Wet sludge gasification treatment method capable of energy self-sustaining

A treatment method, wet sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the high cost of sludge treatment, high energy cost, secondary pollution cost and other issues to achieve the effect of reducing social environmental protection burden, eliminating secondary pollution, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

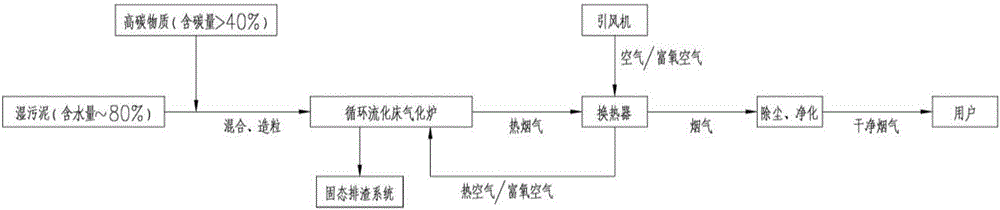

[0025] Add 10kg of bituminous coal (63.44% carbon content) to 100kg of sludge with a water content of 80%. After mixing evenly, pulverize and granulate the mixture particles below 10mm, and send them to the circulating fluidized bed gas by screw conveyor. The gasification reaction is carried out at about 950-1050 ℃, and the generated flue gas passes through the heat exchanger to preheat the air. The energy of the whole system is self-sustaining, and can transport 900MJ of abundant energy outward.

Embodiment 2

[0027] Add 100kg of biomass (with a carbon content of 40.36%) to 100kg of sludge with a moisture content of 80%, and after mixing evenly, crush and granulate the mixture particles below 10mm, and send them to the circulating fluidized bed through a screw conveyor In the gasification furnace, preheated air is blown in, and the combustion gasification reaction is carried out at about 950-1050 ° C. The generated flue gas passes through the heat exchanger to preheat the air. The energy of the whole system is self-sustaining, and can transport 850MJ of abundant energy outward.

[0028] In the present invention, due to the difference in the carbon content of the blended substances, the mixing ratio will be adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com