Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Energy self-sufficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

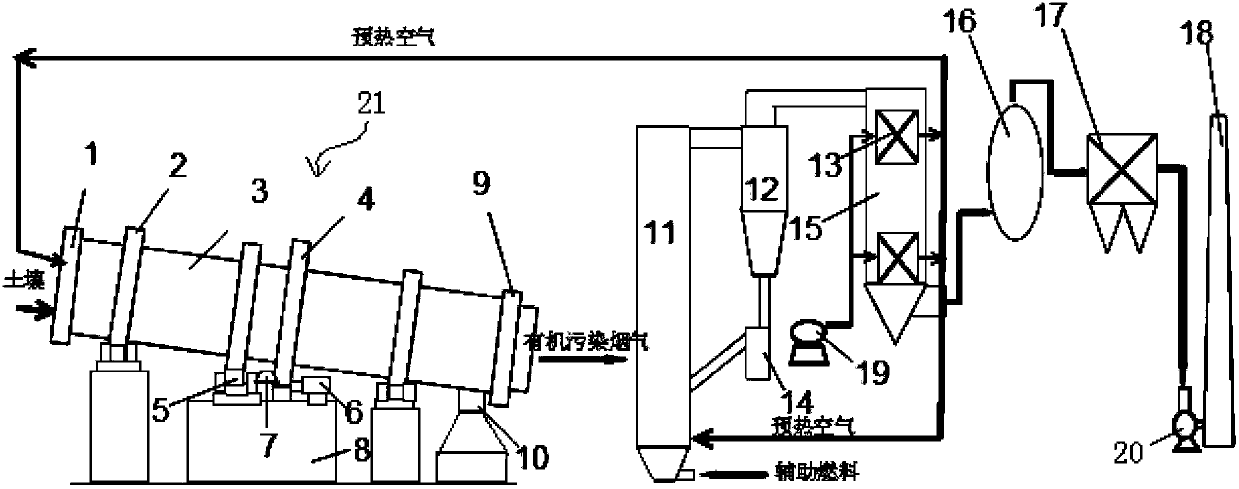

System and method for repairing organic material polluted soil

ActiveCN103008337AClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterEngineering

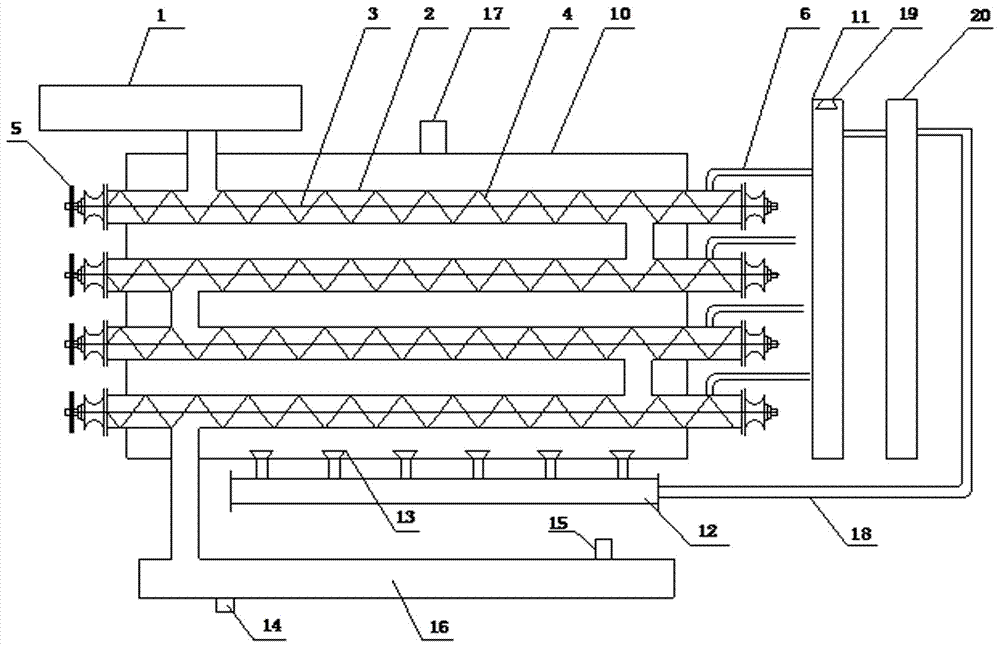

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

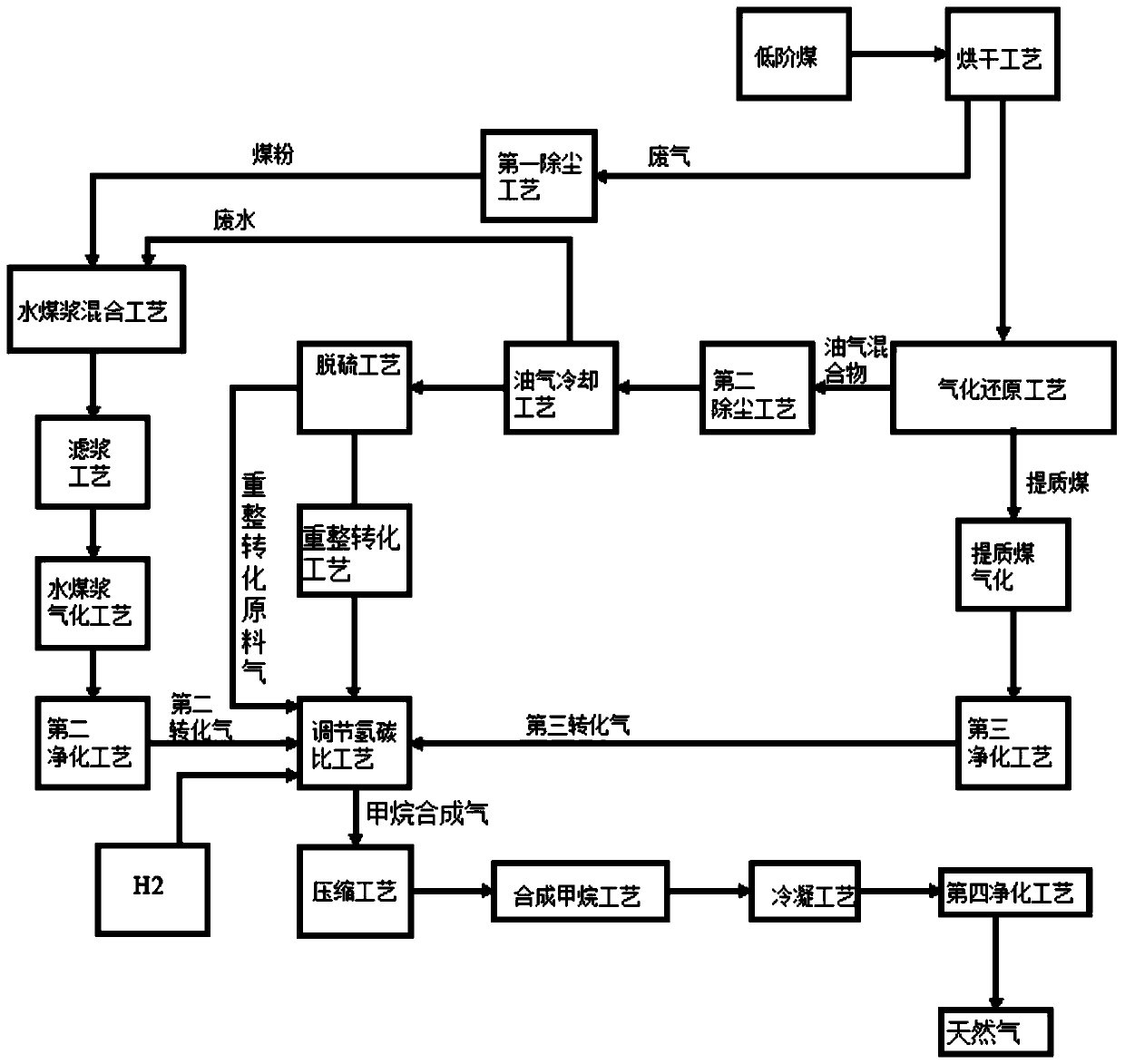

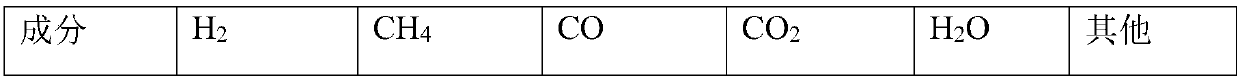

Method using quality-based utilization of low-rank coal to prepare natural gas

PendingCN110055104ALess quantityIncrease energy densityCombustible gas catalytic treatmentGaseous fuelsCoal waterProcess engineering

The invention provides a method using the quality-based utilization of low-rank coal to prepare natural gas. The method includes: drying, performing gasification reduction, performing desulfurization,preparing synthetic gas and preparing the natural gas. The method has the advantages that the raw material of the method mainly comes from the quality-based utilization process of the low-rank coal,high product additional value is achieved, and transportation is benefited; the synthetic gas is prepared by using coal-water slurry, and the reutilization of the low-rank coal solves the problem of environmental pollution; multi-approach gas preparation and high synthetic gas yield are achieved, the economic competiveness of gas preparation using the low-rank coal is enhanced greatly, and efficient, graded and comprehensive utilization of coal resources is achieved; the synthetic gas methane is prepared through the method, the method conforms to the industry policy of clean coal utilization and the current direction of 'turning coal into gas', pipeline transportation is facilitated, the problems that the low-rank coal is prone to dust raising and spontaneous combustion during transportation are solved, and by the quality-based and graded utilization of the low-rank coal, the coal is turned into the gas, west-east natural gas transmission is achieved, and energy self-supply is achieved.

Owner:浙江天禄环境科技有限公司

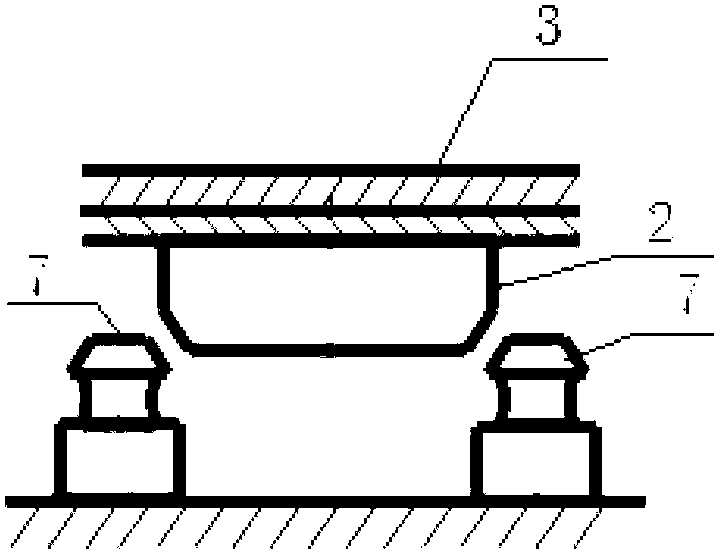

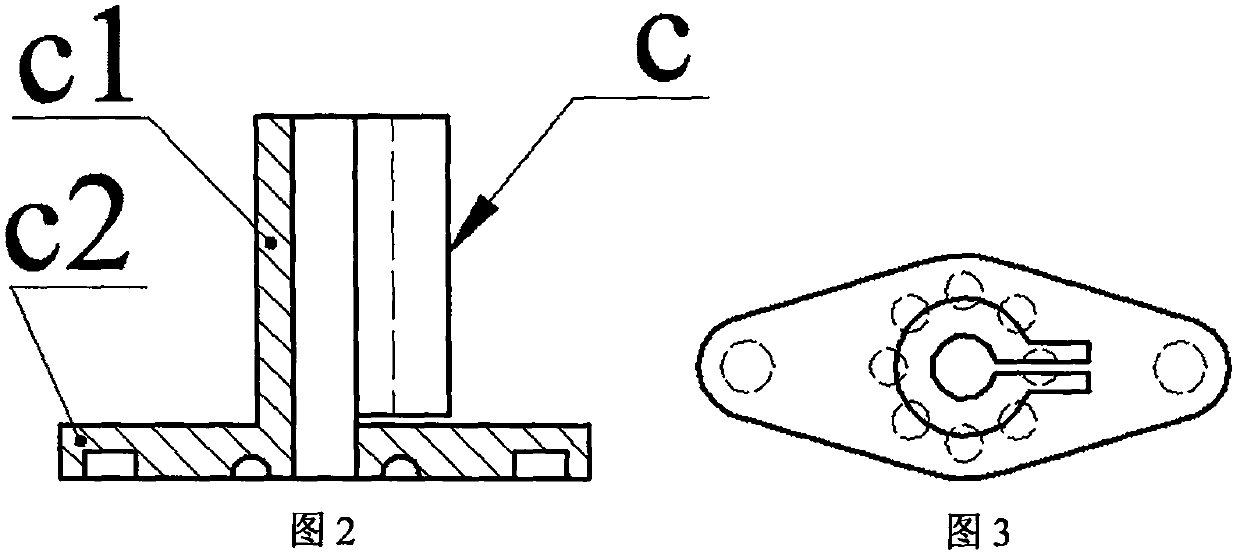

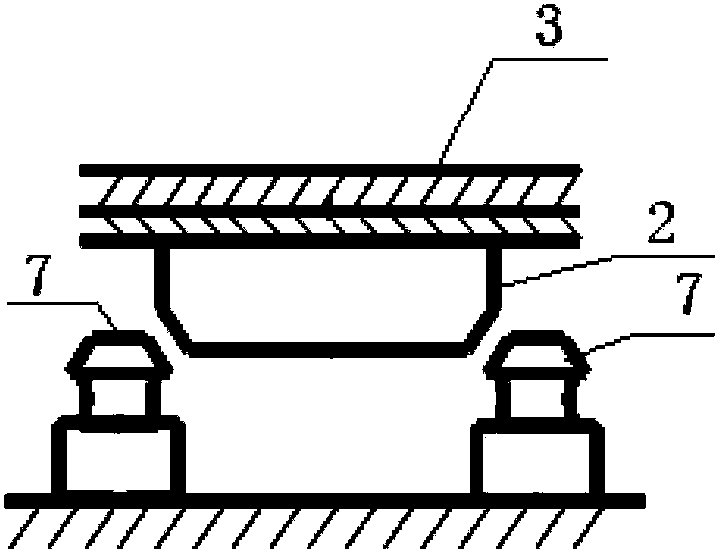

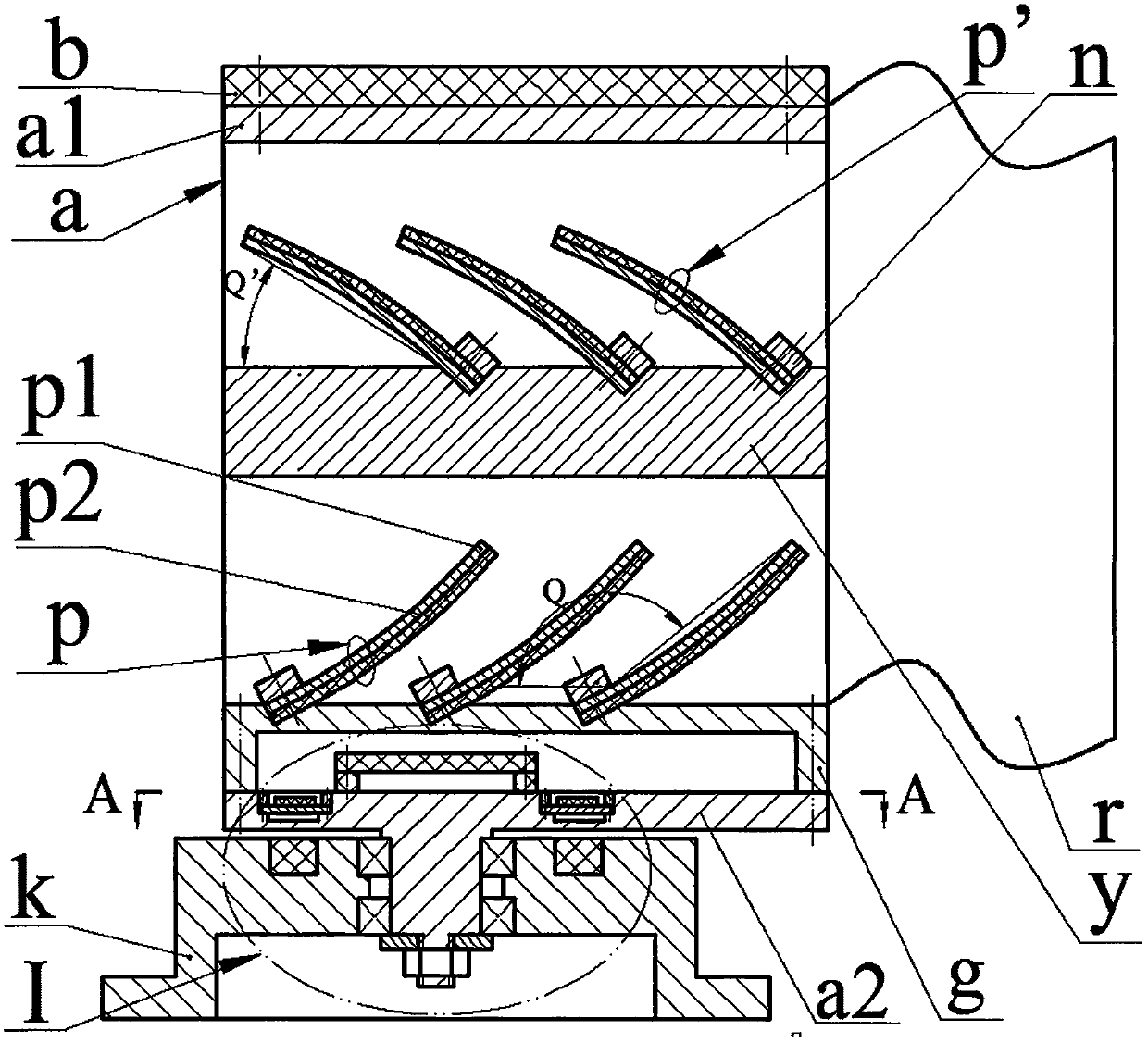

Self-powered anemoscope

ActiveCN107342707ASimple structureLow start wind speedPiezoelectric/electrostriction/magnetostriction machinesIndication/recording movementWind forceInteraction forces

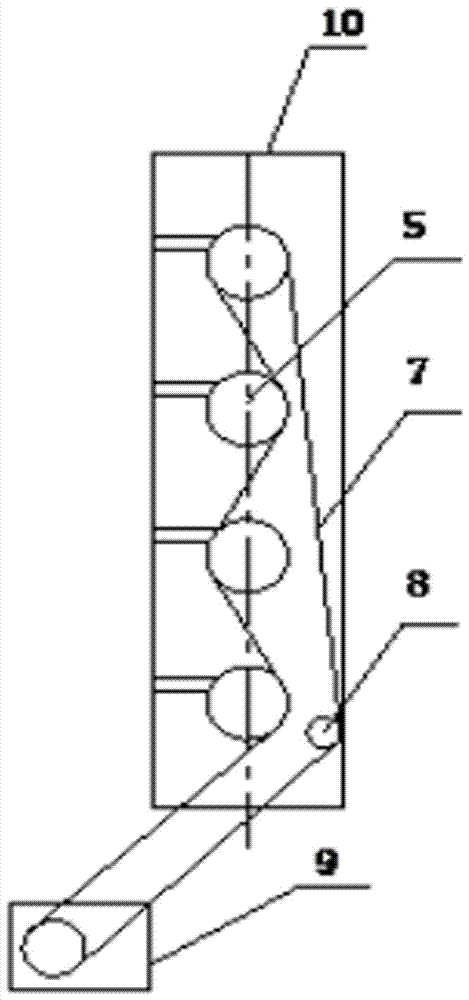

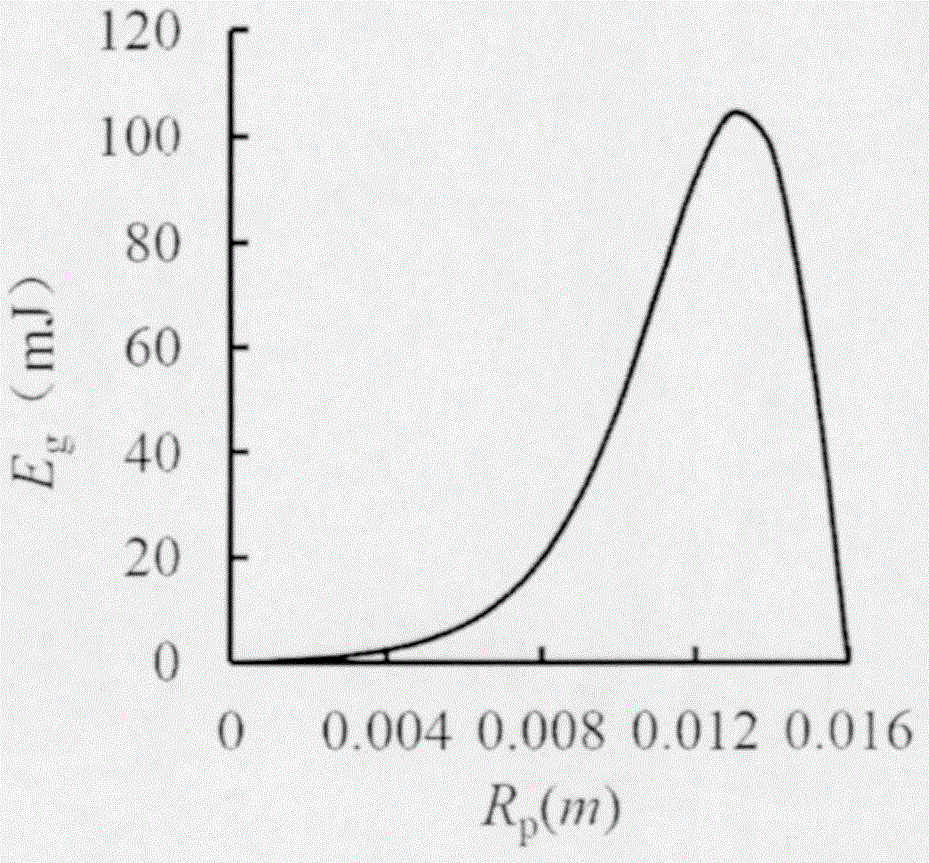

The invention relates to a self-powered anemoscope, belonging to the technical field of wind power measurement. a semi-shaft and sensors are arranged above the swing disc body, a boss, a circular table, and a circuit board are arranged under the disc body, the sensors are uniformly distributed on the circumference by taking the center of the semi-shaft as the circle center, a sail support sleeve with canvas sleeves the semi-shaft, the sail support chassis is pressed on the swing disc body through a group of rollers, two magnets symmetrically arranged at the two sides of the semi-shaft are embedded under the sail support chassis, an outer casing is arranged on a base, an exciter connection board is arranged on the boss of the base, the exciter connection board is provided with a swing rod, an excitation disc is arranged on the swing rod, a stud is arranged on the excitation disc, the stud is connected with the boss of the swing disc, the side wall of the boss of the base is uniformly provided with generating units each consisting of a flat spring and piezoelectric oscillators symmetrically arranged at the two sides of the flat spring, the free end of the flat spring and the edge of the excitation disc contact and don't act with each other, each piezoelectric oscillator is formed by the bonding of a substrate and a piezoelectric sheet, the free end of the substrate is provided with a flange, and the substrate is close to the flat spring and the flange abuts against the flat spring.

Owner:ZHEJIANG NORMAL UNIVERSITY

System and method for repairing organic material polluted soil

ActiveCN103008337BClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterFluidized bed

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

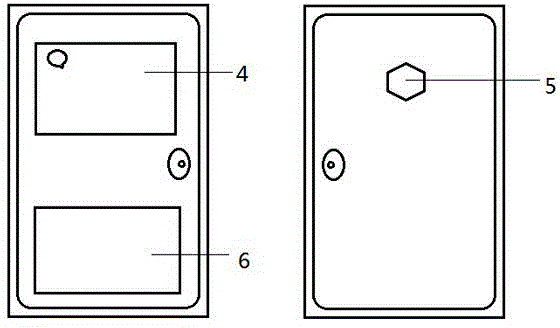

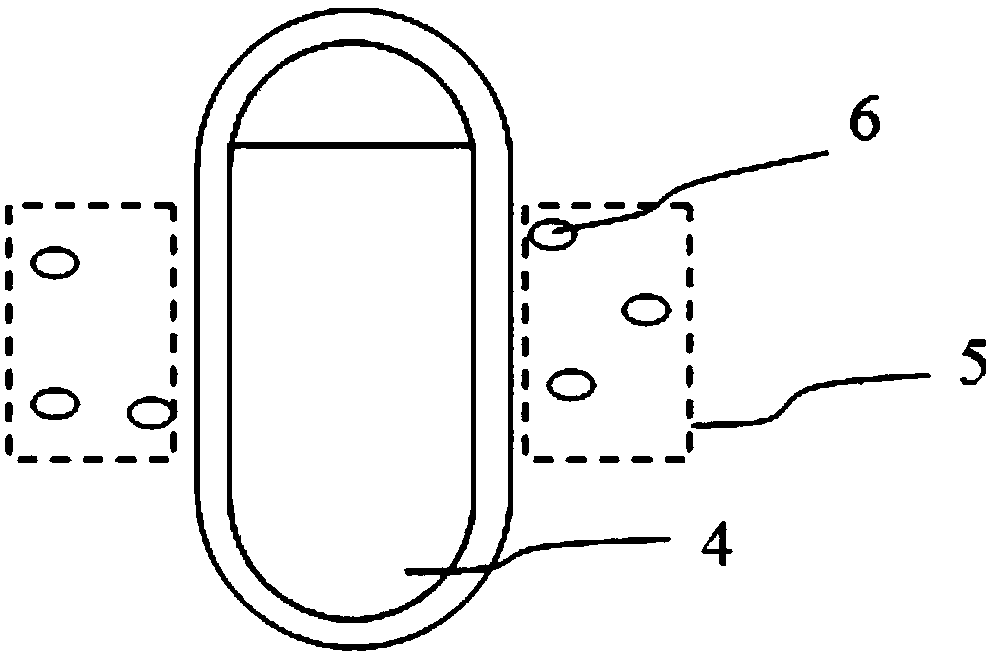

Carbonization device of rotten garbage treatment

PendingCN107513389AImprove purityReduce equipment costsTransportation and packagingSolid waste disposalSpray towerEngineering

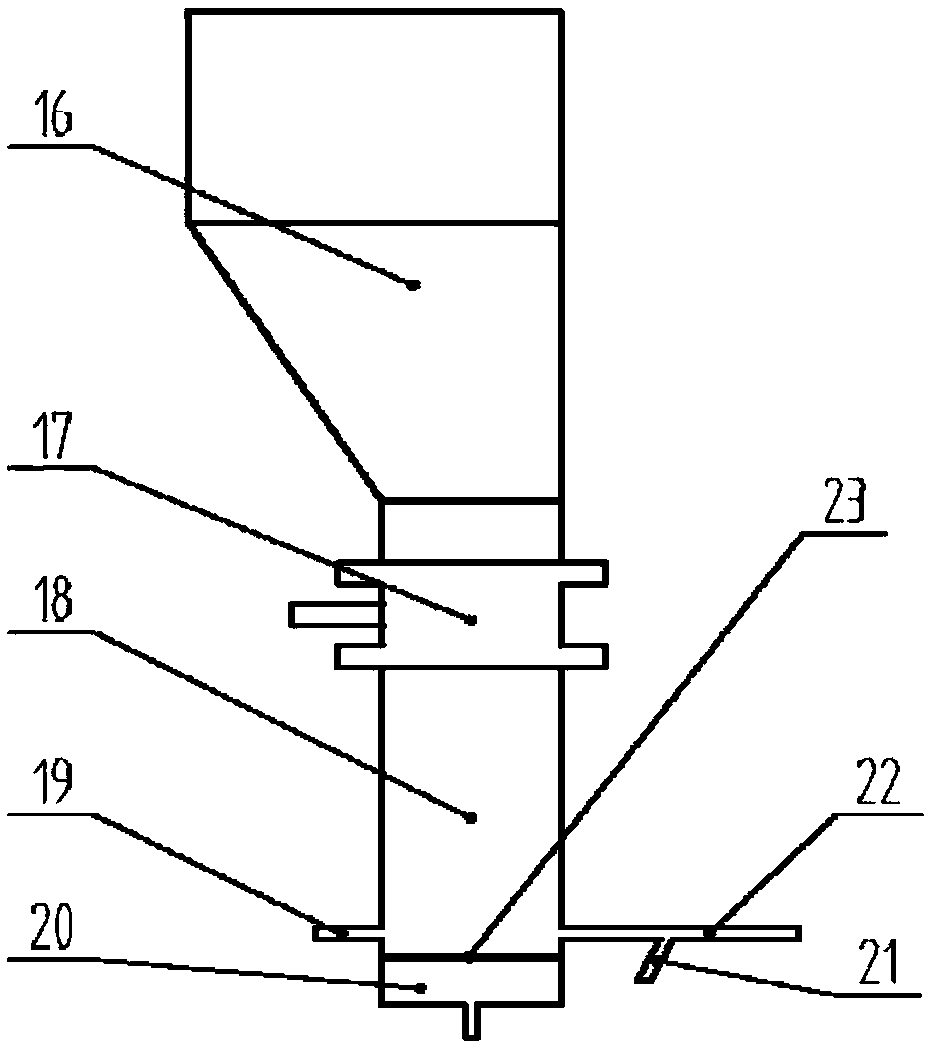

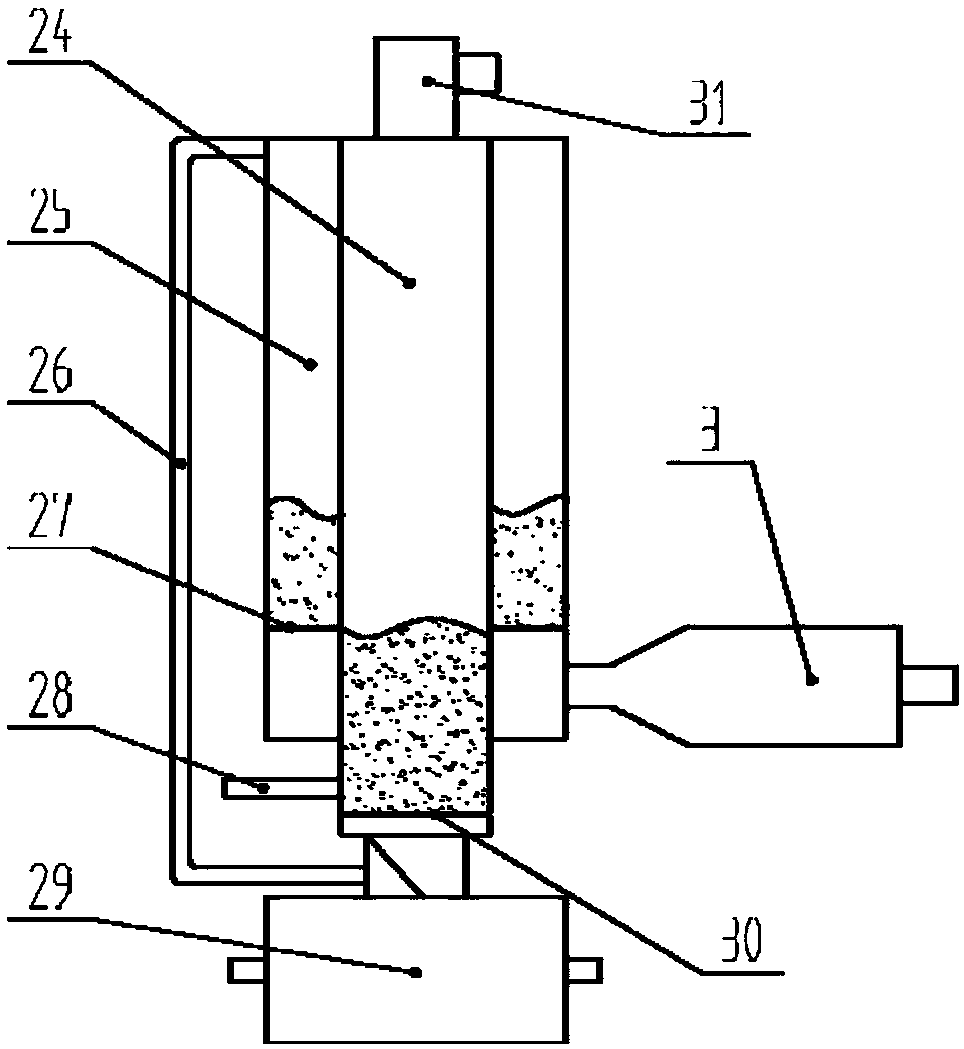

The invention discloses a carbonization device of rotten garbage treatment. The carbonization device comprises a feeding spiral device, a carbonizer, a spraying tower, a cooling tower, a combustible gas recycling tank, a conveying motor and a discharge spiral device, wherein a plurality of conveying tubes are mounted from top to bottom inside the carbonizer; rotating shafts are mounted inside the conveying tubes; spiral plates are mounted on the rotating shafts inside the conveying tubes; transmission wheels are mounted on rotating shafts outside the conveying tubes; transmission motors are used for driving a plurality of transmission wheels to rotate through chains; an upmost conveying tube is connected with the feeding spiral device; a lowermost conveying tube is connected with the discharge spiral device; the outlet of each conveying tube is connected with the inlet of the next conveying tube; gas outlet tubes are mounted at the end parts of the plurality of conveying tubes; the plurality of gas outlet tubes are sequentially connected with the spraying tower and a condensation tower; the gas outlet of the condensation tower is connected with a combustible gas recycling tank; and the combustible gas recycling tank is communicated with a gas stove mounted at the bottom of the carbonizer. After a combustible gas generated through a thermal decomposition reaction is treated, a heat source is provided to the carbonization device, and thus self-sufficiency of energy is achieved.

Owner:BEIJING HAOYE TONGYU TECH

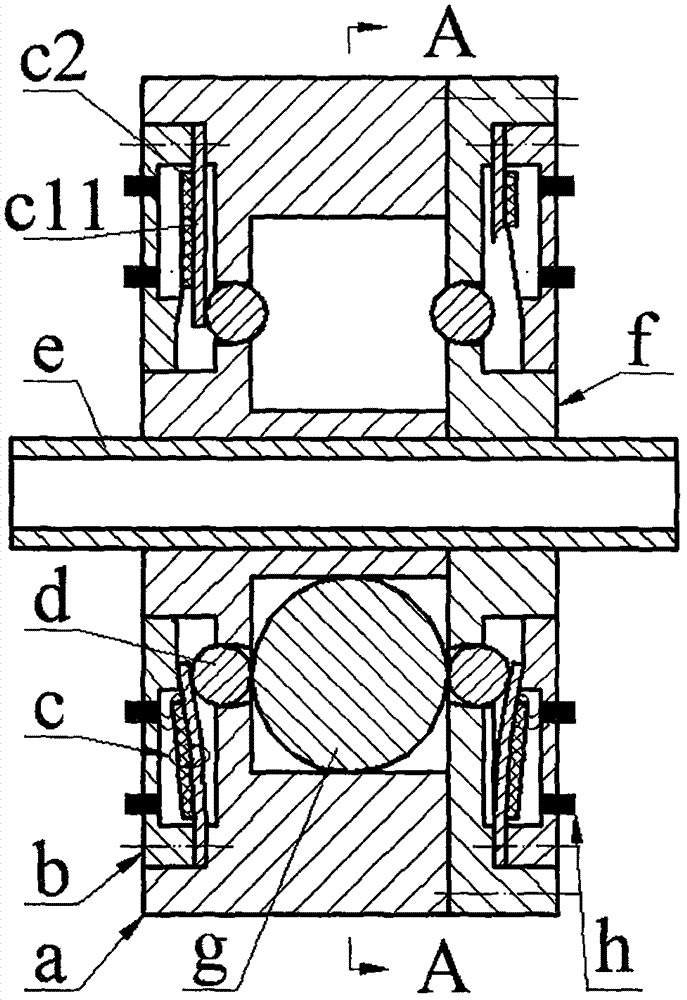

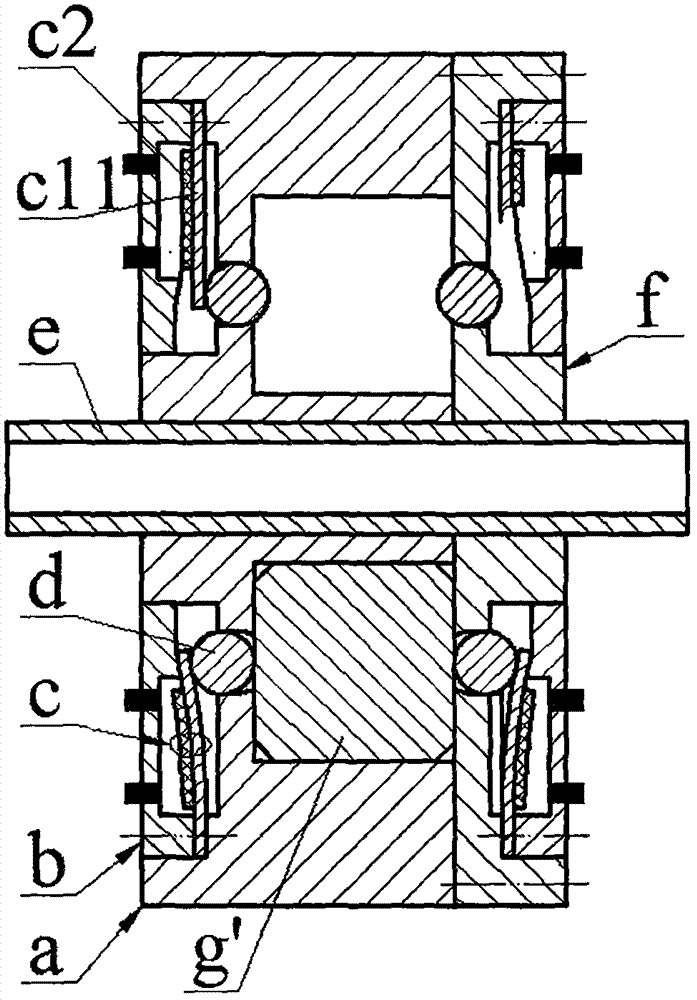

Bicycle alarming lamp

ActiveCN106394744ASimple structureReasonable structural parametersPiezoelectric/electrostriction/magnetostriction machinesOptical signalGenerating capacityInertia force

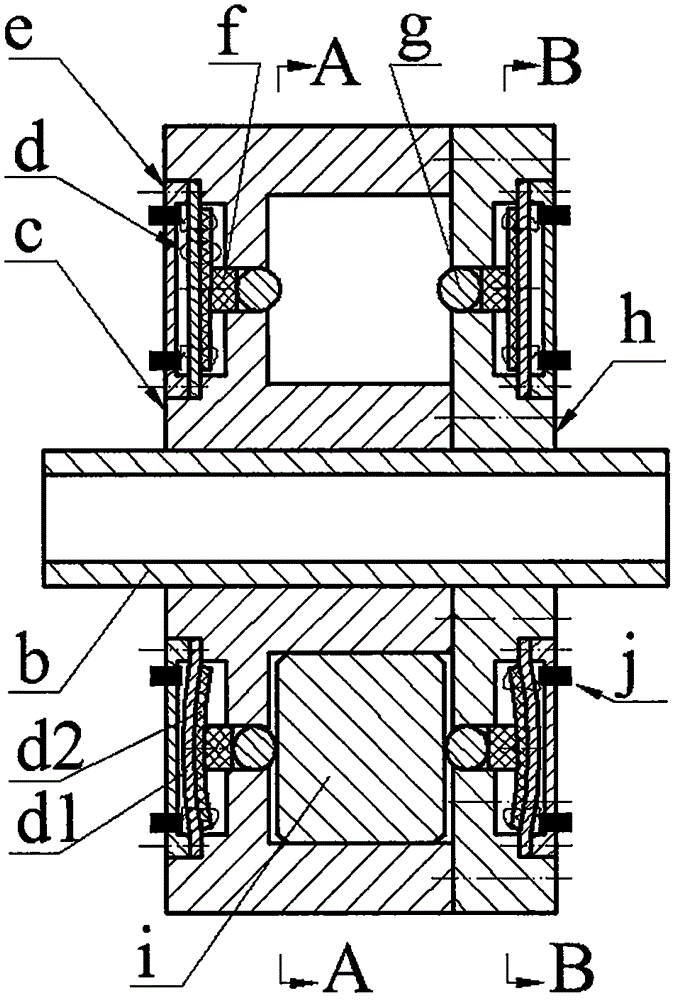

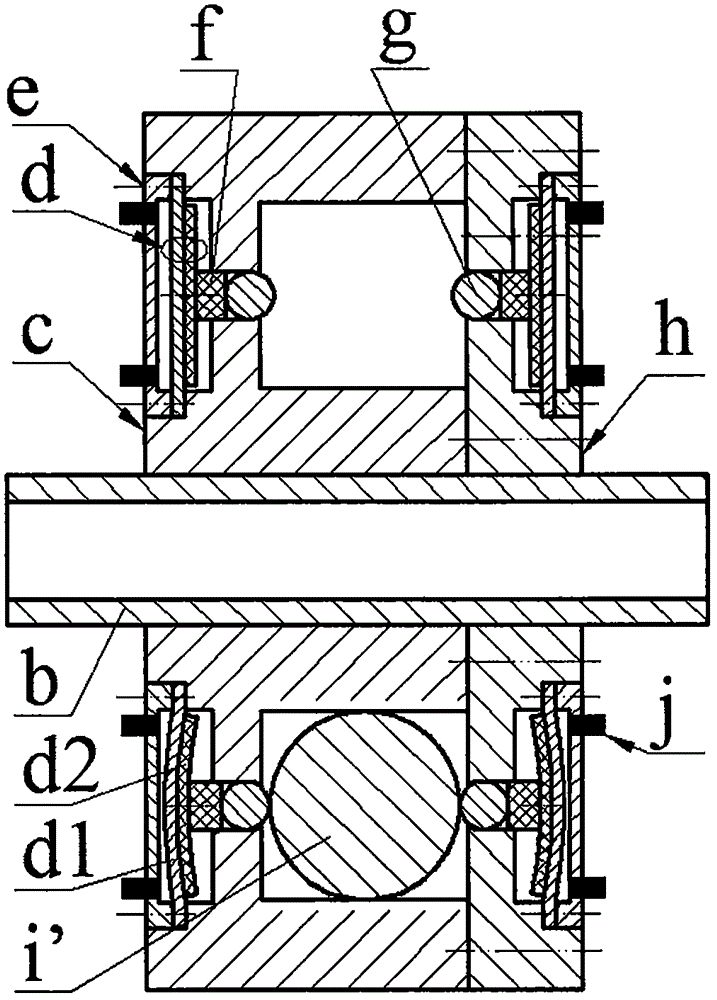

The invention relates to a bicycle alarming lamp, and belongs to the technical field of bicycles. A bicycle wheel shaft sleeve is arranged in an inner hole of a rotary table in a sleeving manner; rotary table sinking cavities and sliding channels are separately formed in two sides of the rotary table; each of the rotary table sinking cavities communicates with the corresponding sliding channel through a guide hole; each side plate with a side plate sinking cavity and a guide hole is mounted on one side, with the corresponding sliding channel, of the rotary table; piezoelectric vibrators are mounted in the rotary table and the side plate sinking cavities through end covers, the number of the piezoelectric vibrators on one side of each sliding channel is the same as that of the piezoelectric vibrators on the other side of the corresponding sliding channel, and the piezoelectric vibrators on the two sides of each of the sliding channel are symmetrically mounted; piezoelectric crystal chips are mounted close to each of the sliding channels; each of the piezoelectric vibrators is connected with a corresponding LED lamp embedded on the corresponding end cover through wires; an elastic cushion is mounted on each of the piezoelectric vibrators; squeezing balls are mounted in the rotary table and the side plate guide holes, and are softly pressed on the corresponding elastic cushions; and cylindrical actuators or spherical actuators are put in each of the sliding channels. The bicycle alarming lamp disclosed by the invention has the advantages and the characteristics that the piezoelectric vibrators are actuated by the inertia force of the actuators, so that fixed supporting is not needed; the piezoelectric vibrators are reasonable in structural parameters, large in electric generating capacity, and wide in effective band; the piezoelectric crystal chips only bear compressional stress and are high in reliability; and the energy required by the bicycle alarming lamp disclosed by the invention is self-contained, and batteries are not needed, so that the bicycle alarming lamp is convenient to use.

Owner:ZHEJIANG NORMAL UNIVERSITY

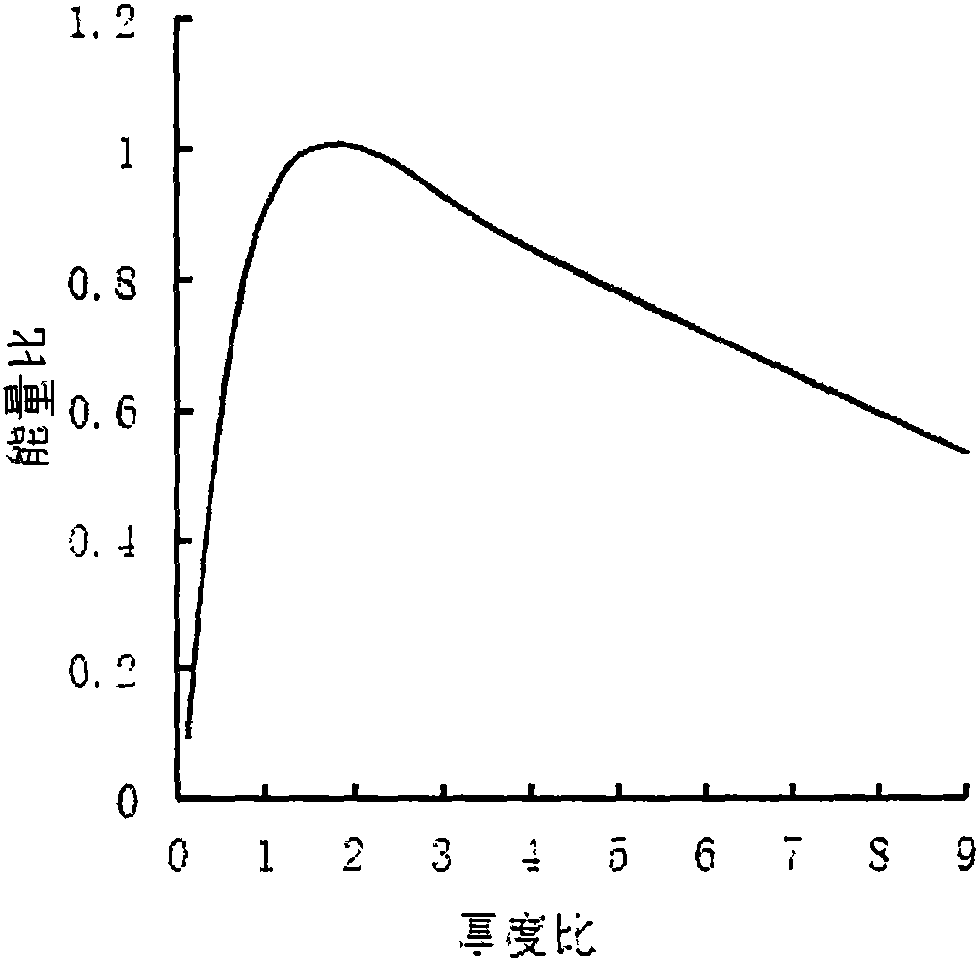

Small mobile rapid pyrolysis liquefaction apparatus for agricultural and forestal biomass

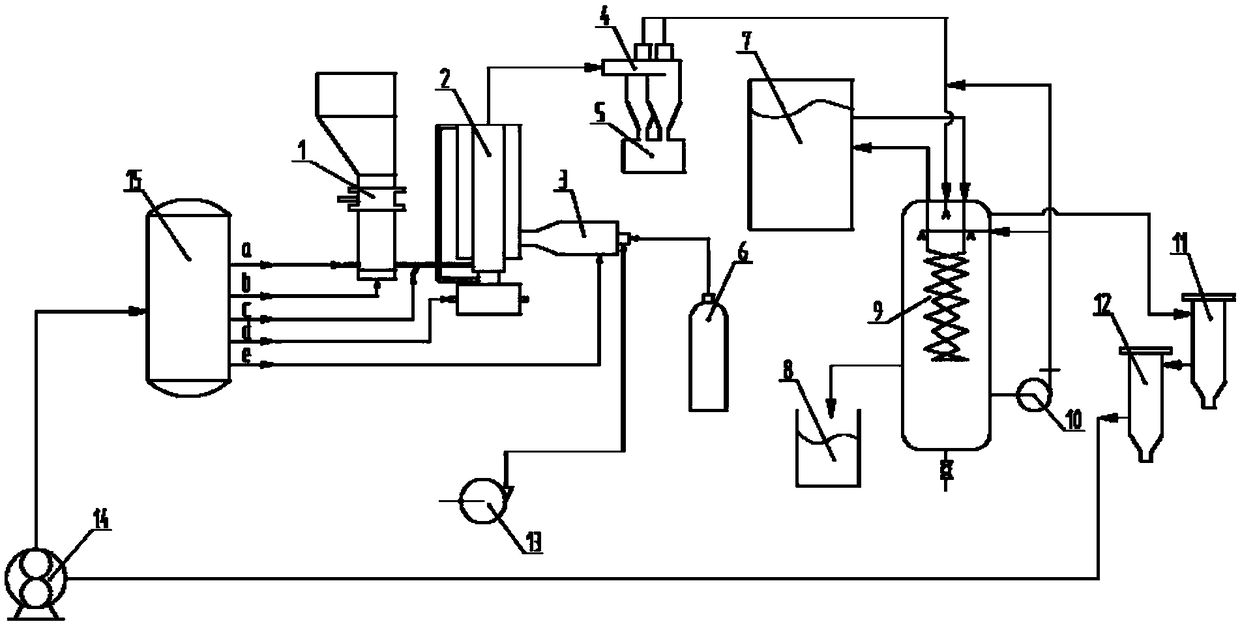

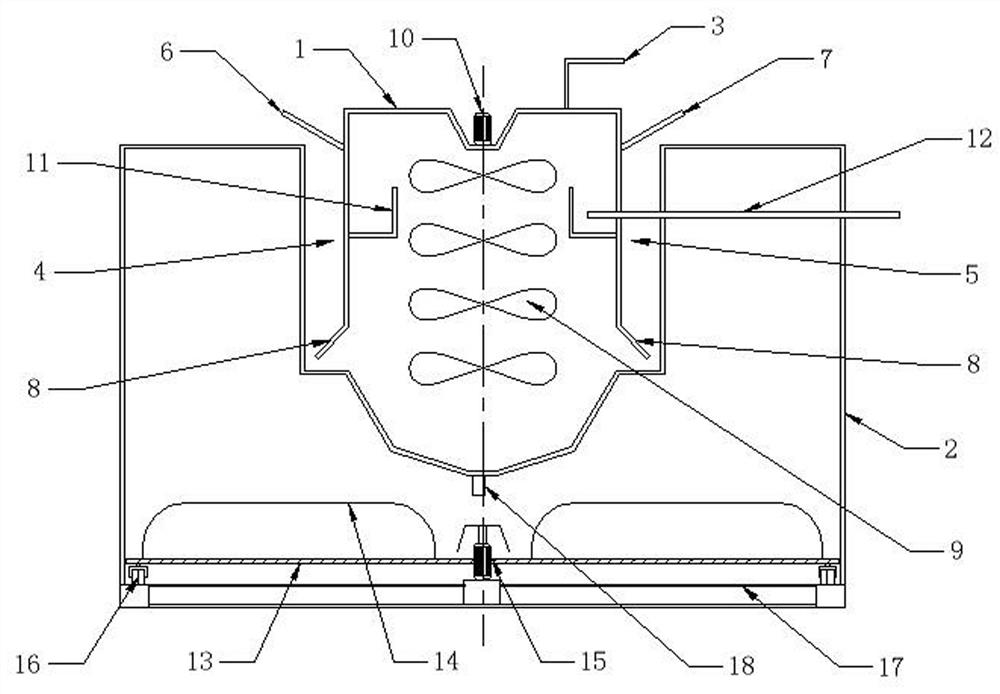

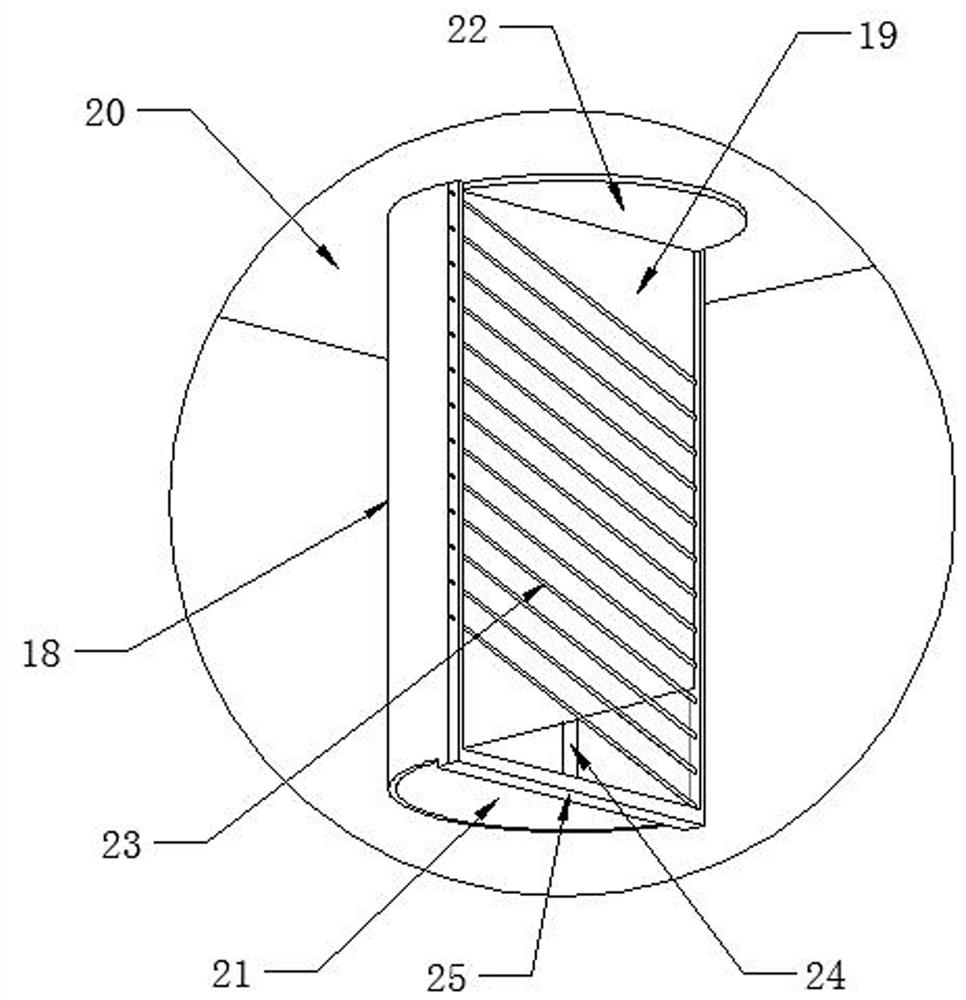

InactiveCN109111940ACompact structureEnergy self-sufficiencyDirect heating destructive distillationBiofuelsGas cylinderSelf heating

The invention relates to a small mobile rapid pyrolysis liquefaction apparatus for agricultural and forestal biomass, belonging to the technical field of biomass energy. The rapid pyrolysis liquefaction apparatus comprises a fluidized bed-spouted bed double pneumatic feeder, a bushing type double fluidized bed reactor, a combustion furnace, a cyclone separator, a charcoal collecting tank, a gas cylinder, a water tank, an oil storage tank, an injection-spraying composite condenser, a primary gas purifier, a secondary gas purifier, a gas buffer tank, etc. The apparatus of the invention is applicable to on-site rapid pyrolysis liquefaction conversion in areas with concentrated agricultural and forestal biomass, e.g., forest farms and villages; the apparatus is integrally designed on a trailerplatform, and is compact in the structure of all the components, free of superfluous moving parts, stable in operation and convenient for outdoor mobile operation; and a by-product, i.e., non-condensable gas, produced in pyrolysis of the apparatus is made full use of and is subjected to closed-circuit circulation, so self-supply of most energy is realized and the requirements for self-heating pyrolysis and environment friendliness are met.

Owner:BEIJING FORESTRY UNIVERSITY

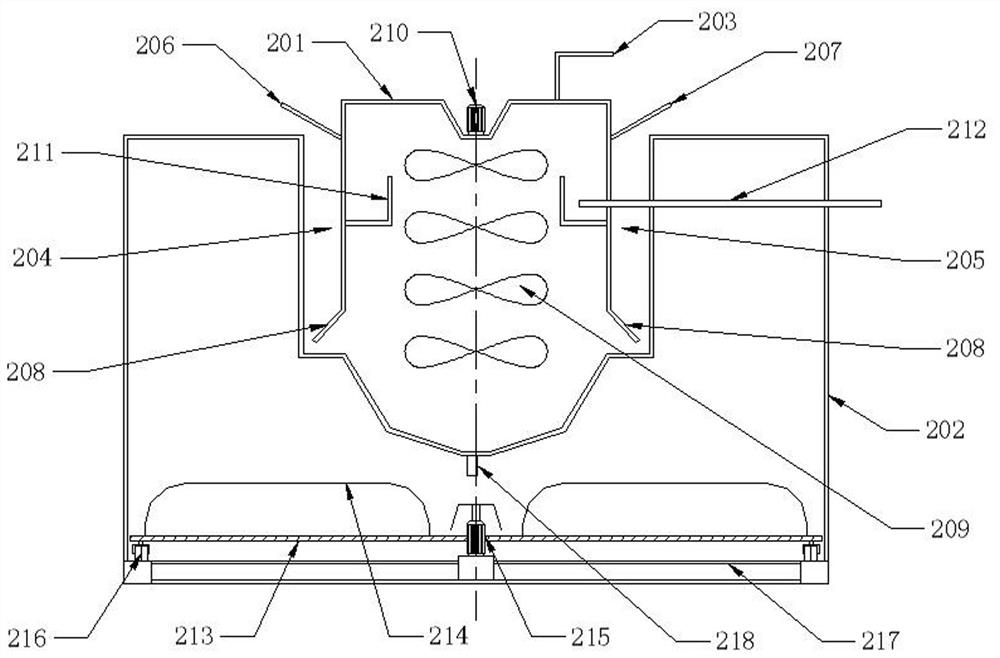

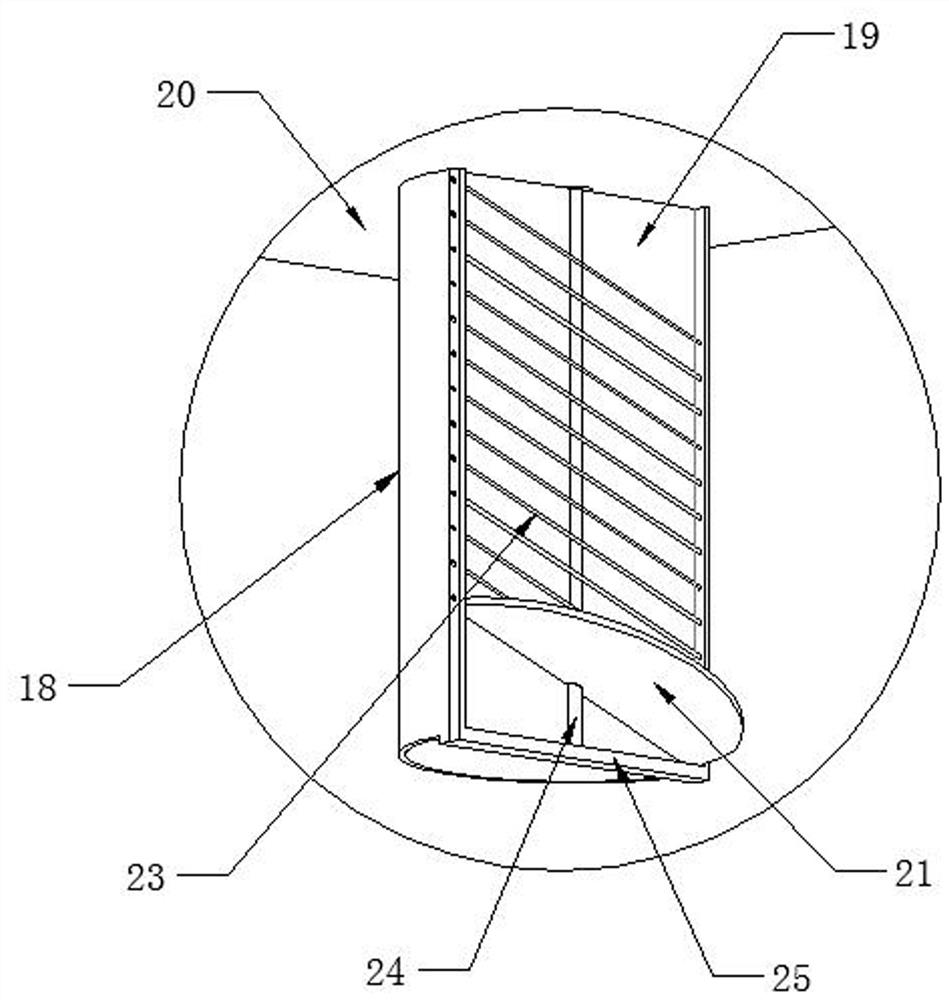

Wind speed wind direction monitoring device

ActiveCN107576816AIncrease power generation capacityAvoid damageIndication/recording movementFluid speed measurementRepulsion forceEngineering

The invention relates to a wind speed wind direction monitoring device and belongs to the wind monitoring technology field. A bottom wall of an upper casing is provided with a through hole, a side wall of the upper casing is provided with an upper ring stand, an end portion of the side wall of the upper casing is equipped with an upper cover, a top wall of a lower casing is provided with an axialstand with a through hole, a side wall of the lower casing is provided with a lower ring stand, an end portion of the side wall of the lower casing is mounted on a cross board of a support, the crossboard is equipped with a circuit board, the axis stand is equipped with an axial sleeve embedded with a magnetic column, an end portion of the axial stand is connected with the bottom wall of the upper casing through a screw, the bottom wall of the upper casing or the top wall of the lower casing is embedded with sensors, the sensors are uniformly distributed on circumference taking a center of the axial stand as the circle center, the upper and lower ring stands are equipped with arc-shaped piezoelectric oscillators of which free ends are equipped with magnetic sheets, substrates of the piezoelectric oscillator are mounted close to the upper ring stand or the lower ring stand, acting force between the magnetic sheets and the magnetic columns is repulsion force, one end of a swing arm of an exciter is provided with an arc-shaped connection board, the other end is provided with a hollow cylinder, the connection board is mounted on the axial sleeve, a plane of the swing arm is embedded with circular magnets, and the circular magnets are arranged on the circumference of the sensors.

Owner:ZHEJIANG NORMAL UNIVERSITY

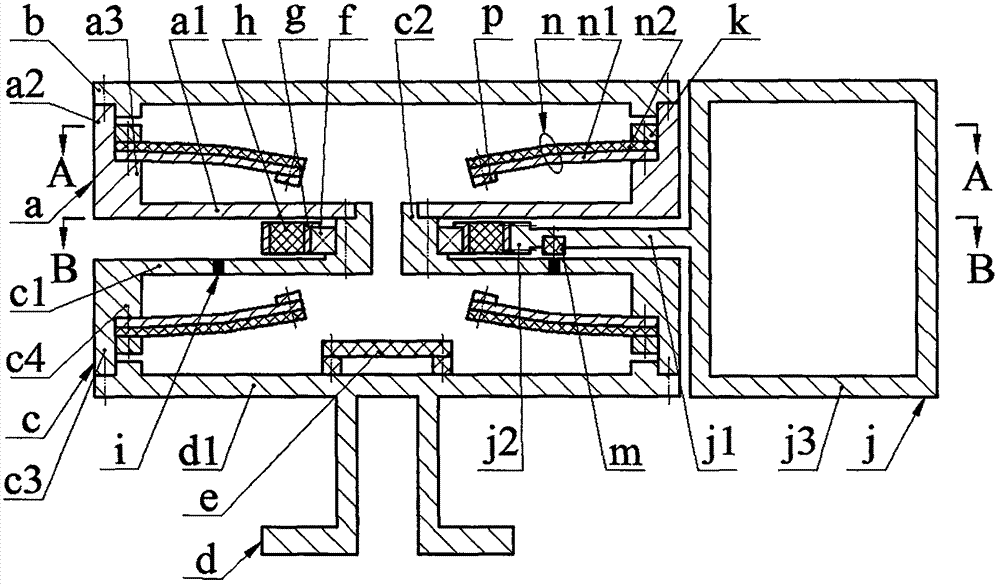

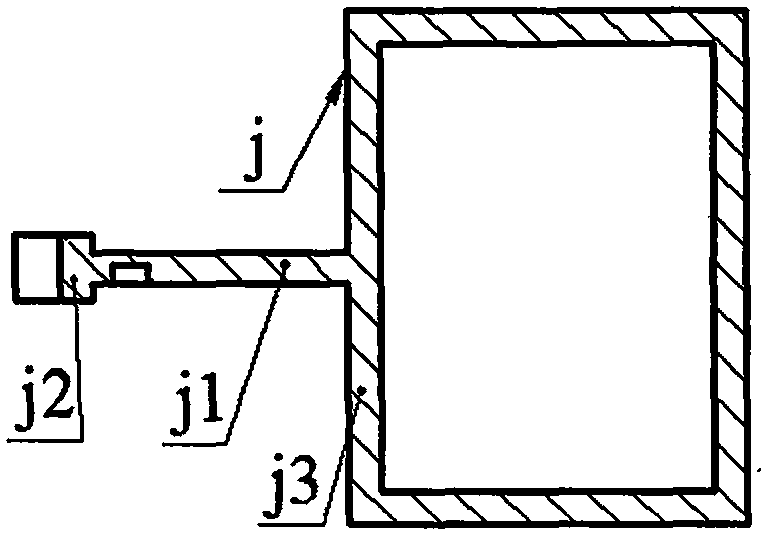

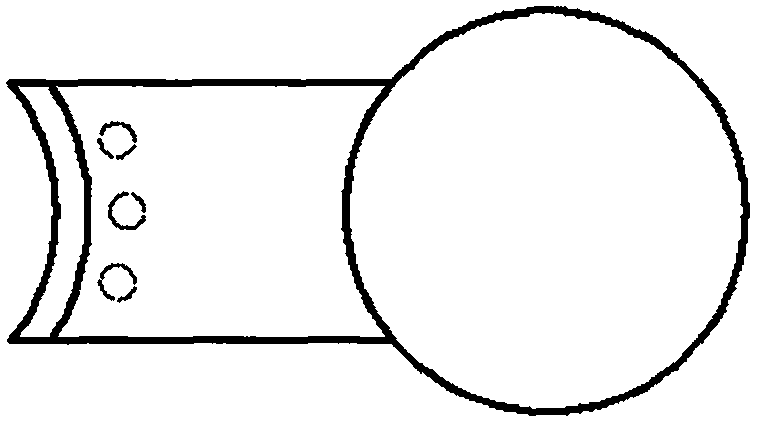

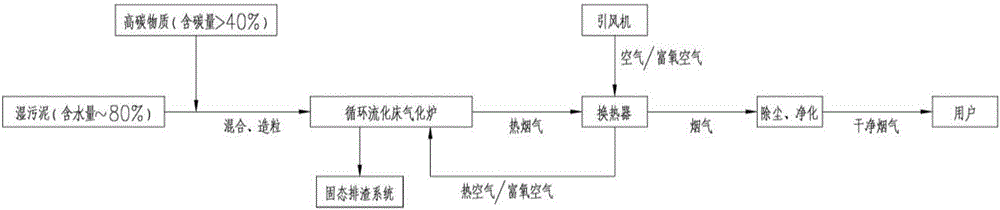

Wet sludge gasification treatment method capable of energy self-sustaining

InactiveCN105694976AReduce processing costsAvoid secondary pollutionSludge treatment by thermal conditioningSpecific water treatment objectivesSludgeHigh carbon

The invention discloses a wet sludge gasification treatment method capable of energy self-sustaining. The method comprises the following steps: S1. adding a high-carbon substance into sludge until the mass mixing ratio of the sludge to the high-carbon substance is (50-90):(50-10), uniformly mixing the sludge and high-carbon substance, and granulating to obtain a granular mixture with the granularity of less than 10mm; S2. sending the granular mixture into a circulating fluid bed gasification furnace through a screw conveyer, heating air to 700-750 DEG C by a heat exchanger, sending the heated air into the circulating fluid bed gasification furnace, and carrying out combustion gasification reaction on the granular mixture and hot air at the high temperature of 950-1050 DEG C, wherein the high-temperature fume generated after reaction flows into the heat exchanger to heat the inside air, and the fume subjected to heat exchange is subjected to dust separation to become clean fume which is used by customers. The method can implement system internal energy self-sustaining, and is capable of preventing secondary pollution and obviously lowering the sludge treatment cost.

Owner:WISDRI ENG & RES INC LTD

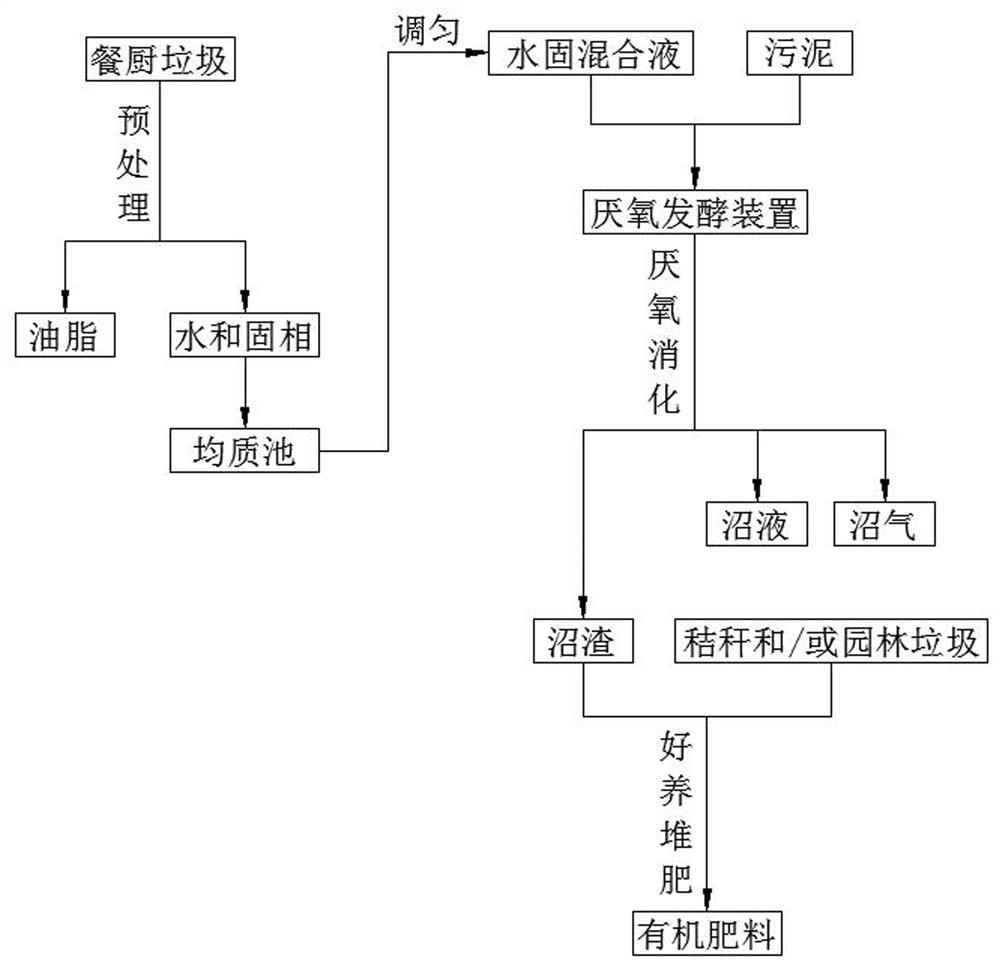

Kitchen waste integrated treatment system based on biotechnology and energy coupling

ActiveCN112592809AAvoid influenceIncreased degradation rateBioreactor/fermenter combinationsBio-organic fraction processingProcess engineeringEnvironmental engineering

The invention provides a kitchen waste integrated treatment system based on biotechnology and energy coupling, and belongs to the technical field of kitchen waste treatment. The problems that resources are wasted to a certain extent, aerobic composting and anaerobic digestion have many defects and the like in an existing garbage treatment method are solved. The kitchen waste integrated treatment system comprises a pretreatment device, an anaerobic fermentation device and an aerobic composting device; the pretreatment device treats kitchen waste into water-solid mixed slurry; the anaerobic fermentation device performs anaerobic digestion on the water-solid mixed slurry and generates biogas, biogas slurry and biogas residues; the aerobic composting device is used for performing aerobic composting on the biogas residues; the anaerobic fermentation device comprises an anaerobic tank; the aerobic composting device comprises an aerobic tank; the top of the aerobic tank is provided with a recess; and the anaerobic tank is arranged in the recess. The kitchen waste integrated treatment system has the advantages that an anaerobic digestion technology and an aerobic composting technology supplement each other; continuous feeding and a two-phase process of a single anaerobic tank are realized by adopting two stages of feeding cabins; and simultaneous treatment of multiple kinds of garbageis realized.

Owner:ZHEJIANG NORMAL UNIVERSITY

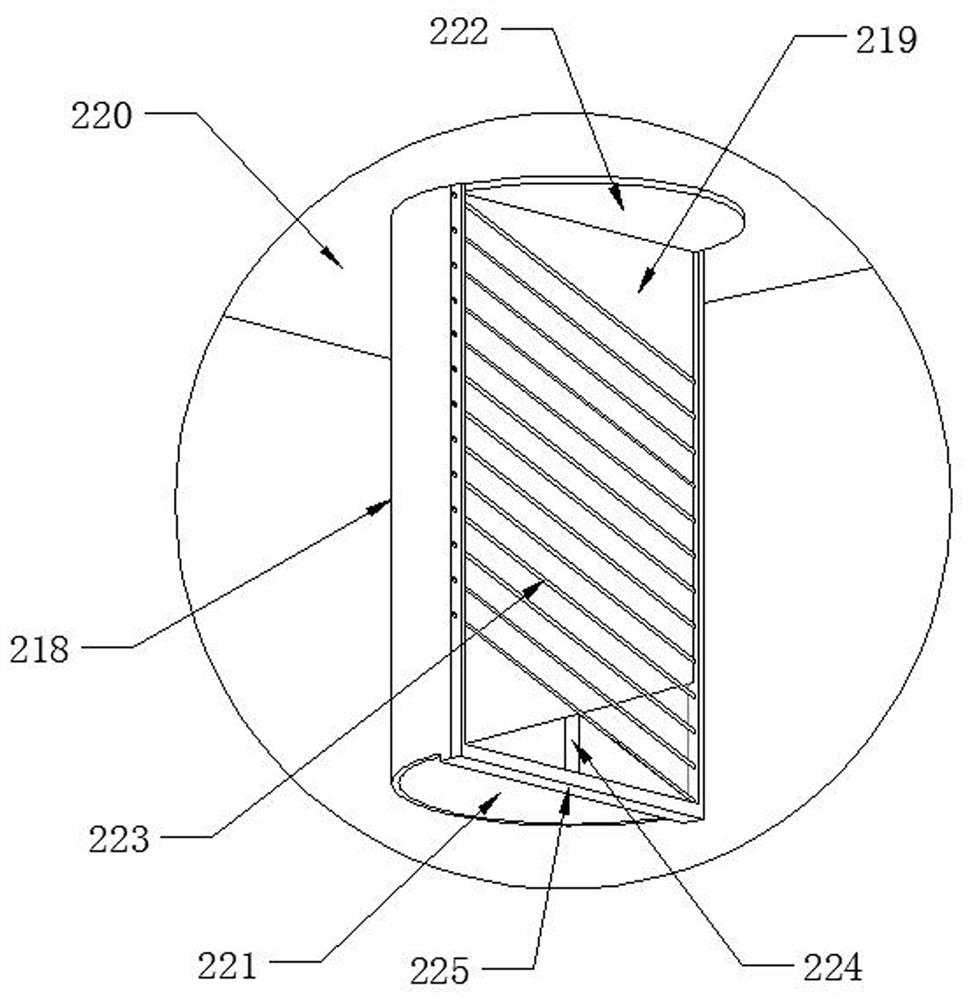

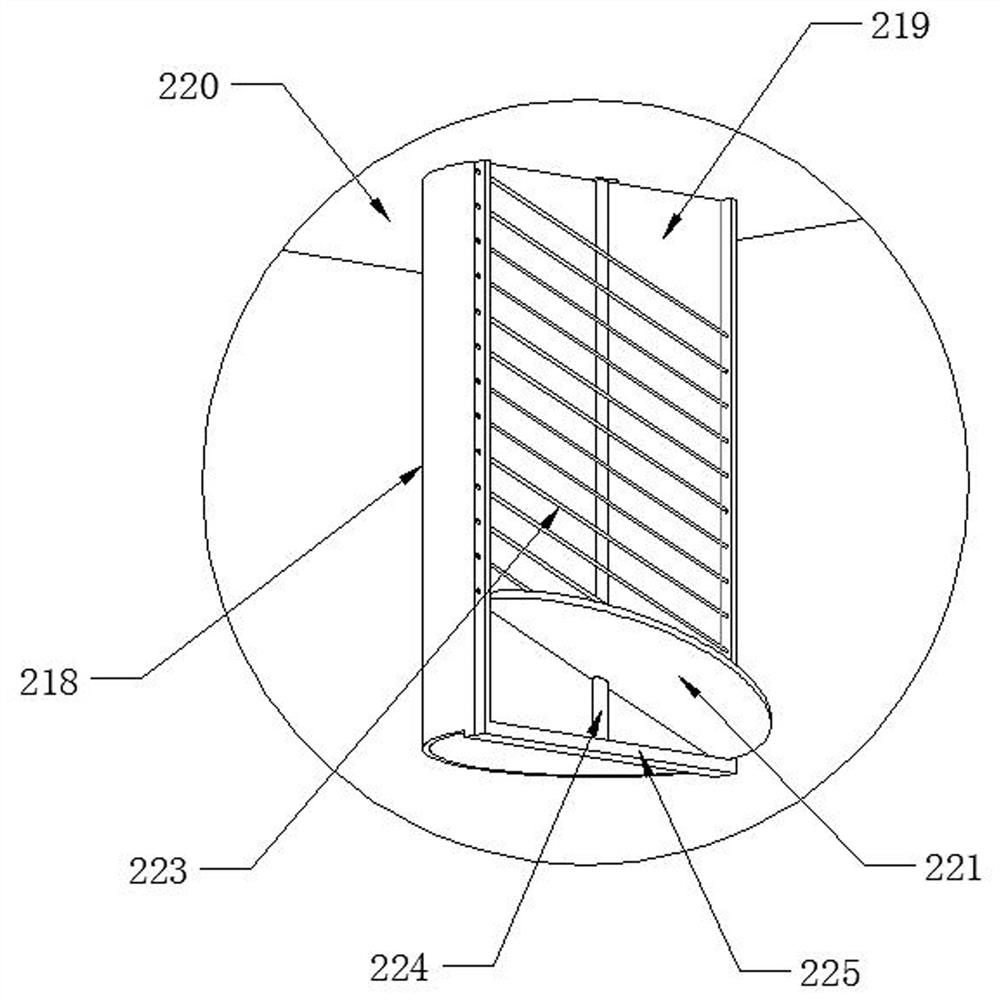

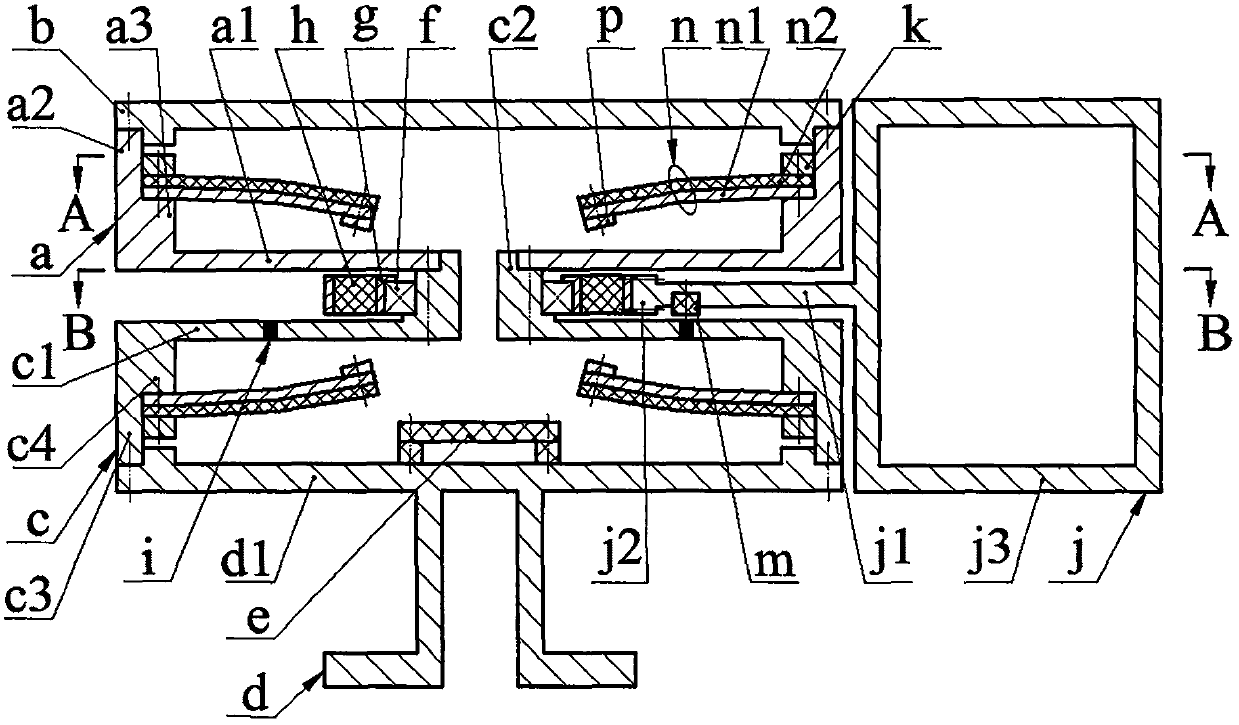

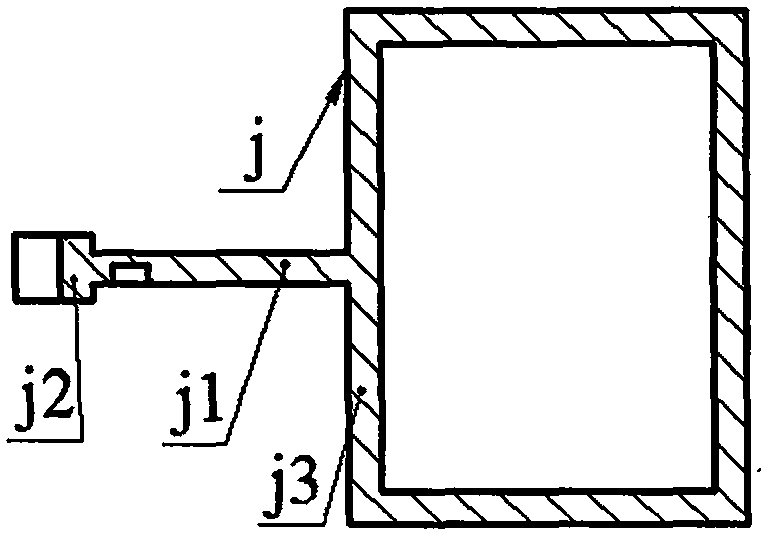

Piezoelectric wind direction wind speed measurement device

ActiveCN107561308ASimple structureLow start wind speedIndication/recording movementFluid speed measurementElectricityMeasurement device

The invention relates to a piezoelectric wind direction wind speed measurement device and belongs to the wind force measurement technical field. A photovoltaic cell sheet is arranged on the upper wallof a main body; a semi-shaft is arranged at the lower part of the lower wall of the main body; sensors, a circuit board and a shell are arranged at the upper part of the lower wall of the main body;the sensors are uniformly distributed on a circumference which adopts the axis of the semi-shaft as a center; the circuit board and the sensors are arranged in a cavity formed by the shell and the lower wall of the main body; the semi-shaft is mounted on a base through a bearing; two magnets are embedded in the base; the centers of the magnets are located on the same circumference with the centersof the sensors; the magnets are symmetrically arranged at two sides of the semi-shaft; sensing vibrators are installed on the shell; a partition board is installed between the front wall and back wall of the main body; energy harvesting vibrators are installed on the partition board; the sensing vibrators and the energy harvesting vibrators tilt towards the left side and right side of the main body respectively; flag sails are mounted at the external sides of the front wall and rear wall of the main body; the energy harvesting vibrators and the sensing vibrators are of pre-bent structures formed through bonding substrates and piezoelectric sheets together, the radius of the piezoelectric sheets being larger than the radius of the substrates; the substrates of the energy harvesting oscillators are adjacent to the partition board; and the piezoelectric sheets of the sensing vibrators are adjacent to the shell.

Owner:ZHEJIANG NORMAL UNIVERSITY

A biomass pyrolysis co-production gas/biochar production process

ActiveCN105273731BIncrease gas calorific valueHigh calorific valueBiofuelsEnergy inputAir preheaterWater vapor

Owner:HEFEI DEBO BIOENERGY SCI & TECH

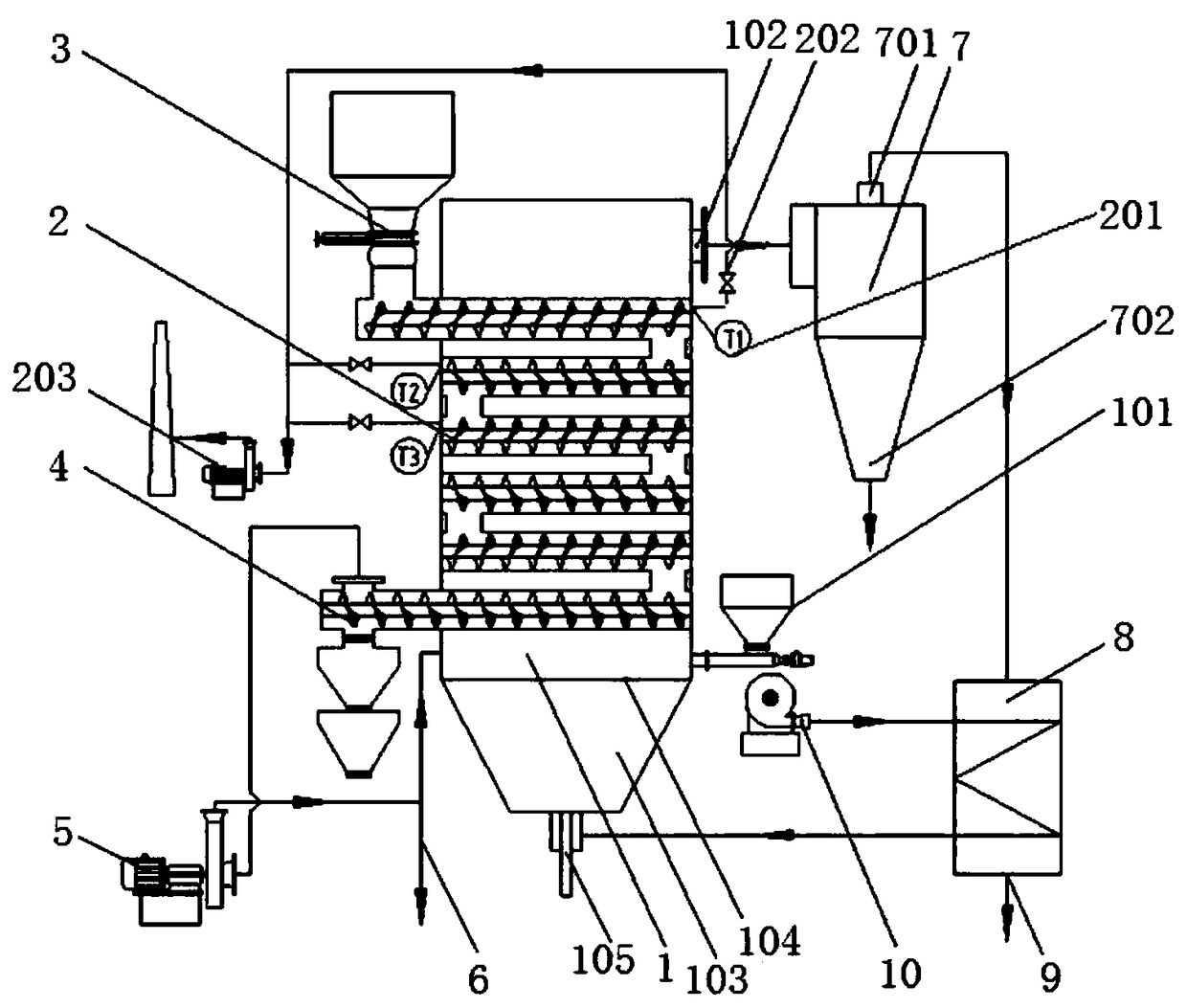

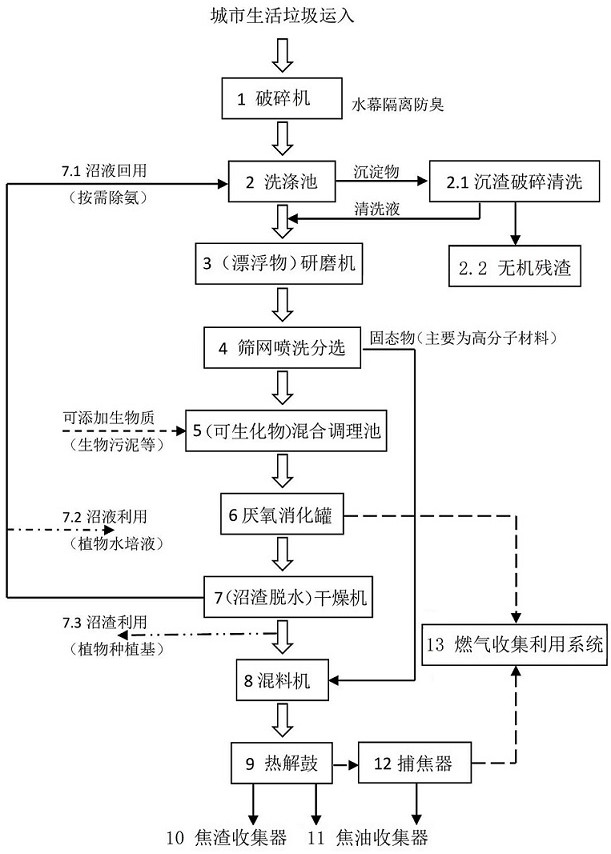

Municipal garbage wet type process treatment method

ActiveCN111804713ANo secondary pollutionEasy to handleWaste processingSolid waste disposalProcess engineeringDomestic waste

The invention provides a municipal garbage wet type process treatment method. According to the method, garbage is crushed and then conveyed to a washing tank to be washed; sediment is sent to a sorting machine to be crushed and washed to separate out inorganic residues; garbage washing liquid and floating substances on the washing tank are both conveyed into a grinding machine; ground materials are washed and sieved; an oversize product is dried and fed into a mixer, and an undersize product is sent into a mixing and conditioning tank; when the water quality and temperature meet the requirements, the mixture in the mixing and conditioning tank is fed into an anaerobic digestion tank to generate biogas, biogas fluid and biogas residues; the biogas residues are dewatered and dried and are conveyed into a pyrolysis drum together with the dried oversize product; and thermal cracked fuel gas of which tar is removed and the biogas are both fed into a fuel gas collection and utilization system. Through the municipal garbage wet type process treatment method, harmless, quantity reducing and recycling treatment of garbage is realized, and the recycling comprehensive utilization rate of thegarbage is increased.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of anaerobic digestion treatment method of kitchen waste

ActiveCN112845531BIncrease profitEnergy self-sufficiencyBio-organic fraction processingWaste processingOil and greaseProcess engineering

The invention provides an anaerobic digestion treatment method for kitchen waste, which belongs to the technical field of kitchen waste treatment. It solves the problems that resources are wasted to a certain extent in the existing garbage disposal methods, which are not environmentally friendly, and there are still many disadvantages in aerobic composting and anaerobic digestion. The present invention comprises the following steps: ①, pretreat the kitchen waste, and separate oil and water-solid mixed liquid; ②, send the water-solid mixed liquid into a homogeneous pool and mix thoroughly; ③, send the thoroughly mixed water-solid mixed liquid into Anaerobic digestion is carried out in the anaerobic fermentation device, and anaerobic digestion produces biogas, biogas residue and biogas slurry; ④, the generated biogas residue is added to the aerobic composting device for thermal composting, and at the same time, the aerobic composting device is continuously filled with straw and / or nutrients such as garden waste. The invention has the advantages that the anaerobic digestion technology and the aerobic composting technology complement each other; the continuous feeding and the two-phase process of a single anaerobic tank are realized by adopting two-stage feeding cabins; and multiple kinds of garbage are processed simultaneously.

Owner:ZHEJIANG NORMAL UNIVERSITY

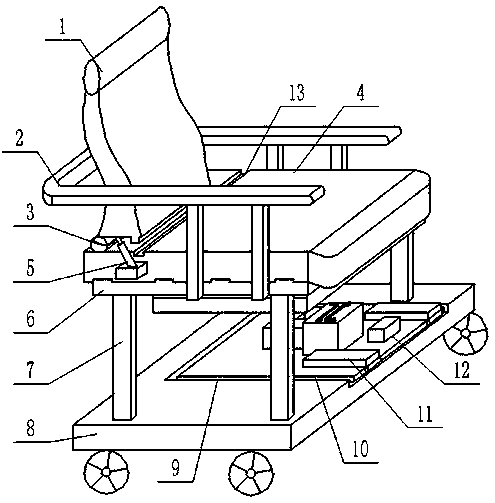

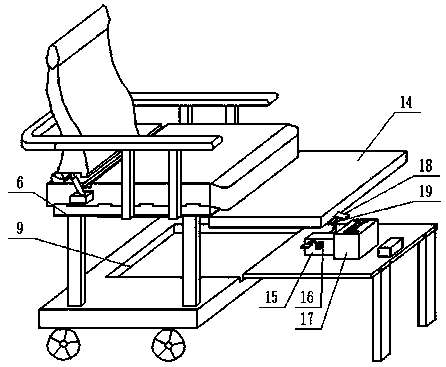

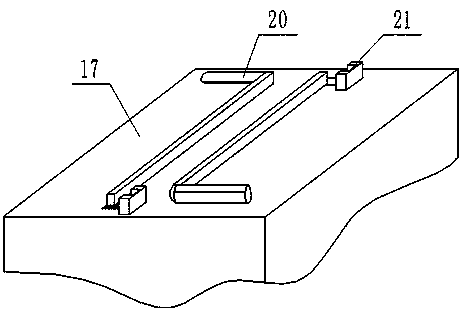

Multifunctional office chair

The invention discloses a multifunctional office chair. The multifunctional office chair comprises a back cushion, a seat cushion, a mounting supporting plate, a base, an apparatus mounting plate, anextending plate, an apparatus seat, a handle seat, a pedal and a protection handle, wherein a rotating shaft is fixedly connected with the lower part of the back cushion; the rotating shaft is embedded to the seat cushion; a mounting clamping groove is formed in the seat cushion; a rod support is arranged on the left side of the interior of the seat cushion; a hydraulic rod is fixedly connected with the rod support; the back cushion is fixedly connected with the other side of the hydraulic rod; the mounting supporting plate is arranged below the seat cushion; two fixed columns are fixedly connected with sides of the mounting supporting plate; U-shaped handles are fixed on the fixed columns; the extending plate is arranged below the mounting supporting plate; four supporting columns are fixed below the mounting supporting plate; the supporting columns are welded with the base; a moving groove is formed in the base; the apparatus mounting plate is arranged in the moving groove; two brackets are arranged on the apparatus mounting plate. The multifunctional office chair is complete in functions, convenient to operate, provided with fitness equipment, and convenient for doing physical exercises.

Owner:扬州华瑞家居用品有限公司

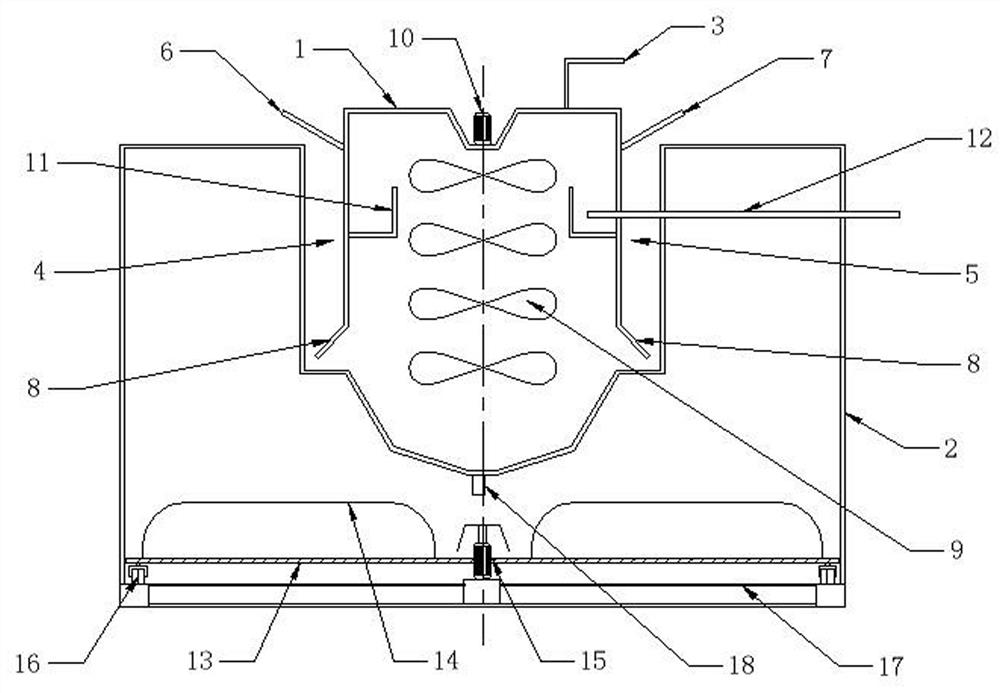

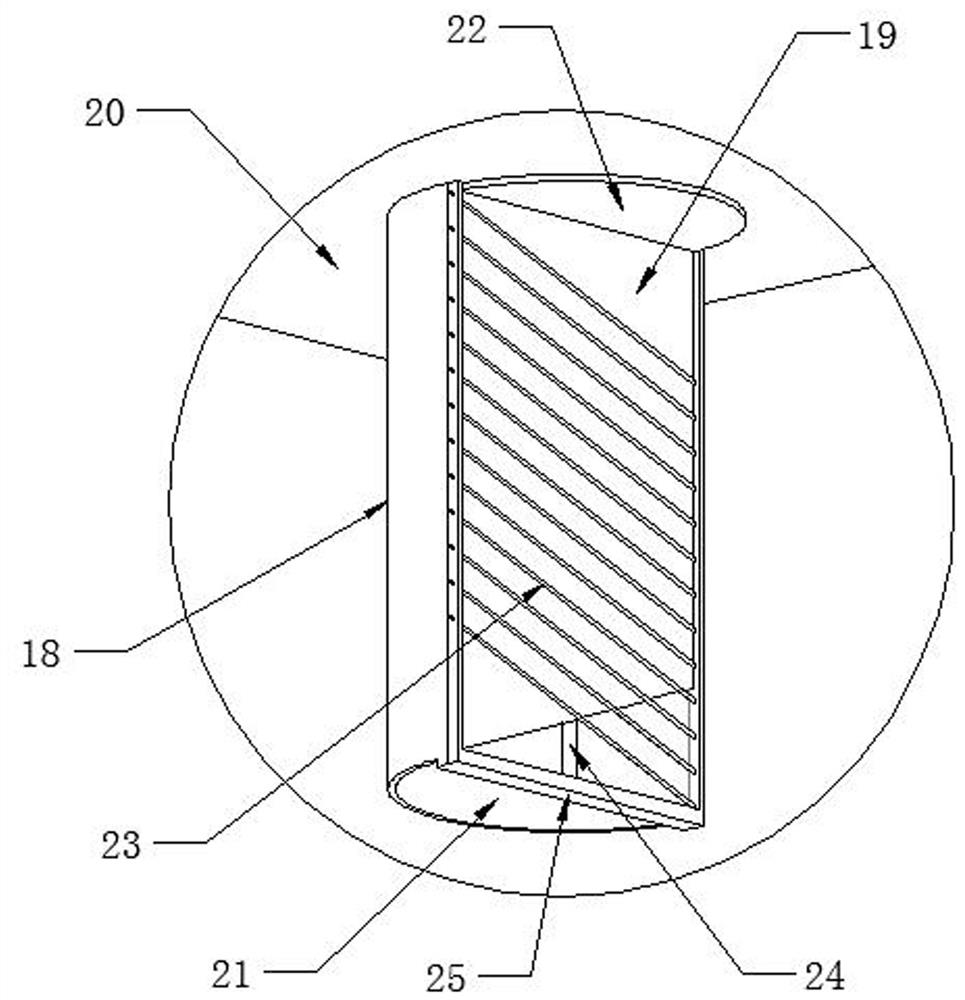

Kitchen waste treatment all-in-one machine

ActiveCN112845533AIncrease profitEnergy self-sufficiencyBio-organic fraction processingTransportation and packagingProcess engineeringEnvironmental engineering

The invention provides a kitchen waste treatment all-in-one machine which belongs to the technical field of kitchen waste treatment, and solves the problems that an existing garbage treatment method wastes resources to certain extent, is not green and environmentally friendly, and has many defects in anaerobic composting and aerobic digestion. The kitchen waste treatment all-in-one machine comprises an anaerobic fermentation device and an aerobic composting device, wherein the anaerobic fermentation device comprises an aerobic tank, a biogas collecting hole is formed in the top of the aerobic tank; the aerobic composting device comprises an aerobic tank, a pit is formed in the top of the aerobic tank; the aerobic tank is arranged in the pit; an addition sandwich layer is formed between the inner wall of the pit and the anaerobic tank; the lower part of the addition sandwich layer communicates with an anaerobic digestion tank through a delay supply mechanism; the bottom of the anaerobic digestion cavity communicates with anaerobic composting cavity, and a communication portion is equipped with a biogas sag discharge mechanism. The kitchen waste treatment all-in-one machine has the advantages of integrating an aerobic digestion technology with an anaerobic composting technology, realizes continuous feeding and two-phase process of a single anaerobic tank through two-stage feeding, and can treat multiple kinds of garbage at the same time.

Owner:ZHEJIANG NORMAL UNIVERSITY

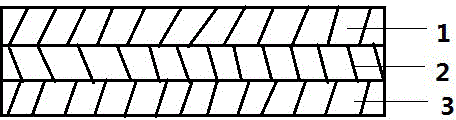

Composite wooden door with message handwriting and smoke alarming functions

InactiveCN104453618ABeautiful appearanceEnergy self-sufficiencySpecial door/window arrangementsDoor leavesHandwritingFiber

The invention discloses a composite wooden door with message handwriting and smoke alarming functions. The composite wooden door comprises an inner door sheet, an outer door sheet and a door core sheet which is embedded between the inner door sheet and the outer door sheet. The door sheets are mainly made of plant fiber composite wood. The composite wooden door is characterized in that the door core sheet is filled with plant fibers and lime; a message handwriting panel is embedded on the outer face of the door and is a magnetic tablet; a smoke alarming device is embedded in the inner door sheet, and a solar panel can automatically store solar energy to provide power for an alarm; the message function is available, self-sufficient power is provided, and safety and environmental protection are realized.

Owner:NANKAI UNIV BINHAI COLLEGE

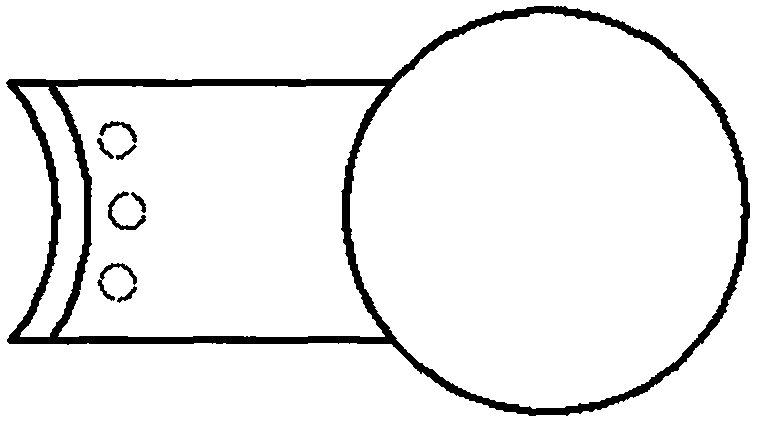

A self-luminous bicycle warning light

InactiveCN106100443BEnergy self-sufficiencyIncrease power generationPiezoelectric/electrostriction/magnetostriction machinesOptical signalCantilevered beamPiezoelectric actuators

The invention relates to a self-luminous bicycle warning light, and belongs to the technical field of the bicycle. A bicycle wheel shaft sleeve is arranged in a rotary plate inner hole in a sleeving manner; an annular cavity and a sliding way which are connected through a guiding hole are arranged on the two sides of the rotary plate; a side plate which is equipped with an annular cavity and a guiding hole are mounted on the side face of the sliding way; substrates with metal cantilever beams are both mounted in the annular cavities of the rotary plate and the side plate through end covers; the metal cantilever beams and glued piezoelectric crystal plates form piezoelectric vibrators; the piezoelectric vibrators on the rotary plate and the side plate are equal in quantity and are symmetrically mounted; the piezoelectric vibrators are connected with LED lamps which are embedded on the end covers through wires; extrusion rolling balls are mounted in the guiding holes of the rotary plate and the side plate; rolling exciters are placed in the sliding way; a limiting surface is arranged on the end cover; and a sinking cavity is formed in the limiting surface. The self-luminous bicycle warning light has the advantages and characteristics as follows: the relative movement between the rotary plate and the corresponding exciters is realized through inertial force, and the piezoelectric vibrators are excited; the warning light does not need to be fixed and supported; after the piezoelectric vibrators are deformed, the stress on each point is the same, and only the pressure stress is supported; and meanwhile, the self-luminous bicycle warning light is high in electric energy production, high in reliability, self-sufficient in energy, energy-saving, environment-friendly, and convenient to use without requiring a battery.

Owner:ZHEJIANG NORMAL UNIVERSITY

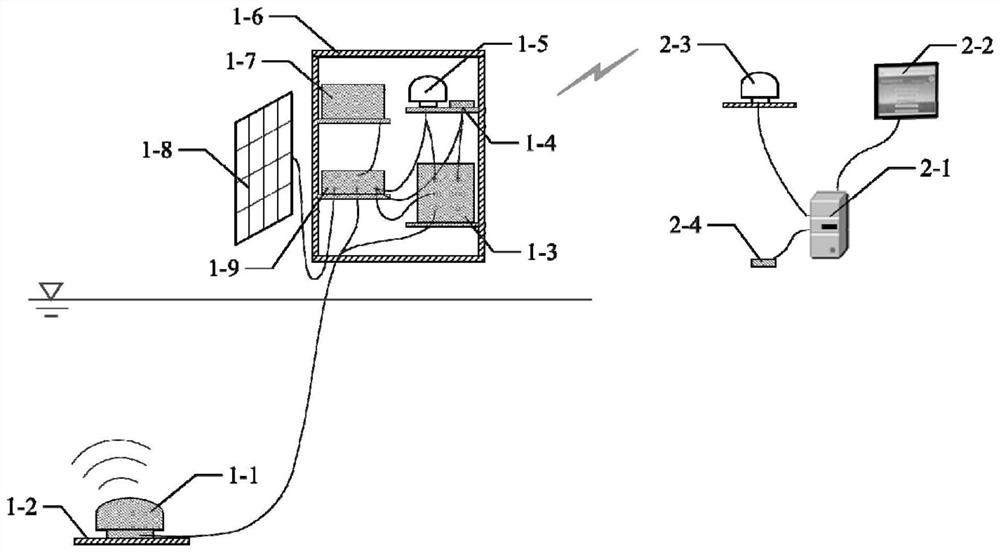

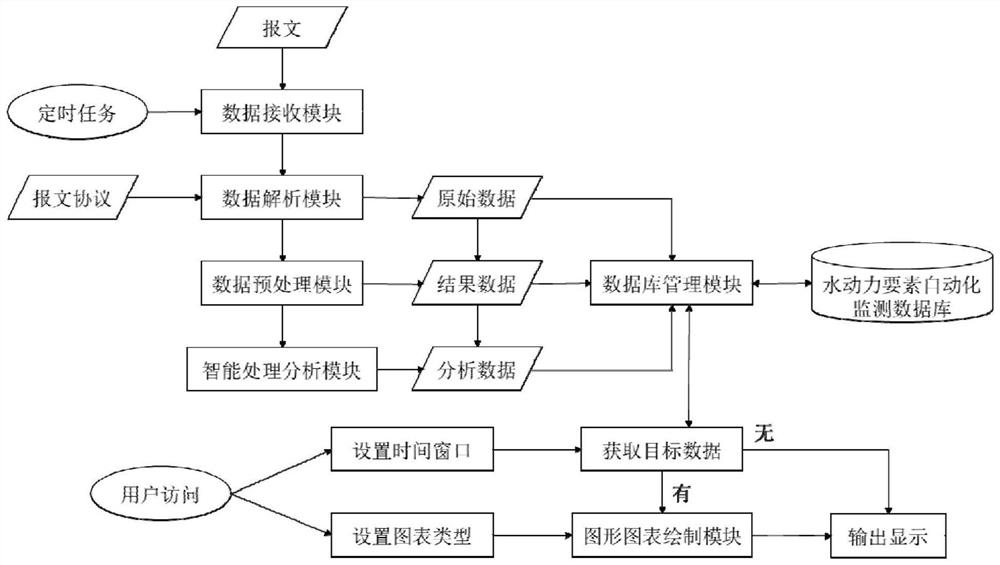

A multifunctional automatic monitoring platform for hydrodynamic elements

ActiveCN111510200BRealize synchronous automatic acquisitionFlexible layoutHydrodynamic testingMeasuring open water movementData acquisitionEngineering

The invention discloses a multifunctional automatic monitoring platform for hydrodynamic elements, which includes a remote data sharing center arranged on the shore and an on-site automatic observation station for hydrodynamic elements. The platform and the self-recording hydrodynamic sensor placed on the bottom of the water are equipped with a data collector, a communication module I and a solar power supply system on the platform, and the remote data sharing center includes a data server with a built-in database, a communication module II and a display terminal. The data server sends collection control instructions to the data collector, and the data collector collects the monitoring data of the self-recording hydrodynamic sensor and sends the monitoring data to the data server. The data server is equipped with a remote data real-time monitoring and dynamic sharing application system. The invention has the characteristics of all-weather automatic collection, multi-element high-precision synchronous observation, real-time processing and dynamic sharing.

Owner:TIANJIN SURVEY & DESIGN INST OF WATER TRANSPORT ENG

A high-efficiency energy-saving temperature-controlled water treatment system and method for treating water

ActiveCN111675421BAvoid wastingAvoid pollutionTreatment involving filtrationMultistage water/sewage treatmentElectrochemical degradationWater vapor

The invention discloses a high-efficiency, energy-saving and temperature-controlled water treatment system and a method for treating water, including a water pressurization module, a particle filtering module, an electrochemical degradation module, a microbial desalination module, a phase-change heat storage module, a condensation reflux module, Solar module; the phase-change heat storage module includes a phase-change heat storage panel, the phase-change heat storage panel is used as the wall of the electrochemical degradation module, and the water temperature in the electrochemical degradation module is maintained at 40°C-80°C, so It is described that the condensation reflux module is arranged at the exhaust gas outlet of the electrochemical degradation module, and the water vapor and organic volatiles in the exhaust gas are condensed and refluxed to the electrochemical degradation module; the electrochemical degradation module includes an anode and a cathode, and the anode and the cathode pass through The wire is connected with the DC power supply, and the DC power supply is connected with the solar power generation module; the system energy provided by the present invention does not need to consume external electric energy, and can maintain the electrochemical degradation module and the microbial desalination module at the optimum temperature.

Owner:NANJING DAIMONTE TECH CO LTD

A wind speed and wind direction monitoring device

ActiveCN107576816BIncrease power generation capacityAvoid damageIndication/recording movementFluid speed measurementRepulsion forceEngineering

Owner:ZHEJIANG NORMAL UNIVERSITY

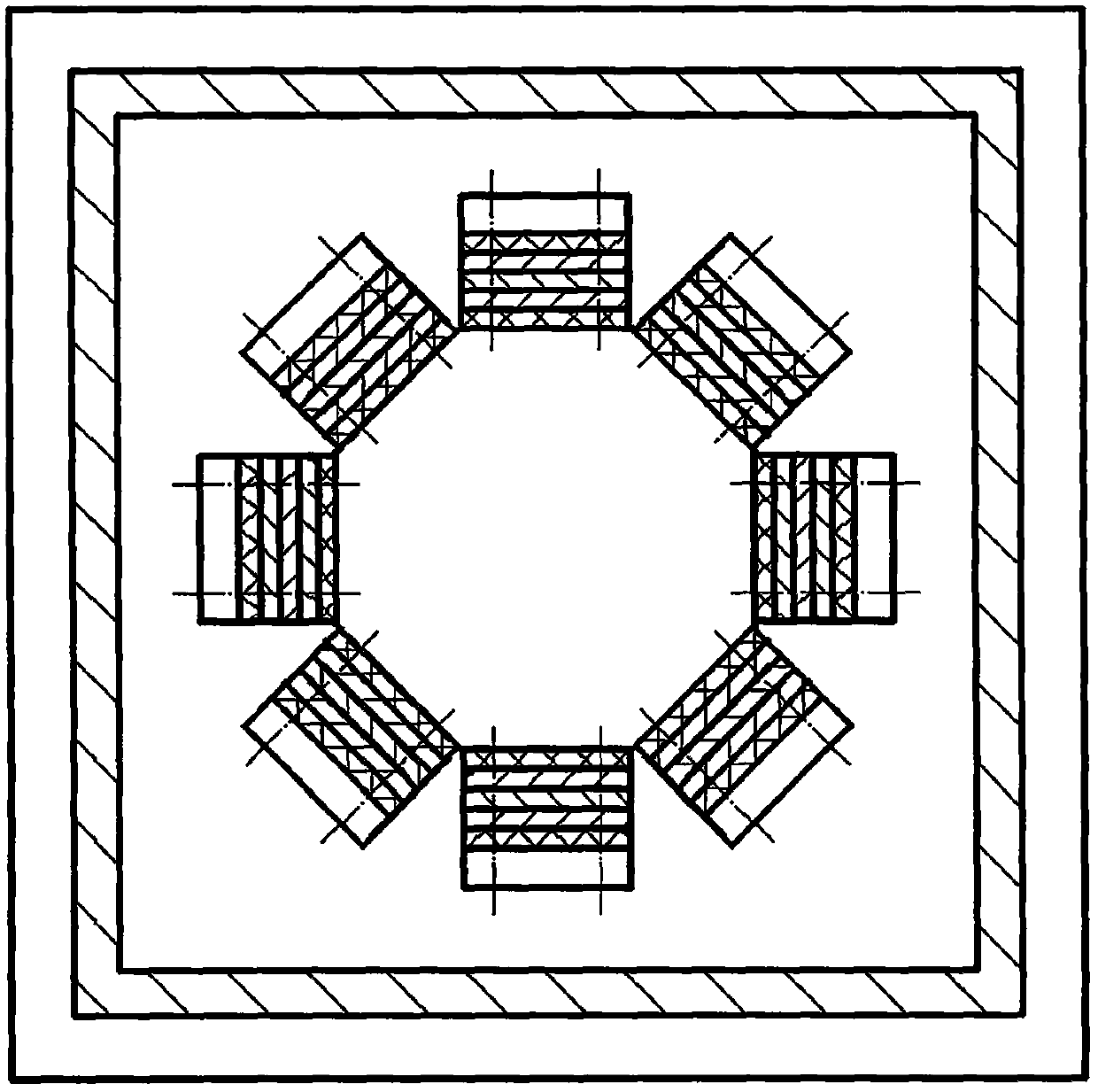

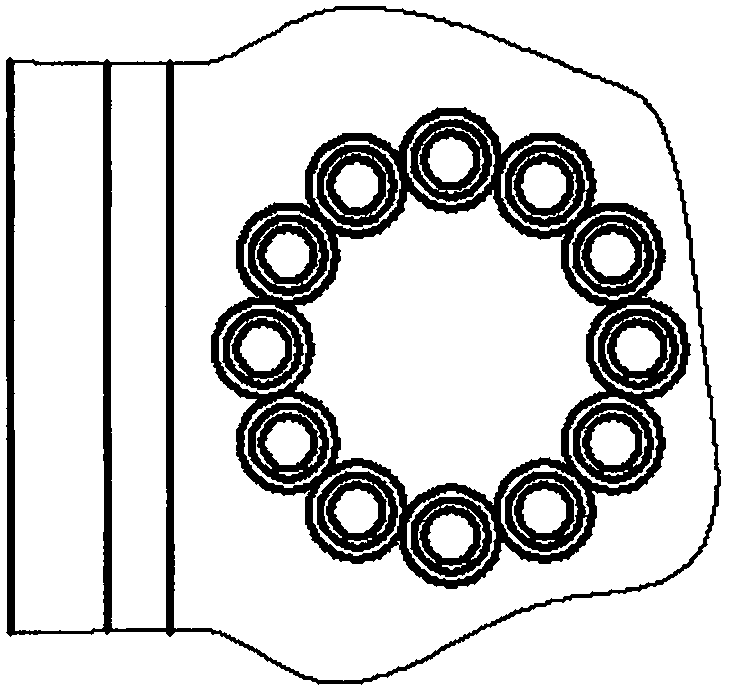

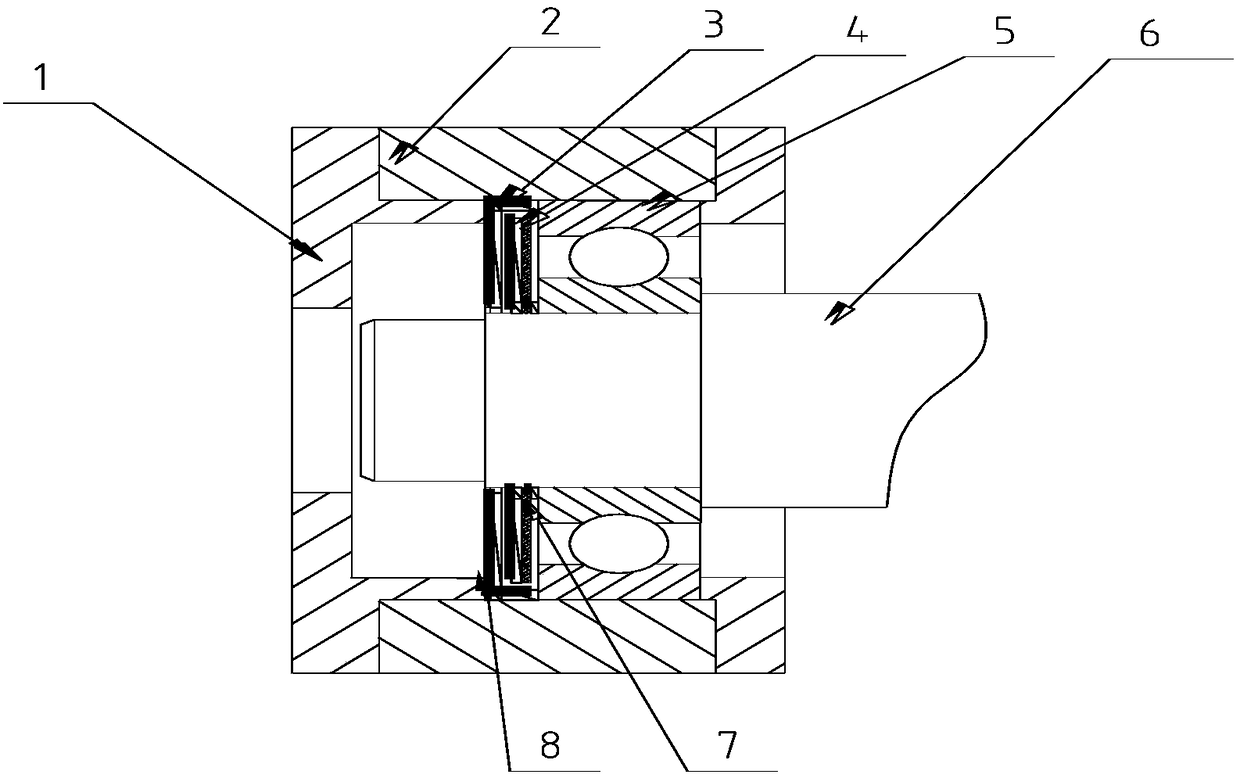

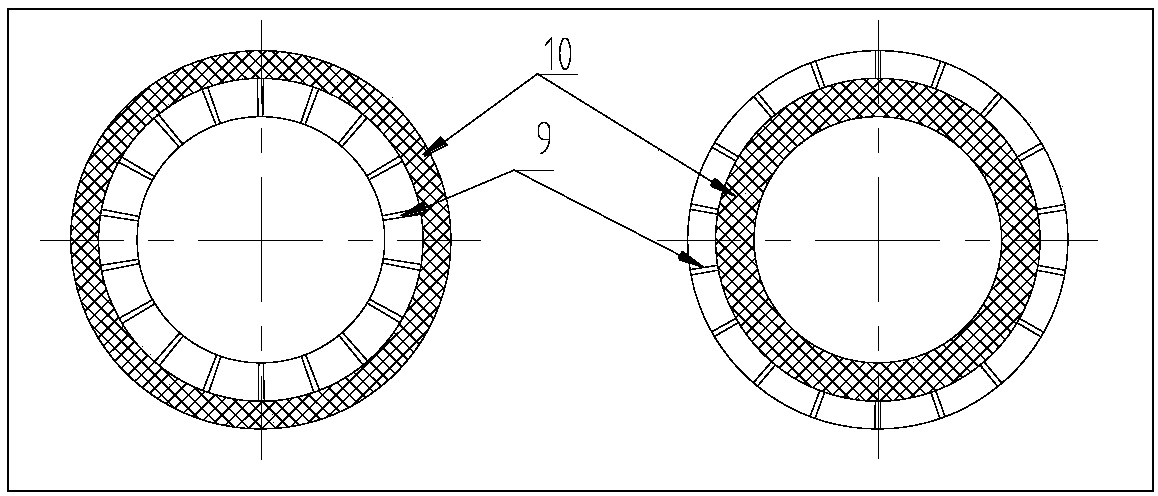

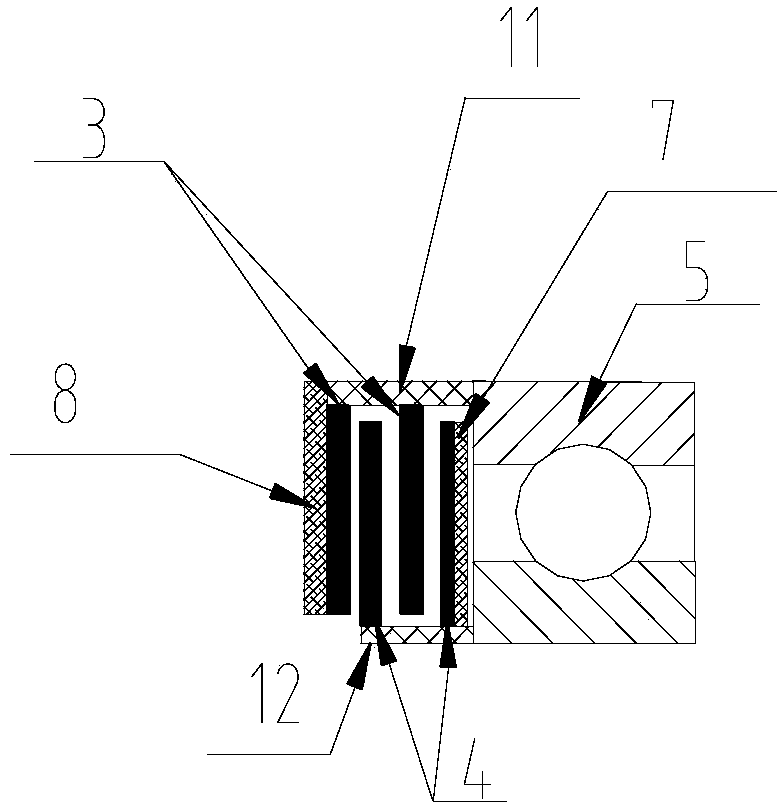

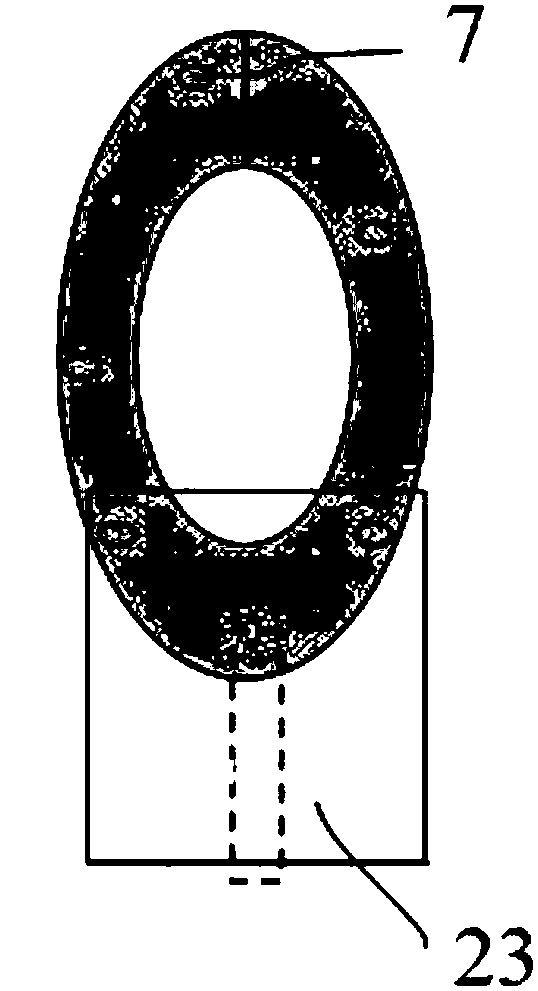

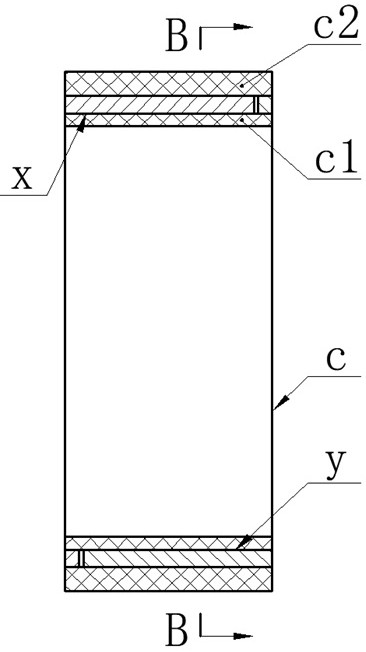

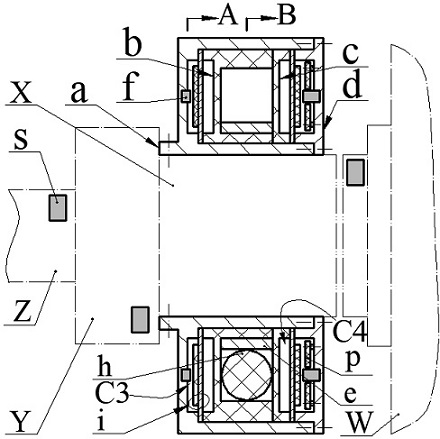

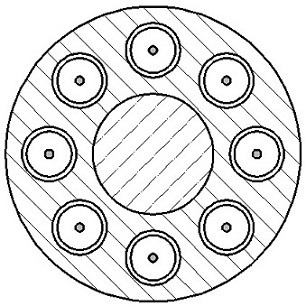

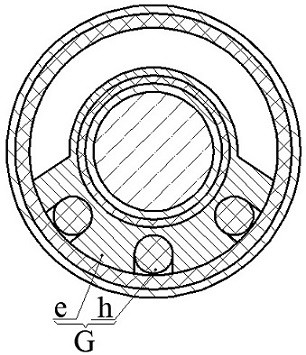

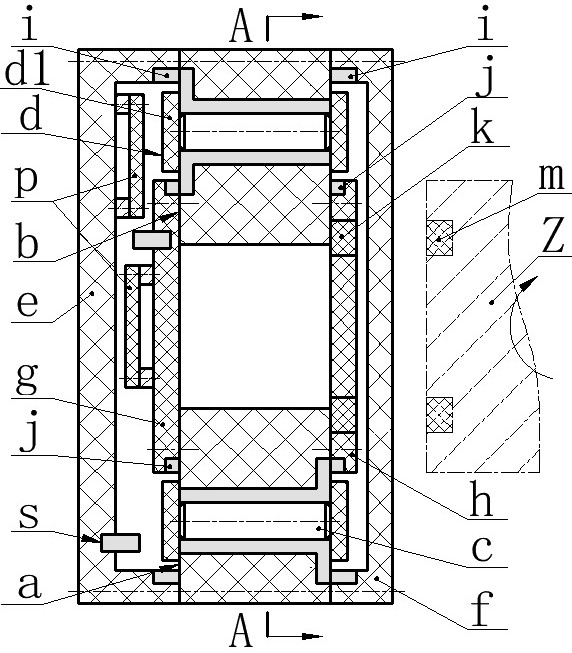

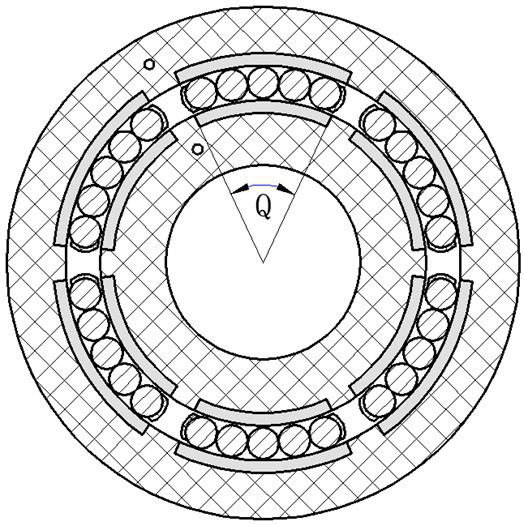

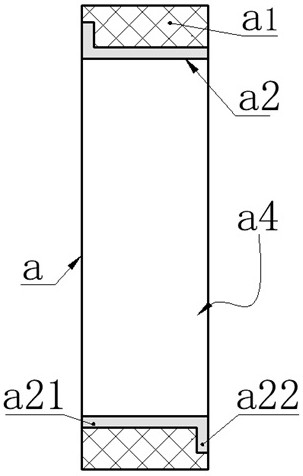

Self generating assembly applicable to rolling bearing test system

InactiveCN108429353AAchieve self-sufficiencySelf-sufficient and reliableCircuit arrangementsHigh magnetic field strengthRolling-element bearing

The invention discloses a self generating assembly applicable to a rolling bearing test system, which is mounted in bearing working space and comprises moving rings and stationary rings concentricallyand axially arranged. The stationary rings are arranged at the outer ring of the bearing, and the moving rings are arranged at the inner ring of the bearing; guide bars and magnetic grids are arranged at the inner ring and the outer ring of the stationary rings; positions, relative to the guide bars and the magnetic grids of the stationary rings, at the inner ring and the outer ring of the movingrings are also provided with magnetic grids and guide bars; in a condition in need of higher electric energy or higher magnetic field strength, at least two sets of stationary rings and moving ringsare adopted for mutual stagger arrangement; and in a condition in need of AC power supply, two poles of the magnetic grids are distributed at intervals. As the magnetic grids and the guide bars are arranged on the stationary rings and the moving rings, electric energy is generated through relative movement of the stationary rings and the moving rings, an integrated electric energy conditioning system is matched, and in narrow bearing serving space, self supply of energy for a stationary component test system and a rotating parts test system can be realized at the same time.

Owner:XI AN JIAOTONG UNIV

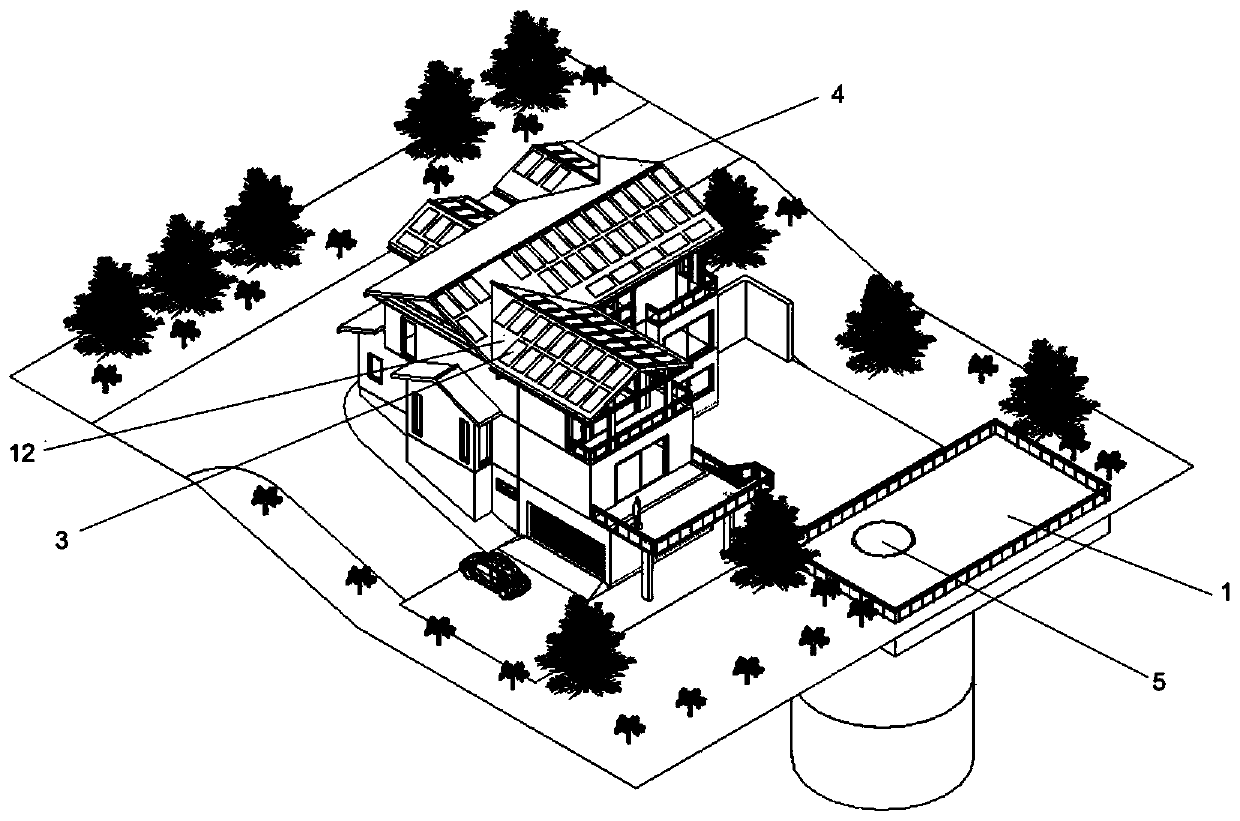

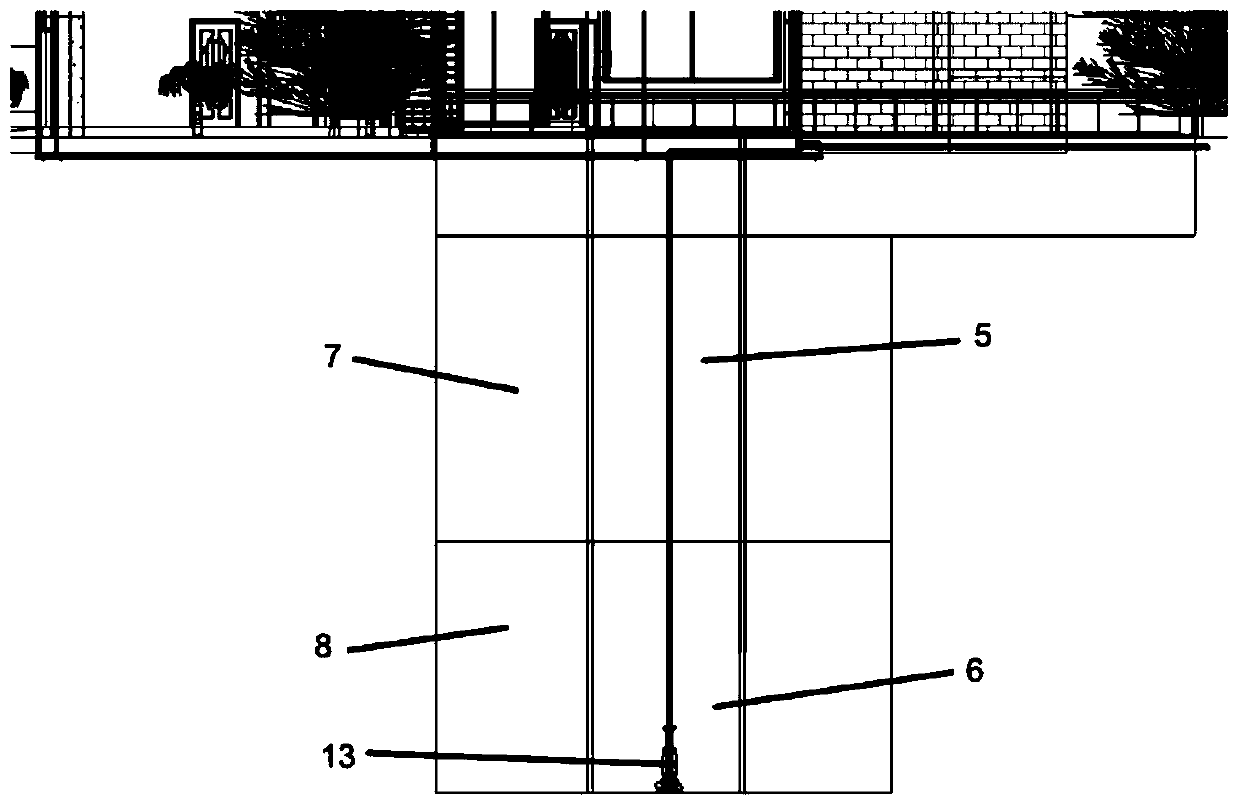

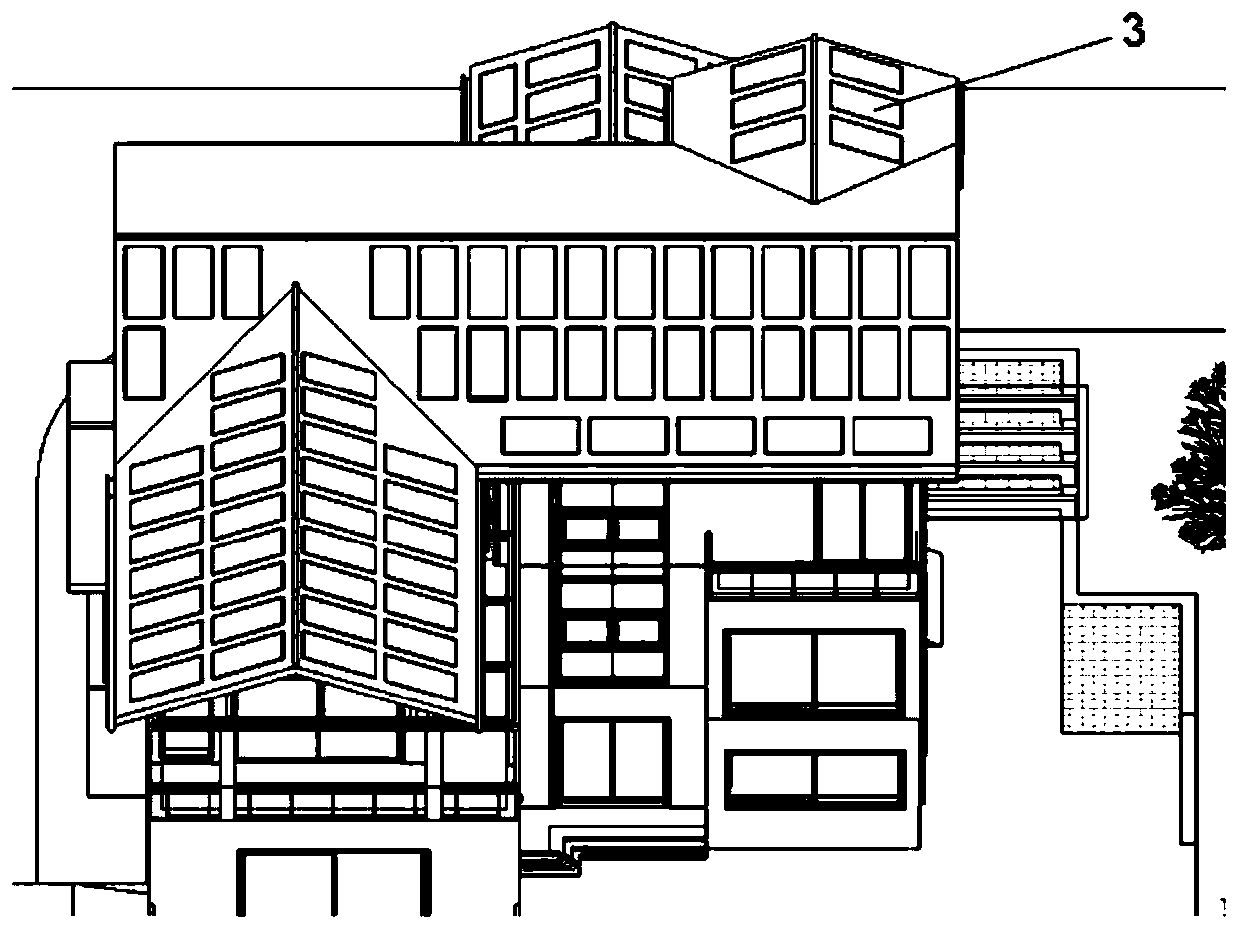

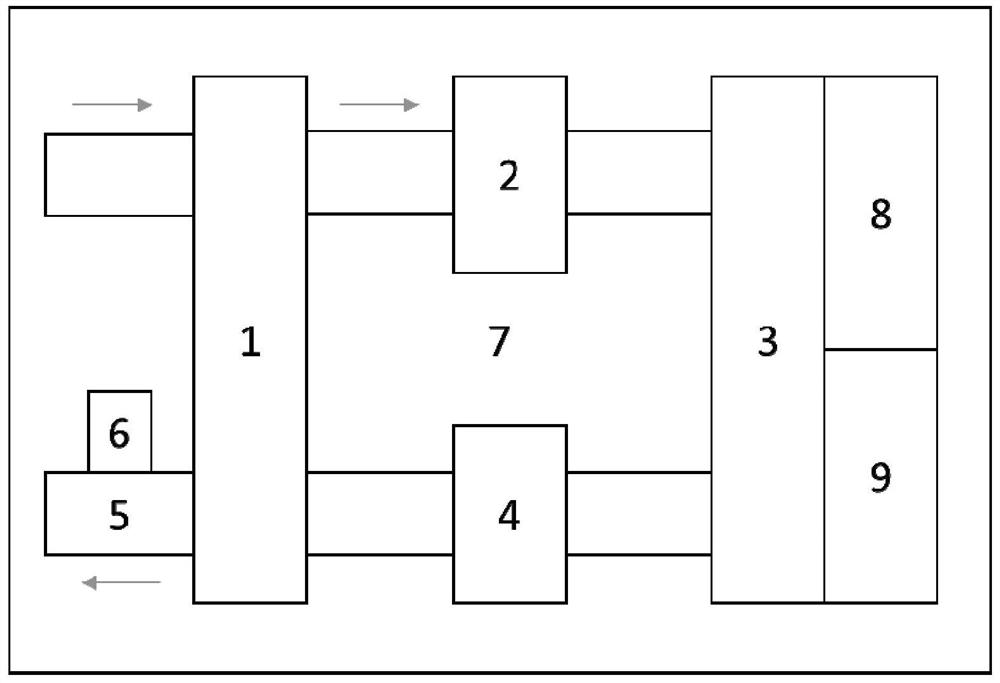

Building energy recycling system

InactiveCN110847522AReduce energy consumptionEnergy self-sufficiencyPhotovoltaic supportsRoof covering using slabs/sheetsSolar sourceHeat conservation

The invention discloses a building energy recycling system, which comprises a solar energy utilization system and a rainwater reusing system. The rainwater reusing system comprises a rainwater gutterarranged on one side of the roof, a water heat-preservation partition layer arranged on the lower part of the roof, and a water storage pond arranged on the ground, and the rainwater gutter communicates with the water storage pond through a rainwater pipe; a water well is arranged in the water storage pond, and water in the water well communicates with the water heat-preservation partition layer through a submersible pump; and the solar energy utilization system comprises a photovoltaic panel roof frame arranged on the top face of the roof, a solar photovoltaic panel is arranged on the photovoltaic panel roof frame, the solar photovoltaic panel is electrically connected with the submersible pump, and the photovoltaic panel roof frame and the water heat-preservation partition layer jointlyadjust the internal temperature of a building. Solar energy is converted into electrical energy to be provided for electrical equipment in a building energy comprehensive utilization system, thus theinterior of the building achieves the effects of warmness in winter, coolness in summer, and energy consumption self-sufficiency, and by collecting and utilizing rainwater, natural energy sources suchas solar energy sources and underground energy sources are absorbed and utilized to achieve energy conservation and environmental protection.

Owner:ZHEJIANG COLLEGE OF CONSTR

Efficient energy-saving temperature control water treatment system and water treatment method thereof

ActiveCN111675421AAvoid wastingAvoid pollutionTreatment involving filtrationMultistage water/sewage treatmentElectrochemical degradationFiltration

The invention discloses an efficient energy-saving temperature control water treatment system and a water treatment method thereof. The efficient energy-saving temperature control water treatment system comprises a water pressurization module, a particle filtration module, an electrochemical degradation module, a microbial desalination module, a phase change heat storage module, a condensation reflux module and a solar module; the phase change heat storage module comprises a phase change heat storage plate; the phase change heat storage plate is used as a wall body of the electrochemical degradation module; the temperature of water in the electrochemical degradation module is maintained to be 40-80 DEG C; and the condensation reflux module is arranged at the tail gas outlet of the electrochemical degradation module and is used for condensing and refluxing water vapor and organic volatile matters in tail gas to the electrochemical degradation module; the electrochemical degradation module comprises an anode and a cathode, the anode and the cathode are connected with a direct-current power supply through wires, and the direct-current power supply is connected with a solar power generation module. The system is provided with a power supply and does not need to consume external electric energy, and the electrochemical degradation module and the microbial desalination module can bemaintained at the most suitable temperature.

Owner:NANJING DAIMONTE TECH CO LTD

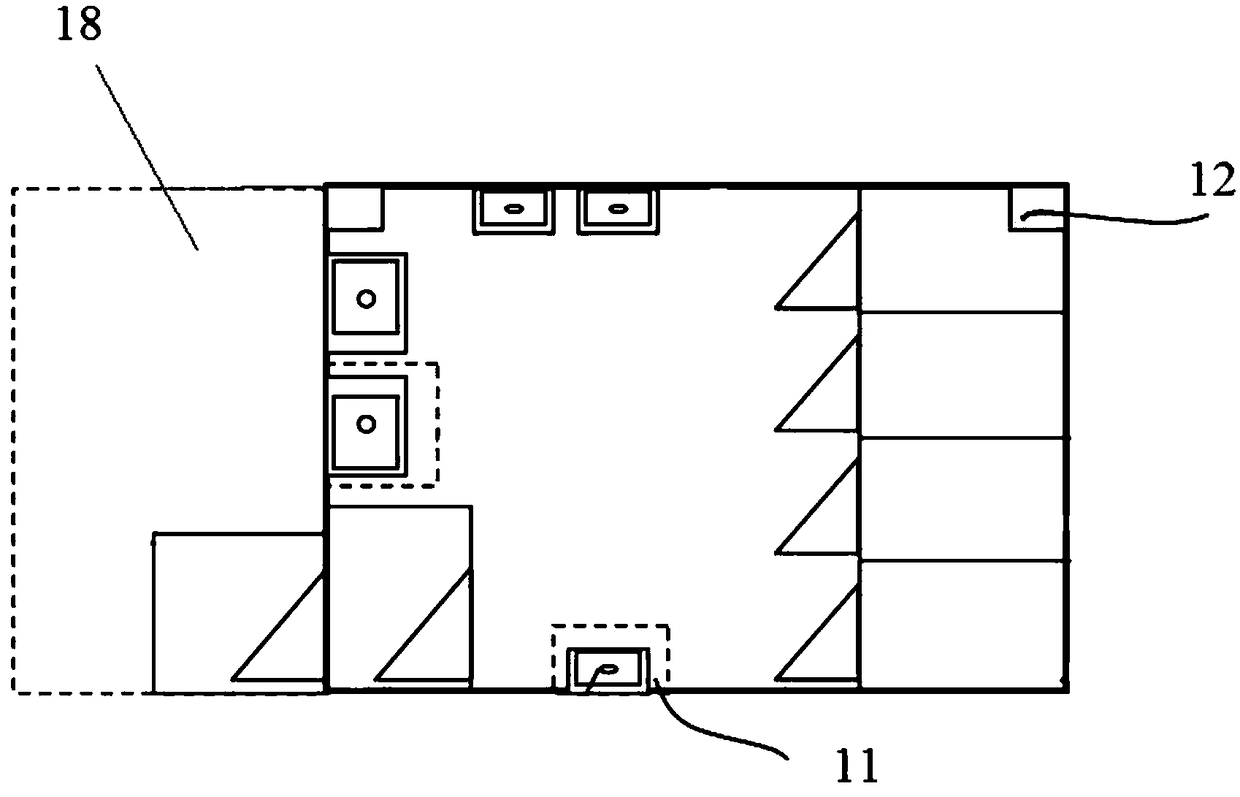

A safe and intelligent public toilet

ActiveCN106088678BEasy to transportEasy to installPhotovoltaic supportsAutomatic obstacle detectionElectricityWater source

The invention discloses a safe and intelligent public washroom. The safe and intelligent public washroom is characterized by comprising a washroom body and equipment; the washroom body comprises modules which can be divided and combined in multiple splicing modes; the equipment comprises modules which can be divided and combined in multiple splicing modes, and the modules of the equipment can be embedded into the modules of the washroom body; the washroom body comprises a wall and ground module, a roof module, a ventilation module and a pipeline channel module, and the wall module, the ventilation module and the pipeline channel module can be spliced and combined according to different directions and positions. The modules which can be divided and combined in the spliced mode are adopted in the washroom body and the equipment, and the public washroom is convenient to transport and install, flexible to combine and capable of being installed in a remote mountain area, an area short of water and electricity and a place with severe environment. As a water collecting tank and a water accumulating tank are arranged, natural rain and water are fully used as a water source for the washroom, and manpower and financial resources are saved.

Owner:SUZHOU UNIV

wheel warning light

ActiveCN112735298BEnergy self-sufficiencyNo electromagnetic interferenceOptical signalIlluminated signsCapacitancePotential difference

The invention relates to a wheel warning light, which belongs to the technical field of new energy and warning lights. Including shell, shaft sleeve, turntable, fixed plate, end cap and luminous body, the bottom wall of the shell is mounted on the shaft sleeve, the end cap is mounted on the end of the shell wall, and the end cap is crimped with the bottom wall of the shell. The left electrode ring, the turntable and the right electrode ring; the fixed plate is rotatable on the shaft sleeve; the bottom wall and the end cover of the housing are provided with illuminants; a moving electrode group is embedded between the inner and outer layers of the turntable, and the moving electrode group consists of Composed of left and right electrodes; the left electrode and the right electrode are connected to the luminous body through wires, rectifier bridges and capacitors; the fixed plate is a fan-shaped structure, and the fixed electrode group and inertial block are embedded in the plate of the cylindrical surface of the fixed plate. The fixed electrode group consists of strips The fixed electrode is composed of a fixed electrode; during the relative rotation of the turntable and the fixed disk, heterogeneous friction charges and potential differences are generated between the contact surfaces. The continuous rotation between the fixed disk and the turntable makes the potential difference between the left and right electrodes alternately increase and decrease, and the luminous body emits light.

Owner:ZHEJIANG NORMAL UNIVERSITY

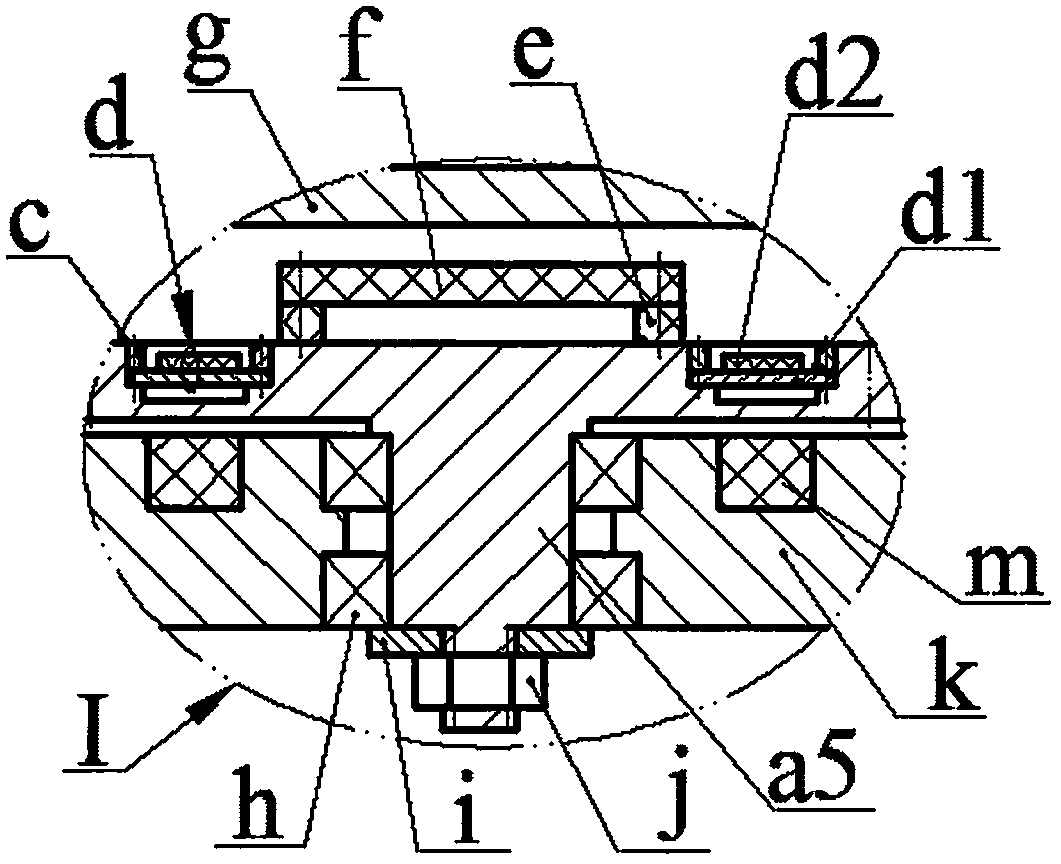

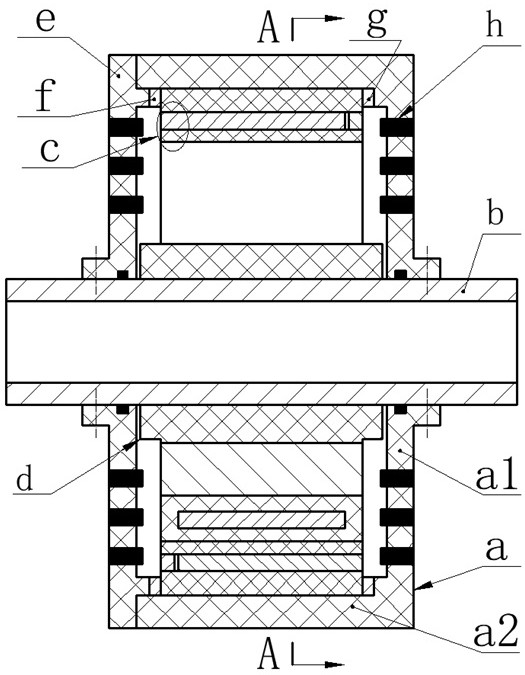

Cutting force measuring device

ActiveCN113369995ASmall tangential follower forceRaise the natural frequencyMeasurement/indication equipmentsNew energyEngineering

The invention relates to a cutting force measuring device, and belongs to the technical field of new energy and cutting force monitoring. The cutting force measuring device is composed of a machine shell, a ring frame, a ring plate, a ring cover, an exciter, a limiting block, a sensor, a circuit board and transducers, wherein a rolling body of the exciter is a magnetic ball or a magnetic column; the transducers are formed by bonding coupling sheets and piezoelectric sheets; the sensor is arranged on a drill bit, a clamp or a main shaft, and the circuit board is arranged on the ring cover; the machine shell is installed on the main shaft, the ring cover is installed at the end of an outer ring groove of the machine shell, a protruding ring of the ring cover is arranged in the outer ring groove, and the transducer, the ring frame, the ring plate and the transducer are sequentially connected between the protruding ring and the bottom wall of the outer ring groove in a pressing mode; and the exciter is mounted in an inner ring groove of the ring frame, and the coupling sheets of the transducers are made of a ferromagnetic material. When the main shaft rotates, the transducers and the exciter rotate relatively, the exciter forces the transducers to generate reciprocating axial bending deformation and convert mechanical energy into electric energy, the electric energy is supplied to the sensor after being processed by a conversion circuit, and the sensor obtains relevant cutting force parameters in real time and then transmits the relevant cutting force parameters through a transmitting unit.

Owner:ZHEJIANG NORMAL UNIVERSITY

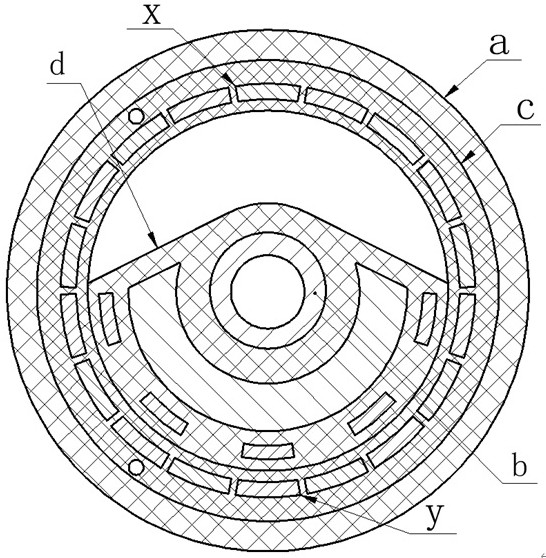

Gearbox state monitoring system

ActiveCN112834213AThe overall structure is simpleReduce volumeMachine gearing/transmission testingWind energy generationCondition monitoringElectric energy

The invention relates to a gearbox state monitoring system, and belongs to the technical field of self-powered monitoring and new energy. The left and right shells are arranged on two sides of the fixed ring, the left and right baffles are arranged on two sides of the movable ring, and the shells and the baffles are provided with circuit boards and sensors; active and passive magnets are respectively embedded on the rotating shaft and the right baffle, the rollers are arranged between the fixed ring and the movable ring and are divided into roller groups, the fixed ring consists of a fixed ring body and left and right fixed electrode groups, and the movable ring consists of a movable ring body and left and right movable electrode groups; the fixed electrode ring pressure and the movable electrode ring pressure are respectively connected to fixed terminals of the fixed electrode group or the movable electrode group close to the fixed electrode ring pressure; the rollers are in rolling contact with the movable and fixed electrodes to generate different inductive charges, potential differences exist between the left and right fixed and movable electrode groups, the roller groups are alternately contacted and separated from the electrodes in the fixed and movable electrode groups when the rollers rotate, the potential differences between the left and right fixed electrode groups and between the left and right movable electrode groups are alternately increased and decreased, and mechanical energy is converted into electric energy. The generated electric energy is supplied to the sensor, and parameters obtained by the sensor are transmitted out through the transmitting unit.

Owner:ZHEJIANG NORMAL UNIVERSITY

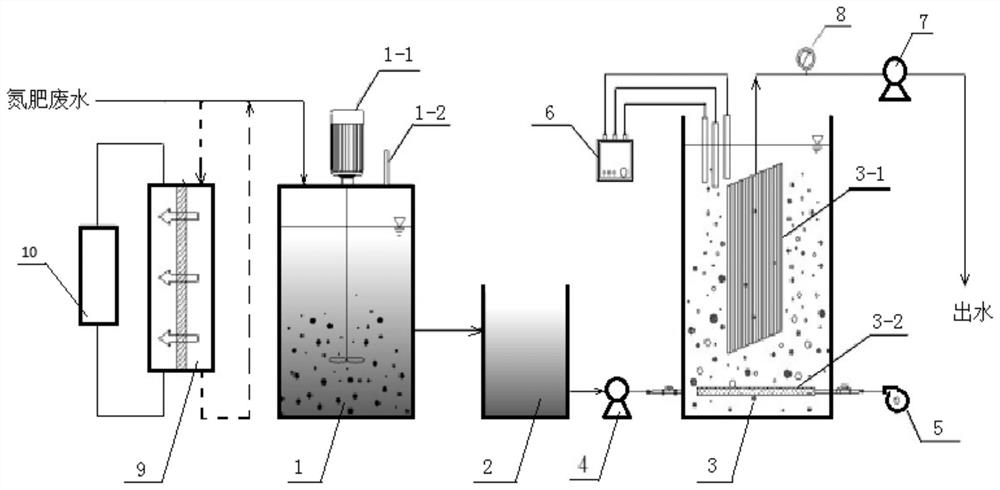

A method for synergistic and low-consumption removal of multi-pollutants in nitrogen fertilizer wastewater

ActiveCN109809630BAchieving low-consumption cooperative removalReduce energy consumptionWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenWater production

A method for synergistic and low-consumption removal of multi-pollutants in nitrogen fertilizer wastewater, which relates to a wastewater treatment method, and it is to solve the technical problems of high cost and high energy consumption of the existing nitrogen fertilizer wastewater treatment method, the method: one, nitrogen fertilizer Anaerobic digestion treatment of wastewater directly or after pretreatment to remove most of the organic matter and sulfur-containing pollutants in the wastewater; 2. Adjust the pH value; 3. Autotrophic denitrification treatment to pollute the remaining organic matter, sulfide and ammonia nitrogen synergistic removal. The pretreatment is to carry out forward osmosis concentration treatment. The indicators of effluent treated by the method of the present invention are: COD<50mg / L, ammonia nitrogen<15mg / L, total nitrogen<25mg / L, sulfide<0.5mg / L. It can be used in the field of wastewater treatment.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

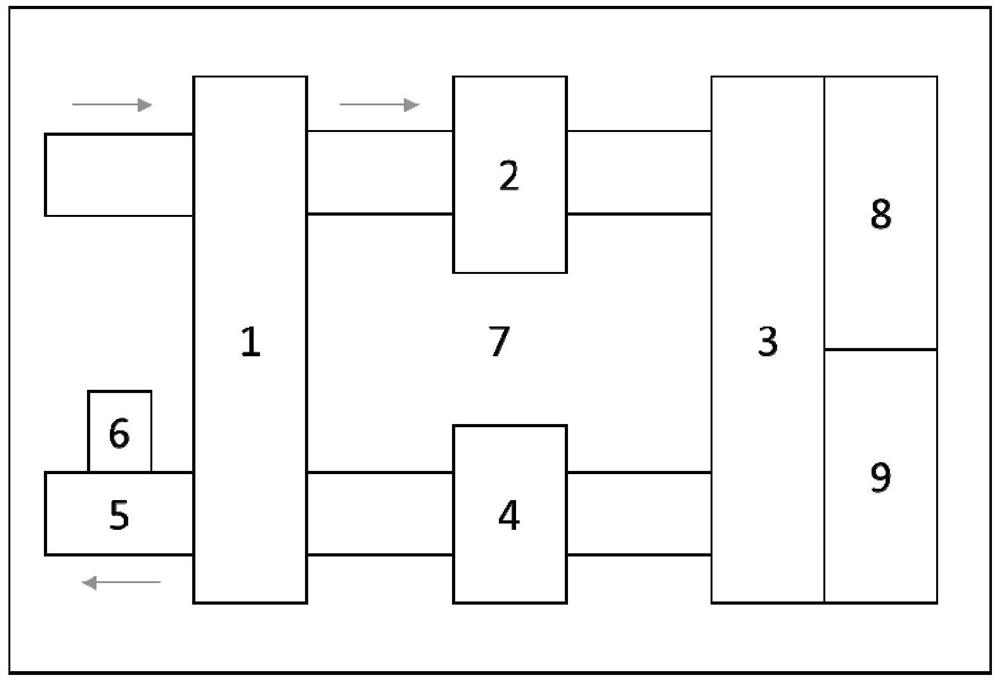

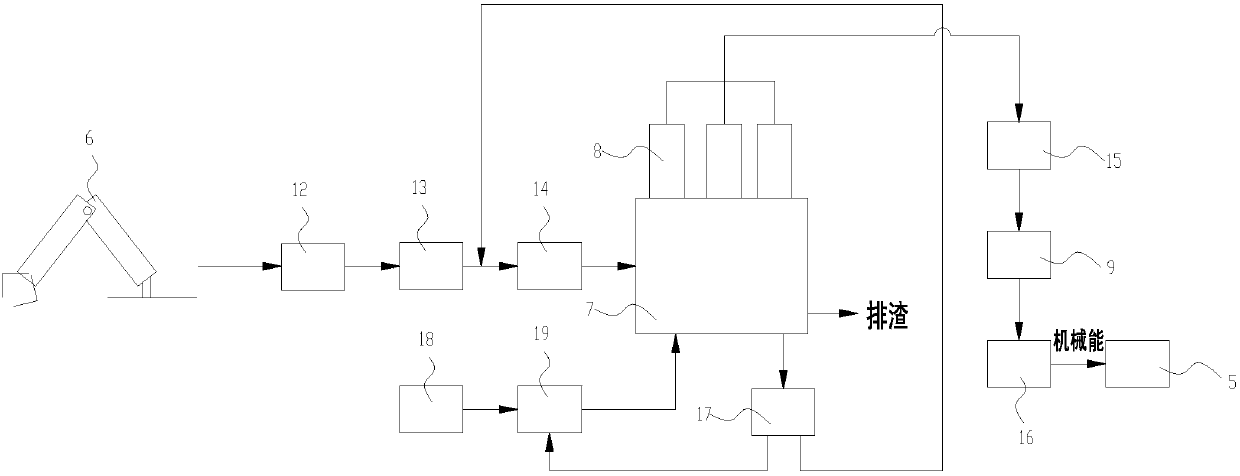

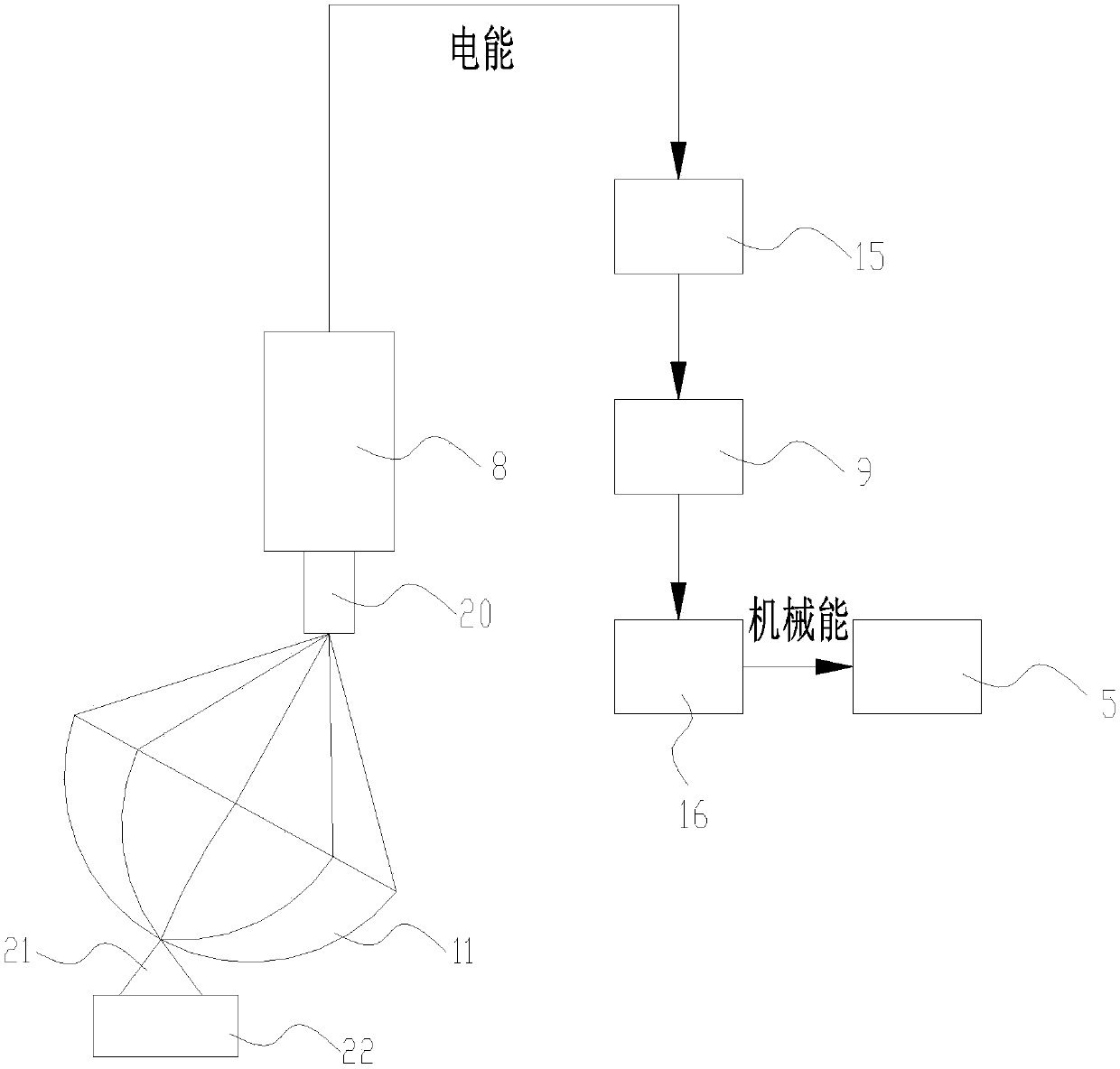

Energy self-feed mobile platform

PendingCN107891759AExtended working hoursEnergy self-sufficiencyVehicular energy storageAir flow to electrical conversionThermal energyRational use

The invention discloses an energy self-feed mobile platform which has novel structure and can effectively utilize various energies. The platform comprises a resource collecting mechanism for collecting external resource of the mobile platform; a resource processing mechanism which is used for processing the resources collected by the resource collecting mechanism to obtain heat energy; an energy conversion mechanism which is used for converting the first energy into electric energy used by energy consuming machineries; an energy storage mechanism which is used for storing and outputting a second energy for the energy consuming machineries. The present invention provides an energy self-feed mobile platform that uses a resource collection mechanism to collect resources that can be utilized,and processes the collected resources within a resource processing mechanism. The energy conversion mechanism converts the above-mentioned first energy source into required electrical energy. The platform is self-sufficient in energy, improving the operating time of the mobile platform, cruising miles, and making rational use of natural renewable resources.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com