Method for removing reinforced concrete chimney

A technology of reinforced concrete and concrete, which is applied in building maintenance, construction, building construction, etc., can solve the problems of fast collapse of chimneys, high construction costs, and long hours of high-altitude operations, and achieves simple demolition steps and low construction costs , The effect of the overall force is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

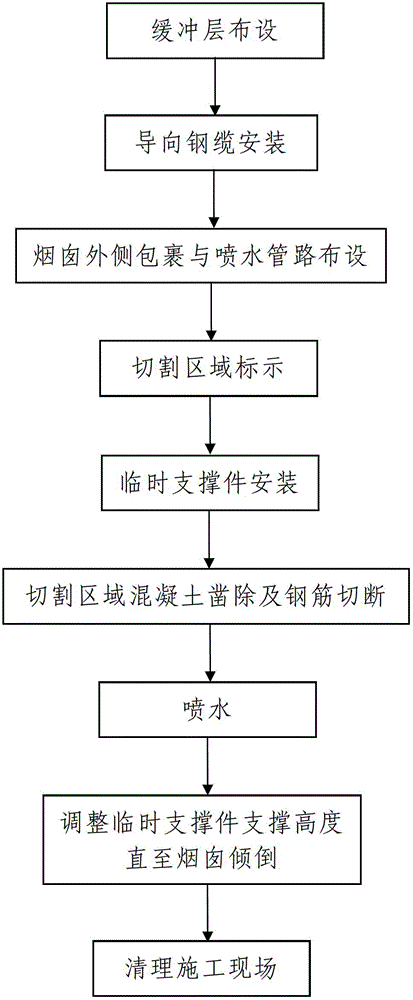

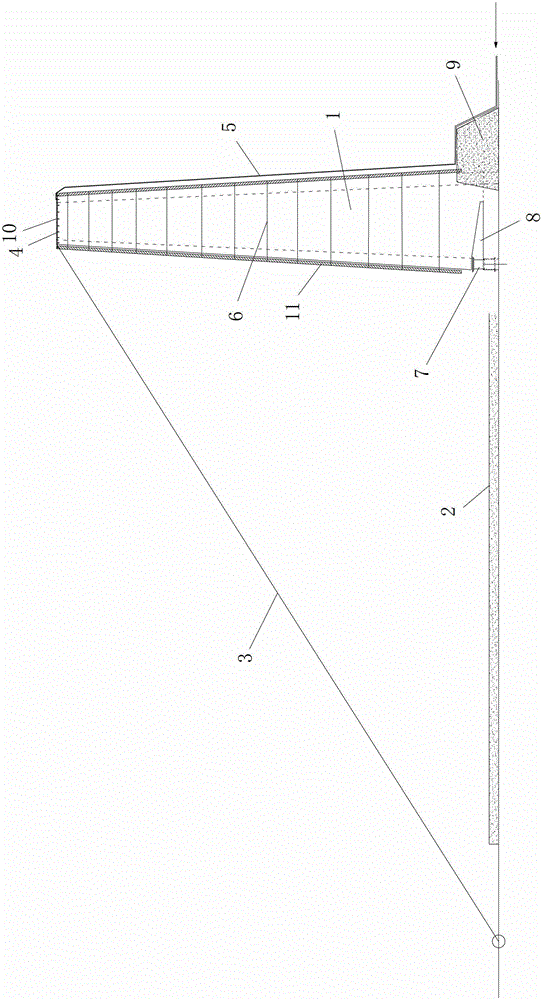

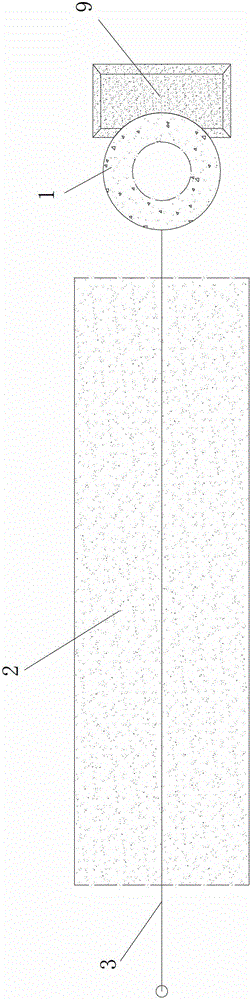

[0048] like figure 1 In the shown method for removing a reinforced concrete chimney, the removed reinforced concrete chimney 1 is arranged vertically, and the inside of the reinforced concrete chimney 1 is provided with a steel skeleton arranged vertically, and the steel skeleton includes a plurality of Vertical reinforcement; the cross-section of the reinforced concrete chimney 1 is circular and its outer diameter gradually increases from top to bottom, see figure 2 , image 3 and Figure 4 . During actual construction, the demolition method includes the following steps:

[0049] Step 1, laying out the buffer layer: according to the surrounding environment where the reinforced concrete chimney 1 is located, determine the dumping position and direction of the reinforced concrete chimney 1, and lay a buffer layer 2 on the determined dumping position.

[0050] In this embodiment, the buffer layer 2 is a loose soil cushion layer with a thickness of 1.0m to 1.5m, and the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com