Municipal garbage wet type process treatment method

A technology of municipal solid waste and a treatment method, which is applied in the field of municipal solid waste wet treatment technology, and can solve the problem of low comprehensive utilization rate of waste resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

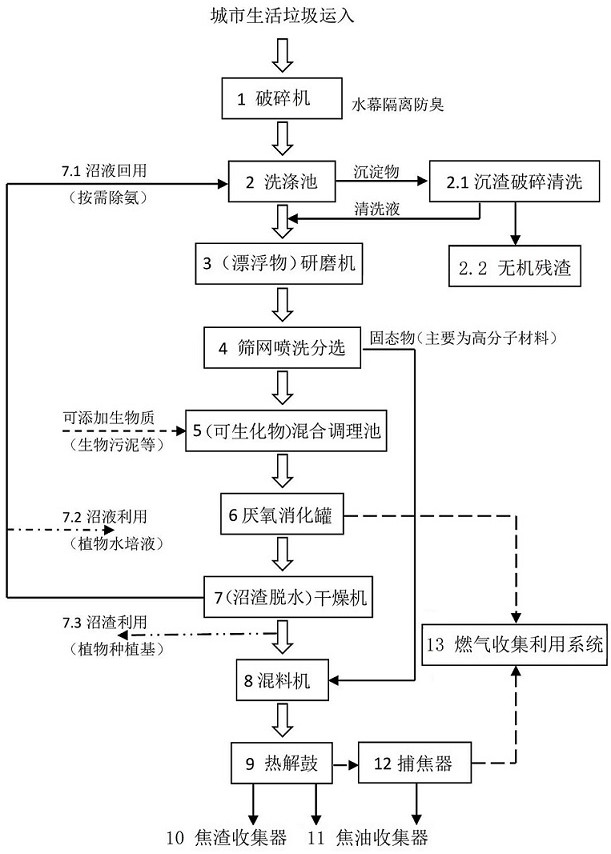

[0035] figure 1 Shown, a wet process treatment method for municipal solid waste is carried out according to the following steps:

[0036] Step 1), crushing, washing and separation

[0037] After the garbage arrives, it is input to the crusher 1. After being crushed, it is sent to the washing pool 2. There is circulating water in the pool. The water circulation method is continuous in and out, or sequence batch in and out. Adjustable; control the flow state of the water in the washing tank 2, so that the garbage can be fully turned and washed in the water, and the soluble pollutants carried by the garbage enter the liquid phase in a dissolved state and fine particles in a suspended state;

[0038] Light solids and insoluble macromolecules are salvaged out of the water as floating objects;

[0039] Step 2), the sediment is crushed, cleaned, and ground

[0040] The components with larger specific gravity settle to the bottom of the washing tank, are collected in the sorter, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com