A nested in-situ controlled blasting demolition method for conical buildings

A technology for controlling blasting and building, which is applied in the direction of blasting, etc., to achieve good promotion and application prospects, direct economic benefit improvement, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

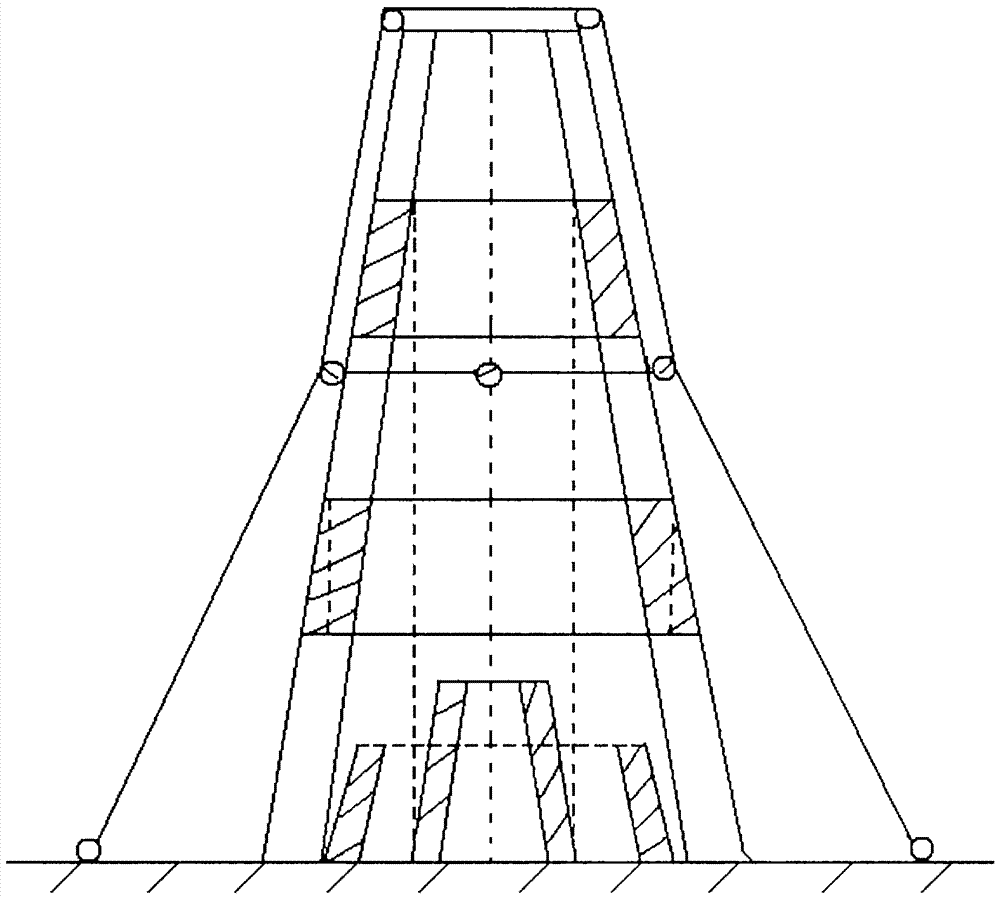

[0030] First, according to the geometric characteristics and symmetry of the inverted cone of the conical building, divide the conical building into sections according to the actual height, structure and site requirements, and set the decomposition height as L n (At present, the height of the general conical building is below 240 meters, which can be divided into 2-4 sections);

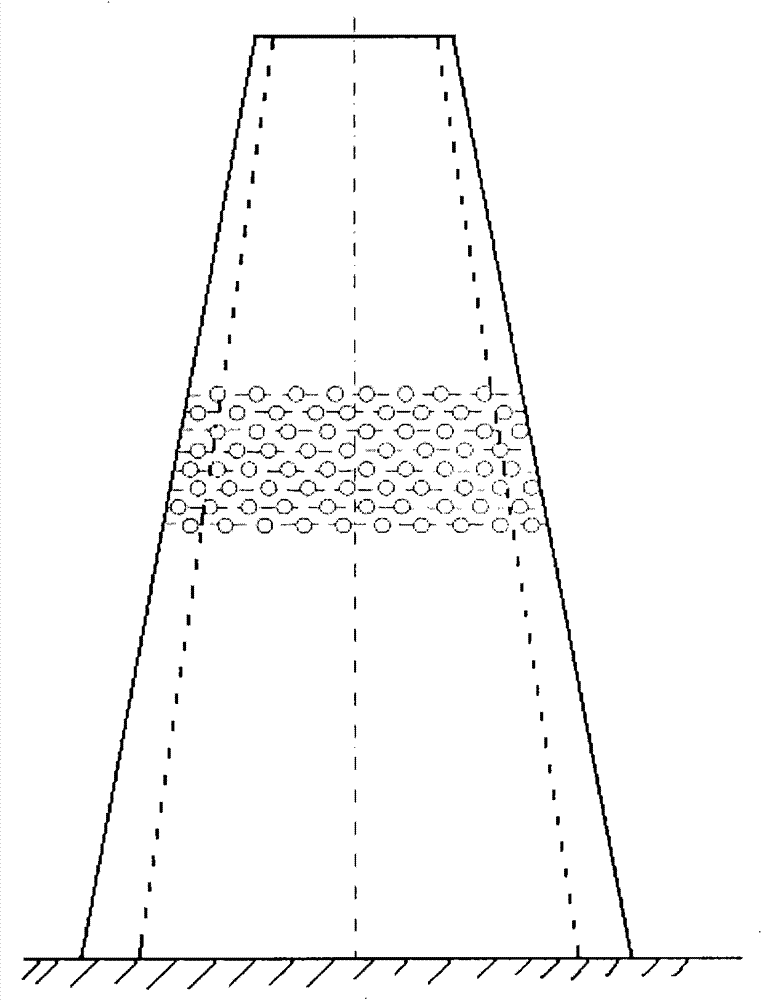

[0031] Secondly, observe the division of conical buildings and set an annular gap under each section. The setting of the height of the annular gap must satisfy 1. The maximum number of stacks of conical buildings. 2. The height of the upper conical building is greater than that of the lower conical building. Shaped building height, where the formula for calculating the maximum number of stacks is: (N max is the maximum nesting number, D nxn is the inner diameter of the conical building in the previous section, D nw is the outer diameter of the nth section of the conical building, K is the stacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com