Reinforced concrete bottom plate cutting method based on wire saw process

A cutting method and reinforced concrete technology, which is applied in the direction of metal sawing equipment, sawing machine accessories, sawing machine devices, etc., can solve the problems of large deformation of steel bars, high noise, and slow demolition speed, achieving small impact, low noise, and easy demolition fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

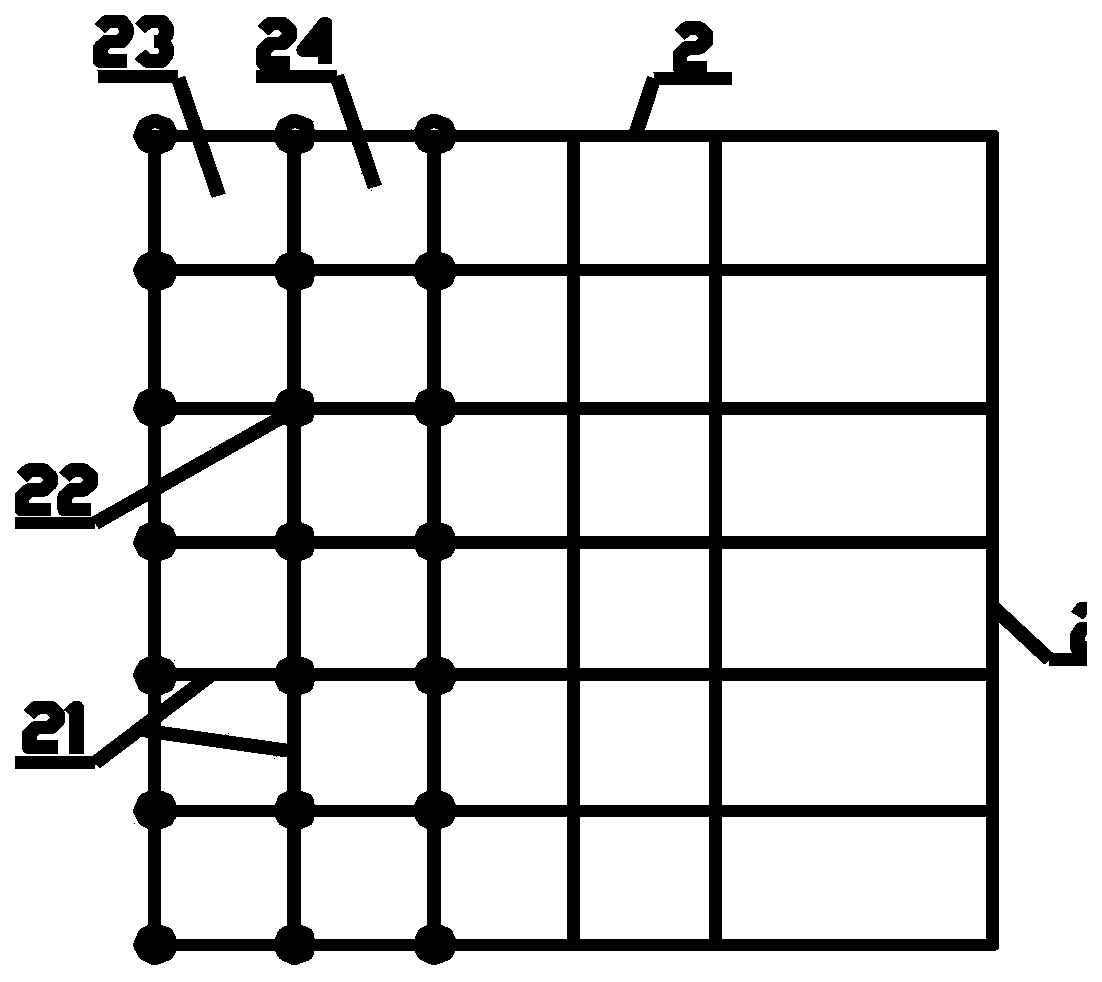

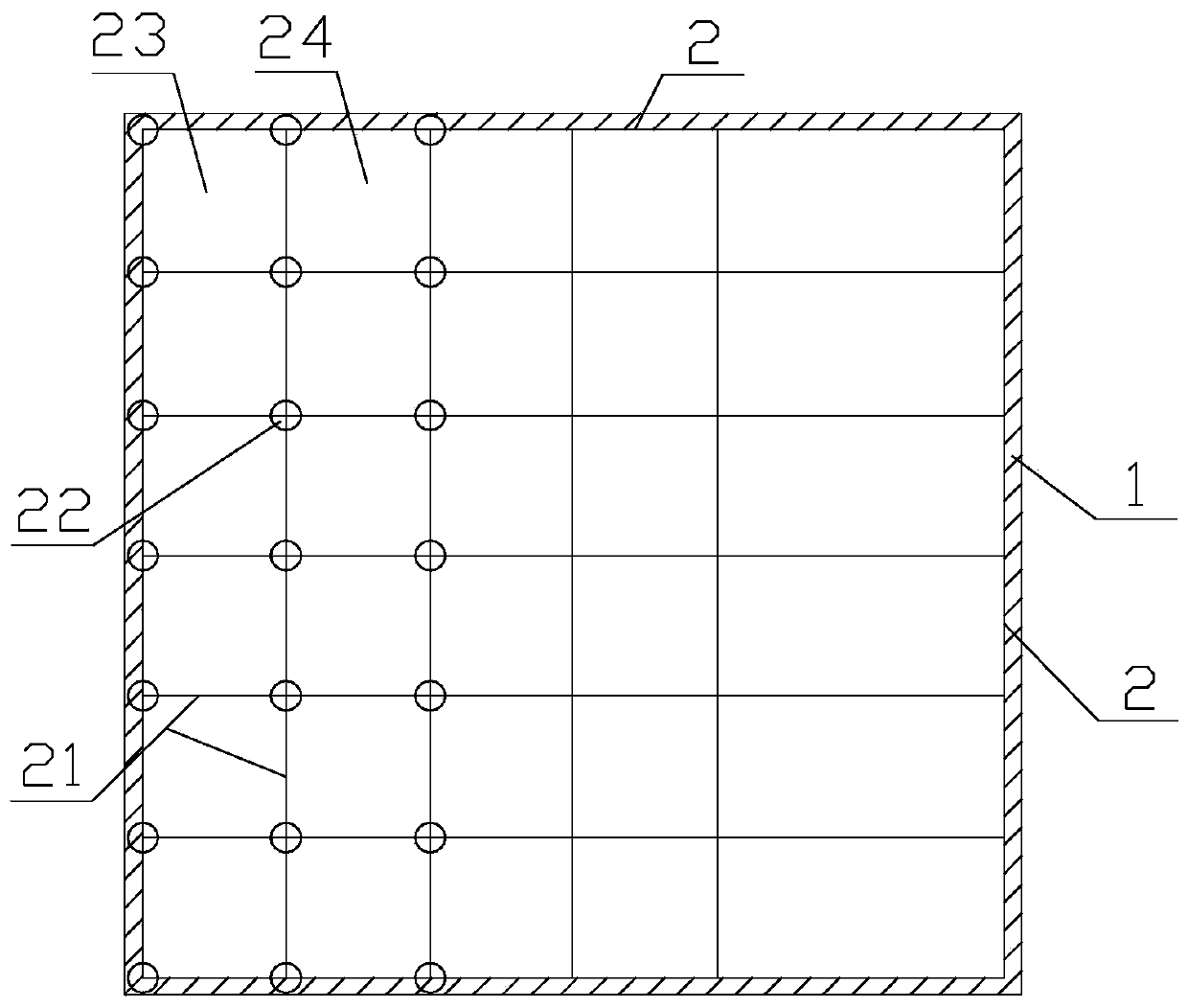

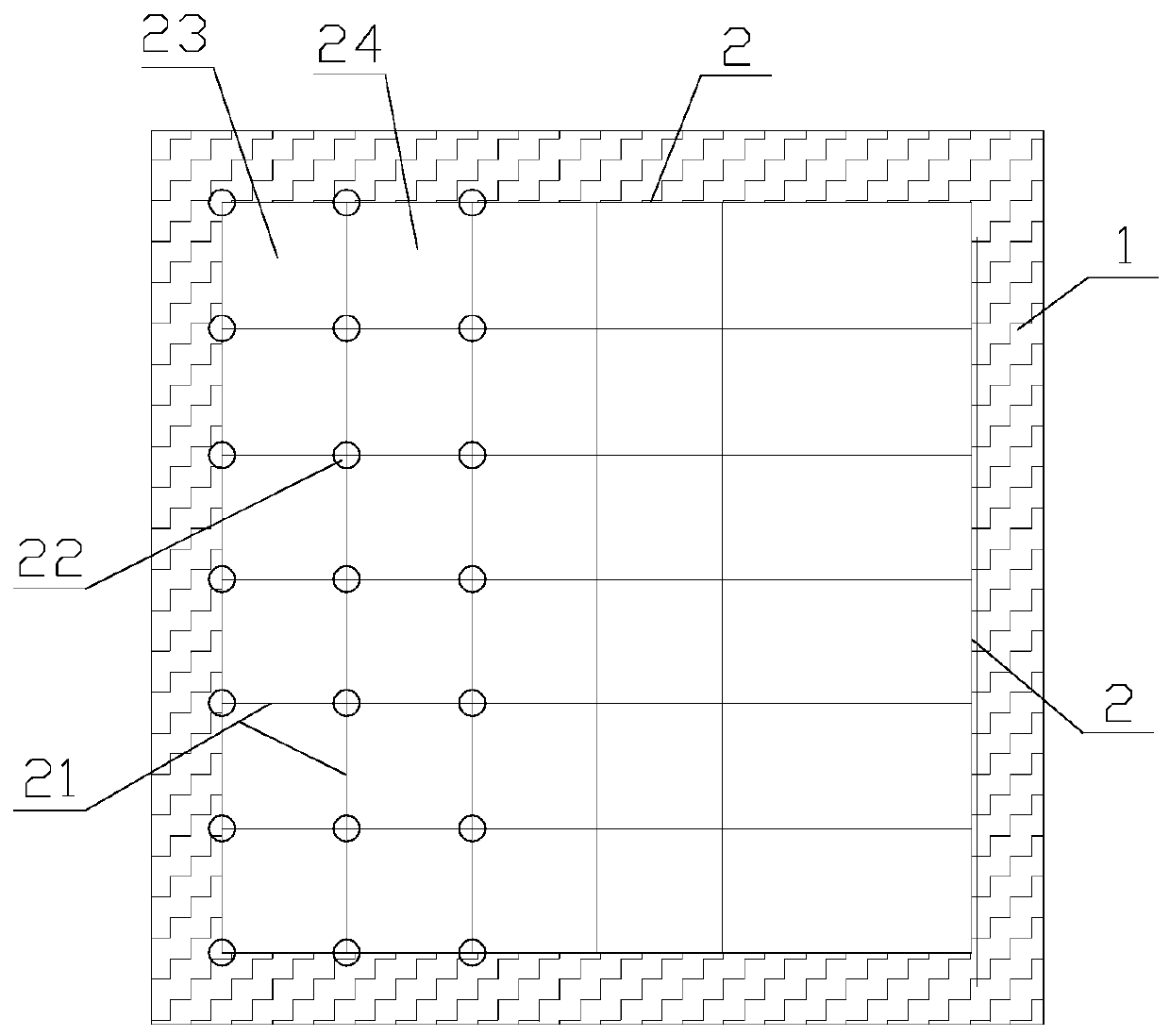

[0037] Such as Figure 1-4 As shown, a kind of reinforced concrete floor cutting method based on the wire saw process of the present invention comprises the following steps:

[0038] 1) Determine the reserved area 1 and the cutting edge 2 according to the cutting range of the base plate, draw several sections of cutting lines 21 in the cutting area surrounded by the cutting edge 2, and determine the position of the drilling hole 22;

[0039] 2) Utilize a drilling machine to drill a hole at the drill hole 22, and the aperture is greater than the diameter of the directional wheel 5 of the wire saw cutting device;

[0040] 3) Use the wire saw cutting device to cut the reinforced concrete along the cutting line 21, and the cut reinforced concrete block 23 is moved out of the cutting area by a hoisting machine.

[0041] Among them, in step 1), the reserved area 1 is determined according to the steel bar construction process in the later stage of floor removal. If the steel bar is ...

Embodiment 2

[0046] Such as Figure 5-7As shown, a wire saw cutting device includes an orbital wire saw cutting machine 3, an adjustable vertical rod 4, an orientation wheel 5 and a wire saw 6, and the orbital wire saw cutting machine 3 is provided with a drive wheel 31, so The adjustable vertical rod 4 is two, the adjustable vertical rod 4 can move up and down, and a directional wheel 5 is respectively arranged on the top and bottom of the adjustable vertical rod 4. After the wire saw 6 bypasses the driving wheel 31, its two ends respectively Go around the directional wheels 5 at the top of the two adjustable poles 4, and then go around the directional wheels 5 at the bottom of the two adjustable poles 4 vertically downwards to form a loop. The two adjustable poles 4 are arranged in the same cutting Boreholes 22 at both ends of the line 21.

[0047] Further, the adjustable vertical rod 4 is connected with a fixed support 7, and the fixed support 7 is fixed on the reinforced concrete floo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com