A salt synergistic anti-temperature and anti-salt foam system

A foam system and foaming agent technology, applied in the field of oil displacement agents, can solve the problems of incompatibility and achieve the effects of easy availability of raw materials, good synergistic effect, and good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) System preparation: Take 0.18g of decyl glucoside, 0.03g of disodium fatty alcohol polyoxyethylene ether sulfosuccinate monoester, and add 100ml of formation water during low-speed stirring (the concentration of calcium and magnesium ions accounts for the total salinity 5%) until fully dissolved; then stir at a low speed while adding 0.15g xanthan gum, and after it dissolves completely, a foam system is obtained.

[0021] (2) Foam property test: Preheat 100ml of the foam system to 90°C, pour it into a warningblender mixer, stir at a shear rate of 4000 rpm for 1 min, measure the foam volume, and then measure the half-life of the foam at 90°C. The results are shown in Table 1.

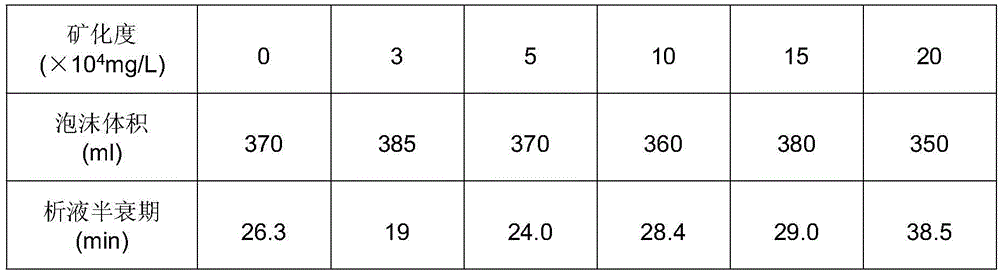

[0022] The foam property of table 1 embodiment 1

[0023]

Embodiment 2

[0025] (1) System preparation: Take 0.2g of alcohol ether glycoside, 0.07g of decyl maltoside, and 0.03g of fatty alcohol polyoxyethylene ether sulfonate, and add 100ml of formation water during low-speed stirring (the concentration of calcium and magnesium ions accounts for the total mineralization 5% of degree), until fully dissolved; then stir at a low speed, add 0.15g xanthan gum, after it dissolves completely, a foam system is obtained.

[0026] (2) Foam property test: Preheat 100ml of the foam system to 90°C, pour it into a warningblender mixer, stir at a shear rate of 4000 rpm for 1 min, measure the foam volume, and then measure the half-life of the foam at 90°C. The results are shown in Table 2.

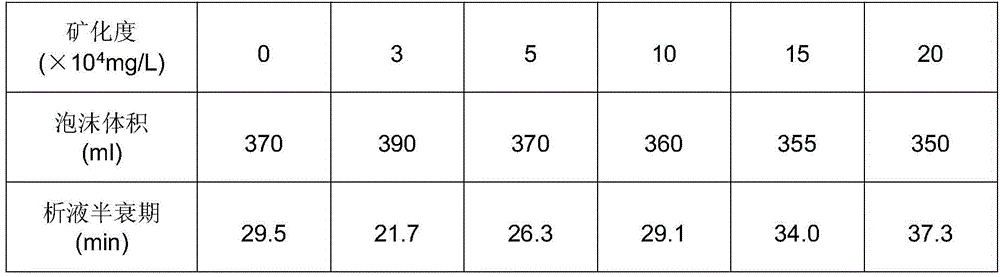

[0027] The foam property of table 2 embodiment 2

[0028]

Embodiment 3

[0030] (1) System preparation: Take 0.15g of alcohol ether glycoside, 0.3g of decyl glucoside, and 0.05g of disodium fatty alcohol sulfosuccinate, and add 100ml of formation water during low-speed stirring (the concentration of calcium and magnesium ions accounts for the total mineralization 5% of the degree), until completely dissolved; then stir at a low speed, add 0.1g hydroxyethyl cellulose, 0.6g xanthan gum, and obtain a foam system after it is completely dissolved.

[0031] (2) Foam property test: Preheat 100ml of the foam system to 90°C, pour it into a warningblender mixer, stir at a shear rate of 4000 rpm for 1 min, measure the foam volume, and then measure the half-life of the foam at 90°C. The results are shown in Table 3.

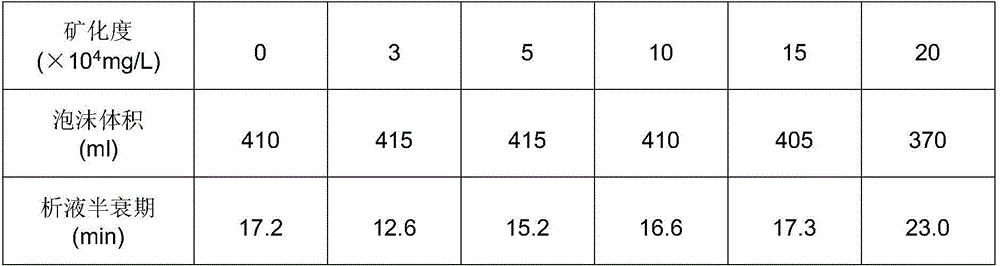

[0032] The foam property of table 3 embodiment 3

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com