Ball type hot blast stove dismantling method

A technology of hot blast stove and hot blast, which is applied to brick blast furnaces, furnaces, blast furnaces, etc., which can solve the problems of slow demolition speed, influence of platform space and bearing capacity, and small range of free movement, so as to save time and labor and speed up demolition progress, the effect of increasing the demolition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

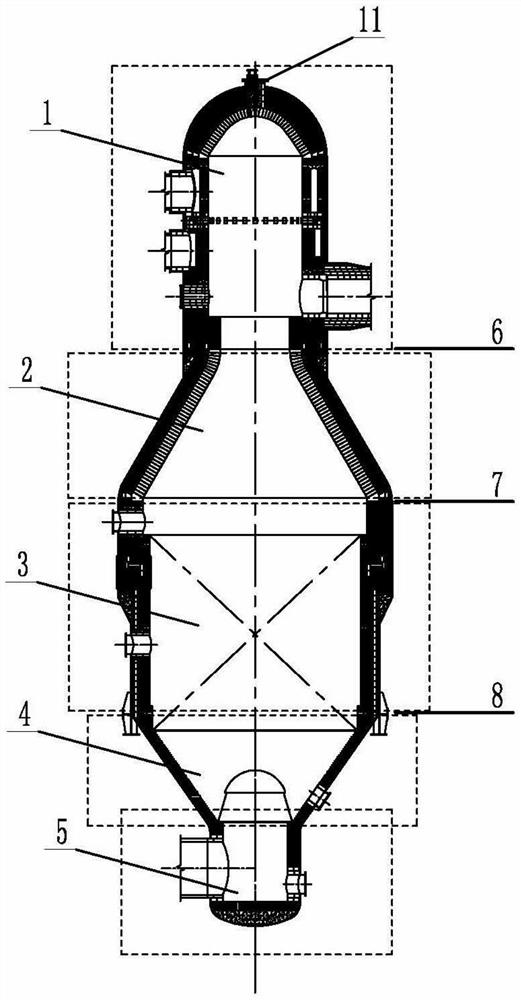

[0090] A method for dismantling a spherical hot blast stove, the demolition method is destructive demolition, including the destructive removal of the steel structure of the furnace shell of the hot blast stove, the lining material of the furnace body of the hot blast stove, and the auxiliary equipment of the steel platform, including the following steps:

[0091] S1. Preliminary work for demolition:

[0092] S11. Unloading hot air bulb:

[0093] Open the ball unloading hole of the lower cone 4 of the hot blast stove, remove the hot blast ball from the ball unloading hole to the outside of the hot blast stove, and empty the regenerator and the inside of the lower cone for subsequent removal of the burner and the furnace lining material of the large vault Inner stacking provides space; in order to save transportation costs, part of the hot air bulbs can be transported away first, and the remaining hot air bulbs can be loaded and transported away together with the lining materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com