Cement kiln tail gas carbonization non-autoclaved aerated concrete wall material product and preparation method thereof

An air-entrained concrete, autoclaved-free technology, applied in the field of building wall materials, can solve the problems of limited practical application, decreased carbonization process, difficult diffusion, etc., and achieves the effects of ensuring mechanical properties, promoting carbonization, and reducing harmful pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

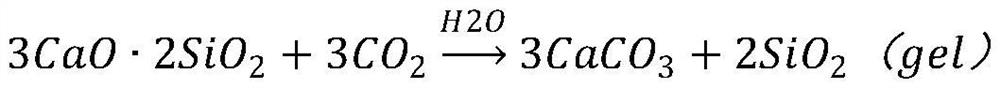

Method used

Image

Examples

Embodiment 1

[0032] A cement kiln tail gas carbonization non-autoclaved aerated concrete wall material product, which consists of the following parts by mass: 50 parts of carbonized active cement, 5 parts of reinforcing material, 10 parts of lime, 10 parts of Portland cement, concrete aggregate tailings powder 25 parts, 1.2 parts of water reducing agent, 50 parts of water, 0.1 part of foaming agent, 0.02 parts of foam stabilizer; the carbonized active cement used is composed of 10.3% α-CS and 21.1% C 3 S 2 , 48.9% of γ-C 2 S, the rest is composed of calcium aluminosilicate and iron phase solid solution, Blaine specific surface area is 400m 2 / kg.

[0033] The preparation of the above-mentioned cement kiln tail gas carbonization-free autoclaved aerated concrete wall material product comprises the following steps:

[0034] (1) Mixing and stirring: First add carbonized active cement, reinforcing material, lime, Portland cement, concrete aggregate tailings powder, water, and water reducing ...

Embodiment 2

[0042]A cement kiln tail gas carbonization non-autoclaved aerated concrete wall material product, which consists of the following parts by mass: 32 parts of carbonized active cement, 2 parts of reinforcing material, 5 parts of lime, 5 parts of Portland cement, and concrete aggregate tailings powder 56 parts, 40 parts of water; 2.0 parts of water reducer, 0.13 parts of foaming agent, 0.03 parts of foam stabilizer; the carbonized active cement used is composed of 23.2% α-CS and 38.6% C 3 S 2 , 14.3% of γ-C 2 S, the rest is composed of calcium aluminosilicate and iron phase solid solution, Blaine specific surface area is 420m 2 / kg.

[0043] The preparation of the above-mentioned cement kiln tail gas carbonization-free autoclaved aerated concrete wall material product comprises the following steps:

[0044] (1) Mixing and stirring: First add carbonized active cement, reinforcing material, lime, Portland cement, concrete aggregate tailings powder, water, and water reducing agen...

Embodiment 3

[0052] A cement kiln tail gas carbonization non-autoclaved aerated concrete wall material product, which consists of the following parts by mass: 40 parts of carbonized active cement, 3 parts of reinforcing material, 9 parts of lime, 8 parts of Portland cement, and concrete aggregate tailings powder 40 parts, 35 parts of water, 1.6 parts of water reducer, 0.16 parts of foaming agent, 0.05 parts of foam stabilizer; the carbonized active cement used is composed of 45.8% α-CS and 27.4% C 3 S 2 , 5.5% γ-C 2 S, the rest is composed of f-CaO, calcium aluminosilicate, iron phase solid solution, Blaine specific surface area is 450m 2 / kg.

[0053] The preparation of the above-mentioned cement kiln tail gas carbonization-free autoclaved aerated concrete wall material product comprises the following steps:

[0054] (1) Mixing and stirring: First add carbonized active cement, reinforcing material, lime, Portland cement, concrete aggregate tailings powder, water, and water reducing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com