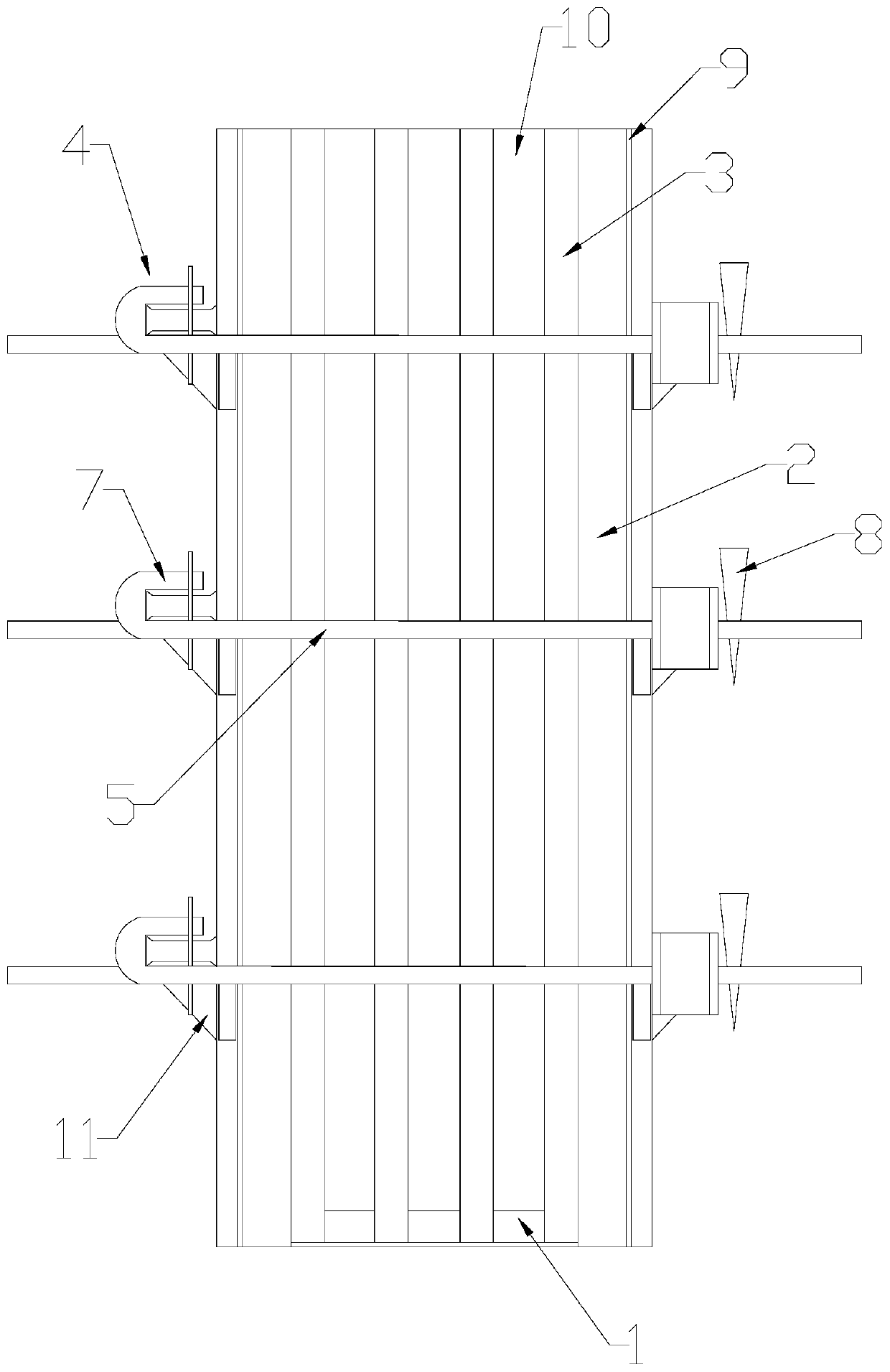

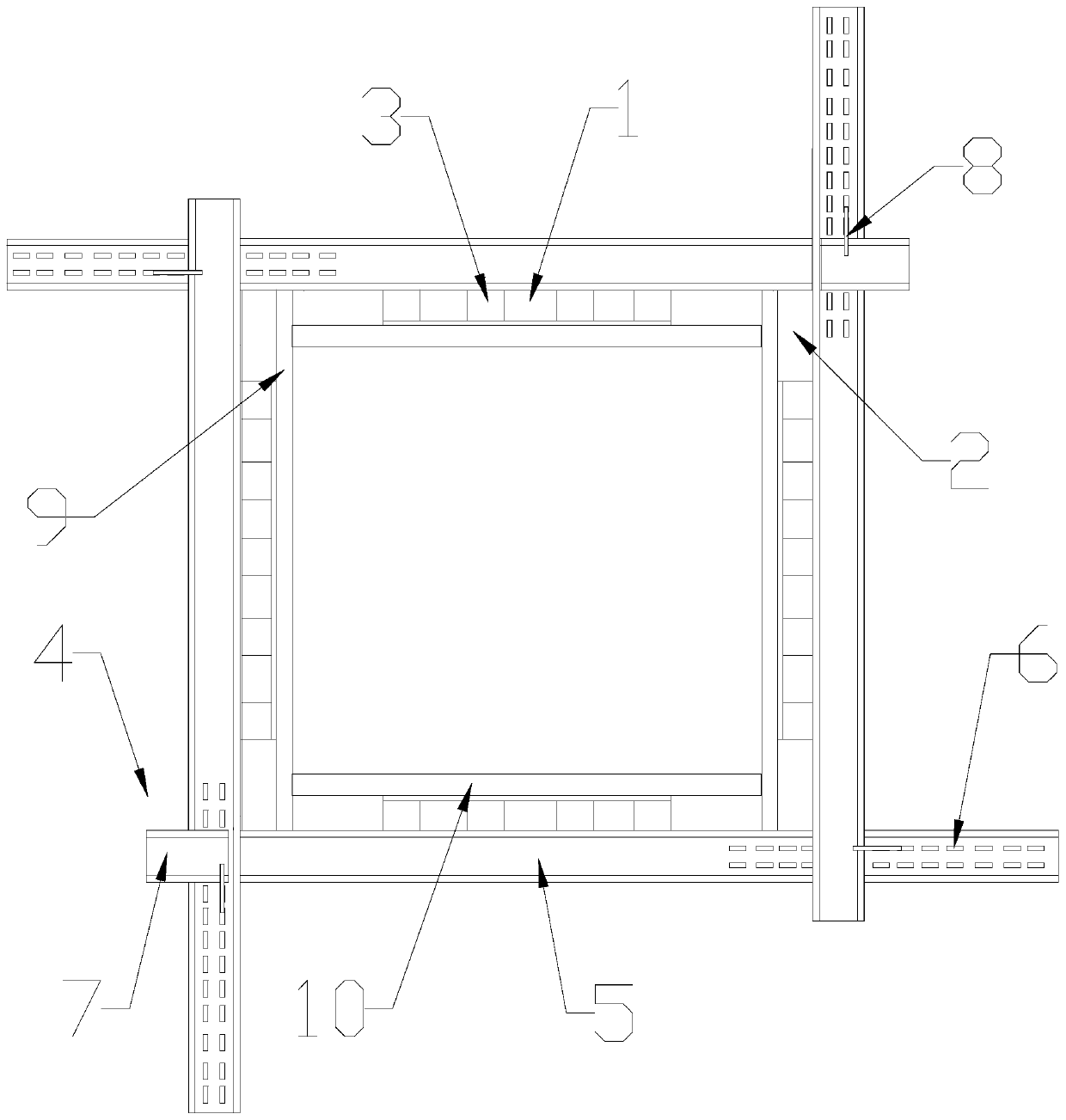

Building frame structure square column reinforcing member formwork and construction method thereof

A technology for frame structures and buildings, which is applied in building structures, on-site preparation of building components, and construction, etc., can solve the problems of formwork expansion and slurry leakage, reduction of turnover times, and holes in formwork, etc. The number of turnovers, the angle of the column and the outside are straight and square, and the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] With the second basement floor as the frame structure, the building area is about 24919.56㎡, the engineering grade is special grade, class I super large garage, the underground fire resistance grade is first grade, the basement waterproof grade is second grade, and the seismic fortification intensity is 7 degrees.

[0047] By adopting the square and round buckle formwork and its construction method of the present invention, the quality of the frame column of the main structure is good, and the pass rate of the cross-sectional size and position of the frame column exceeds 95%. Compared with the traditional reinforcement form, the present invention additionally brings total The economic benefit is about 165,000 yuan.

Embodiment 2

[0049] With the basement floor of the underground garage as the frame structure, the construction area is about 19833.29 square meters, the engineering level is Class I, large-scale garage of type I, the underground fire resistance level is level one, the waterproof level of the basement is level two, and the seismic fortification intensity is 7 degrees.

[0050] By adopting the square and round buckle formwork and its construction method of the present invention, the quality of the frame column of the main structure is good, and the pass rate of the cross-sectional size and position of the frame column exceeds 95%. Compared with the traditional reinforcement form, the present invention additionally brings total The economic benefit is about 115,000 yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com