Gearbox state monitoring system

A state monitoring system and gearbox technology, applied in machine gear/transmission mechanism testing, electric components, electromechanical devices, etc., can solve the problems of magnetic interference, large additional space, small size, etc., and achieve high integration and reliability , strong power generation and power supply capabilities, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

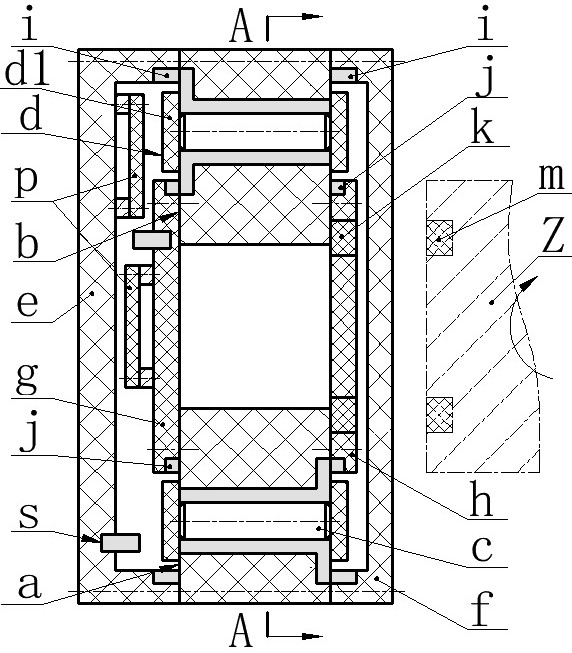

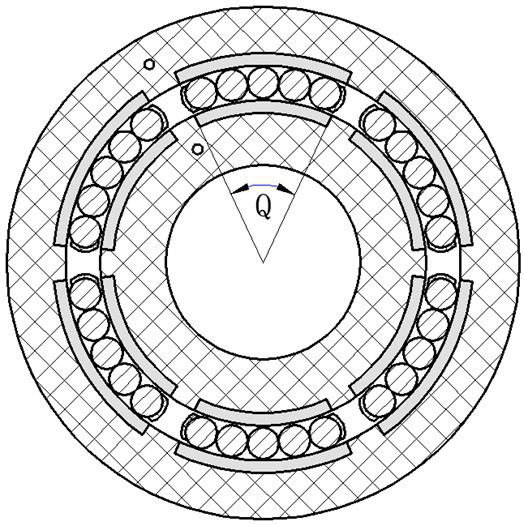

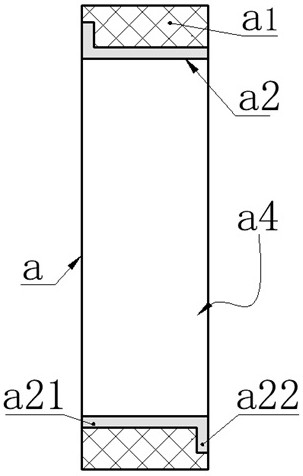

[0019] The present invention proposes a gearbox state monitoring system, which mainly includes a fixed coil a, a moving coil b, a roller c, a bracket d, a left housing e, a right housing f, a left baffle g, a right baffle h; The body e and the right case f are installed on both sides of the fixed coil a through screws, the left baffle g and the right baffle h are installed on both sides of the moving coil b through screws, and both the left case e and the right case f are equipped with There is a fixed electrode ring i, a moving electrode ring j is provided on the left baffle g and the right baffle h, and a circuit board p and a sensor s are installed on the left shell e and the left baffle g; A group of passive magnets k, the rotating shaft Z is inlaid with an active magnet m, the number and installation radius of the active magnet m and the passive magnet k are the same, and the opposite magnetic poles are installed oppositely; the roller c is installed between the fixed coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com