Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Efficient Foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

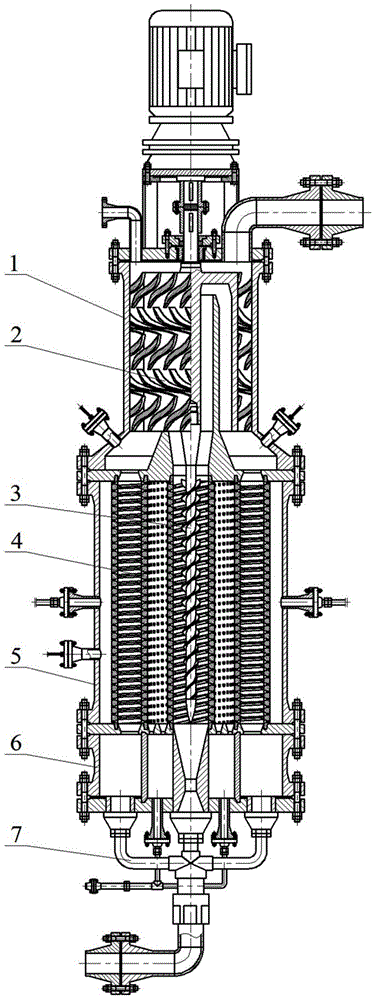

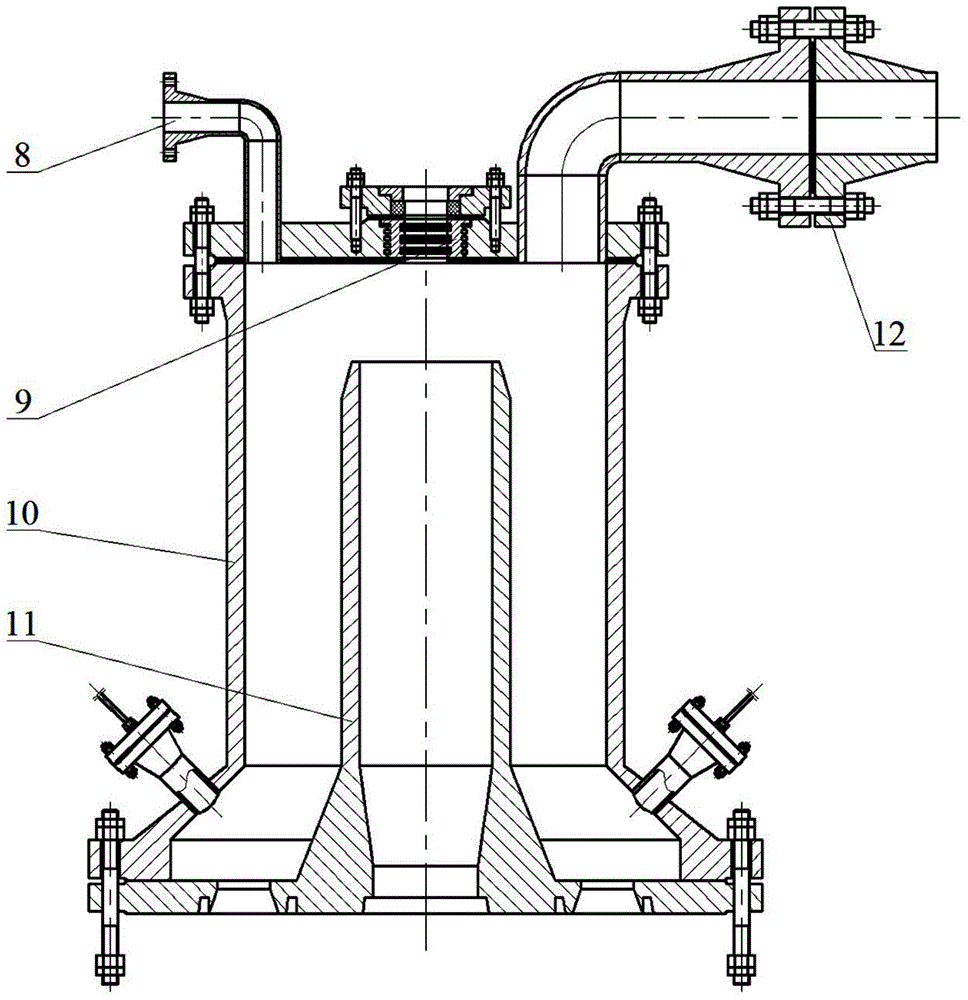

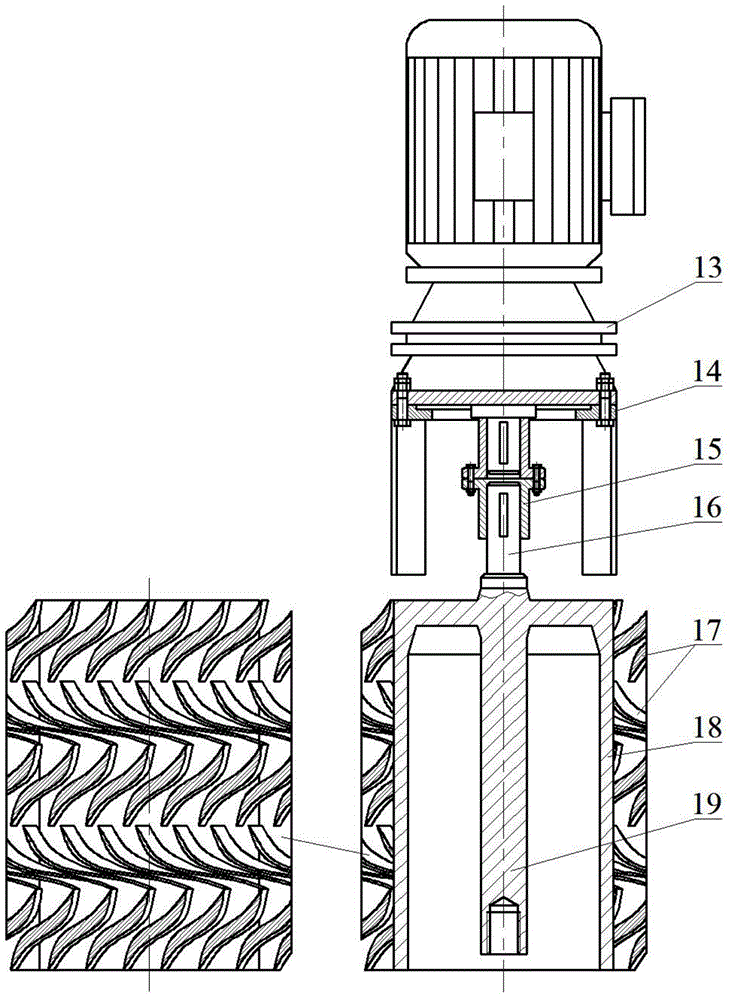

Axial-flow coaxial membrane tube microbubble uniform mixing device

InactiveCN104944495AIncrease the level of mixingIncrease foaming shear areaWater/sewage treatment by flotationCycloneAutomatic control

The invention provides an axial-flow coaxial membrane tube microbubble uniform mixing device which is used for floatation treatment of oily sewage and industrial wastewater. By adopting the coaxial membrane tube / electric-drive multistage-series helical blade special structure, the axial-flow coaxial membrane tube microbubble uniform mixing device implements organic combination of the microporous cyclone foaming and bubble crushing pressurized uniform mixing technique. The membrane tube assembly completes microporous cyclone primary foaming and generates a microbubble-carrying two-phase flow, and the large-diameter membrane tube is combined with the cyclone teeth and high-speed rotating blades, thereby increasing the foaming area of the rotating liquid flow, enhancing the utilization ratio of the floatation gas and implementing the membrane tube inside / outside bidirectional jet high-efficiency foaming. The pressurized uniform mixer completes axial-flow crushing secondary foaming and generates a small-particle-size bubble flow, the multistage-series helical blades shear and crush the bubbles, and the mixing uniformity between the microbubbles and sewage is high, thereby simultaneously implementing the functions of bubble spiral pressurization and self-cooling. The foaming uniform mixing control system remotely and automatically controls the floatation gas flow rate in the gas supply manifold, the sewage flow rate in the liquid supply manifold and the rotating speed of the variable-frequency motor.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

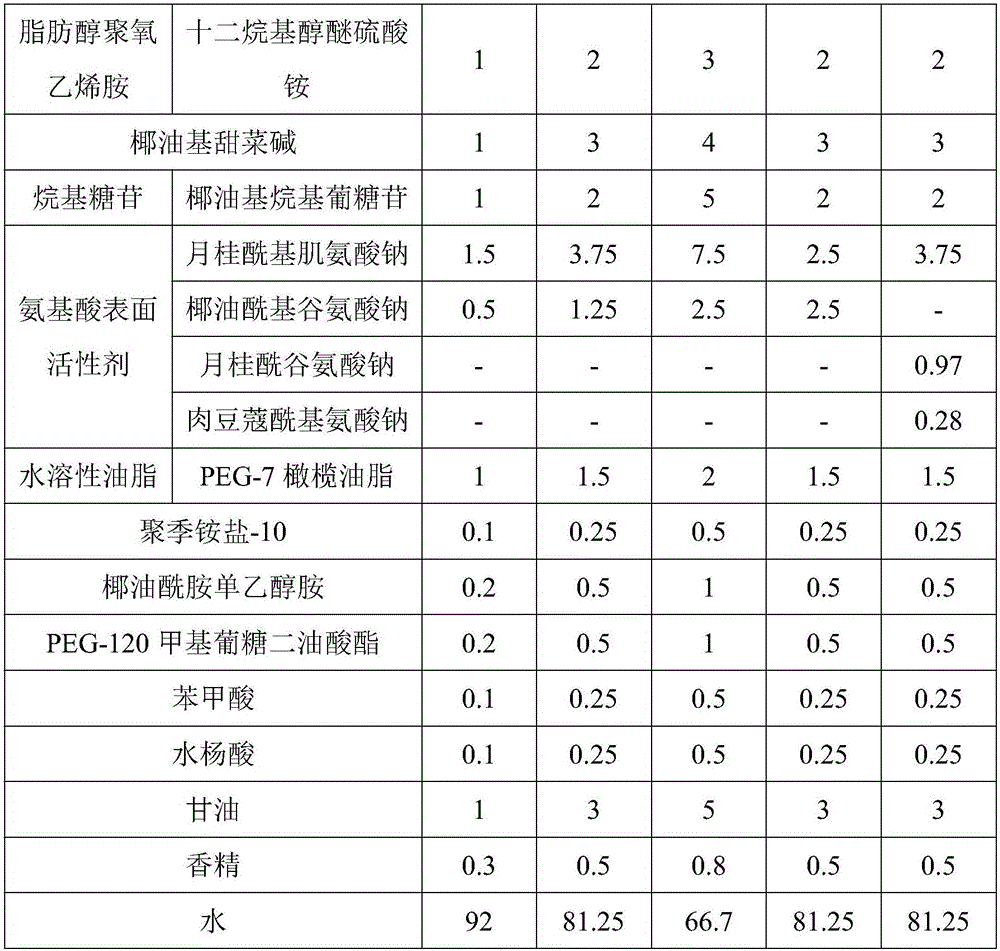

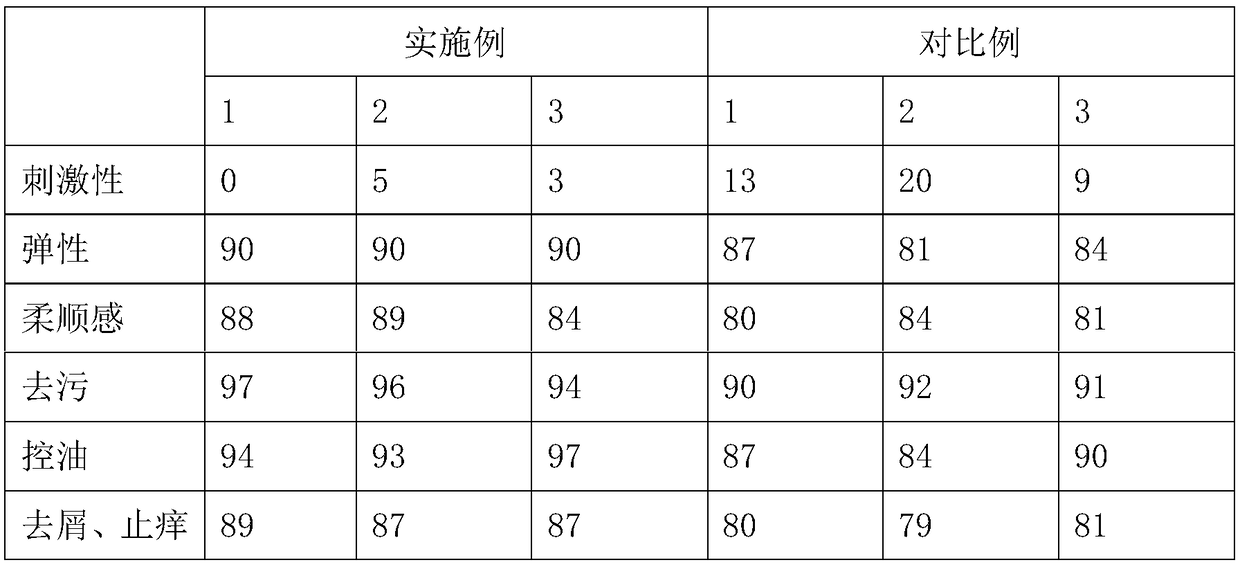

Moderate amino acid shampoo and preparation method thereof

The invention belongs to the field of daily chemical products, and particularly relates to moderate amino acid shampoo and a preparation method thereof. The amino acid shampoo comprises the following components: fatty alcohol polyoxyethylene amine, coco-betaine, alkyl polyglycoside, an amino acid surfactant, water-soluble grease, polyquaternium-10, cocamidopropyl monoethanolamine, PEG-120 methyl glucose dioleate, benzoic acid, salicylic acid, glycerin, essence and water. The amino acid shampoo has high foaming and foam stabilizing performance, moderate cleaning and washing capability and good moisturizing effects; washed hair is bright, smooth, elastic and high in combability; the amino acid shampoo is moderate, nontoxic and non-irritating to skin, comfortable, soft and moist.

Owner:壹田(广州)生活健康用品有限公司

Liquid Cleaning Compositions and Methods of Use and Manaufacture

InactiveUS20100323946A1Efficient FoamingEasy to cleanNon-ionic surface-active compoundsLiquid soapsSulfonateFoaming agent

This invention encompasses a light duty liquid detergent composition that includes a C14-C15 alcohol and alcohol ethoxylate sulfate surfactant blend as an efficient and effective foaming agent. The surfactant-based product may be a hand dishwashing liquid, a liquid skin cleanser or any type of cleaning or cleansing product based on surfactants. Specifically, the invention relates to a light duty liquid detergent composition with desirable cleansing properties and foaming capability including an anionic sulfonate surfactant, an amine oxide, a C14-C15 alcohol, and a C14-C15 alcohol ethoxylate sulfate.

Owner:COLGATE PALMOLIVE CO

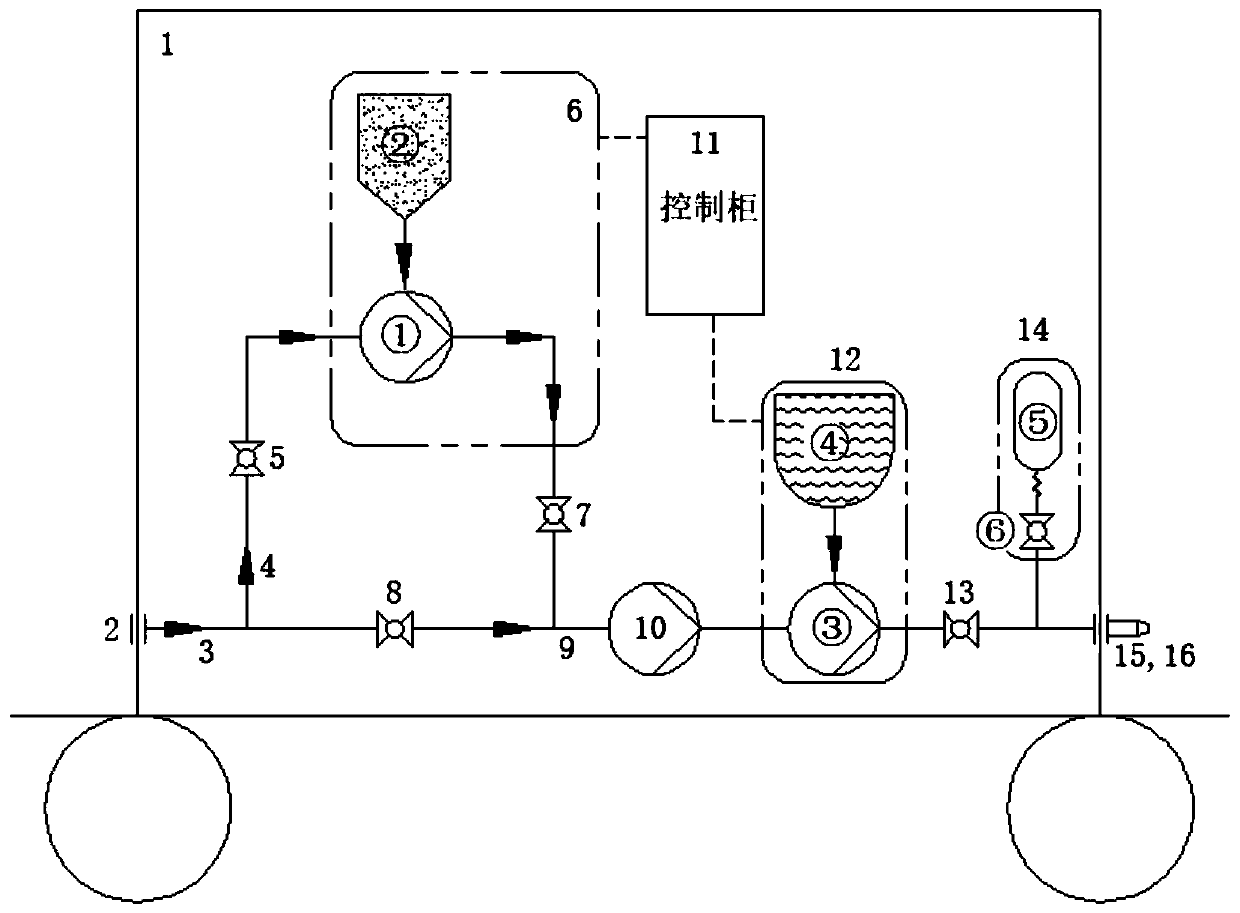

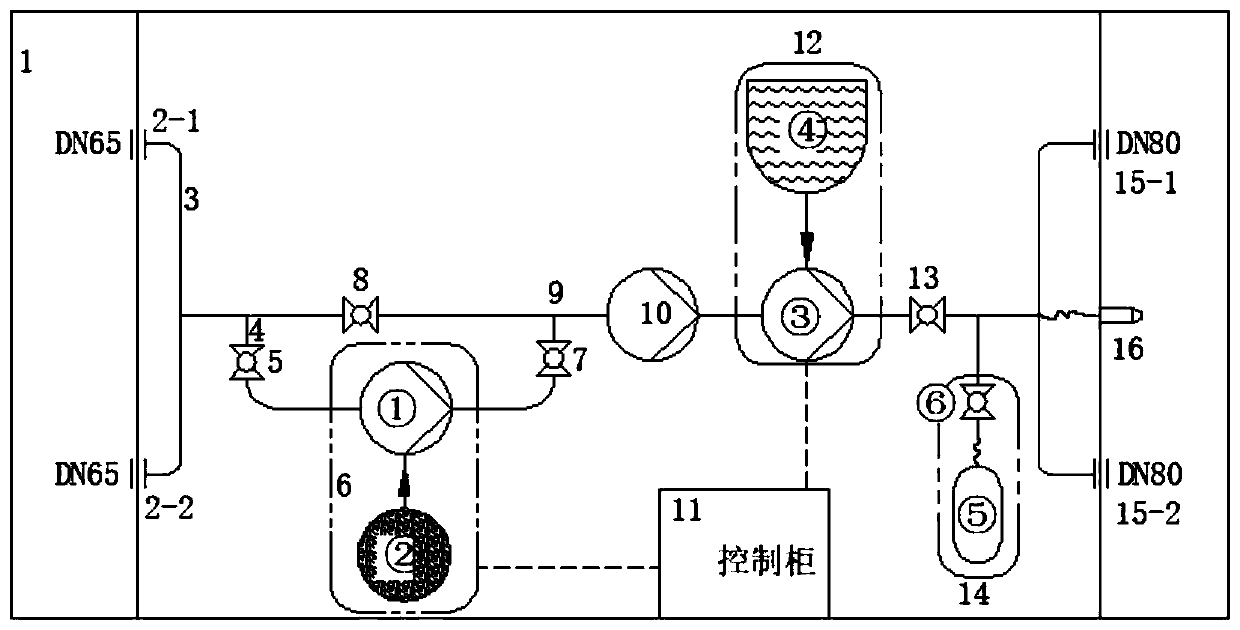

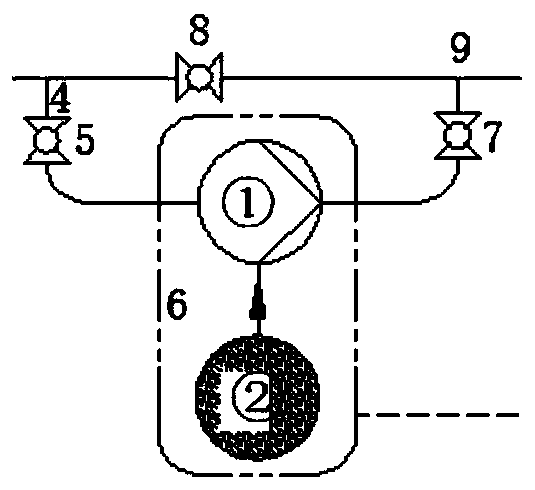

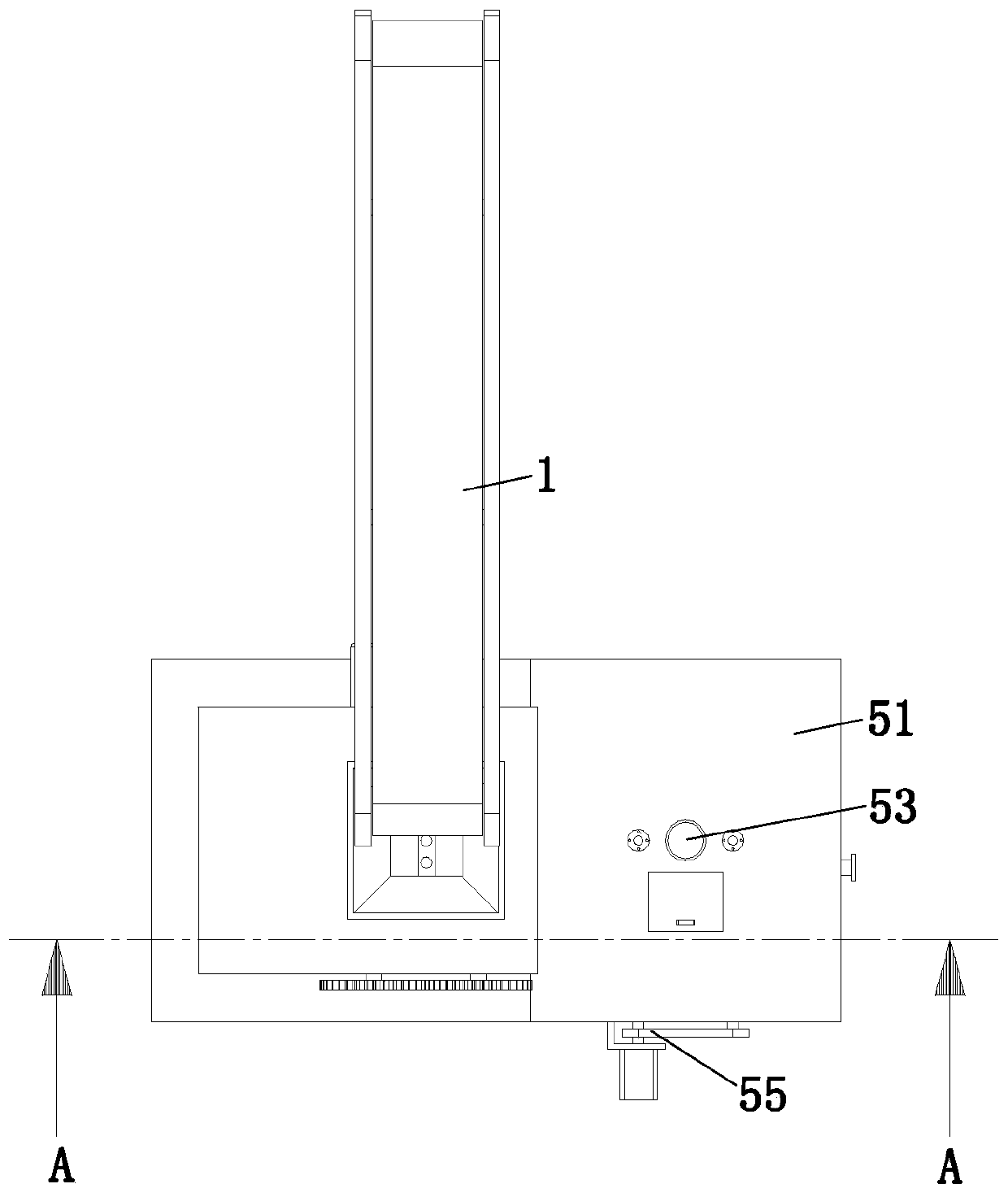

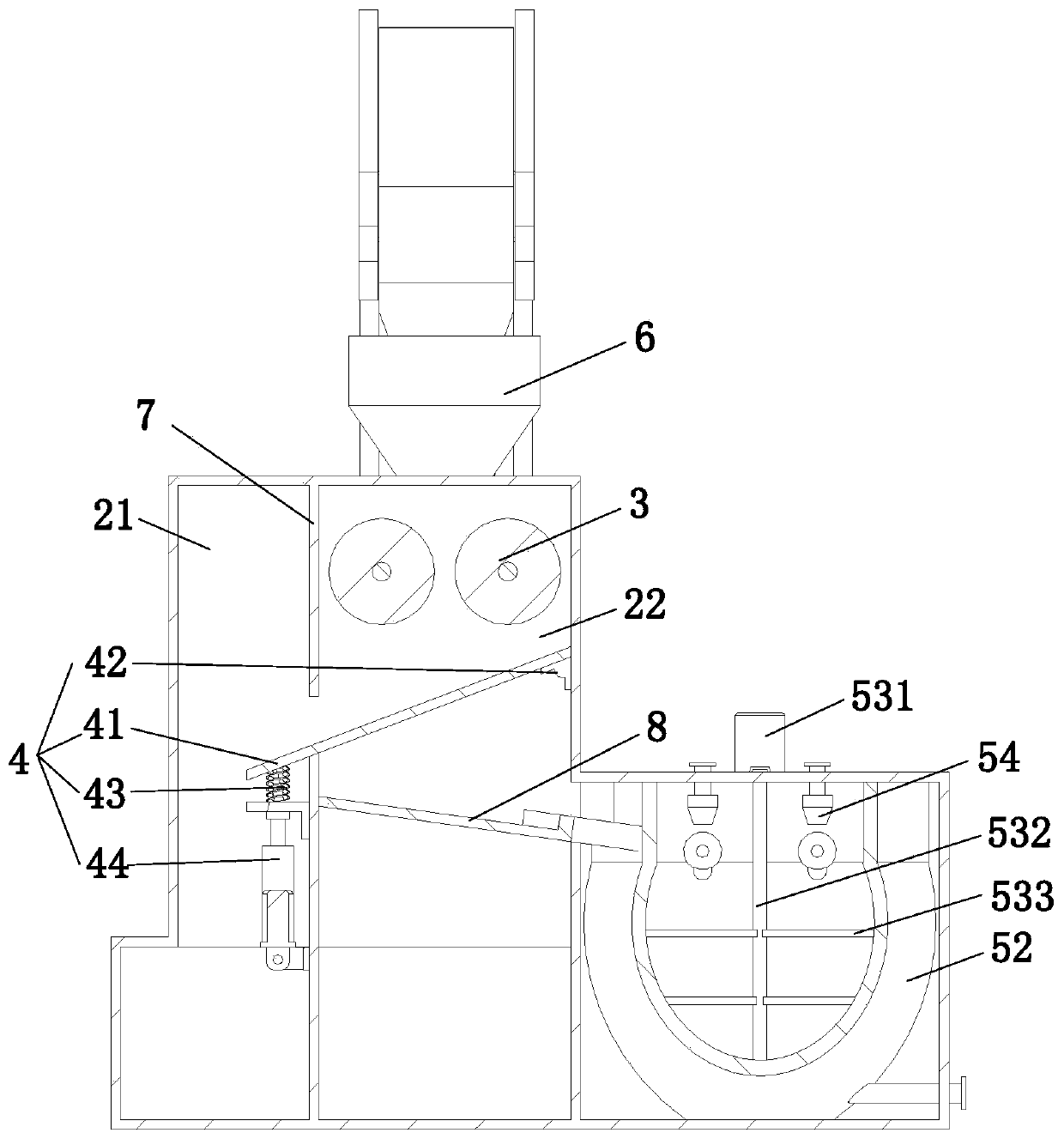

Positive pressure movable type three-phase foam generating device and method

InactiveCN110384883ASolve the problem of organic mixing and foamingEfficient FoamingFire rescuePositive pressureSlurry

The invention relates to the technical field of fire safety, and provides a positive pressure movable type three-phase foam generating device. The positive pressure movable type three-phase foam generating device comprises a skid body trolley, a pressurizing system, a powder adding device, a foam liquid supply system, a positive pressure gas suction type foam jetting system, a foam liquid conveying control valve and a compressed gas source. On the basis of the positive pressure movable type three-phase foam generating device, powder in a powder bin and water injected through a powder adding water feeding pipe from a fire fighting water pipe are mixed under driving of a powder-liquid mixing pump to be prepared into powder slurry, then the powder slurry is injected back to the fire fightingwater pipe, and then is injected into a foam liquid supply system through a powder slurry inlet; the powder slurry (fire fighting water containing particles) and a foam stock solution in a foam stocksolution storage tank are mixed according to the proportion under control of a foam proportion mixer to prepare a foam liquid; and a foam liquid conveying control valve conveys the foam liquid mixed with particles into a foam generator to be mixed with high-pressure gas from the compressed gas source for foaming, and the generated foam is sprayed out by a foam injection cannon for fire extinguishing.

Owner:CHINA PETROLEUM & CHEM CORP +1

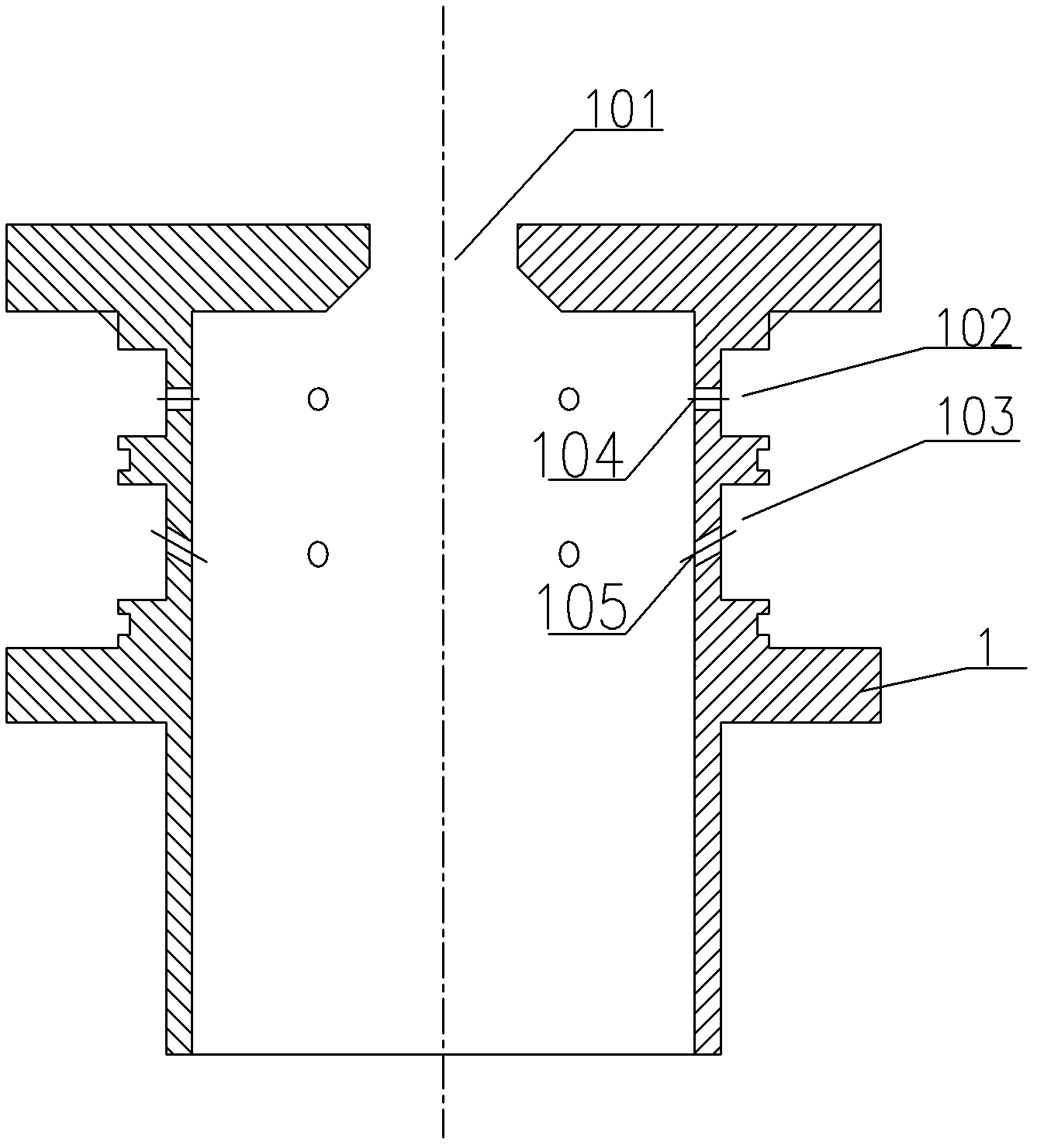

High-molecular material foaming device and application method thereof

The invention discloses a high-molecular material foaming device. The high-molecular material foaming device mainly comprises a foaming mold and a high-frequency electric source, wherein the foaming mold comprises an upper mold and a lower mold, insulated spacers are arranged between the upper mold and the lower mold at intervals, after the high-frequency electric source is powered on, a high-frequency oscillation electric field is generated between the upper mold and the lower mold, in the high-frequency oscillation electric field, polar molecules and / or functional groups inside a to-be-foamed base metal can incessantly switch directions along with the high-frequency oscillation electric field to collide with each other, mutual friction generates heat so as to enable the temperature of the to-be-foamed base metal in a mold chamber to rise, a foaming agent can be heated and decomposed to generate gas, the foaming material expands to fill the whole mold chamber so as to realize foamingof the foaming material. By adopting the foaming device, the rapid, efficient and uniform foaming of a high-molecular material can be realized. The high-molecular material foaming device has a broad application prospect in the material foaming field.

Owner:QUANZHOU NORMAL UNIV

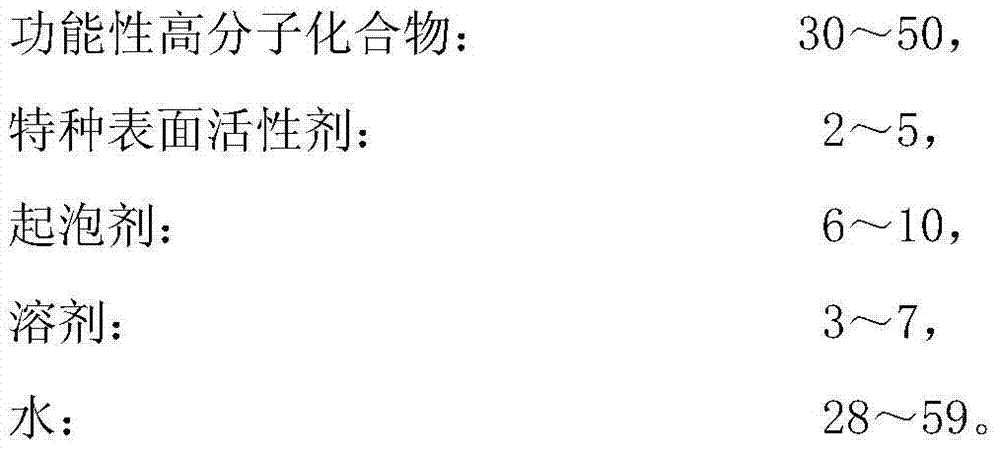

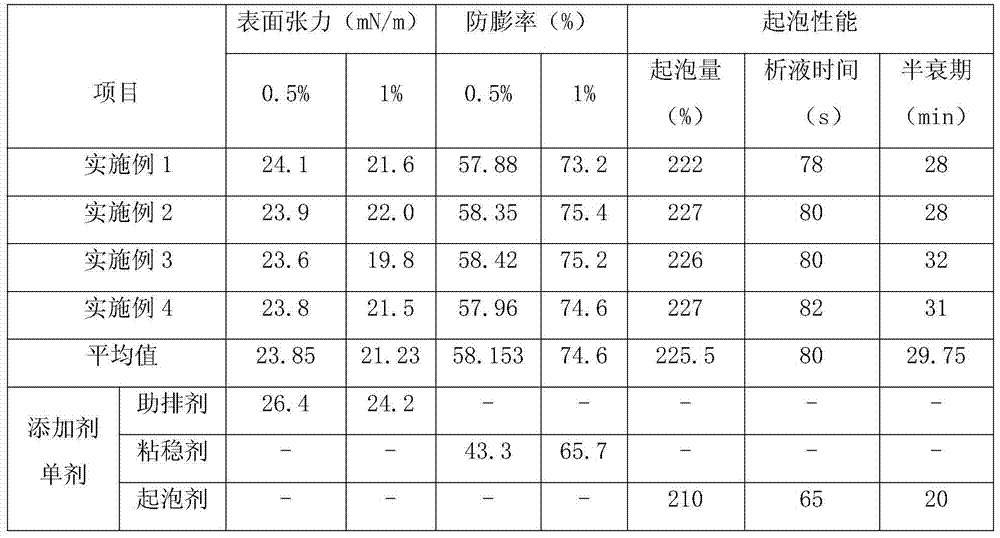

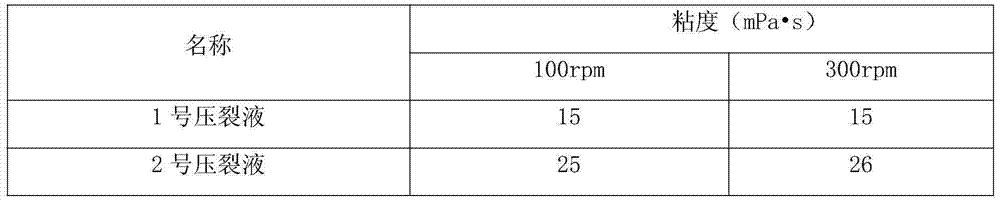

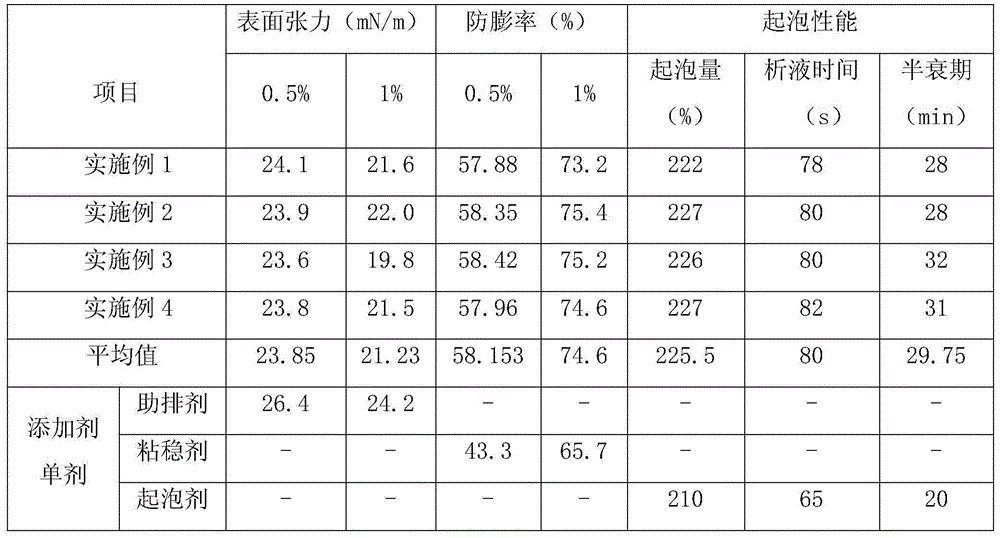

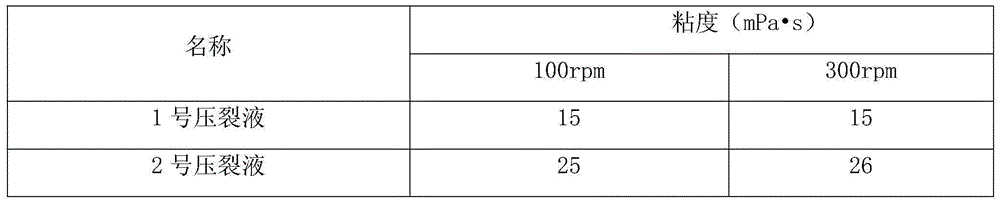

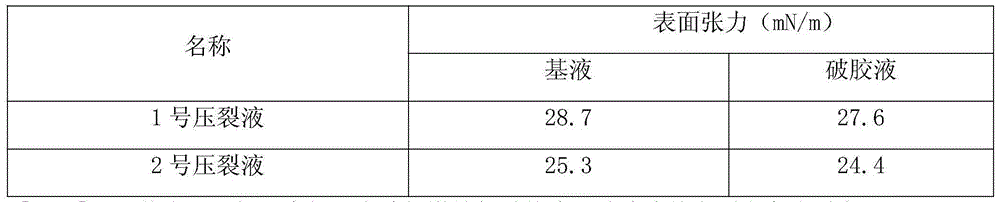

Multifunctional synergist for acidizing and fracturing as well as preparation method thereof

ActiveCN103666441AImprove wettabilityGood shape of broken gel residueDrilling compositionFoaming agentFracturing fluid

The invention discloses a multifunctional synergist for acidizing and fracturing. The multifunctional synergist comprises raw materials in pars by weight as follows: 30-50 parts of a functional macromolecular compound, 2-5 parts of a special surfactant, 6-10 parts of a foaming agent, 3-7 parts of a solvent and 28-59 parts of water. A preparation method of the multifunctional synergist for acidizing and fracturing comprises the steps of preparation of the functional macromolecular compound, weighing and mixing. According to the multifunctional synergist for acidizing and fracturing, the performance of additives in acid liquor and fracturing fluid is regulated, so that the compatibility of the additives is strengthened, the fracturing liquid is better in rheological property, wettability and gel-breaking residue form, and the damage of the fracturing liquid is reduced; the synergist has good functions of sterilization, discharge assistance, foaming and clay swelling prevention; the preparation method for the multifunctional synergist for acidizing and fracturing has the advantages of simplicity in preparation, convenience in preparation, low cost and the like.

Owner:四川省博仁达石油科技有限公司

Concrete synergist

The invention relates to the technical field of concrete admixtures, in particular to a concrete synergist, comprising 40-80 parts of triisopropanolamine, 5-15 parts of sodium lignosulfonate, 1-10 parts of tea saponin, and sugar factory waste liquor 1 to 5 parts, 0.2 to 1.8 parts of ethyl acetate, and 0.1 to 0.9 parts of redispersible latex powder. The concrete synergist of the invention can improve the strength of the concrete, make the cement fully hydrated, and save the cement consumption.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

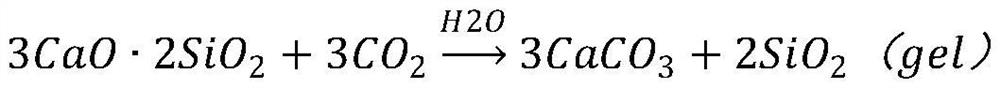

Cement kiln tail gas carbonization non-autoclaved aerated concrete wall material product and preparation method thereof

ActiveCN113956070AQuick buildGood mechanical propertiesSolid waste managementCeramicwareFoaming agentPortland cement

The invention relates to a cement kiln tail gas carbonized non-autoclaved aerated concrete wall material product and a preparation method thereof. The concrete wall material product comprises the following components: 30-50 parts of carbonized active cement, 1-5 parts of a reinforcing material, 5-10 parts of lime, 5-10 parts of Portland cement, 20-60 parts of concrete aggregate tailing powder, 30-50 parts of water, 0.2-2 parts of a water reducing agent, 0.1-2 parts of a foaming agent and 0.02-0.5 part of a foam stabilizer. The preparation method comprises the following steps: uniformly stirring the components or directly adding the components into slurry and uniformly stirring; molding the stirred slurry, demolding, and curing at 50-60 DEG C for 4-8 hours; and feeding the mixture into a carbonization curing kettle filled with cement kiln tail gas, curing for 8-24 hours under the conditions that the temperature is 10-50 DEG C, the relative humidity is 50-100%, the CO2 volume concentration is 15-30% and the pressure is 2-4 atmospheric pressure, and then curing for 3-14 days under the natural conditions that the temperature is 10-30 DEG C and the relative humidity is 50-90%. The non-autoclaved aerated concrete carbonized through the cement kiln tail gas absorbs a large amount of CO2, does not need autoclaved curing, is fast in strength development and low in water absorption rate, and has good heat preservation, heat insulation, sound insulation and fireproof performance.

Owner:HUAXIN CEMENT

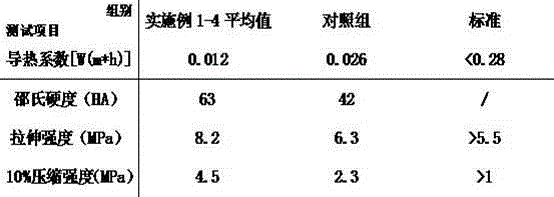

High-hardness impact-resisting heat-insulation foaling plastic

The invention discloses high-hardness impact-resisting heat-insulation foaling plastic. The high-hardness impact-resisting heat-insulation foaling plastic is prepared from, by weight, 20-25 parts of polystyrene resin, 40-55 parts of polyurethane resin, 20-25 parts of phenolic resin, 10-15 parts of urea formaldehyde resin, 4-7 parts of diethylaminopropylamine DEAPA, 2-5 parts of azobisformamide AC, 0.9-1.2 parts of polydimethylsiloxane-polyoxyalkylene copolymer, 1-4 parts of talcum powder, 0.3-0.6 part of quartz powder, 1.4-1.7 parts of hollow microspheres, 1-4 parts of bentonite, 20-25 parts of diatomite, 10-13 parts of calcium carbonate, 5-8 parts of polyethylene-octene copolymer elastomer and 12-16 parts of glass fiber, wherein the polydimethylsiloxane-polyoxyalkylene copolymer is obtained by polydimethylsiloxane and polyoxyalkylene through blending modification, and the polyethylene-octene copolymer elastomer is obtained by polyethylene and octene through blending modification. Air bubbles in the high-hardness impact-resisting heat-insulation foaling plastic are even, the heat conductivity coefficient is reduced, the heat-insulation performance is improved, and the hardness and impact resistance are further greatly improved.

Owner:ZIBO KUAKE MEDICINE TECH

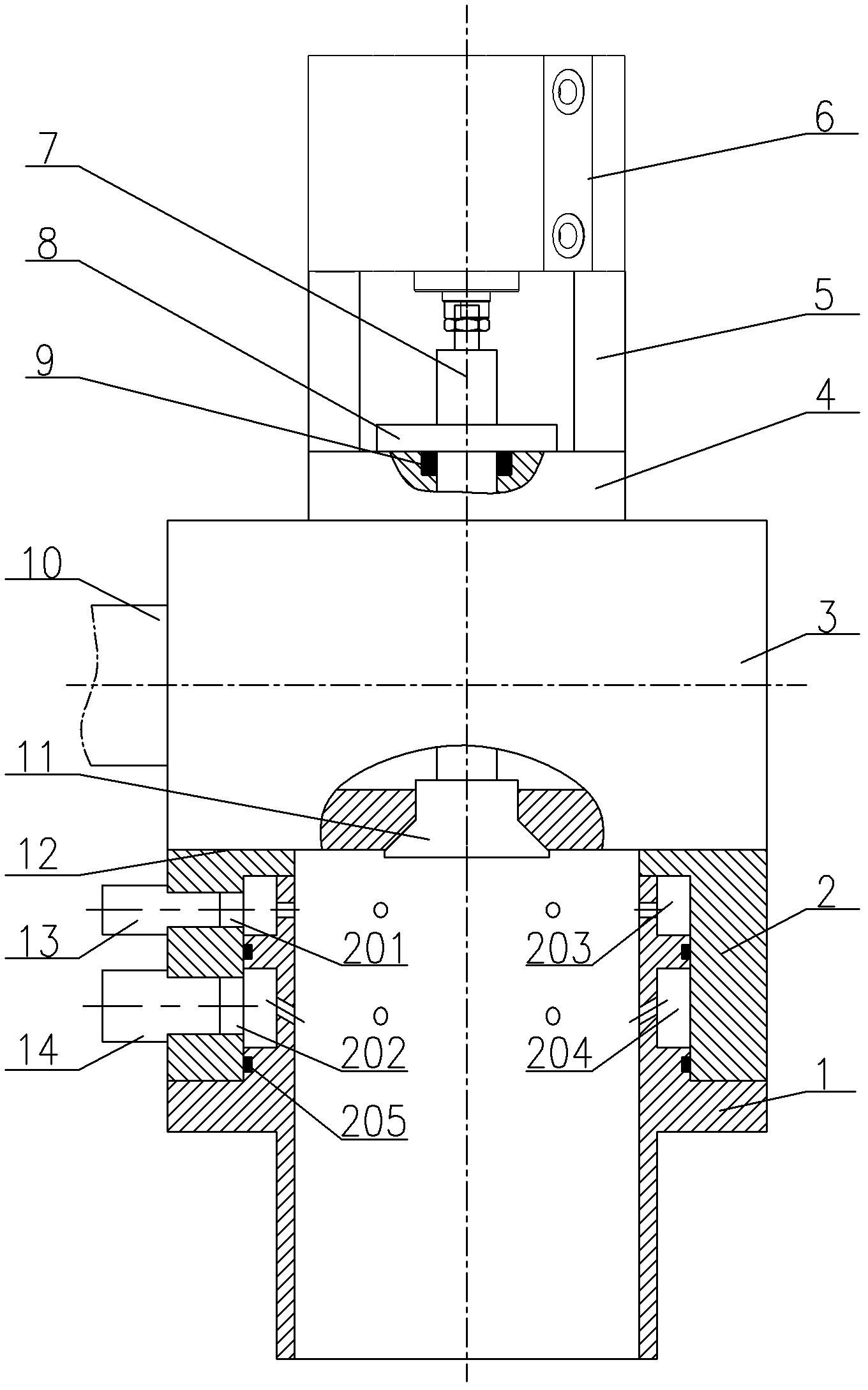

Foaming device for foamed asphalt

ActiveCN102505610AEfficient foamingQuality improvementSpray nozzlesRoads maintainenceSpray nozzleAsphalt

A foaming device for foamed asphalt comprises a foaming nozzle, a water nozzle, an air nozzle, an asphalt pipe, and an asphalt on-off control mechanism, wherein the water nozzle and the air nozzle are communicated with the foaming nozzle; an asphalt spout communicated with the asphalt pipe is formed on the foaming nozzle; and the asphalt on-off control mechanism is used for controlling whether the asphalt spout is communicated with the foaming nozzle or not. The foaming device is characterized in that two sealed ring-shaped cavities taking the foaming nozzle as a center are formed on the outer wall of the foaming spray nozzle in parallel; a spout communicated with the foaming nozzle cavity of the foaming nozzle is formed on the side wall of each ring-shaped cavity; the sealed ring-shaped cavities are in sealed connection with the water nozzle and the air nozzle respectively, and both arranged below the asphalt spout; and the ring-shaped cavity, which is nearer to the asphalt spout, is connected with the water nozzle. Through the adoption of the foaming device, high-temperature liquid asphalt is in full contact with water and compressed air, so as to improve the quality of the foaming of asphalt, and ensure the efficient foaming of the asphalt; and the problems of scaling and blockage of the asphalt spout are effectively solved.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Heat-resisting high-toughness polystyrene resin foaming plastic

The invention discloses heat-resisting high-toughness polystyrene resin foaming plastic. The heat-resisting high-toughness polystyrene resin foaming plastic is prepared from, by weight, 40-55 parts of polystyrene resin, 2-3.5 parts of potassium titanate fibers, 11-16 parts of coconut fiber, 2-6 parts of polytetrafluoroethylene, 1-1.5 parts of 3,5-tert-butyl-4-hydroxy phenyl, 15-20 parts of talcum powder, 6-11 parts of silicon carbide powder, 4-13 parts of kaolin, 1.2-1.8 parts of bis(2-ethylhexyl) phthalate, 1.1-1.6 parts of zinc stearate, 1-1.5 parts of butyl p-hydroxybenzoate and 2-5 parts of foaming agents. The heat-resisting high-toughness polystyrene resin foaming plastic has the good heat-insulating property and the good strength and toughness, and the impact-resisting property of the plastic is improved.

Owner:ZIBO KUAKE MEDICINE TECH

Quinoa shampoo and preparation method thereof

The invention discloses quinoa shampoo and a preparation method thereof. The quinoa shampoo contains the following components in percentage by weight: 3%-7% of a quinoa extracting solution A, 4%-6% ofa quinoa extracting solution B, 2%-5% of a quinoa extracting solution C, 5%-10% of an anionic surfactant, 1%-10% of a zwitterionic surfactant, 0.5%-3% of a nonionic surfactant, 0.02%-0.1% of a chelating agent, 0.1%-0.3% of a pH regulator, 0.5%-3% of an esterification agent, 0.1%-0.5% of a cationic conditioning agent, 0.1%-3% of a scalp conditioning agent, 0.1%-1% of a preservative and the balanceof deionized water, wherein the pH value of the quinoa shampoo is 6.9-7.1. According to the preparation method, the quinoa shampoo is prepared from the components in a specific preparation sequence and process. A surfactant which is widely applied to shampoos at present is replaced with the quinoa extracting solutions, so that the quinoa shampoo has excellent foaming capacity and cleaning capacity, the overall simulation of the shampoo is reduced due to the affinity with the skin, and the shampoo is capable of killing bacteria, relieving itching, removing dandruff and controlling the secretion of grease. The quinoa extracting solutions can be used for preparing hairdressing care products such as a hair moistening cream and a hair conditioner, and the elasticity, tenacity, luster and smoothness of the hair can be improved.

Owner:广东博然堂生物科技有限公司

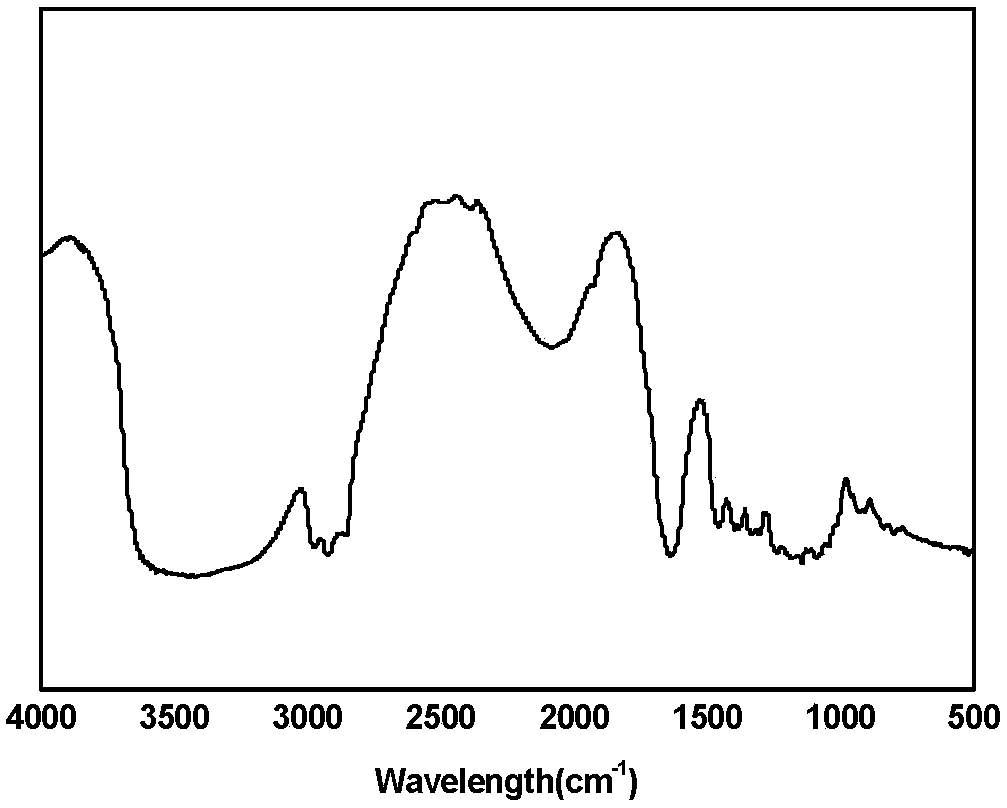

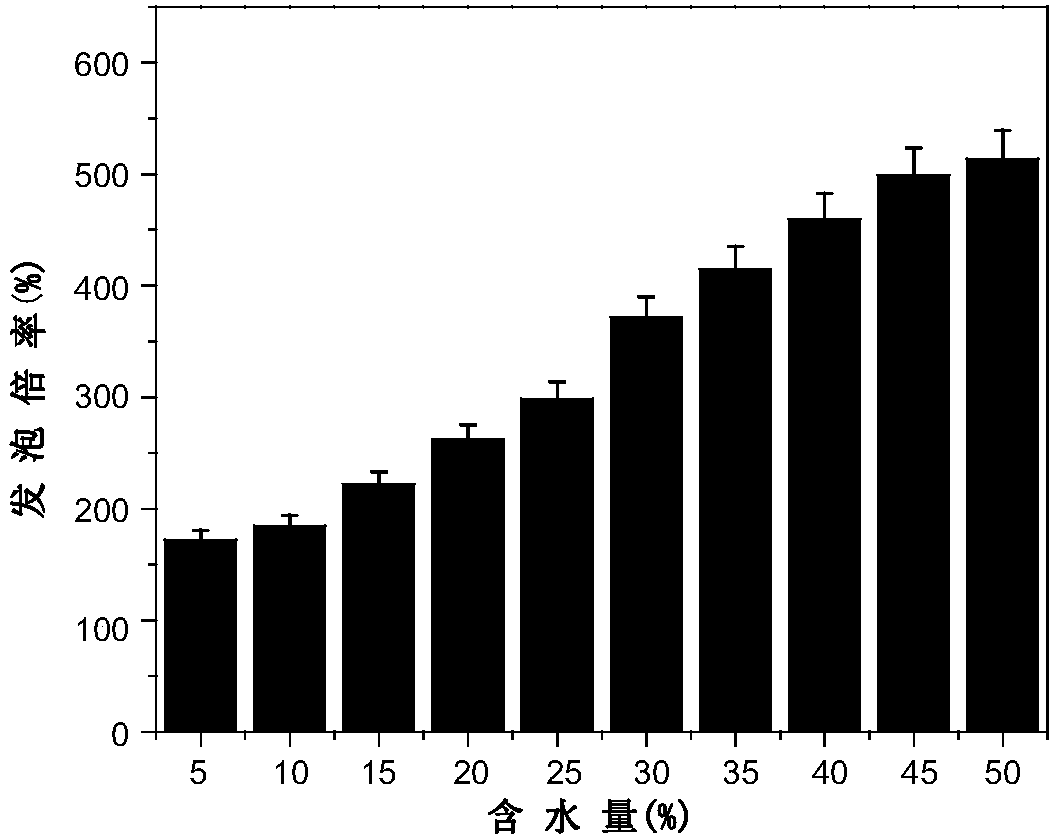

Structural polymer foam stabilizer for foam fracturing and method for preparing structural polymer foam stabilizer

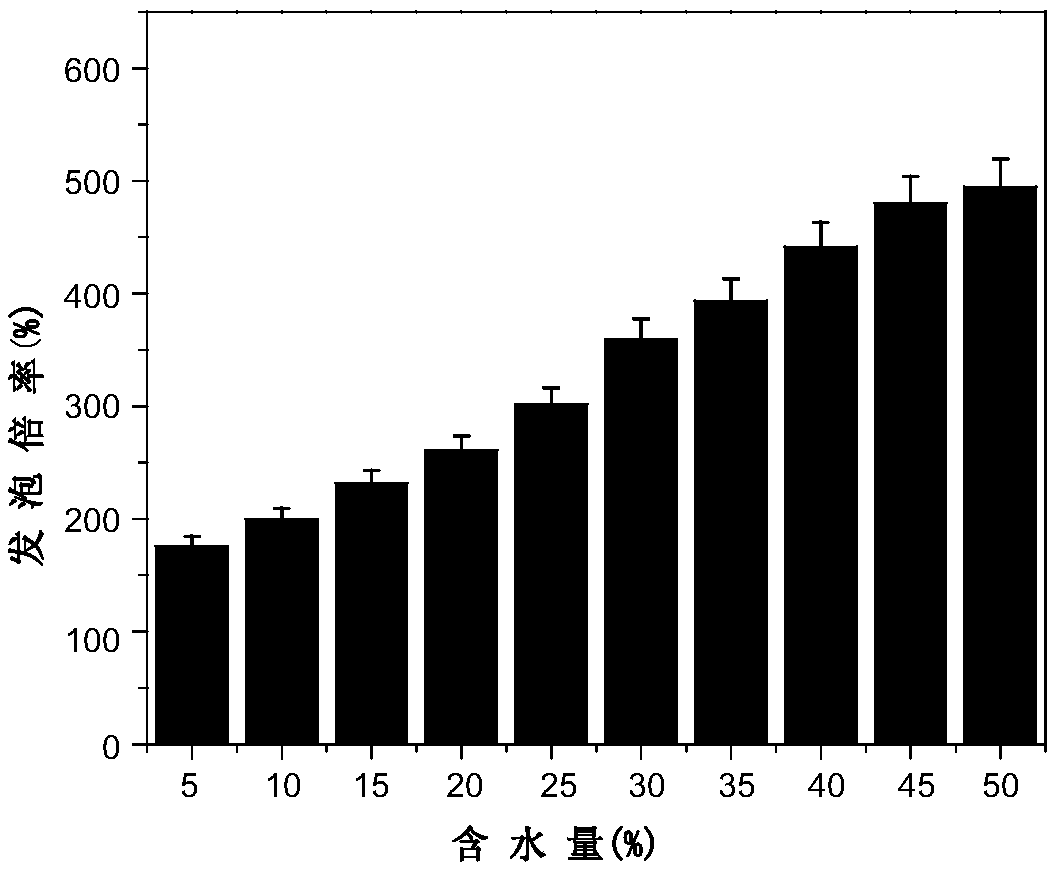

ActiveCN106928957AReduce drainageReduce gas diffusionDrilling compositionCarrying capacityPolymer science

The invention provides a structural polymer foam stabilizer for foam fracturing and a method for preparing the structural polymer foam stabilizer. The structural polymer foam stabilizer is characterized in that the foaming ratio of aqueous solution with 0.3 wt% of structural polymer foam stabilizer is higher than or equal to 600%, and the half life of the aqueous solution is longer than or equal to 12 h. The method includes steps of carrying out multilevel initiation polymerization on deionized water, solubilizers, water-soluble monomers with ethylene groups, structural monomers, anionic surface-active monomers, anionic surfactants, oxidation-reduction system initiators and azo-initiators to obtain polymerization products; heating the polymerization products until the temperatures of the polymerization products reach 80-95 DEG C and carrying out heat reaction for 8-24 h to allow the molecular weights of obtained polymers to be 2000-4000 thousands so as to obtain the structural polymer foam stabilizer. The structural polymer foam stabilizer and the method have the advantages that the structural polymer foam stabilizer is excellent in foam stabilization performance and efficient in foaming performance, high in sand carrying capacity and operability and low in cost and is temperature-resistant and shear-resistant, and excellent solubilization synergistic effects can be realized.

Owner:北京爱普聚合科技有限公司

Novel composite cake foaming emulsifier and manufacture method thereof

InactiveCN104012592ARich sourcesStrong volumeDough treatmentBakery productsFood additiveLiquid layer

The present invention relates to the technical field of food additives, in particular to a novel composite cake foaming emulsifier and a manufacture method thereof. The novel composite cake foaming emulsifier comprises the following raw materials in percentage by weight: 15%-25% of rice syrup, 40%-50% of water, 20%-30% of polyglyceryl fatty ester, 3%-7% of tween-80, and 3%-7% of monostearin. The manufacture method comprises the following steps: respectively weighting the above raw materials according to the above proportion; heating, stirring and mixing the raw materials; adding the mixture into a high-shear emulsification mochine and subjecting the mixture to comprehensive effects such as strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impingement tear and turbulence in narrow clearances of stators and rotors through powerful kinetic energy brought by high tangential line speed and high frequency mechanical effect which are generated by high speed rotation of the rotors, so that two phases or multiple phases of the raw materials which repel each other or are poorly soluble can be quickly, uniformly and finely dispersed, emulsified and dissolved, and finally the high-quality and stable composite cake foaming emulsifier can be obtained.

Owner:ANHUI DANYAN FOOD

Process for producing graft copolymer latex

There is provided a process for producing a copolymer latex obtained by graft-polymerizing a rubber latex and a graft-polymerizable monomer without decreasing productivity. In case of removing non-reacted monomer from a rubber latex before graft polymerization, non-reacted monomer is removed in a short time by adding an electrolyte to control foaming of a rubber latex, and a graft copolymer latex is prepared without decreasing productivity.

Owner:KANEKA CORP

Cleaner for tempered glass and preparation method of cleaner

InactiveCN107057881AWon't hurtEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlcoholEther

The invention discloses a cleaner for tempered glass and belongs to the technical field of the tempered glass. The cleaner is prepared from, by weight, 30-50 parts of ethyl alcohol, 15-20 parts of isopropanol, 12-15 parts of ethanediol, 1-3 parts of epoxidized soybean oil, 4-6 parts of essence, 5-8 parts of antifreezing agent, 0.1-0.5 part of corrosion inhibitor, 0.2-1.5 parts of surfactant and 70-80 parts of water. The surfactant is prepared from dimethylododecylamine oxide, ethylene glycol butyl ether, alkylolamide and Turkey red oil, and the weight ratio of dimethylododecylamine oxide to ethylene glycol butyl ether to alkylolamide to Turkey red oil is 2.5:1:1:1.5. The invention further discloses a preparation method of the cleaner for the tempered glass. Preparation is simple, the antifreezing capacity is high, dirt on the tempered glass can be effectively removed, and no damage is caused to the glass.

Owner:合肥钢骨玻璃制品有限公司

Tri-perfluor decyl silicon-polyethyoxyl-naphthalenesulfonic acid sodium multielement compound as well as preparation method and application thereof

InactiveCN108558929AAchieving FoamingFine foamSilicon organic compoundsFluid removalWaxEthylene oxide

The invention discloses a tri-perfluor decyl silicon-polyethyoxyl-naphthalenesulfonic acid sodium multielement compound as well as a preparation method and application thereof. The multielement compound is prepared from perfluor decane, trifluoroalkyl silane, ethylene oxide and p-croceic acid through compounding. The preparation method comprises the following steps: mixing the perfluor decane andthe trifluoroalkyl silane, acidifying, heating to 150-170 DEG C, adding ethylene oxide, further adding p-croceic acid after reactions, and finally adjusting the pH value to 8-9.5, thereby obtaining the multielement compound. The multielement compound disclosed by the invention is applied to oil fields to carry out foam oil expelling. The multielement compound disclosed by the invention is not onlycapable of generating foams efficiently, but also good in foam stabilization effect, has no spectrum separation in stratum migration, particularly has a good foam oil expelling effect on high oil content (the oil content is 80-95%) and high wax foam systems, and meanwhile is simple in preparation method, high in operability and low in cost.

Owner:NANJING NORMAL UNIVERSITY

Natural plant type body wash and preparation method thereof

InactiveCN103690400ANatural health goodGood beauty effectCosmetic preparationsToilet preparationsEnvironmental resistanceSucrose

The invention relates to natural plant type body wash and a preparation method thereof. The body wash is formed by mixing the following components in parts by weight: 70-90 parts of limonene, 1-3 parts of olive oil and multiple environment-friendly nonirritant surfactants according to a ratio of 1:(3-5). The surfactants are prepared from mixed two or three of coconut diethanolamide, sucrose fatty acid ester, alkyl glycoside, fatty acid methyl ester sulfonate, rhamnolipid and octadecyl dimethyl ammonium chloride. The body wash can be prepared by uniformly mixing the main components and the surfactants by using a stirring machine in the stirring speed of 1,000r / min to 2,000r / min, subsequently standing for 60-120 minutes, adding water to emulsify according to a ratio of 1:(1.5-3.0), and uniformly mixing up at normal temperature. The body wash is simple in process, convenient to operate and undemanding in preparation condition, energy consumption can be effectively reduced, beneficial conditions can be provided for production, and the raw materials adopted by the body wash are all recyclable resources with good biodegradability, good stability, nonirritant for skin and excellent effects such as decontamination and sterilization.

Owner:TIANJIN LIUHONG TECH DEV

Cubic silicon carbide anticorrosive wear-resistant coating and preparation method thereof

InactiveCN111040576AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsCubic silicon carbideCarbide silicon

The invention discloses a cubic silicon carbide anticorrosive wear-resistant coating. The cubic silicon carbide anticorrosive wear-resistant coating is prepared from the following raw materials in parts by mass: 40-60 parts of water-based resin, 10-20 parts of deionized water, 10-20 parts of titanium dioxide, 2-6 parts of cubic silicon carbide micro-powder, 5-10 parts of a filler, 0.1-0.5 part ofa defoaming agent, 0.1-0.5 part of a wetting agent, 0.05-0.2 part of a thickening agent and 0.2-0.6 part of a water-based drier. The invention also discloses a preparation method of the cubic siliconcarbide anticorrosive wear-resistant coating. The preparation method comprises the following steps: preparing a mixture by a step-by-step method, adding deionized water and assistants, and carrying out dispersing and filtering to obtain the coating. According to the coating, the water-based resin is used as a film-forming substance, so a curing agent is not required to be added, and the corrosionresistance and wear resistance of the coating are improved; the method provided by the invention is beneficial for full and uniform mixing of the components, ensures full play of the effects of the assistants, and does not need heating in the preparation process; and the coating can be used without blending, so the application range of the coating is enlarged.

Owner:XIAN BOER NEW MATERIAL CO LTD

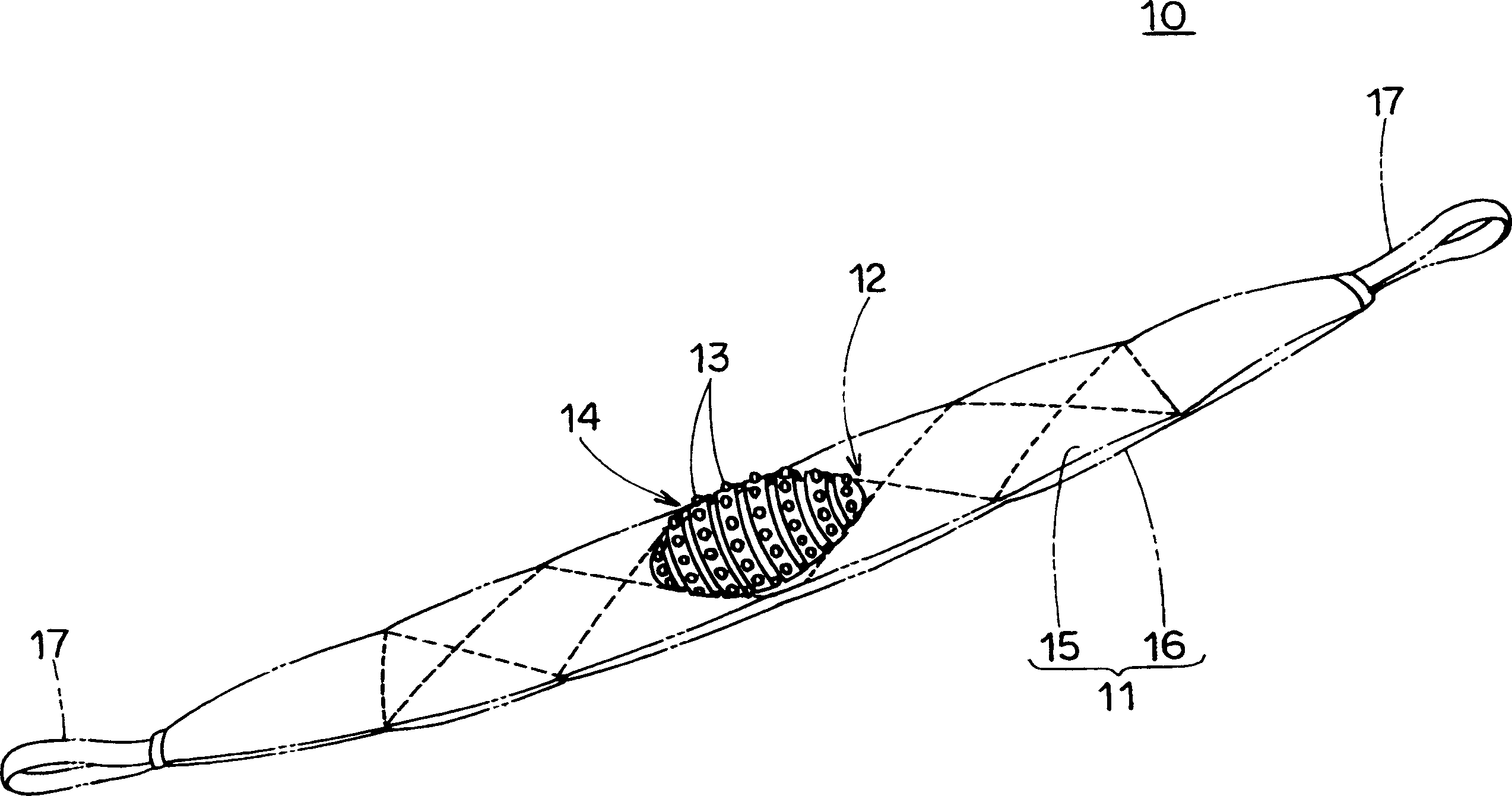

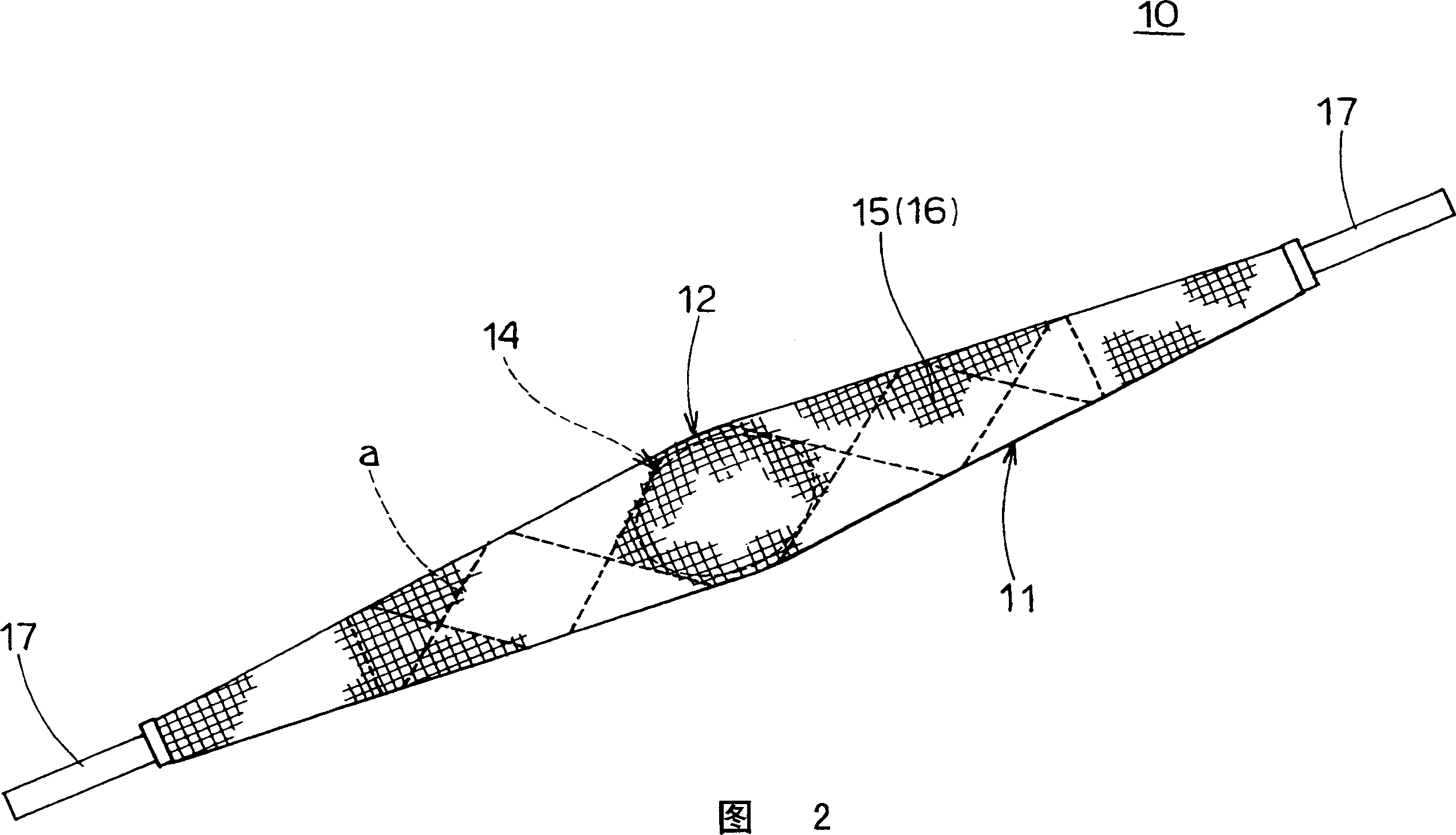

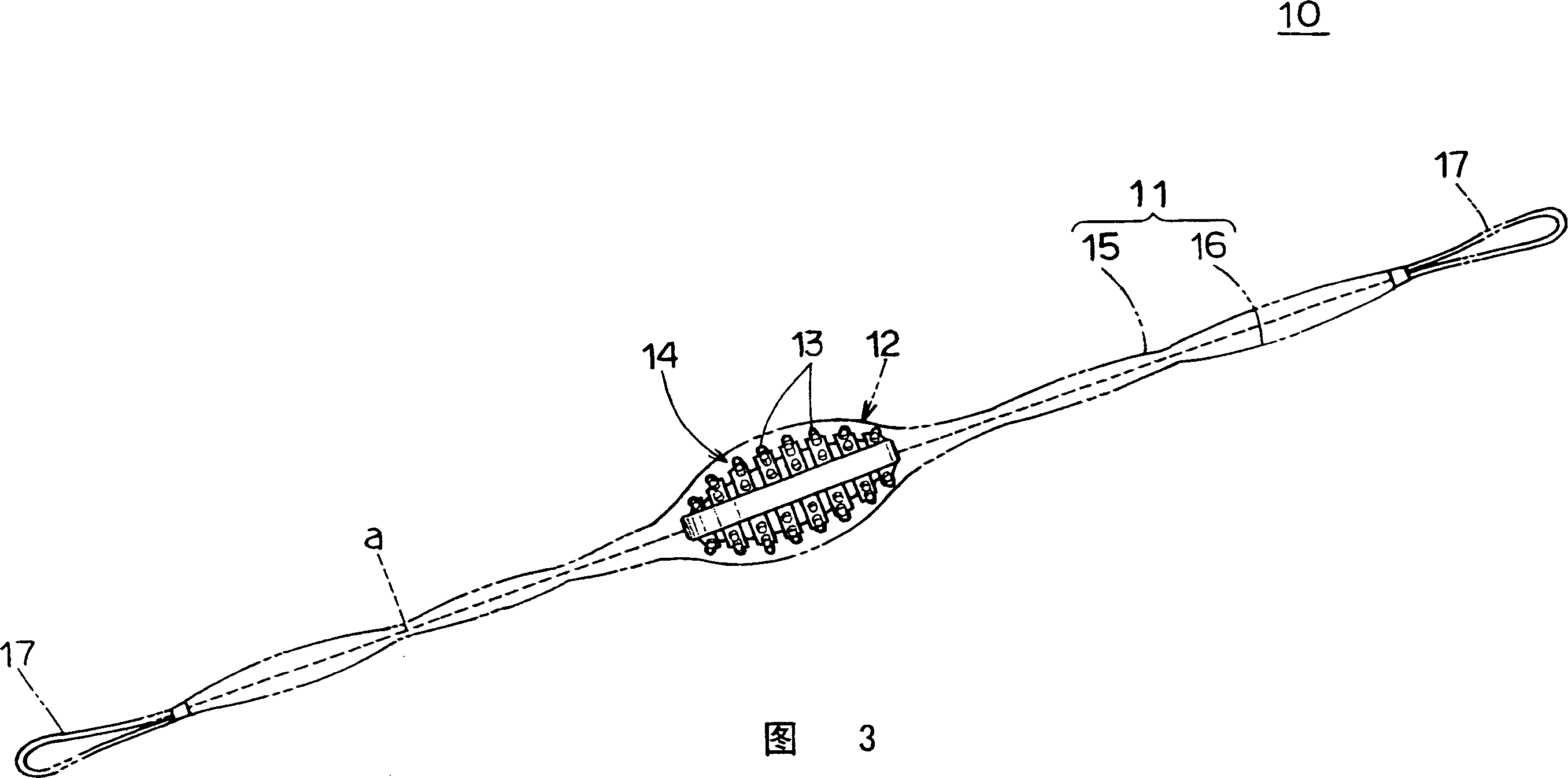

Bath used towel,Absterge implement and cleansing appliance

The present invention provides a bathing towel that can provide effective cleaning and massage to the body using a rugged block even if arranging any part of the rugged block in any direction of the towel for use without needing skill to use the towel. The rugged block 14 is enclosed in a fixed state in a bag part 12 disposed at an intermediate part in the length direction of a towel body 11. Consequently, an application method of the bathing towel 10 does not need skill, and even if any part of the rugged block is arranged in any direction of the towel to use the bathing towel 10, washing and massage to the body effectively utilizing the rugged block 14 can be performed.

Owner:金田晃雄 +1

Chemical material polyurethane foaming machine

The inventing discloses a chemical material polyurethane foaming machine which comprises a foaming machine shell and a stirring mechanism fixedly mounted on the foaming machine shell for mixing a foaming agent. The foaming machine shell comprises a foaming barrel, a joint pipe penetrating into the foaming barrel vertically is arranged at the bottom of the foaming barrel, the stirring mechanism comprises a hollow stirring shaft penetrating into the foaming machine shell and a connecting sleeve rotatably connected to the lower end of the stirring shaft, the connecting sleeve is also connected to the upper end of the joint pipe, the joint pipe are connected to the stirring shaft, a plurality of connected ventilating branch pipes are distributed on the stirring shaft, and the foaming machine also comprises an inner supporting mechanism fixedly mounted on each ventilating branch pipe and a flexible glue air bag mounted on each inner supporting mechanism. The foaming machine integrates an air inlet mechanism and a stirring mechanism through a gas circuit design, so that the foaming efficiency and the effect and quality of forming a foaming material are improved greatly.

Owner:山东誉中新材料股份有限公司

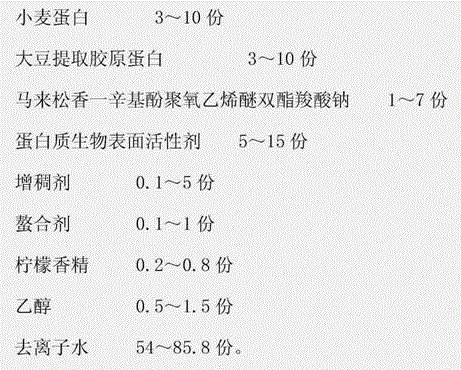

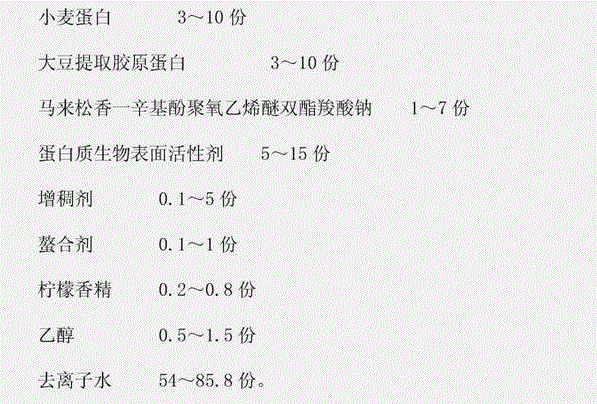

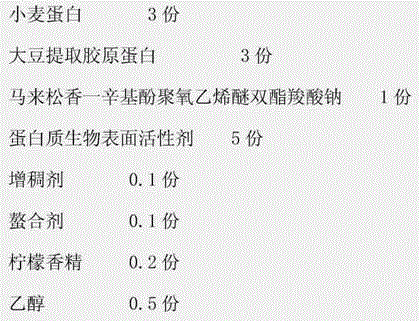

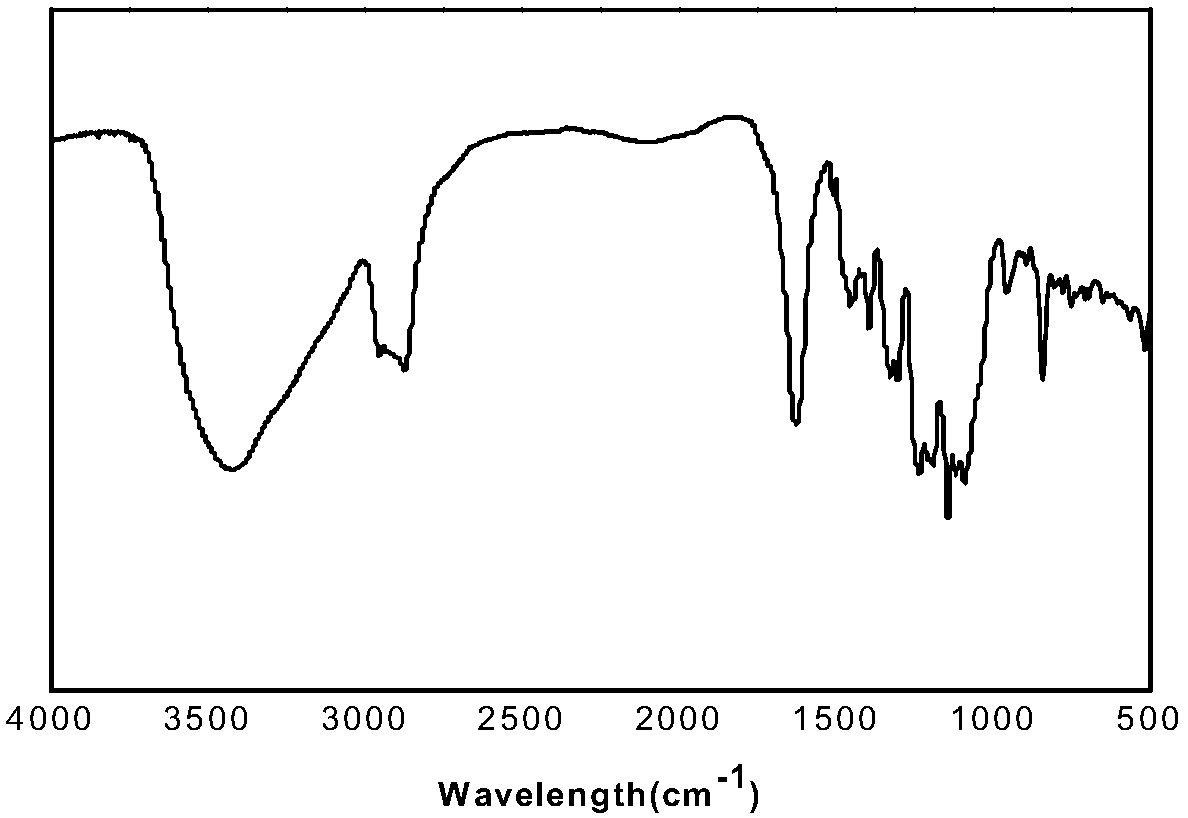

Environmentally friendly liquid detergent

InactiveCN105802745AImprove elasticityExcellent decontaminationAnionic surface-active compoundsDetergent perfumesChemistryRosin

The invention discloses an environmentally friendly liquid detergent. The environmentally friendly liquid detergent comprises, by mass, 3-10 parts of a wheat protein, 3-10 parts of a soybean extract collagen, 1-7 parts of maleic rosin-octylphenol polyoxyethylene ether diester carboxylate sodium, 5-15 parts of a protein biosurfactant, 0.1-5 parts of a thickening agent, 0.1-1 part of a chelating agent, 0.2-0.8 parts of lemon essence, 0.5-1.5 parts of ethanol and 54-85.8 parts of deionized water. The environmentally friendly liquid detergent utilizes the wheat protein and soybean extract collagen. The wheat protein has good foaming characteristics, emulsibility, a water binding capacity and oxidation resistance, is rich in a plurality of active enzymes, especially contains lipoxygenase and amylase with good activity, effectively decomposes fat and starch in food residues and has a limited decontamination capability and the soybean extract collagen can supply decontamination effects, can improve skin elasticity, can be used for a long time and does not damage hands.

Owner:高启金

Dimethyl-monoperfluor decyl silicon-polyethyoxyl-sodium benzenesulfonate polycompound as well as preparation method and application thereof

InactiveCN108484657AEfficient FoamingGood foam stabilitySilicon organic compoundsDrilling compositionSilanesEthylene oxide

The invention discloses a dimethyl-monoperfluor decyl silicon-polyethyoxyl-sodium benzenesulfonate polycompound as well as a preparation method and application thereof. The polycompound is prepared from perfluor decane, dimethyl fluoroalkyl silane, ethylene oxide and p-hydroxybenzenesulfonic acid through compounding. The preparation method comprises the following steps: mixing perfluor decane withdimethyl fluoroalkyl silane, acidifying, heating to 150-170 DEG C, adding ethylene oxide, implementing a reaction, adding the p-hydroxybenzenesulfonic acid, and finally adjusting the pH value to 8-9.5, thereby obtaining the polycompound. The polycompound is applied to foam oil expelling in an oil field. The polycompound disclosed by the invention is not only capable of efficiently forming foams,but also good in foam stabilization effect, is free of spectrum separation in stratum migration, and is particularly good in foam oil expelling effect in low-seepage and water sensitive oil field; andbesides, the polycompound is simple in preparation method, good in operability and low in cost.

Owner:NANJING NORMAL UNIVERSITY

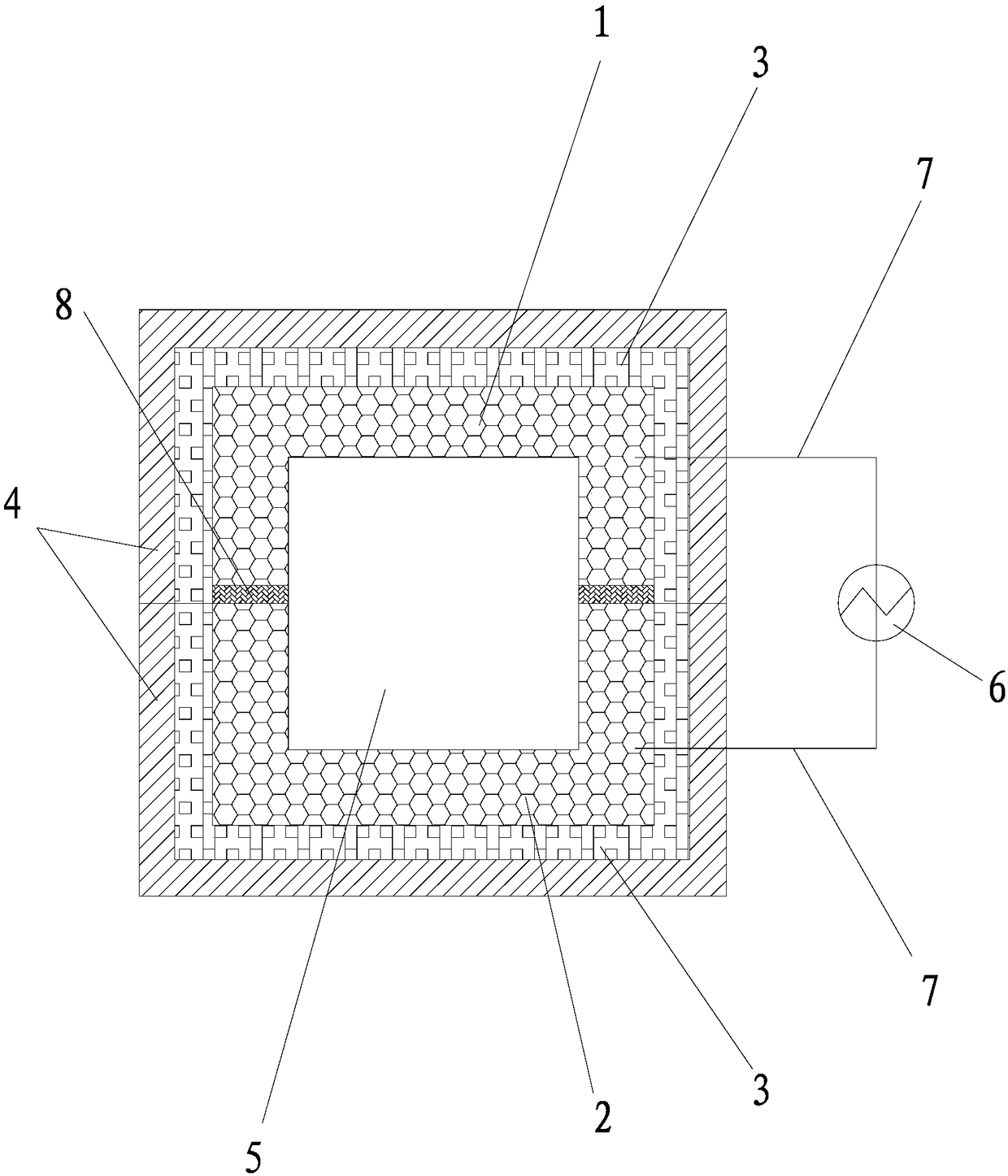

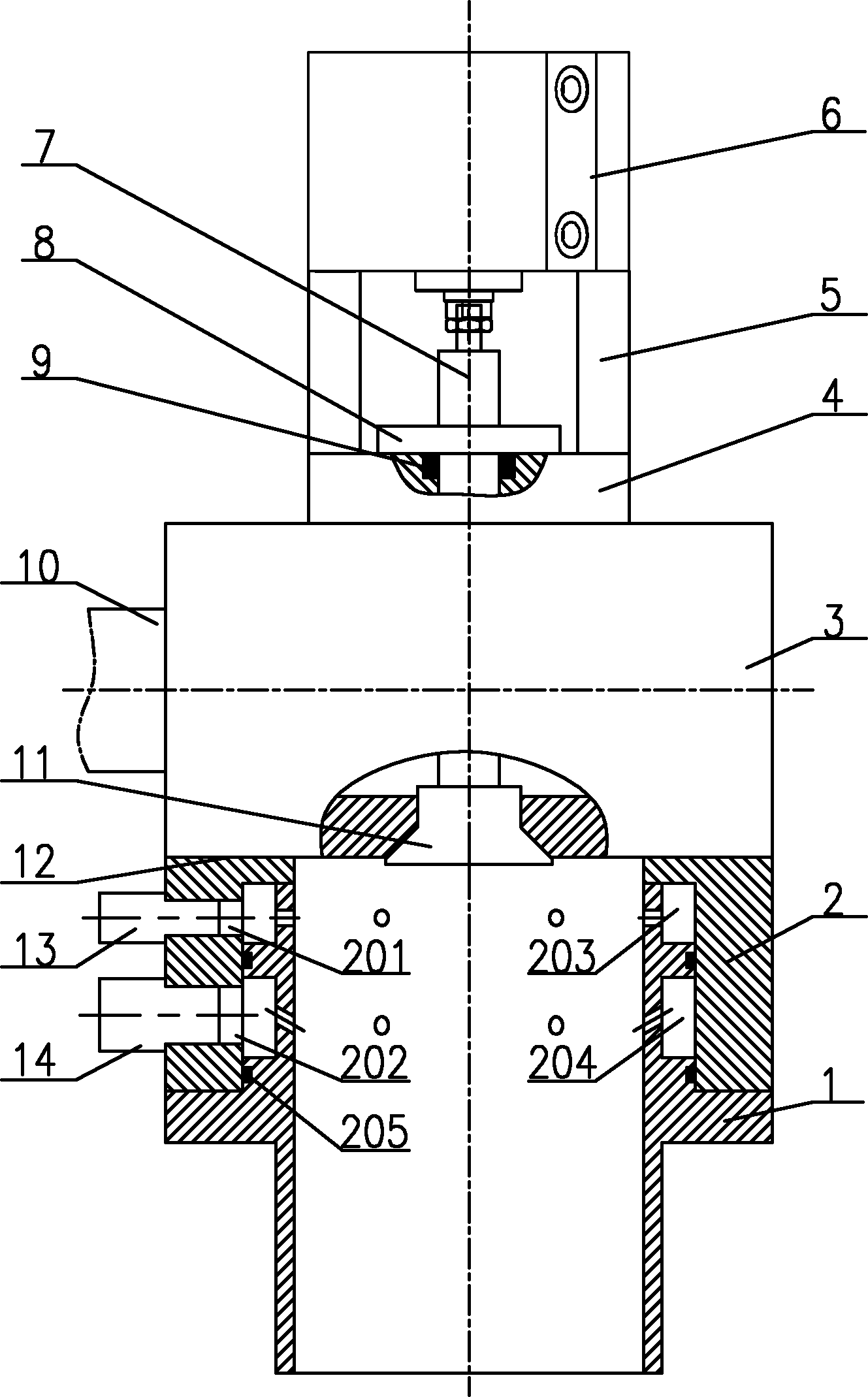

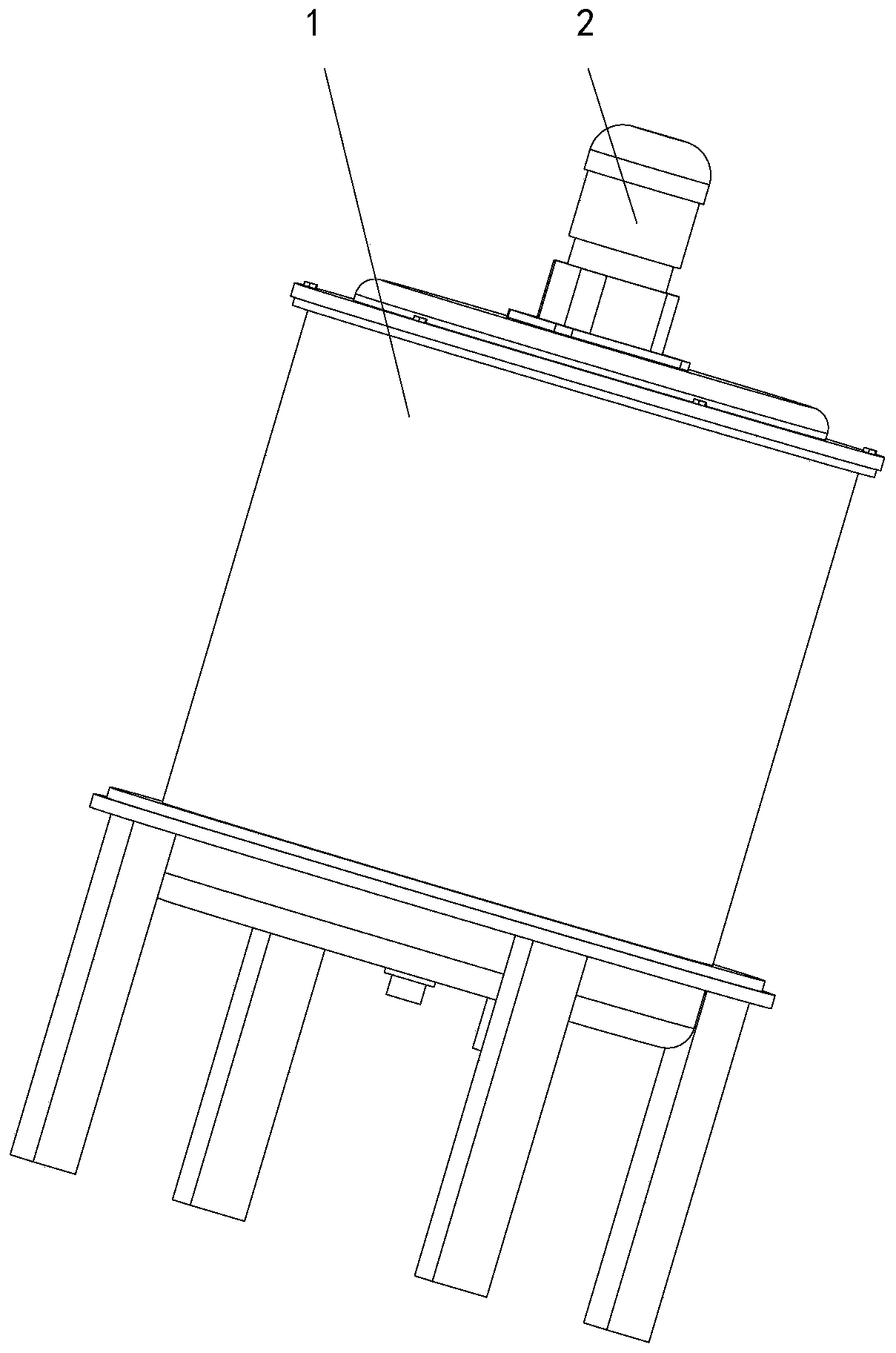

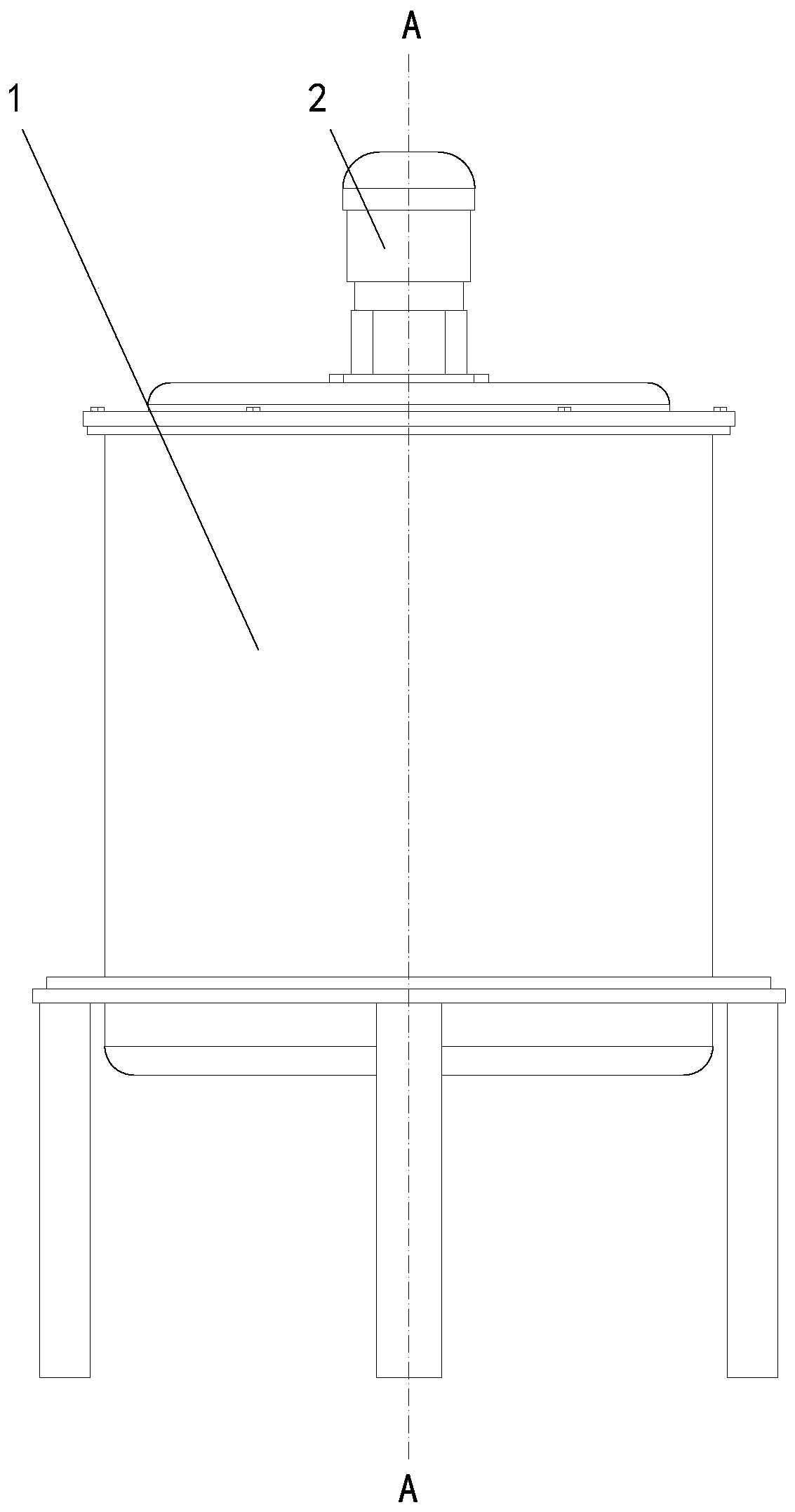

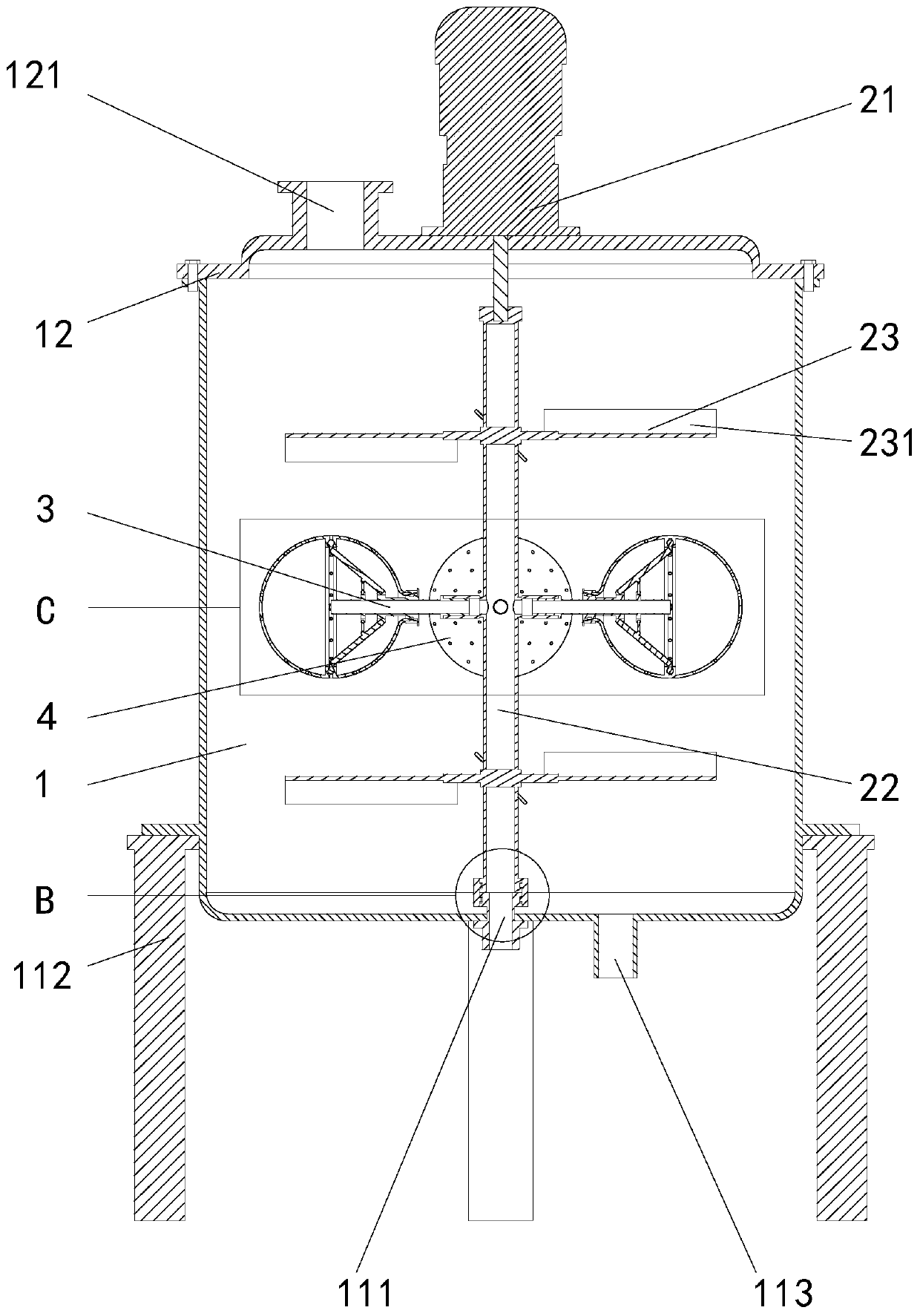

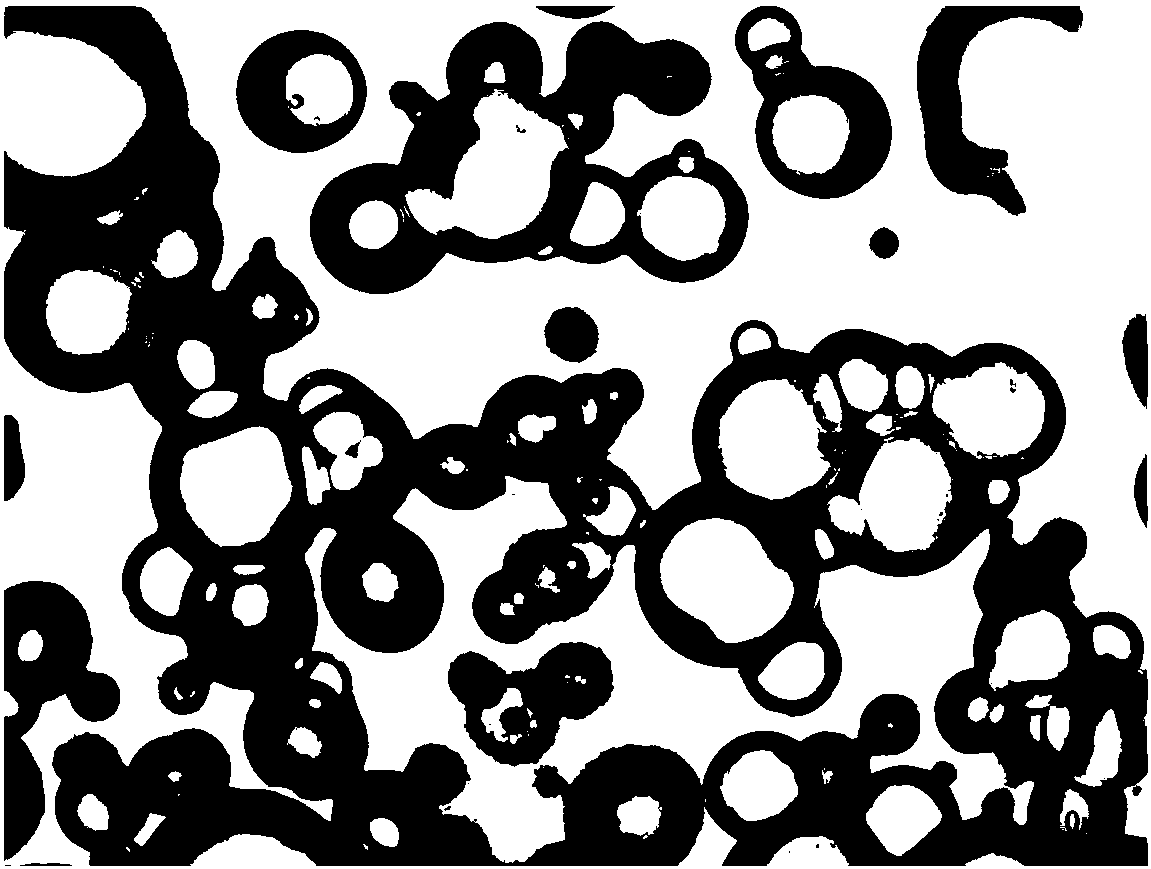

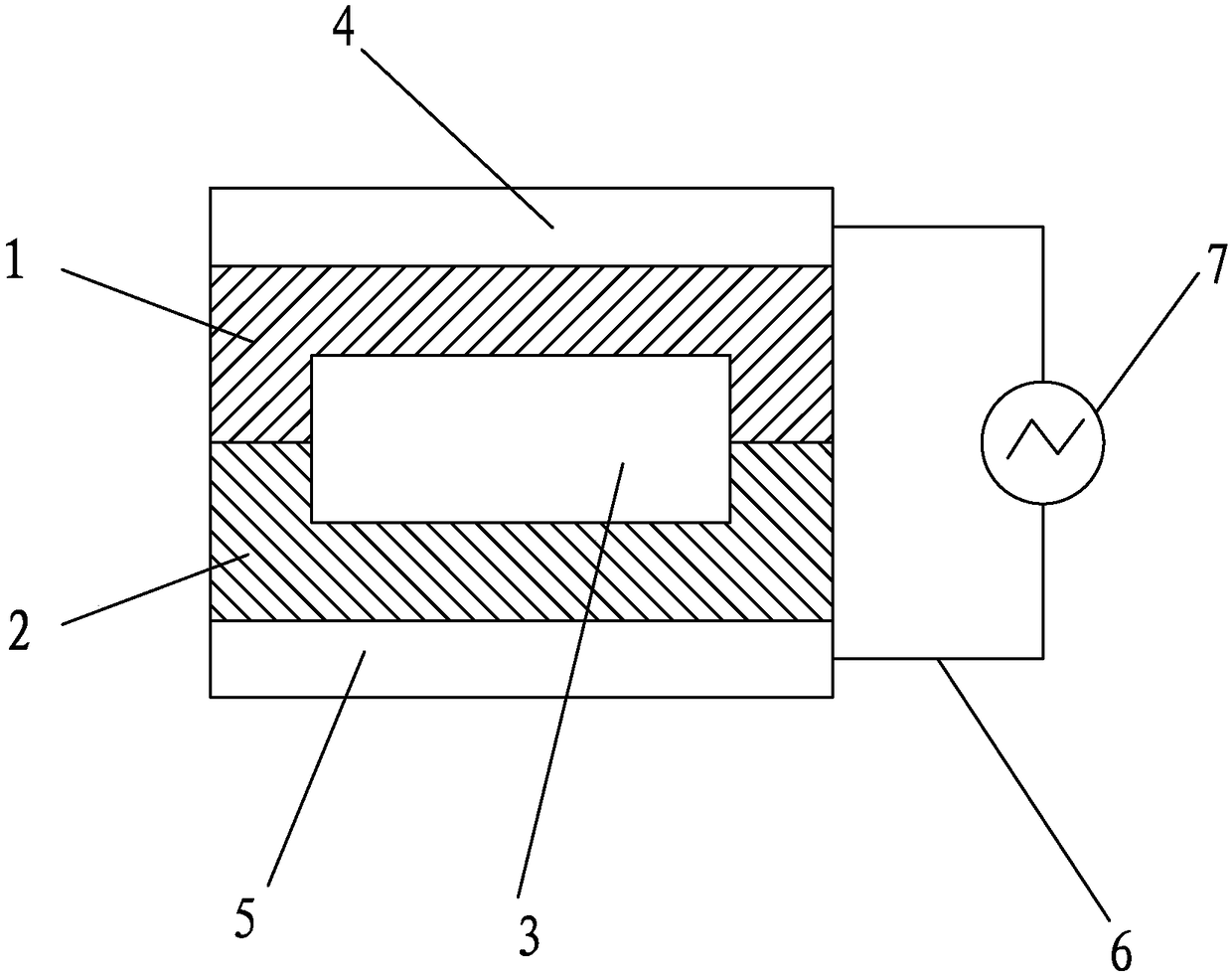

Polymer foaming and forming device

PendingCN108372621ASolve technical problems such as uneven heatingHeating evenlyRadio frequencyPolymer chemistry

The invention discloses a polymer foaming and forming device and belongs to the technical field of polymer foaming and forming equipment. The polymer foaming and forming device comprises a mould, wherein the mould comprises an upper mould body and a lower mould body; the upper mould body and the lower mould body can be closed to form a sealed mould cavity; a radio-frequency electrode A and a radio-frequency electrode B are respectively arranged on the outer surface of the upper mould body and the outer surface of the lower mould body. The polymer foaming and forming device further comprises aradio-frequency power supply, and the radio-frequency electrode A and the radio-frequency electrode B are respectively connected with a positive electrode and a negative electrode of the radio-frequency power supply through cables. Compared with the prior art, the polymer foaming and forming device disclosed by the invention has the advantages of evenness in heating, quick heating speed, high-efficiency foaming and ability in saving required foaming time, improving production efficiency and reducing cost.

Owner:QUANZHOU NORMAL UNIV

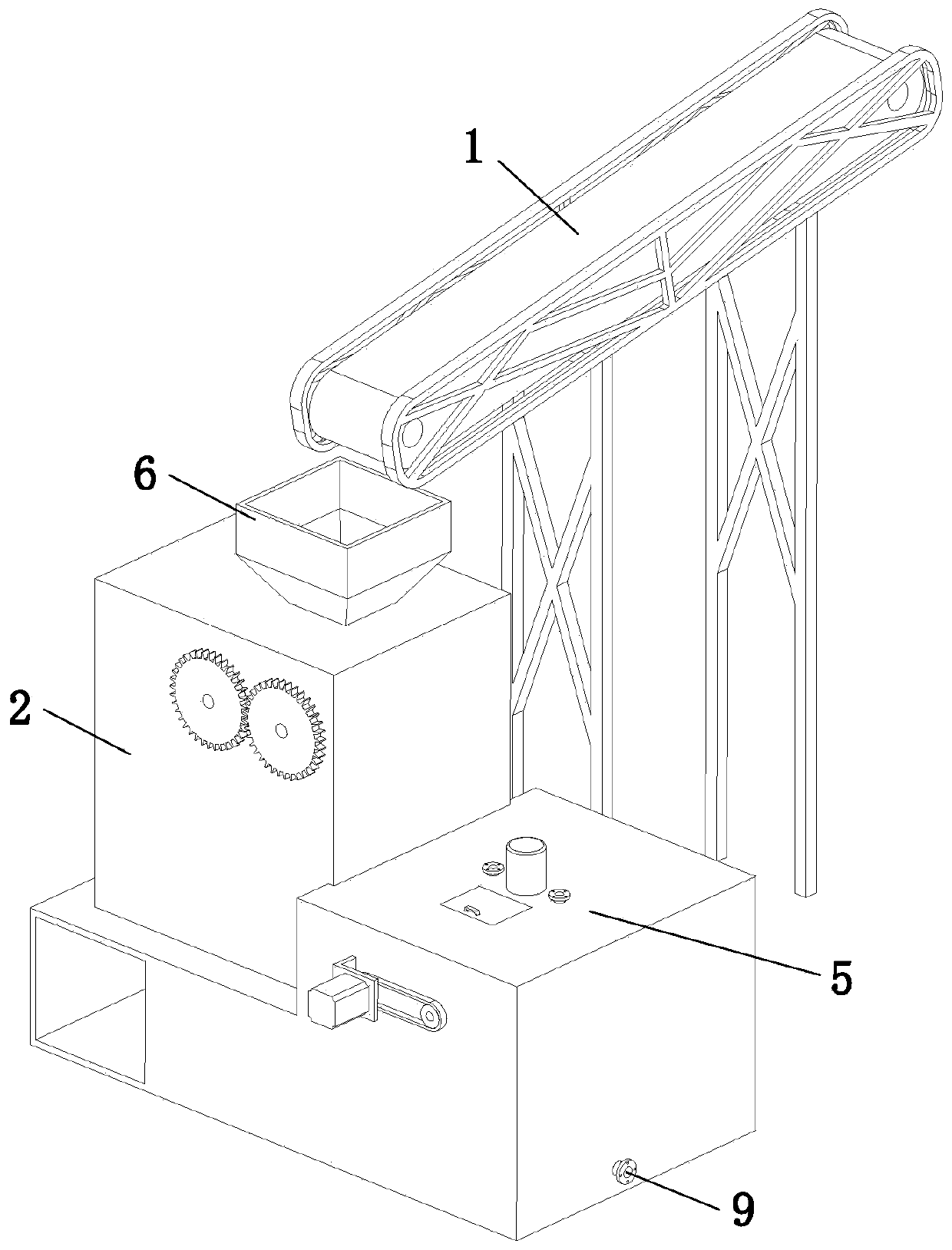

Asphalt foaming device

ActiveCN111455780ASave engineering investmentGood for waste disposalRoads maintainenceBuilding materialAsphalt

The invention relates to the field of road building material production equipment, and discloses an asphalt foaming device. The device comprises a conveying belt, a treatment box, a crushing mechanism, a screening mechanism and a mixing mechanism, the conveying belt is arranged beside the treatment box; a feeding hole communicated with the interior of the treatment box is formed in the top of thetreatment box; the output end of the conveying belt is in butt joint with the feeding port. An inner space of the treatment box can be divided into a first cavity and a second cavity; the crushing mechanism and the screening mechanism are both mounted in the second cavity; an inclined guide plate is arranged below the screening mechanism; the guide plate is positioned in the second cavity, and oneend of the guide plate extends to the mixing mechanism; the waste asphalt mixture can be automatically crushed and screened, subsequent asphalt regeneration is facilitated, resource waste and engineering investment are saved, contact between water and the regenerated asphalt and the asphalt foaming quality are improved, efficient asphalt foaming is guaranteed, and the practicability is high.

Owner:枣庄旗胜建设集团有限公司

High-efficiency glass cleaning agent and preparation method thereof

InactiveCN108865494AGood effectEasy to prepareInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistrySodium carboxymethylcellulose

The invention provides a high-efficiency glass cleaning agent and a preparation method thereof. The high-efficiency glass cleaning agent is prepared from the following components: modified zeolite powder, sodium dodecyl benzene sulfonate, sodium carboxymethyl cellulose, modified bentonite, fatty alcohol polyoxyethylene ether, sodium alginate, sodium citrate, a polyethylene glycol solution, a detergent, propylene glycol, a chelating agent, a preservative and deionized water. The glass cleaning agent prepard by the method is remarkable in cleaning effect, simple in preparation method and wide inapplication scope, is free from undesirable odor, has no harm to a human body, does not need to be washed with a great deal of clean water, and saves a great deal of manpower and material resources,thus being worth popularizing and producing.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

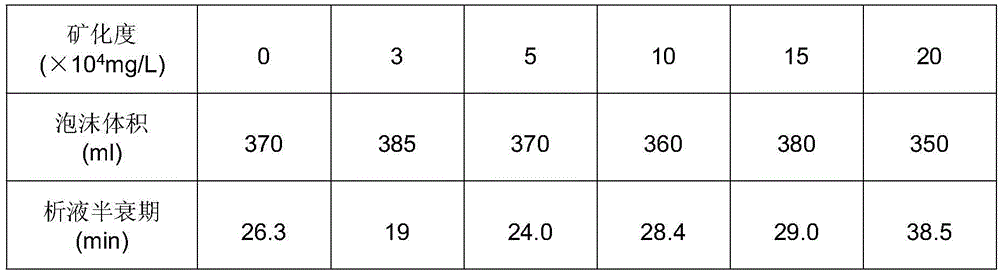

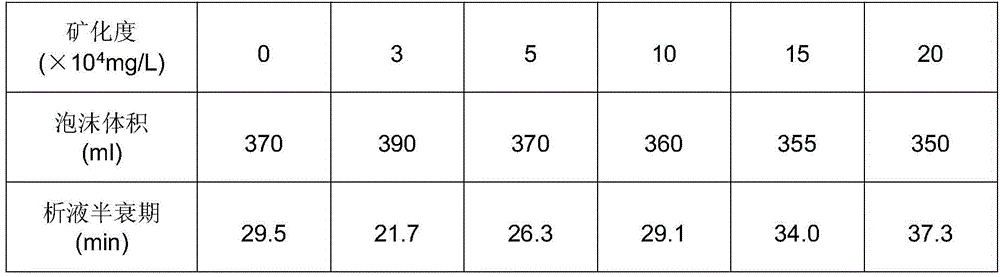

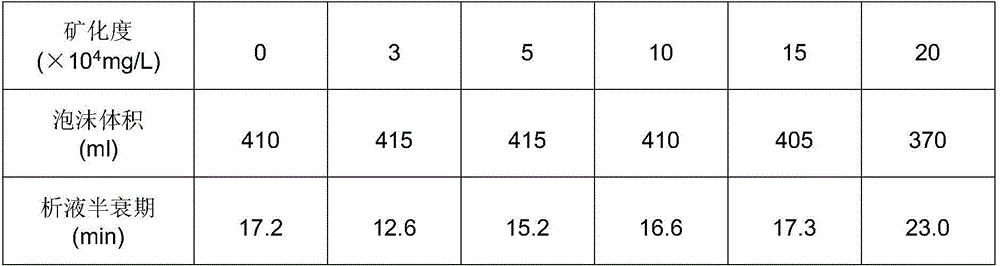

A salt synergistic anti-temperature and anti-salt foam system

The invention discloses a salt synergistic anti-temperature and anti-salt foam system. The system comprises the following components in percentage by weight: 0.05-0.5% of foaming agent, 0.05-0.2% of foam stabilizer and the balance of formation water or simulated formation water. The foaming agent is formed by compounding a nonionic surfactant and an anionic surfactant according to the mass ratio of (6: 1)-(9:1). The foam stabilizer is one or more of xanthan gum, hydroxyethyl cellulose and polyvinyl alcohol. The salt synergistic anti-temperature and anti-salt foam system disclosed by the invention has strong anti-temperature, anti-salt and anti-calcium and magnesium capabilities and can realize good foaming under the conditions that the temperature is 90 DEG C, the degree of mineralization is 20*10<4>mg / L and the concentration of calcium and magnesium ions is 1*10<4>mg / L, the foam stability is increased along with the increases in the degree of mineralization, the nonionic surfactant and the anionic surfactant have a good synergistic effect, and the salt synergistic anti-temperature and anti-salt foam system can be directly used for ultra-high temperature and ultra-high salt oil deposits with not high foam strength requirements, is easy to obtain raw materials and has good environmental compatibility.

Owner:SOUTHWEST PETROLEUM UNIV

A multi -functional efficiency increase agent and its preparation method for an acidified fracture

ActiveCN103666441BImprove wettabilityFunction increaseDrilling compositionAcid fracturingFoaming agent

The invention discloses a multifunctional synergist for acidizing and fracturing. The multifunctional synergist comprises raw materials in pars by weight as follows: 30-50 parts of a functional macromolecular compound, 2-5 parts of a special surfactant, 6-10 parts of a foaming agent, 3-7 parts of a solvent and 28-59 parts of water. A preparation method of the multifunctional synergist for acidizing and fracturing comprises the steps of preparation of the functional macromolecular compound, weighing and mixing. According to the multifunctional synergist for acidizing and fracturing, the performance of additives in acid liquor and fracturing fluid is regulated, so that the compatibility of the additives is strengthened, the fracturing liquid is better in rheological property, wettability and gel-breaking residue form, and the damage of the fracturing liquid is reduced; the synergist has good functions of sterilization, discharge assistance, foaming and clay swelling prevention; the preparation method for the multifunctional synergist for acidizing and fracturing has the advantages of simplicity in preparation, convenience in preparation, low cost and the like.

Owner:四川省博仁达石油科技有限公司

Jade enamel paint

InactiveCN106497285ABright colorRealistic patternFireproof paintsAnti-corrosive paintsSodium BentoniteLacquer

The invention relates to building paint applied to interior walls, in particular to jade enamel paint. The jade enamel paint comprises water, hydroxyethyl cellulose, dispersing agent, glycol, light calcium carbonate, sodium bentonite, ground calcium carbonate, talcum powder, wollastonite, silicone-acrylate emulsion, coalescing agent, hydroxypropyl methyl cellulose, pH value regulating agent, defoamer and thickener. The jade enamel paint has the advantages of high breathability, water resistance, scrubbing resistance, high adhesion strength, non-existence of powdering, peeling and bulging, relative flame resistance effect, simplicity and convenience in construction, optional matching of various patterns, variety in texture selection and the like.

Owner:赵永福

Methyl-bis-perfluorodecylsilicon-polyethoxy-naphthalenesulfonic acid sodium salt polynary compounds as well as preparation method and application thereof

InactiveCN108503666AEfficient FoamingGood foam stabilityGroup 4/14 element organic compoundsDrilling compositionChromatographic separationEthylene oxide

The invention discloses methyl-bis-perfluorodecylsilicon-polyethoxy-naphthalenesulfonic acid sodium salt polynary compounds as well as a preparation method and application thereof. The polynary compounds are formed by compounding perfluorodecane, monomethyl difluorosilane, ethylene oxide and p-hydroxynaphthalenesulfonic acid; and the preparation method comprises the following steps: mixing the perfluorodecane and the monomethyl difluorosilane, performing acidification, performing heating to temperature of 150-170 DEG C, adding the ethylene oxide, performing a reaction, adding the p-hydroxynaphthalenesulfonic acid, and finally adjusting a pH to 8-9.5, so as to obtain one polynary compound. The polynary compounds disclosed by the invention are used in oil fields for foam flooding; the polynary compounds not only can be foamed simply and efficiently, but also have an excellent foam stabilizing effect, do not have chromatographic separation when being transported in a formation, and especially have an excellent foam flooding effect in low-permeability and water-sensitive oil fields; and the preparation method is simple, and has high operability and low costs.

Owner:NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com