Positive pressure movable type three-phase foam generating device and method

A foam generating device and mobile technology, applied in fire rescue and other directions, can solve the problems of location limitation, immobility, limited fire extinguishing ability, etc., and achieve the effects of high reliability, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0057] Foam fire extinguishing system in petrochemical tank area and oil depot area

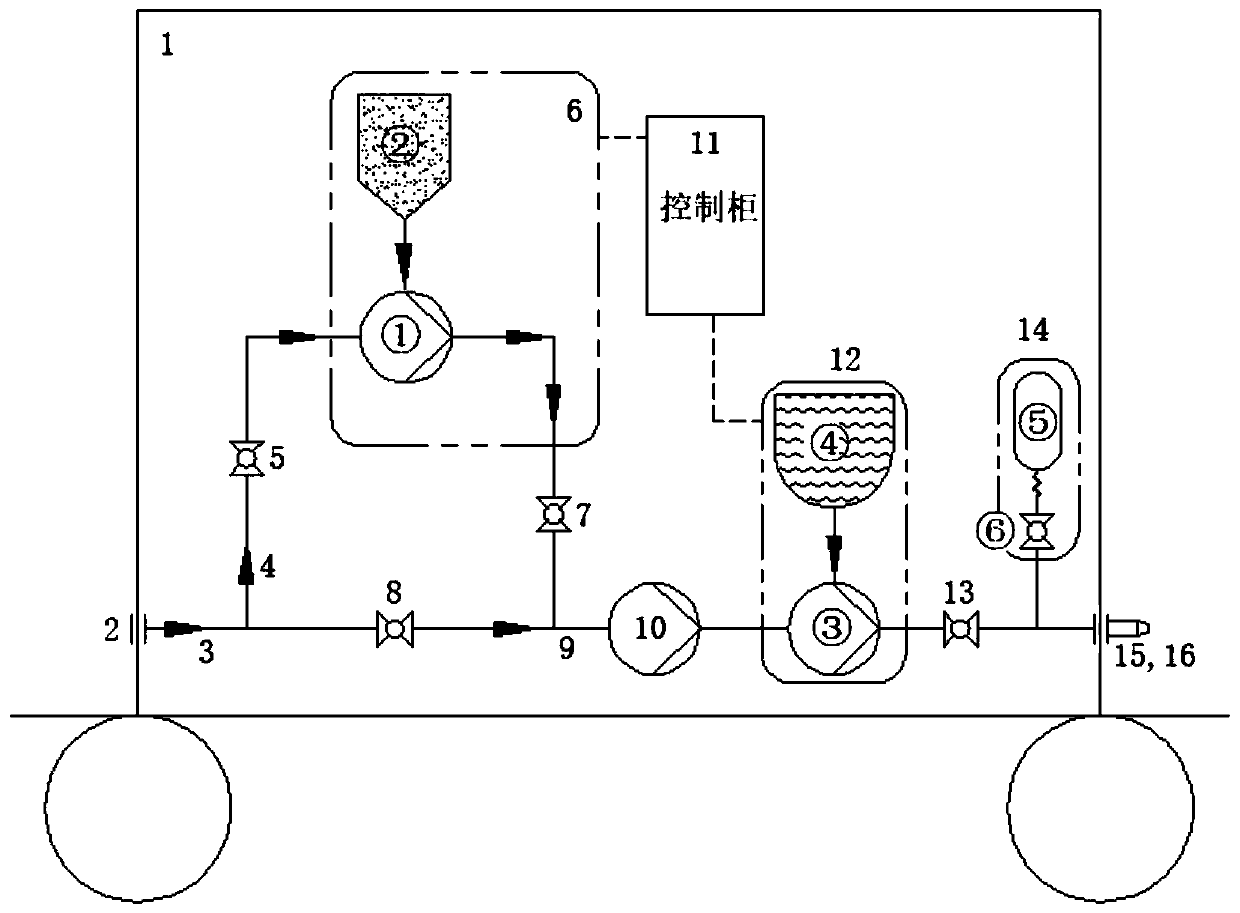

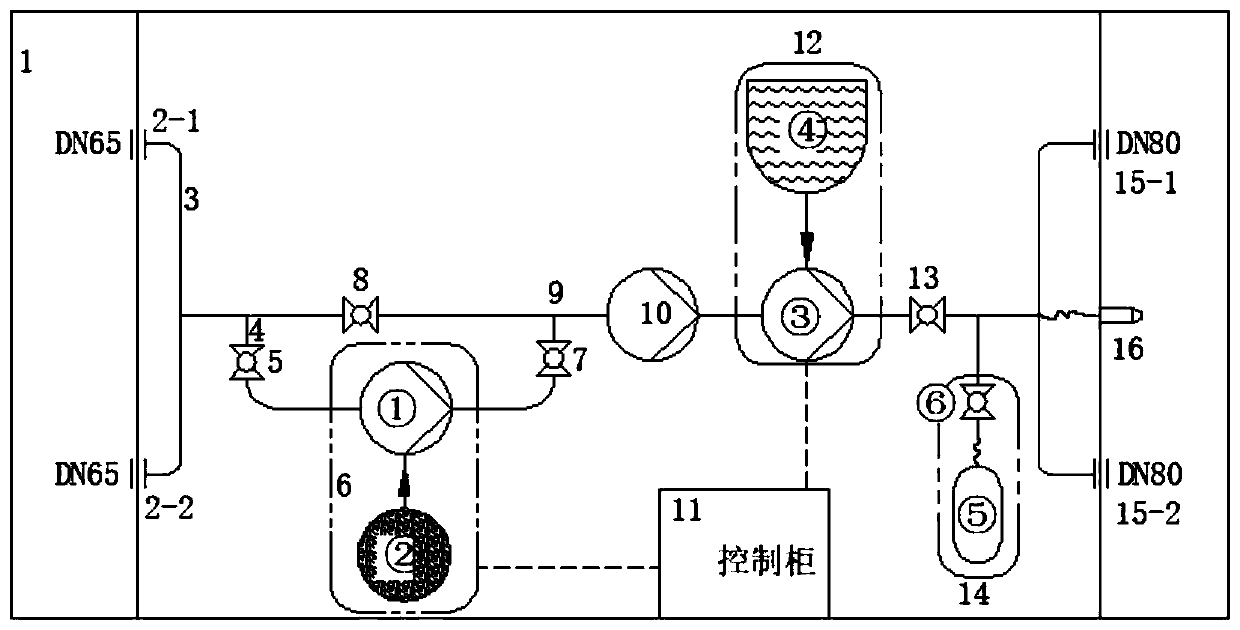

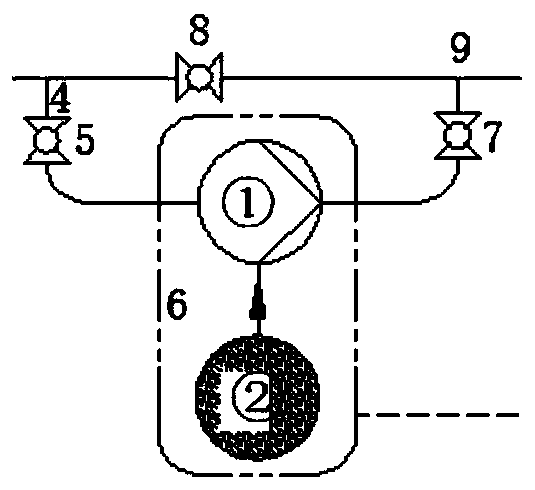

[0058] The positive pressure mobile three-phase foam generating device is integrated into a skid and is mounted on a skid body trolley 1. The fire water interface 2 on the water inlet side of the skid cart 1 can be connected to the fire hydrant on the station to take water through two fire hoses. The fire water switch valve 8 can be normally opened. Open the powder feeding device inlet valve 5 on the powder feeding water inlet pipe 4 to introduce fire-fighting water into the powder feeding device 6, start the powder-liquid mixing pump ①, the solid powder in the powder bin ② enters the powder-liquid mixing pump ①, and passes through the control cabinet 11 The program set in advance uniformly mixes the solid powder and water according to a certain ratio, and then injects the slurry mixed with particles into the fire-fighting water pipe 9 through the slurry delivery switch valve 7 . Then, the ...

Embodiment example 2

[0060] Use fire trucks to spray foam to extinguish fires

[0061] The positive pressure mobile three-phase foam generating device is integrated into a skid and is mounted on a skid body trolley 1. The fire water interface 2 on the water inlet side of the skid cart 1 can be connected to the fire hydrant on the station to take water through two fire hoses. The fire water switch valve 8 can be normally opened. Open the powder feeding device inlet valve 5 on the powder feeding water inlet pipe 4 to introduce fire-fighting water into the powder feeding device 6, start the powder-liquid mixing pump ①, the solid powder in the powder bin ② enters the powder-liquid mixing pump ①, and passes through the control cabinet 11 The program set in advance uniformly mixes the solid powder and water according to a certain ratio, and then injects the slurry mixed with particles into the fire-fighting water pipe 9 through the slurry delivery switch valve 7 . Then, the high-pressure water pump 10...

Embodiment example 3

[0063] The foam solution outlet 15 is connected with the fire nozzle of the fire truck, sprayed through the fire truck, and foamed by the injector on the fire truck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com