A biomass pyrolysis co-production gas/biochar production process

A biomass pyrolysis and biomass gas technology, which is applied in the fields of biofuels, petroleum industry, indirect heating and dry distillation, etc., can solve the problems of unstable gasification, poor economic benefits, low calorific value, etc., and achieve simple and reliable production equipment. Advanced technology and good production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

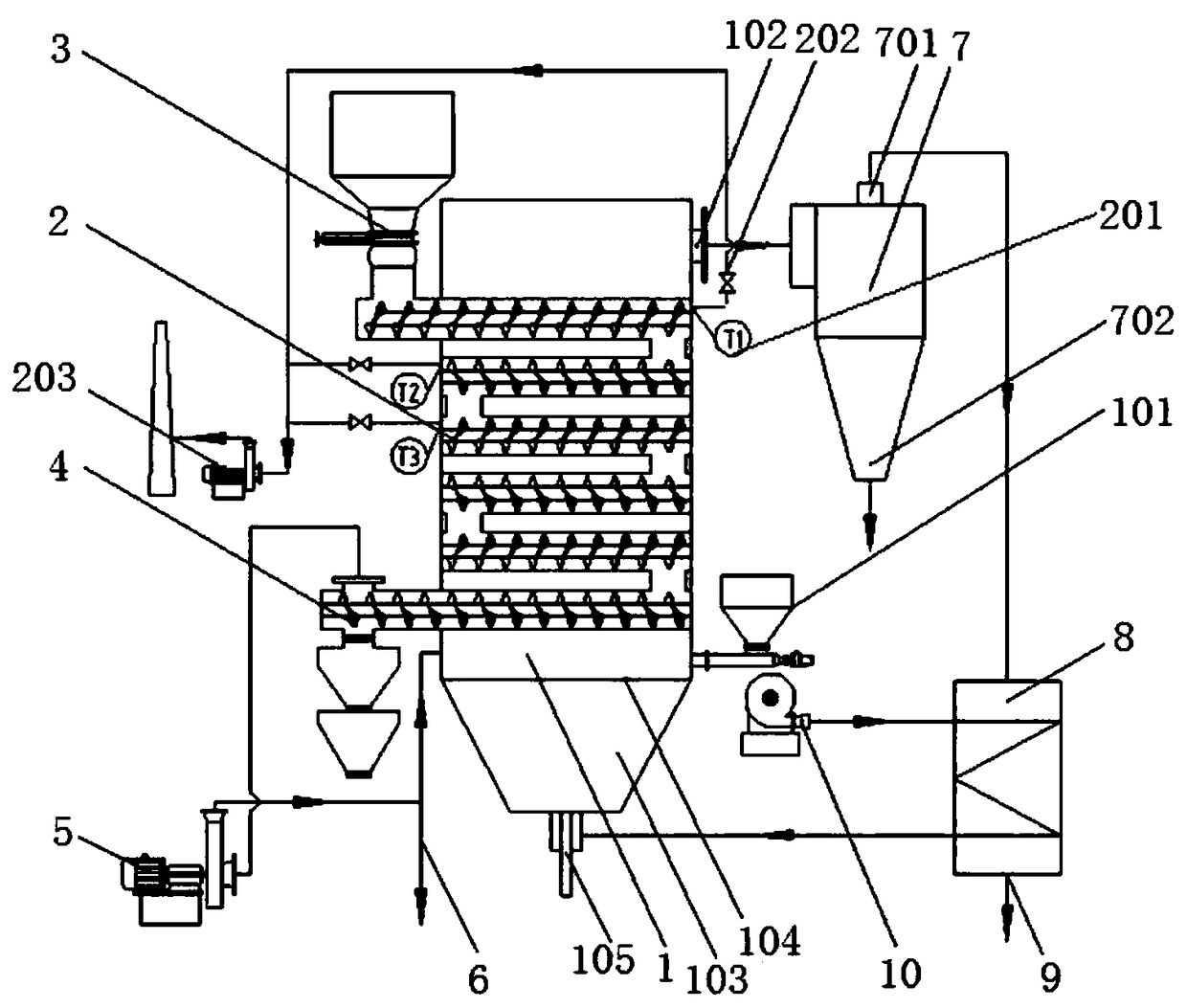

[0027] 25% water content, 3 cm particle diameter wood blocks are fed into the pyrolysis gasification auger 2 through the feeding device 3 . The pyrolysis and gasification auger 2 continuously transports the biomass. After heating, the free water and bound water in the biomass evaporate, and the temperature is measured after passing through the temperature monitor 203 (T1 is 80°C, T2 is 120°C, and T3 is 140°C) Selectively open the regulating valve 202 (T2 post-regulating valve), and discharge the steam through the steam induced draft fan 201 . The biomass raw material continues to be transported through the pyrolysis and gasification auger 2 for pyrolysis and gasification to generate high-temperature biomass gas and biochar. In the pyrolysis gasification auger 2, the raw material is separated by high-temperature biomass gas and biochar through the charcoal gas separation device 4, and the separated biochar is collected. The fixed carbon content of the biochar is 80.7%; the spec...

Embodiment 2

[0029] The rice husks with a water content of 15% and a particle diameter of 2 cm are fed into the pyrolysis and gasification auger 2 through a feeding device 3 . The pyrolysis and gasification auger 2 continuously transports the biomass. After heating, the free water and bound water in the biomass evaporate, and the temperature is measured after passing through the temperature monitor 203 (T1 is 110°C, T2 is 140°C, and T3 is 160°C) Selectively open the regulating valve 202 (open the regulating valve after T1), and discharge the steam through the steam induced draft fan 201. The biomass raw material continues to be transported through the pyrolysis and gasification auger 2 for pyrolysis and gasification to generate high-temperature biomass gas and biochar. In the pyrolysis gasification auger 2, the raw material is separated by high-temperature biomass gas and biochar through the charcoal gas separation device 4, and the separated biochar is collected. The fixed carbon content ...

Embodiment 3

[0031] 33% water content, 8 cm particle size bamboo pieces are fed into the pyrolysis and gasification auger 2 through the feeding device 3 . The pyrolysis and gasification auger 2 continuously transports the biomass. After heating, the free water and bound water in the biomass evaporate, and the temperature is measured after passing through the temperature monitor 203 (T1 is 60°C, T2 is 102°C, and T3 is 120°C) Selectively open the regulating valve 202 (the regulating valve after opening T3), and discharge the steam through the steam induced draft fan 201. The biomass raw material continues to be transported through the pyrolysis and gasification auger 2 for pyrolysis and gasification to generate high-temperature biomass gas and biochar. In the pyrolysis gasification auger 2, the raw material is separated by high-temperature biomass gas and biochar through the charcoal gas separation device 4, and the separated biochar is collected. The fixed carbon content of the biochar is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com