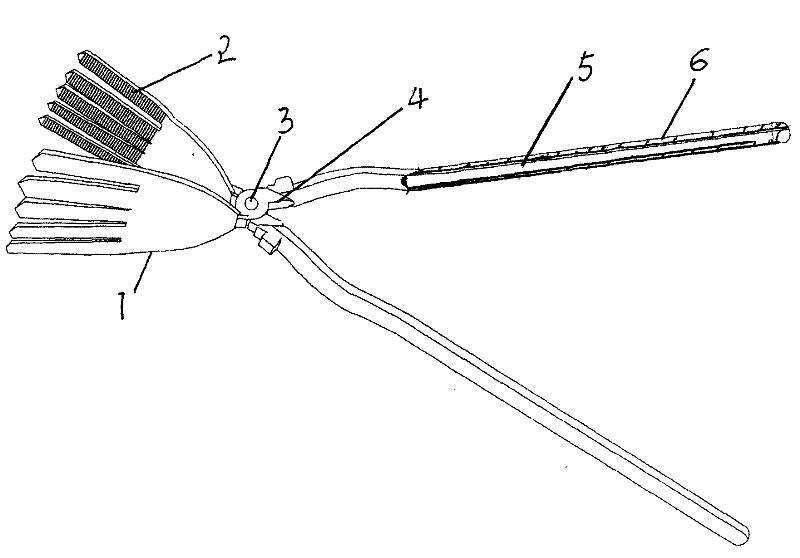

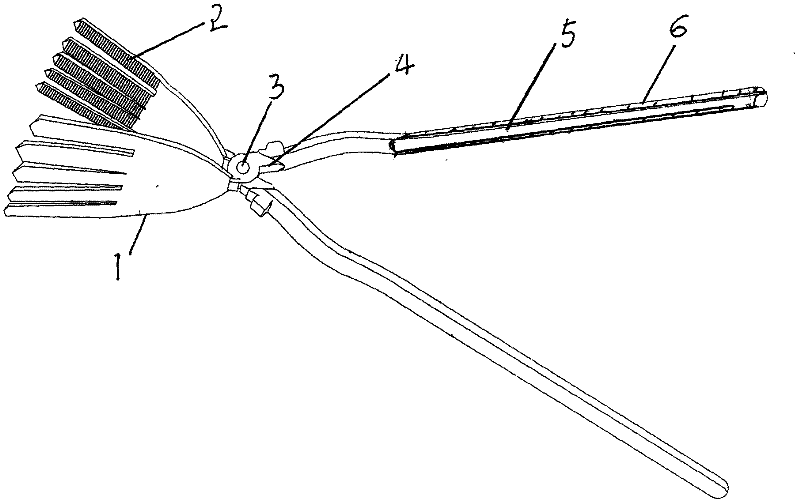

Special hand-shaped tongs with long insulated handles for removing bird nest from transmission tower

InactiveCN102371570AWon't hurtReduce labor intensityMetal-working hand toolsTransmission towerFinger joint

The invention discloses a pair of special hand-shaped tongs with long insulated handles for removing a bird nest from a transmission tower. The pair of special hand-shaped tongs comprises a pair of hand-shaped tong heads, namely a metal tong head and a tong shaft tong head, wherein, two short wedge handles are arranged on the other end of a tong shaft corresponding to the hand-shaped tong heads, and a long insulated tong handle which is not shorter than half a meter is fixed on each of the short wedge handle; insulating sheaths are respectively sheathed on the long insulated tong handles; and uniformly distributed transverse silk slots are respectively arranged on tong finger joint surfaces of the hand-shaped tong heads. When used for removing a bird nest from a transmission tower, the pair of special hand-shaped tongs has the advantages of high removal speed and high safety and is labor-saving for a worker.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

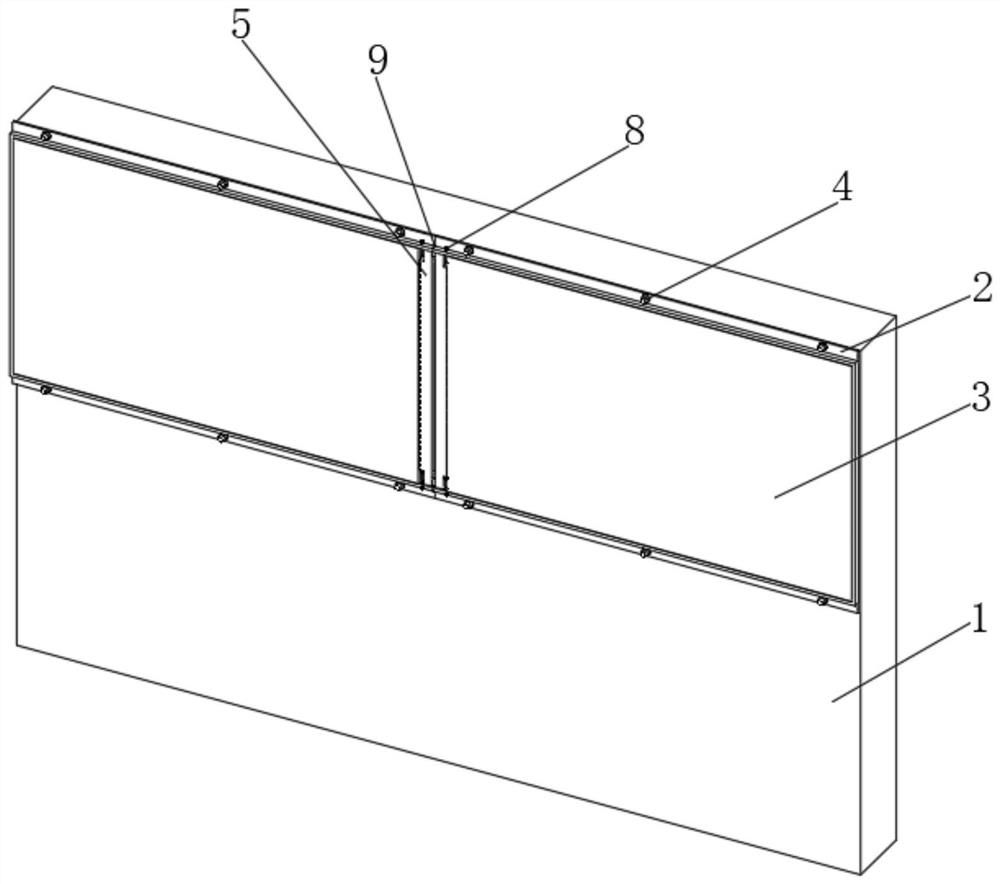

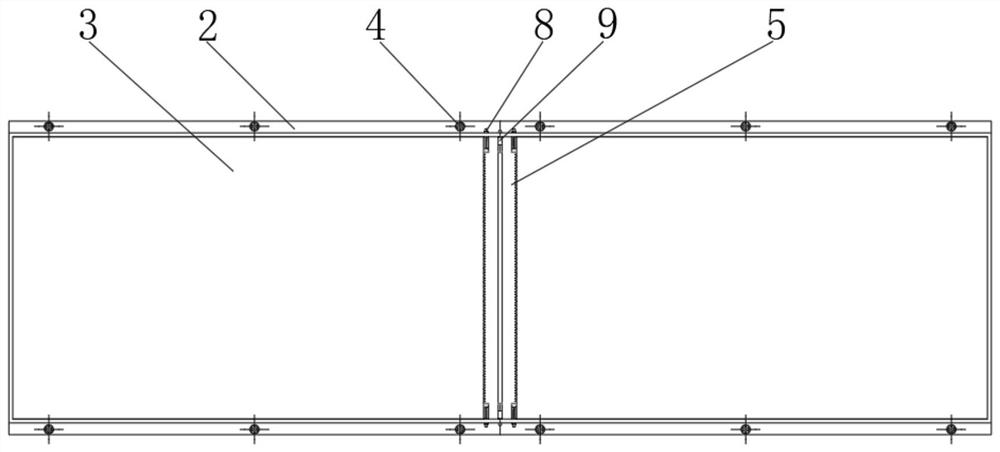

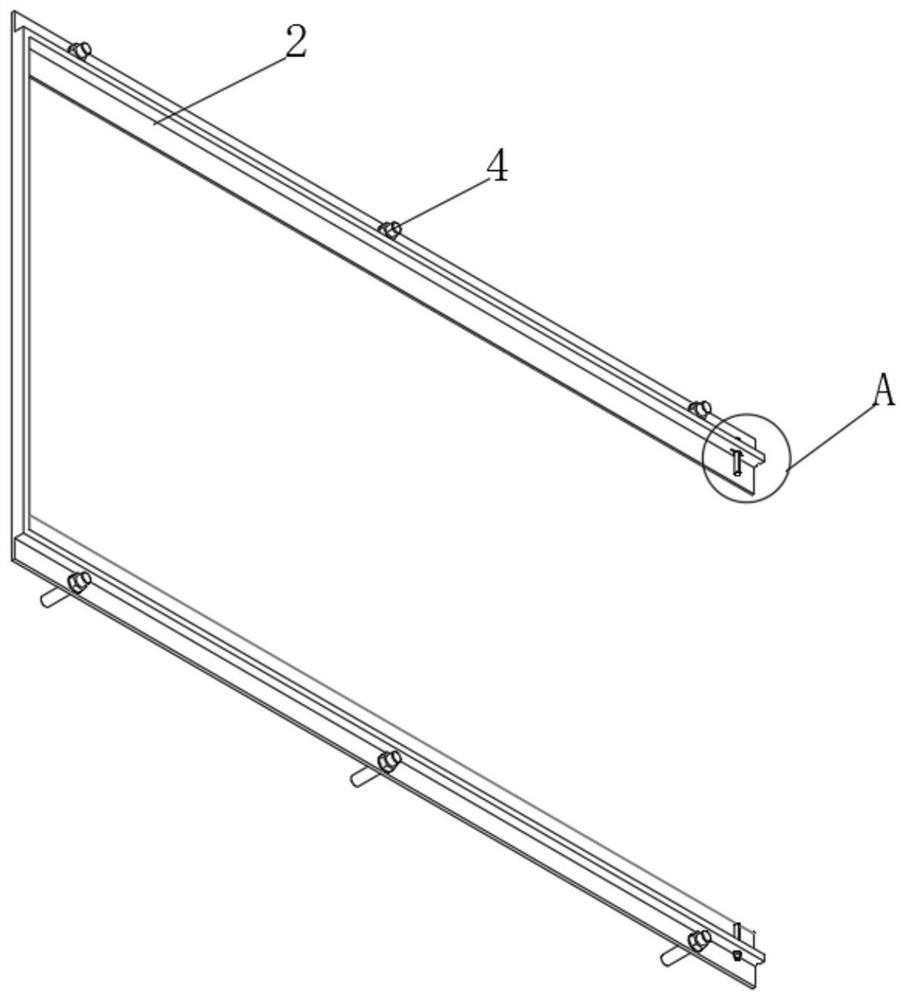

Convenient installation structure of prefabricated concrete assembly type wallboard

PendingCN112343214AIntegrity guaranteedAvoid cleaningConstruction materialWallsButt jointArchitectural engineering

The invention belongs to the technical field of assembly type wallboard installation, and discloses a convenient installation structure of a prefabricated concrete assembly type wallboard. The convenient installation structure comprises a wall body, installation frames and a wallboard; No.1 expansion screws are fixedly installed on the wall body and the installation frames; the number of the installation frames is two; the ports of the two installation frames are correspondingly contacted; the wall body and the installation frames are fixedly connected through the No.1 expansion screws; and the wallboard is fixedly installed on the wall body. According to the convenient installation structure of a prefabricated concrete assembly type wallboard, the two installation frames are installed onthe wall body, the two installation frames are in butt joint, then the wallboard is placed on the inner extending edges of the two installation frames respectively, AB glue is used for primary adhesion, and then other fixing procedures are carried out, so that the structure of the wallboard cannot be damaged in the whole process, holes do not need to be formed in the wallboard, the integrity of the wallboard is maintained, after the wallboard is disassembled subsequently, the wallboard can still be used again according to decoration requirements, and waste and waste cleaning are avoided.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Terminal dismantling device for automobile wire harness recovery

ActiveCN110170808ARealize highly integrated workReduce laborVehicle connectorsLine/current collector detailsMechanical engineeringCable harness

The invention relates to the field of dismantling equipment, in particular to a terminal dismantling device for automobile wire harness recovery. The terminal dismantling device for automobile wire harness recovery comprises a base and a controller and also comprises a feeding mechanism, a peeling mechanism and a discharging mechanism. The feeding mechanism is arranged at one end of the top of thebase to feed an automobile wire harness to the peeling mechanism. The peeling mechanism is arranged next to the feeding mechanism to peel a terminal of the automobile wire harness fed by the feedingmechanism. The discharging mechanism is arranged below the peeling mechanism to discharge the dismantled automobile wire harness. The feeding mechanism comprises a pushing assembly, a reversed U-shaped supporting rod, a driving assembly and a clamping assembly. The peeling mechanism comprises a reversed U-shaped supporting rack, a supporting table, a compression assembly and a sliding assembly. The terminal dismantling device for automobile wire harness recovery dismantles the terminal of the automobile wire harness by means of automatic equipment replacing manual operation and dismantles theterminals of the automobile wire harnesses in batches. Meanwhile, the terminal dismantling device has a discharging function, is convenient and practical, saves the dismantling time, and saves the production costs of an enterprise and a plant.

Owner:嘉善哈耐斯电子科技有限公司

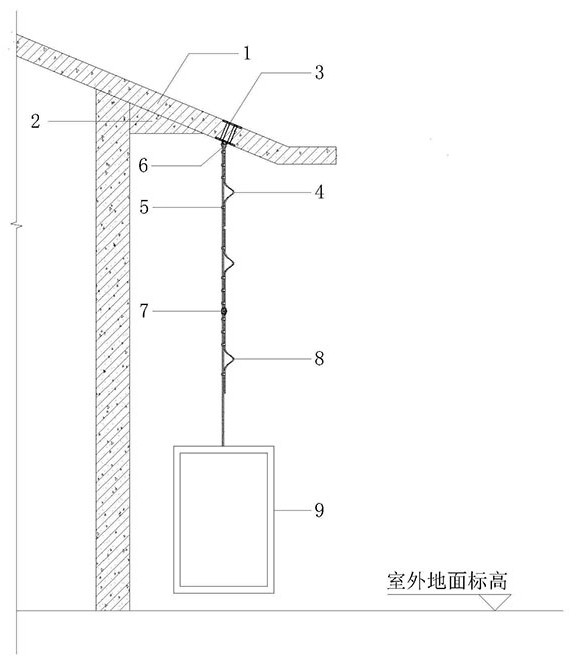

Counter-weight-free and bracket-free mounting and dismounting method of hanging basket on sloping roof cornice

ActiveCN113530285AEasy to operateQuick installationBuilding repairsScaffold accessoriesArchitectural engineeringHanging basket

The invention discloses a counter-weight-free and bracket-free mounting and dismounting method of a hanging basket on a sloping roof cornice. The counter-weight-free and bracket-free mounting method comprises the step of: carrying out reinforcing processing on the position of the sloping roof cornice; embedding a plurality of hanging basket embedded parts in the sloping roof cornice, wherein each hanging basket embedded part comprises two anchor plates and a plurality of anchor bars fixedly arranged between the two anchor plates, at least one hanging ring is fixedly connected to the bottom of one anchor plate, and the hanging ring is embedded downwards; assembling a hanging basket platform; enabling a transfer steel wire rope to be penetrated into the hanging ring, combining the part, which penetrates through the hanging ring, of the transfer steel wire rope and the part, which does not penetrate through the hanging ring, of the transfer steel wire rope together in the vertical direction, carrying out fixing through a steel wire rope buckle, reserving a plurality of safety bends on the transfer steel wire rope, and reserving a connecting ring at the bottom of the transfer steel wire rope for being connected with a working steel wire rope; after the working steel wire rope is hung, enabling the working steel wire rope to vertically fall to the ground along the wall surface; and connecting a hoisting steel wire rope with the hanging basket and equipment in the hanging basket. A bracket and a counterweight do not need to be mounted when the hanging basket is mounted, the hanging basket is directly suspended by the hanging ring of the sloping roof, and mounting speed is high.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Reinforced concrete bottom plate cutting method based on wire saw process

InactiveCN111014819AEasy to cutAchieve reductionMetal sawing devicesMetal sawing accessoriesReinforced concreteDiamond wire saw

The invention discloses a reinforced concrete bottom plate cutting method based on a wire saw process. The method comprises the following steps: 1) determining a reserved area and cutting edge lines according to a cutting range of a bottom plate, drawing a plurality of cutting lines in the cutting area surrounded by the cutting edge lines, and determining drilling positions; 2) using a drilling machine to drill holes at the drilling positions, wherein the hole diameter is larger than the diameter of a directional wheel of a wire saw cutting device; 3) cutting reinforced concrete by the wire saw cutting device along the cutting lines, and moving cut reinforced concrete block out of the cutting area by using a hoisting machine. According to the method, the reinforced concrete bottom plate isbroken by the diamond wire saw process, dismantling speed is high, noise is low, and the influence on the structure in the dismantling process is small.

Owner:RANKEN RAILWAY CONSTR GROUP

Device for rapidly dismounting bolt of fastener

A device for rapidly dismounting a bolt of a fastener comprises an operation platform. A rotating wheel is mounted on the operation platform. A spindle of the rotating wheel is fixedly connected with one end of a rotating rod, and a notch for fixing a nut is formed in the other end of the rotating rod. A vertical rod is fixedly mounted on the operation platform and sleeved with a sleeve. The sleeve is fixedly connected with one end of a cross rod, and a clamping groove for fixing a screw is formed in the middle of the cross rod. According to the device for rapidly dismounting the bolt of the fastener, the nut is fixed in the rotating rod, a power system is used for driving the rotating rod to rotate, and therefore the bolt is dismounted. The device is simple in structure and can be operated by only one person, and the fastener bolt dismounting efficiency is improved effectively.

Owner:中国葛洲坝集团建设工程有限公司

A device for removing walls

The invention discloses a wall dismantling device including a bottom seat, lifting devices, stand column, a wall dismantling main body, a wall dismantling mechanism and an anti-falling device, whereinthe lifting devices are symmetrically arranged front and back in the bottom seat, the stand column is arranged on the upper end face of the bottom seat, the wall dismantling main body is arranged onthe stand column, the wall dismantling mechanism is arranged on the right side of the wall dismantling main body, and the anti-falling device is arranged on the left side of the stand column. The walldismantling mechanism includes an opening cavity, the opening cavity is formed in the right end face of the wall dismantling main body, and the right end face of the wall dismantling main body is provided with a cotton-shaped body. A plurality of high-pressure water guns arranged front and back, are arranged in the end wall of the opening cavity. A discharge cavity is formed in the lower end of the left side of the opening cavity, and a discharge port is formed in the lower end of the discharge cavity. A stirring motor is fixedly arranged on the front side of the middle portion of the wall dismantling main body, a rotating cavity is formed in the upper end of the stirring motor, and an active rotating shaft is arranged on the left side of the rotating cavity.

Owner:滁州环超智能科技有限公司

Flood diversion pipe band group of dam for above standard flood

InactiveCN105568923ALow costAvoid occupyingHydraulic engineering apparatusEmergency rescueSynthetic materials

A flood diversion pipe band group of a dam for above standard flood belongs to the technical field of hydraulic engineering of dam flood diversion. In case that above standard flood comes, the flood diversion pipe band group is capable of realizing flood diversion to prevent an embankment from bursting; and the flood diversion pipe band group has the advantages of simple structure, finalized design and production, convenient transportation, fast construction, and low manufacturing cost. The flood diversion pipe band group comprises inlet hafnium U-shaped grooves, cage type trash racks, HDPE flap valves, flood diversion pipe bodies, outlet hafnium U-shaped grooves, water delivery bands each having a rigid framework and made of an artificially synthesized material, aprons of a geotechnical synthetic material, sandbag baffle sills, and color strip cloth sandbag scour prevention sections; the flood diversion pipe bodies along with the water delivery bands each having the rigid framework and made of the artificially synthesized material are arranged at equal distances and in parallel, and therefore, the flood diversion pipe band group of the same flood diversion point is constructed as required. The flood diversion pipe band group is arranged dispersedly along two sides, and capable of implementing temporary controllable flood diversion to a farmland at any place without permanently occupying the cultivated land; no special flood retarding basin is needed, and great calamity caused by concentrated flood diversion, and high-investment whole-line flood fighting can be avoided; the detachable and combinable flood diversion pipe band group can be quickly constructed when flood diversion is needed during flood-fighting and emergency rescues, and is convenient to use and manage.

Owner:HEILONGJIANG UNIV

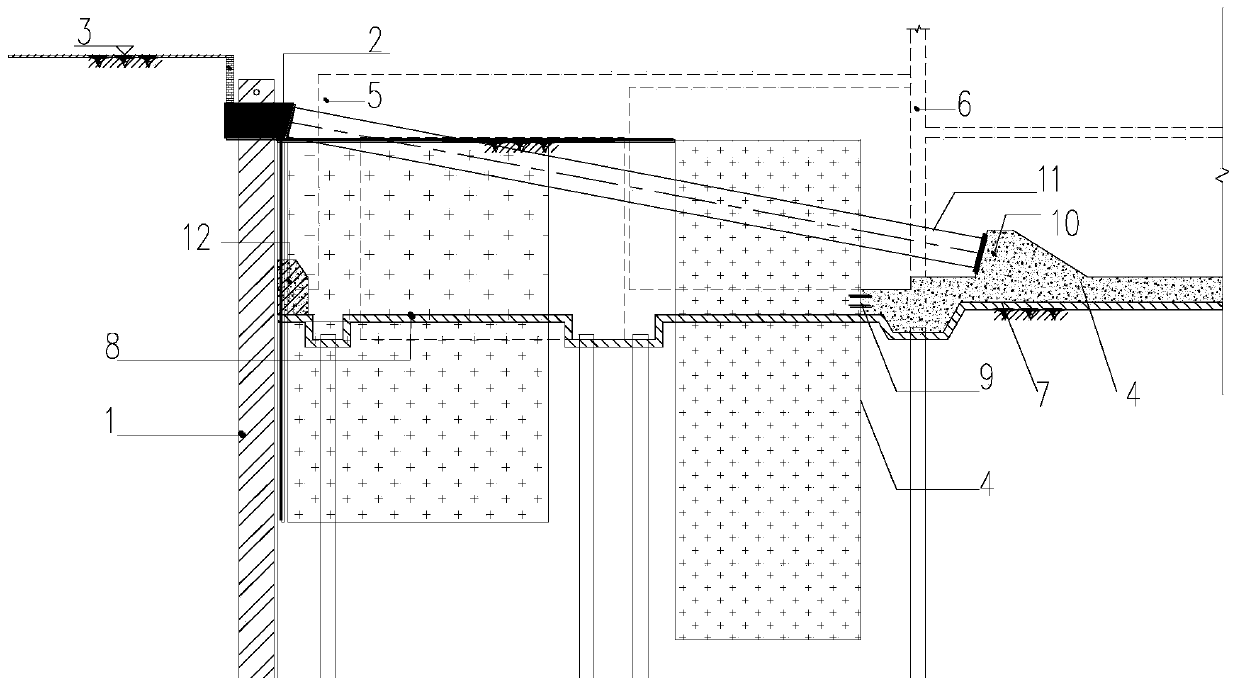

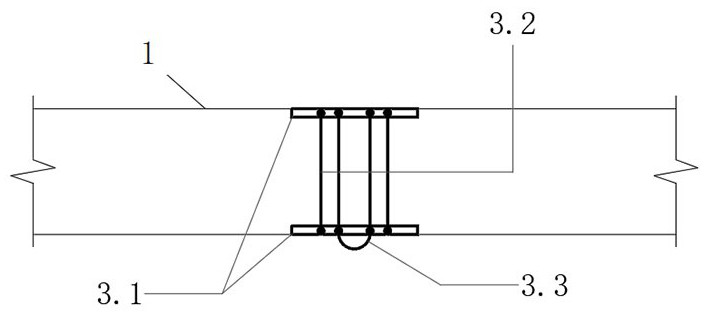

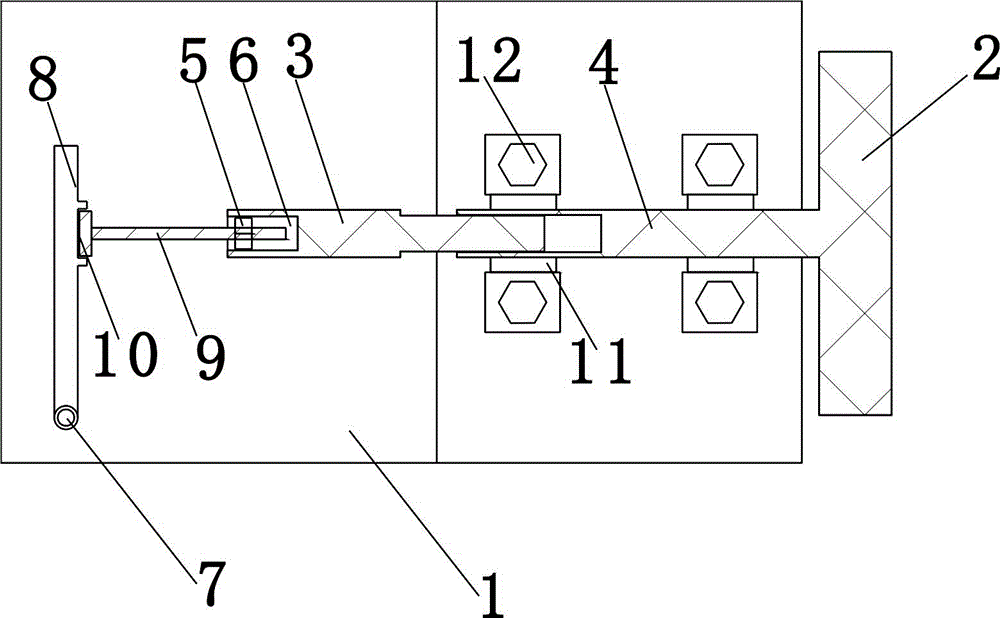

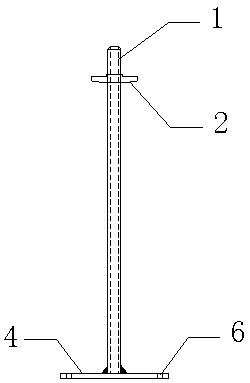

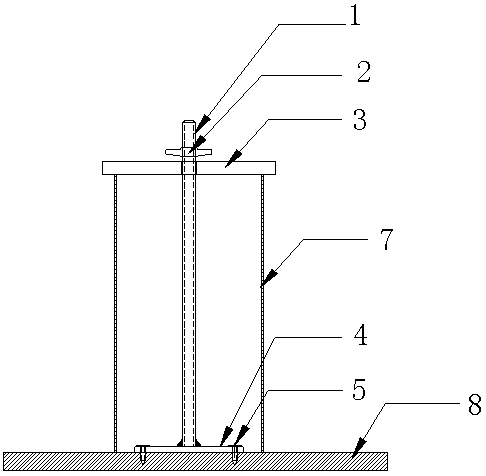

Fixing device for pre-embedded casing pipe and reserved hole and using method

InactiveCN108798008ASimple structureEasy to makeForms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention provides a fixing device for a pre-embedded casing pipe and a reserved hole. The fixing device is used for steel bar binding of reinforced concrete and comprises a bottom plate and a screw. The fixing device is characterized in that the bottom plate (4) is a rectangular or square steel plate, and at least two screw holes (6) are formed in the edge of the bottom plate; the screw (1) is a full-wire screw with the diameter greater than or equal to 12 mm, and the screw is provided with a nut (2) in a matched mode; and one end of the screw (1) is welded and fixed to the center of thebottom plate, and the screw is perpendicular to the bottom plate. The fixing device for the pre-embedded casing pipe and the reserved hole and a using method have the advantages that the fixing deviceis simple in structure, manufacturing is quick and convenient, the quality of the pre-embedded casing pipe and the reserved hole are safe and reliable so as to achieve the effect of non-deviation andnon-moving of the pre-embedded casing pipe, fixing operation of the casing pipe is easy, the installation efficiency is greatly improved, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Wall body environment-friendly dismounting device

The invention discloses a wall body environment-friendly dismounting device. The wall body environment-friendly dismounting device comprises a base, lifting devices arranged in the base in a front-back symmetry mode, a vertical column arranged on the upper end face of the base, a wall surface dismounting main body arranged on the vertical column, a wall surface dismounting mechanism arranged on the right side of the wall surface dismounting main body and a falling-preventing device arranged on the left side of the vertical column. The wall surface dismounting mechanism arranged on the right side of the wall surface dismounting main body comprises an opening cavity formed in the right end face of the wall surface dismounting main body, a sponge-shaped body is arranged on the right end faceof the wall surface dismounting main body, and a plurality of high-pressure water guns arrayed in the front-back direction are arranged on the upper end wall of the opening cavity. An unloading cavityis formed in the lower end of the left side of the opening cavity, an unloading opening is formed in the lower end of the unloading cavity, and a stirring motor is fixedly arranged on the front sideof the middle of the wall surface dismounting main body. A rotating cavity is arranged at the upper end of the stirring motor, and a driving rotary shaft is arranged on the left side of the rotating cavity.

Owner:江苏中柢建设集团有限公司

Ball type hot blast stove dismantling method

ActiveCN113999946AImprove demolition efficiencyAvoid the hassle of removing the linerBrick-hot blast stovesBlast furnace detailsCold airHot air oven

The invention discloses a ball type hot blast stove dismantling method, which is a destructive dismantling method and comprises the steps that a furnace shell steel structure of a hot blast stove, a hot blast stove body lining material and steel platform accessory equipment are all destructively dismantled. The method comprises the following steps that S1, early-stage dismantling work is conducted; S2, a combustor is dismantled; S3, a hot air header pipe platform is dismantled; S4, a large vault is dismantled; S5, an upper-layer ball loading platform is dismantled; S6, a heat storage chamber is dismantled; S7, a lower-layer ball loading platform is dismantled; S8, a lower cone, a grate and a cold air chamber are dismantled; and S9, waste is cleared away. The dismantling method is high in efficiency, low in cost, high in safety and convenient to use and popularize.

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

Aluminum mould pulling piece dismounting tool capable of being repeatedly utilized conveniently

PendingCN111206777AFast demolitionSolve construction problems that are difficult to dismantleForm treatmentRebarSteel tube

The invention provides an aluminum mould pulling piece dismounting tool capable of being repeatedly utilized conveniently. The aluminum mould pulling piece dismounting tool capable of being repeatedlyutilized conveniently comprises a steel tube and a supporting framework, wherein one end part of the steel tube is in the shape of a flat opening; the supporting framework comprises two bent reinforcing steel bars and supporting steel plates, wherein each bent reinforcing steel bar comprises a lap-joint part and a handle part, and an included angle between the lap-joint part and the handle part is an obtuse angle; the lap-joint parts of the two bent reinforcing steel bars are in doubled-sided welding with the other end part of the steel tube; and the supporting steel plates are uniformly andequally welded between the handle parts of the two bent reinforcing steel bars. The dismounting tool provided by the invention is simple in structure, is convenient and quick to hold with the hands for use, is small and reasonable in weight, and is convenient in processing and welding; the handheld supporting framework can break off the head of a pulling piece by a flat opening end of the steel tube, the handheld steel tube can cut off the pulling piece through the supporting steel plates, and the two parts can be used, so that the functions are various. The dismounting tool can quicken the construction progress of dismounting an aluminum mould pulling piece, and reduces damage to a wall surface.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Method for removing reinforced concrete chimney

ActiveCN103015744BSimple stepsEasy to implementBuilding repairsReinforced concreteStructural engineering

Owner:CHINA RAILWAY FIRST GRP CO LTD

Prefabricated shear wall manufacturing equipment and manufacturing method

ActiveCN106217637BEasy to operateFast constructionConstruction materialCeramic shaping apparatusDrive wheelMotor control

The invention provides manufacturing equipment for a pre-cast shear wall. The manufacturing equipment comprises a master console and a slave console which are arranged on a horizontal base plate, wherein a first operation panel and a second operation panel which are oppositely arranged are arranged on the master console and the slave console; and the first operation panel is arranged on the master console through a gear disc, a control motor controls the rotation of the gear disc, the first operation panel and a pre-casting operation table are driven to rotate through the rotation of the gear disc, the second operation panel is arranged on the slave console through a driven wheel, and the pre-cast shear wall, a slave operation table, the second operation panel and the driven wheel are driven to rotate through the rotation of the gear disc after the pre-cast shear wall is fixed on the pre-casting operation table and the slave operation table. The manufacturing equipment and the manufacturing method for the pre-cast shear wall, which are provided by the invention, have the following advantages: the large shear wall can be operated, a rotation angle of the shear wall during a construction installation process can be randomly adjusted through the master console and the slave console which are oppositely arranged, and the advantages of simple operation, fast construction speed and the like are achieved.

Owner:JIANGSU SUZHONG CONSTR GROUP

Reverse dismantling method for high-rise frame structure

ActiveCN114737790AReduce labor intensityFast demolitionBuilding repairsConcrete beamsArchitectural engineering

The invention relates to a reverse dismantling method for a high-rise frame structure, and belongs to the field of building construction. A reverse dismantling method for a high-rise frame structure comprises the following steps that S10, wall structures of the first layer and the second layer are dismantled, beam plates of the second layer are dismantled, frame columns are all dismantled, and the frame columns are replaced with steel columns; s20, the concrete beams on the second layer are dismantled, the main beams are replaced with the steel beams, a plurality of jacking devices are fixed to the steel beams at intervals in the steel beam replacing process, and the jacking devices are used for jacking and supporting the main beams on the third layer; s30, the pushing device is driven to contract, the high-layer frame structure descends, frame columns on the second layer fall into the operation space, and the frame columns on the second layer are dismantled; s40, wall structures and beam plates of the third layer are dismantled, concrete beams of the third layer are dismantled, a jacking device is used for jacking and supporting main beams of the fourth layer, a pushing device is driven to contract, and frame columns of the third layer are dismantled; and according to the step S40, the high-rise frame structure is dismounted layer by layer. The dismantling method for the high-rise frame structure is high in dismantling speed, environmentally friendly and low in labor intensity.

Owner:CHINA 19TH METALLURGICAL CORP

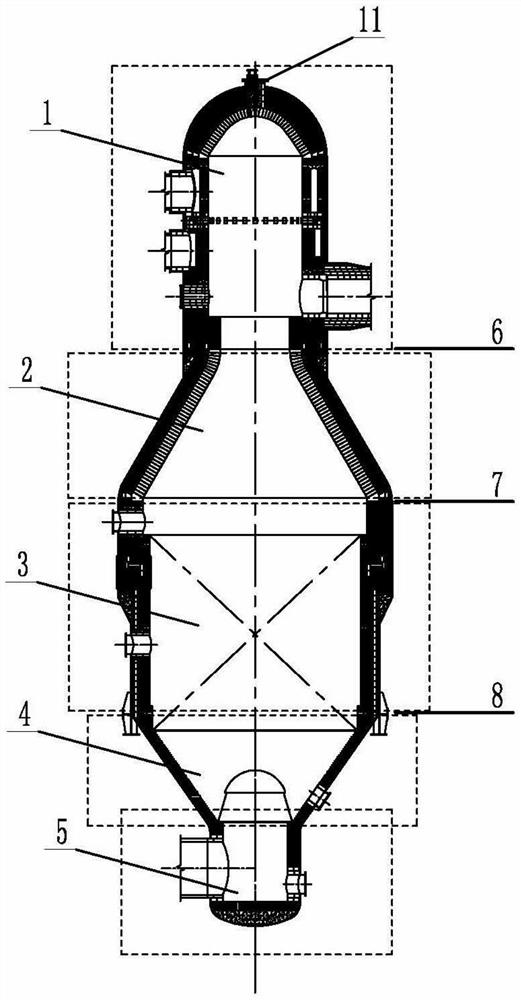

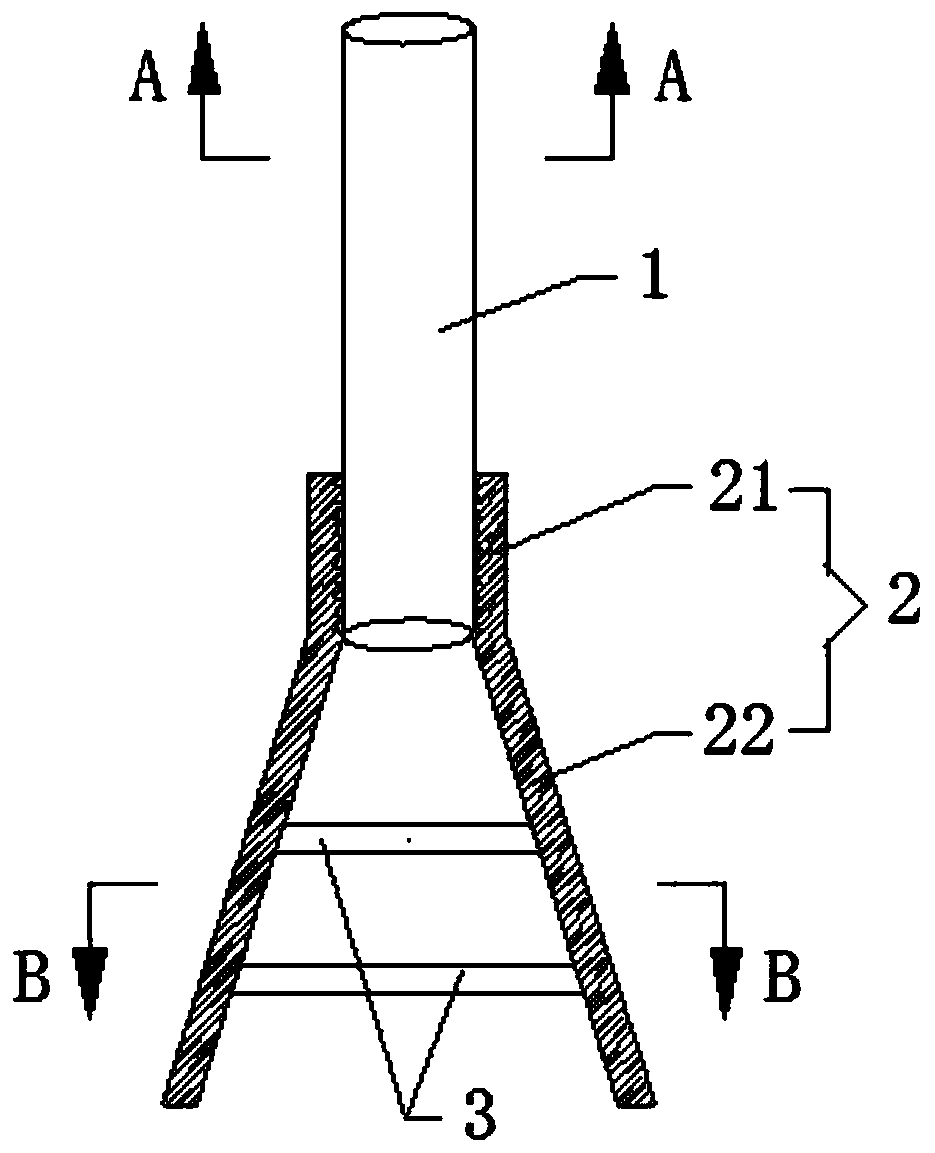

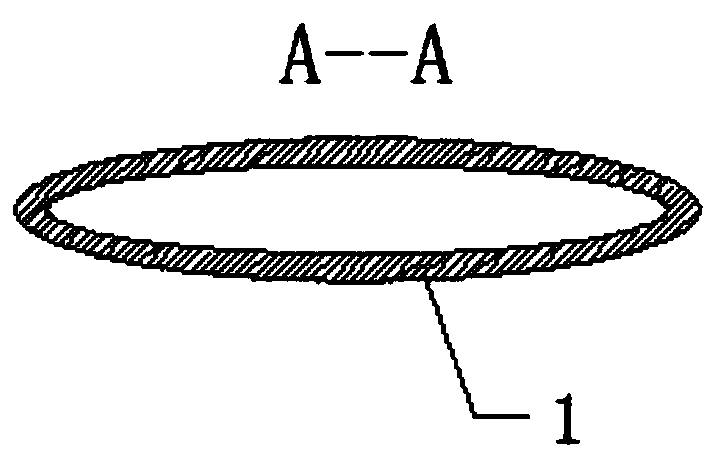

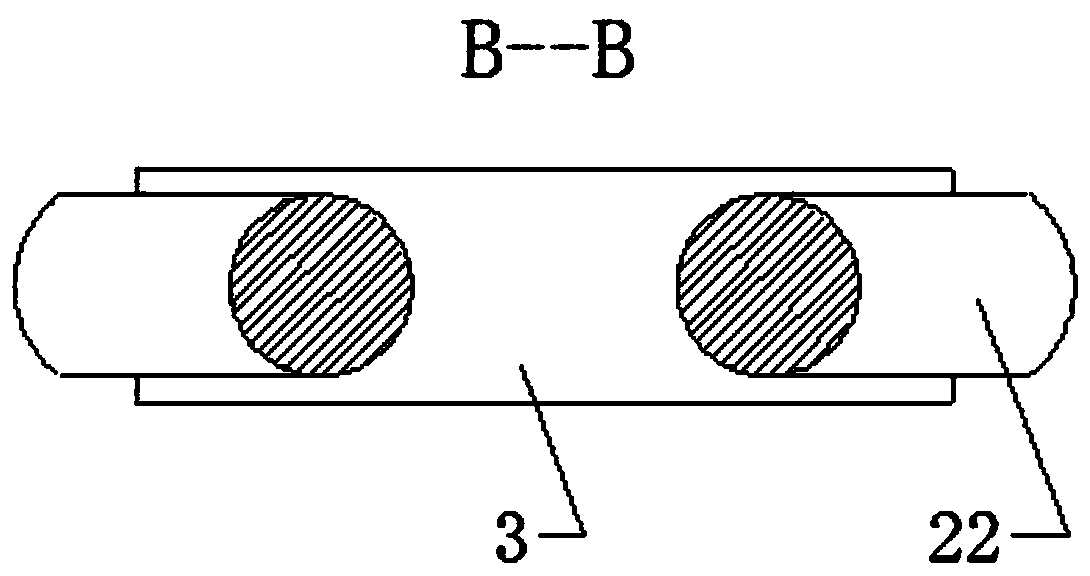

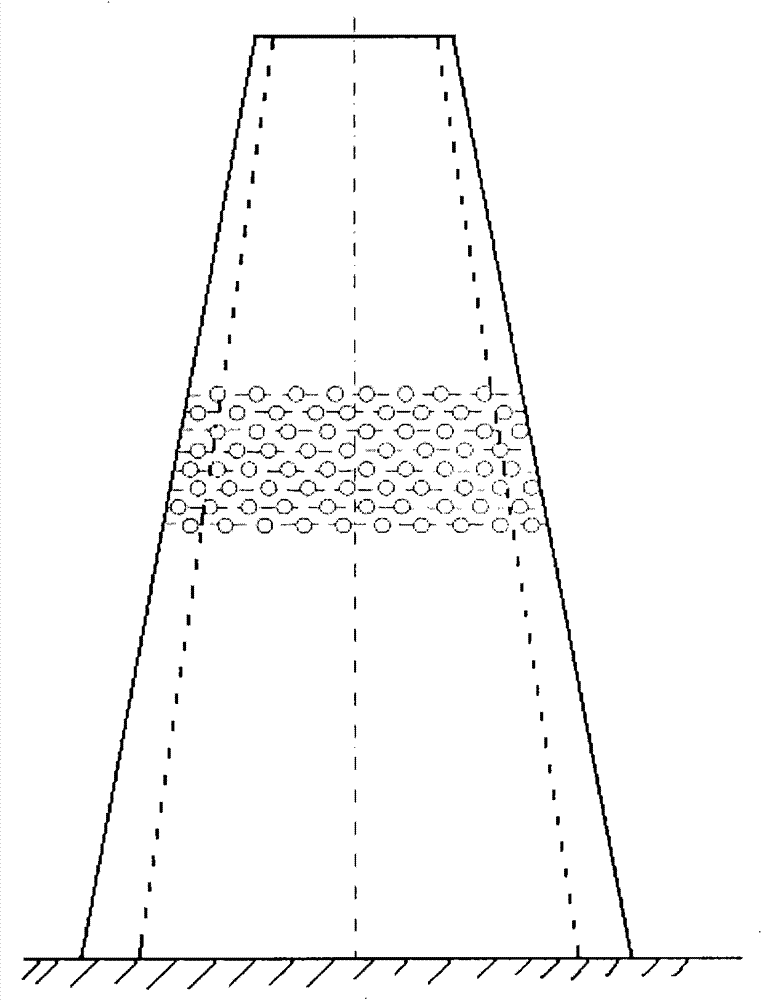

A nested in-situ controlled blasting demolition method for conical buildings

InactiveCN105423831BSolve the technical problems of demolitionPromote productivityBlastingEffective solutionDetonator

A nested in-situ control blasting demolition method for conical buildings, which makes full use of the geometric characteristics and symmetrical structure of conical buildings to reasonably divide them into sections, and sets an annular gap at the bottom of each section according to the nesting conditions. High calculation, blast hole setting, directional device design and digital electronic detonators are used to detonate row by row from bottom to top, symmetrically destroying the reinforced concrete within the range of the annular gap, so that the segment-by-section conical buildings can be accurately inserted into the bottom section of the chimney , the diffusion range of the demolition body is limited to the chimney. The patent is novel in design and simple in process. The demolished conical building falls into the conical structure accurately by means of segmentation, orientation, blasting, and nesting. The diffusion range is controlled within the conical structure without affecting the normal production and operation of surrounding factories. The daily life of residents complies with the national clean, environmental protection and energy-saving policy. Innovation and energy conservation run through the whole process of demolition, effectively solving the world-class technical problem of demolition of towering reinforced concrete conical buildings (structures) in a complex environment without collapse sites.

Owner:张建平

Terminal removal device for recycling automobile wiring harness

ActiveCN110170808BRealize highly integrated workReduce laborLine/current collector detailsVehicle connectorsCable harnessSupport plane

The invention relates to the field of dismounting equipment, in particular to a terminal dismounting device for automobile wire harness recovery. The terminal dismounting device for automobile wire harness recovery comprises a base and a controller, and also comprises a material conveying mechanism, a peeling mechanism and a discharging mechanism, wherein the material conveying mechanism is arranged at one end of the top of the base so as to convey an automobile wire harness to the peeling mechanism; the peeling mechanism is arranged beside the material conveying mechanism so as to perform terminal peeling on the automobile wire harness conveyed by the material conveying mechanism; the discharging mechanism is arranged under the peeling mechanism so as to discharge the automobile wire harness subjected to terminal dismounting; the material conveying mechanism comprises a push moving assembly, a reverse U-shaped support rod, a driving assembly and a clamping assembly; and the peeling mechanism comprises a reverse U-shaped support frame, a support table, a compression assembly and a sliding assembly. The terminal dismounting device for automobile wire harness recovery provided by theinvention has the advantages that automatic equipment is used for replacing manual dismounting; in addition, the automobile wire harness terminal dismounting can be performed in a batch way; meanwhile, a material discharging function is realized; convenience and practicability are realized; the dismounting time is reduced; and the production cost of enterprises and factories is reduced.

Owner:JIASHAN HANAS ELECTRONIC TECH CO LTD

Method for dismantling concrete box girder of under-passing closed frame culvert

InactiveCN110499718AImprove work efficiencyImprove construction efficiencyBridge erection/assemblyBridge strengtheningTruckGantry crane

The invention discloses a method for dismantling a concrete box girder of an under-passing closed frame culvert. The method for dismantling the concrete box girder of the under-passing closed frame culvert comprises the following steps of early-stage preparations, erecting full framing, erecting steel pipe column structures, laying a gantry crane track beam, installing a gantry crane, cutting mainbeam flange plates by adopting a rope saw, eliminating discarded flange plate blocks through hoisting by adopting the combination of the gantry crane and a truck-mounted crane, cutting a main beam box chamber by adopting the rope saw, eliminating discarded main beam box chamber beam blocks through hoisting by adopting the combination of the gantry crane and the truck-mounted crane, and transporting the discarded beam blocks to a designated site by adopting a transportation truck. According to the method for dismantling the concrete box girder of the under-passing closed frame culvert, throughthe design of a temporary support and the cutting steps, the concrete box girder is dismantled by adopting the combination of the truck-mounted crane and the gantry crane; safe and rapid dismantlingof a bridge is achieved; and the method is applicable to rapid dismantling construction of the concrete box girder of the under-passing closed frame culvert in a city bridge.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com