Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Deep curing fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

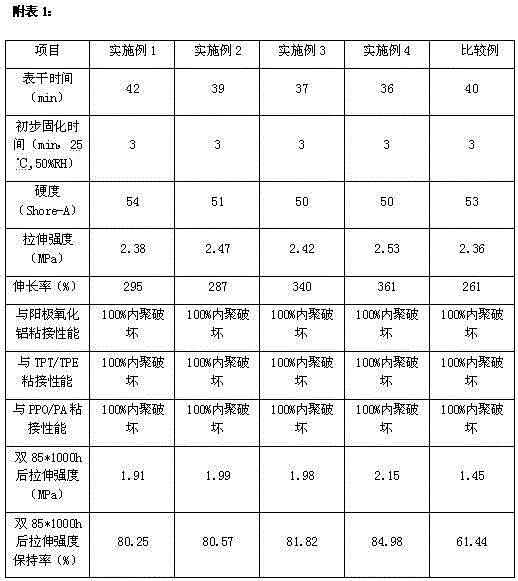

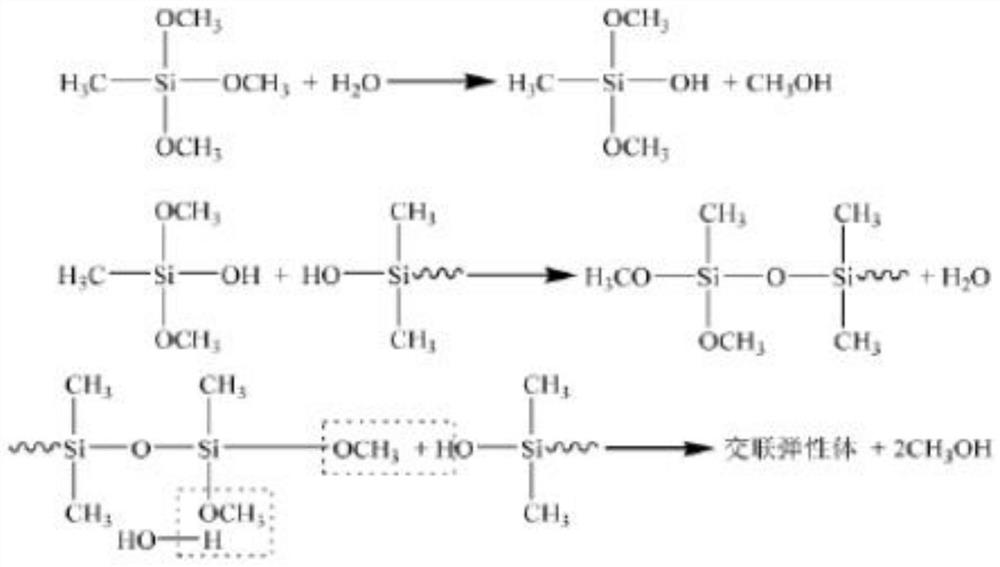

Two-component silicone sealant for solar module resisting damp, heat and ageing and preparation method thereof

InactiveCN102977840AWide range of adhesionImprove room temperature strengthNon-macromolecular adhesive additivesOther chemical processesChemistrySilicone sealant

The invention discloses two-component silicone sealant for a solar module resisting damp, heat and ageing and a preparation method thereof. The sealant consists of a component A and a component B, wherein the component A adopts polydimethylsiloxane as the major material; and the component B comprises dispersion mediums, fillers, cross linking agent, coupling agent and catalyst; the component A comprises the following components in parts by weight: 100 parts of a, omega-dihydroxy polydimethylsiloxane with viscosity of 5000-50000cps, 3 to 20 parts of plasticizer and 50 to 150 parts of fillers; the component B comprises the following components in parts by weight: 100 parts of dispersion mediums, 10 to 45 parts of fillers, 20 to 50 parts of cross linking agent, 5 to 40 parts of silane coupling agent and 0.5 to 2 parts of catalyst; and the ratio of the component A to the component B in parts by weight is 100: (10-20). The sealant has the advantages of fast deep curing, wide adhesion, high strength of normal temperature and excellent resistance to damp, heat and ageing; after ageing for 1000 hours under the double-85 condition, the strength retention rate can be up above 80%; and the sealant is suitable for machine gluing, can largely improve module productivity, and adapts to the requirements of solar module mass production.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

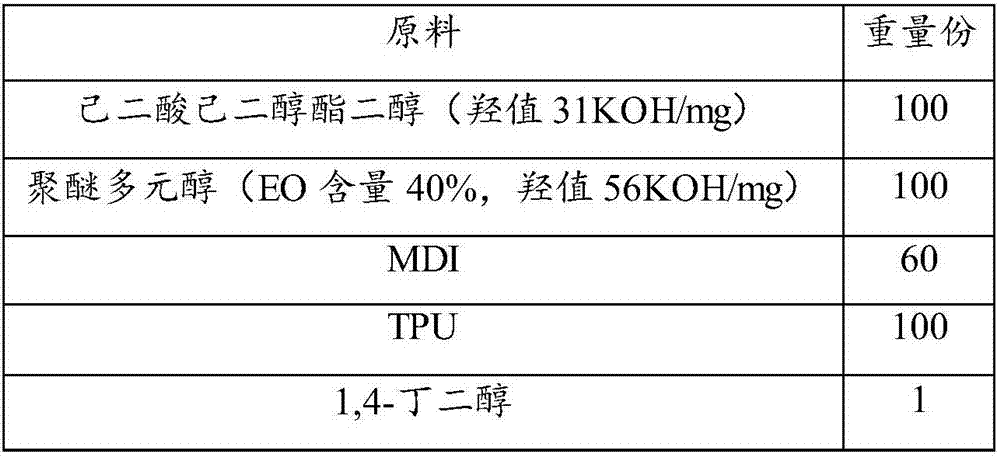

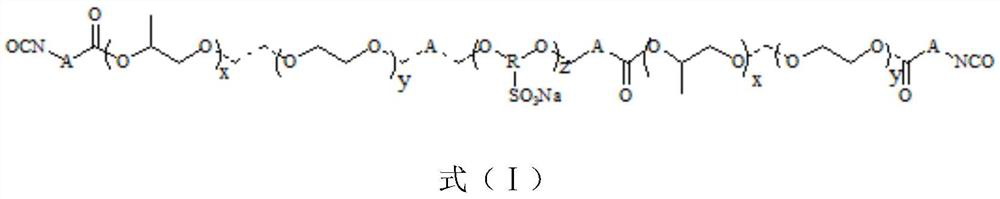

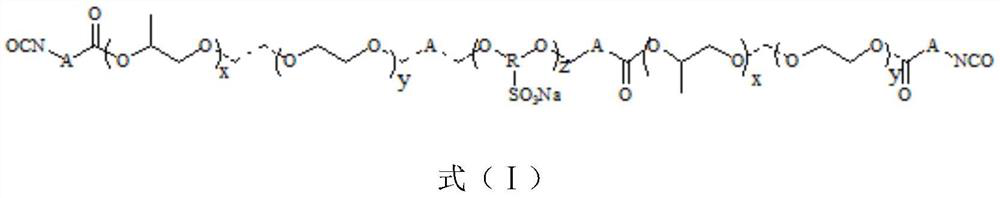

Reaction type polyurethane hot melt adhesive as well as preparation method and application thereof

ActiveCN107987779AGood water permeabilityGood high temperature non-dripping propertiesPolyureas/polyurethane adhesivesPolyesterEthylene oxide

The invention provides a reaction type polyurethane hot melt adhesive as well as a preparation method and application thereof. The reaction type polyurethane hot melt adhesive is prepared from the following raw materials with the components in parts by weight: 100-120 parts of polyester polyol, 1-150 parts of polyether polyol, 50-100 parts of isocyanate, 50-350 parts of a modifier, 1-5 parts of achain extender, 1-5 parts of an antioxidant and 0.01-0.1 part of a catalyst, wherein the mass percentage of ethylene oxide in the polyether polyol is 40-50%; the hydroxyl value is 21-112KOH / mg; the modifier consists of a tackifying resin and a filler in a mass ratio of 1-6 to 1. Due to the addition of the polyether polyol with ethylene oxide of a specific mass content, and under coactions of the modifier of components of specific contents, the water permeability of a hot melt adhesive before curing is improved, and the obtained product is good in high-temperature flow-free property, relativelyrapid deep curing property and excellent thixotropy, and can be used as a hot melt adhesive for vehicle lamps.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Cationic UV and heat dual deeply-curing adhesive and preparation method thereof

InactiveCN105199643ARapid responseDeep curing fastNon-macromolecular adhesive additivesEpoxy resin adhesivesPhotosensitizerOligomer

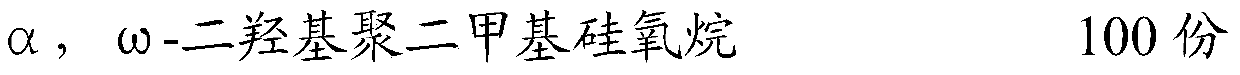

A cationic UV and heat dual deeply-curing adhesive and its preparation method relate to a curing adhesive and its preparation method. The invention aims to solve the problem that an existing UV curing adhesive cannot achieve rapid deep curing and still needs subsequent heating after UV-irradiation. The UV and heat dual deeply-curing adhesive is prepared from, by weight, 60-100 parts of an oligomer resin mixture containing an epoxy group, 5-30 parts of a diluent, 5-15 parts of a coupling agent, 0.75-3 parts of a photoinitiator, 0.75-3 parts of a photosensitizer, 0.075-0.5 part of a thermal initiator and 0-0.2 part of a heat stabilizer. The method comprises the following steps: 1, weighing; and 2, mixing to obtain the cationic UV and heat dual deeply-curing adhesive. According to the invention, a cationic UV and heat dual deeply-curing adhesive and its preparation method can be obtained.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

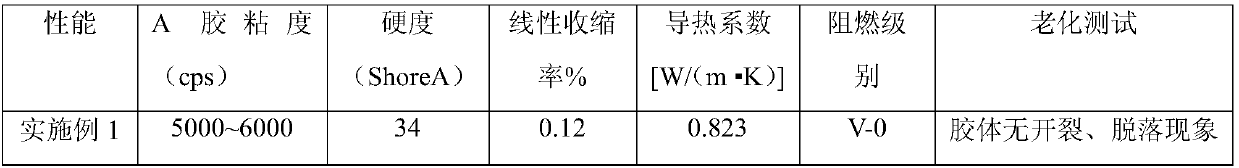

Low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and preparation method and application thereof

InactiveCN107760256AFast curingHigh copy numberNon-macromolecular adhesive additivesMacromolecular adhesive additivesHeat conductingPlasticizer

The invention belongs to the technical field of encapsulating materials, and discloses a low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and a preparation method and application thereof. The organosilicone pouring sealant consists of a component A and a component B, of which the weight ratio of (10:1) to (5:1), wherein the component A consists of the following raw materials in parts by weight: 100 parts of a base adhesive, 30 to 80 parts of a plasticizer A, 0.01 to 3 parts of a coloring material and 0.1 to 1 part of a curing accelerant; and the component B consists of the following raw materials in parts by weight: 80 to 300 parts of a crosslinking agent, 10 to 60 parts of a coupling agent, 0.5 to 1.5 parts of a catalyst and 100to 500 parts of a plasticizer B. The base adhesive consists of the following raw materials in parts by weight: 100 parts of liquid silicone rubber, 3 to 10 parts of reinforcing filler, 20 to 80 partsof heat-conducting filler, 20 to 100 parts of flame-retardant filler, 3 to 10 parts of a surface treating agent and 3 to 20 parts of functional filler.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Ultraviolet-curable resin composition and fiber reinforced resin-based composite material thereof

The invention relates to an ultraviolet-curable resin composition and a fiber reinforced resin-based composite material thereof, and belongs to the technical field of light curing technologies and resin-based composite materials. The ultraviolet-curable resin composition comprises, by weight, 90-110 parts of epoxy resin, 0.1-0.7 parts of a cationic photoinitiator, 0.1-0.5 parts of a thermal initiator, 0-1 part of a photosensitizer, 0-35 parts of an active diluent and 0-30 parts of an additive. The ultraviolet-curable resin composition initiates a cationic polymerization reaction under the irradiation of ultraviolet light; and heat release of the polymerization reaction and the decomposition of the cationic photoinitiator commonly urges the thermal initiator to decompose in order to initiate a self propagating wave polymerization reaction. The ultraviolet-curable resin composition has the advantages of fast curing speed, high curing thickness, and realization of one-stage rapid deep curing. The fiber reinforced resin-based composite material with the composition as a matrix phase has good tensile strength, and curing is not affected by the laying layer number of fibers or the light transmission of a reinforcing phase.

Owner:青岛东正浩机电科技有限公司

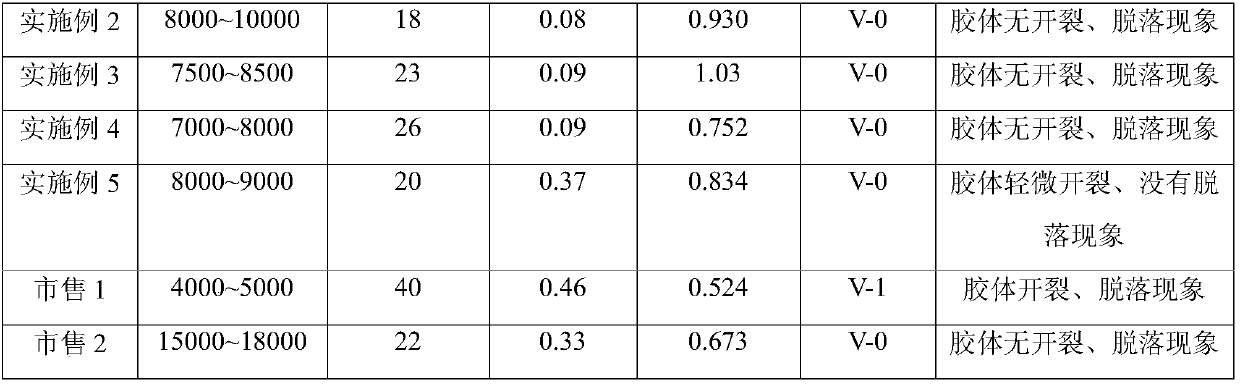

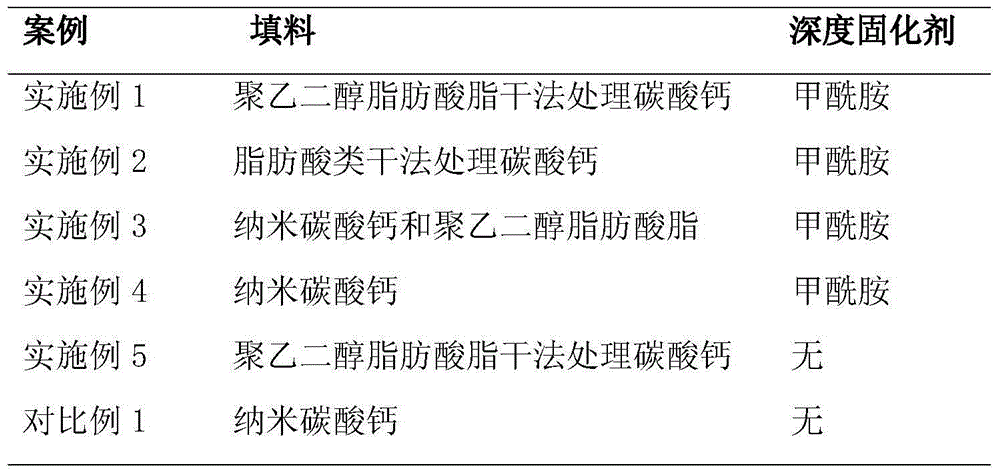

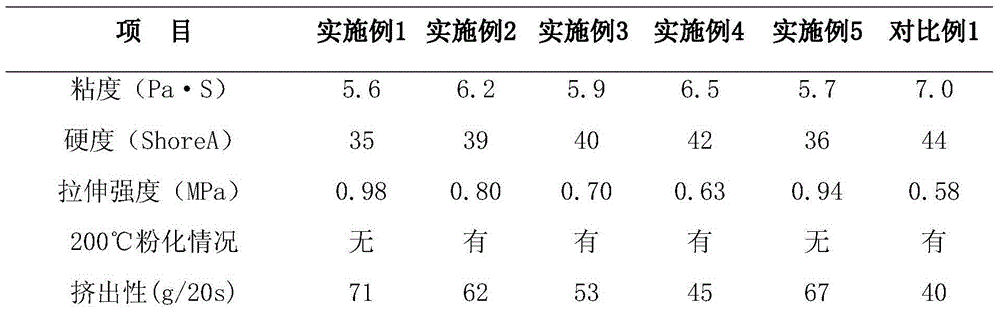

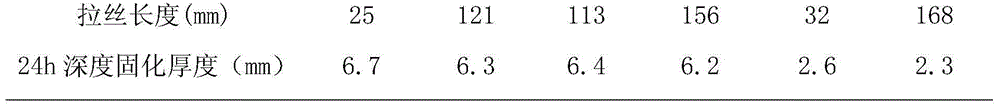

Single-component dealcoholized and room temperature vulcanized organosilicone pouring sealant for leds and preparation method

InactiveCN104449547AImprove liquidityReduce drawingNon-macromolecular adhesive additivesOther chemical processesCross-linkVulcanization

The invention discloses a single-component dealcoholized and room temperature vulcanized organosilicone pouring sealant for LEDs and a preparation method. The pouring sealant is prepared from the following raw materials in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethyl siloxane with a viscosity of 500-15000 mPa.s, 10-50 parts of dry processed nano calcium carbonate, 1-10 parts of calcium chloride, 5-10 parts of white carbon black, 8-20 parts of dimethicone with a viscosity of 100-5000 mPa.s, 3-10 parts of a cross-linking agent, 0.3-5 parts of a coupling agent, 0.5-8 parts of titanium complex, 0.01-0.5 part of organotin and 0.5-10 parts of a deep vulcanization accelerator. The pouring sealant provided by the invention has an excellent flow property with low thread drawing, the capabilities of anti-pulverization at a high temperature and fast and deep curing, and a good mechanical property; the produced gas has good cohesiveness on the base material without corrosive action; the method is simple and feasible in technology, easy to operate and low in production cost, and has preferable economic and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney and preparation method thereof

ActiveCN103396759ALong storage periodImprove performanceNon-macromolecular adhesive additivesCross-linkBrick

The invention discloses an anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney and a preparation method thereof. The preparation method comprises following steps: preparing a component A, mixing 107 silicone rubber, fumed silica, silicon powder, silicone oil, kaolin, and a deep curing addictive together to prepare the component A; preparing a component B, mixing a cross-linking agent, tackifier, catalyst, silicone oil, fumed silica and carbon black to prepare the component B, and mixing the component A and the component B according to a certain ratio to prepare an anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney. The anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney has the advantages of high tensile strength, excellent elongation at break, high shear strength, long operation time, convenience for on-site construction, fast deep curing, and good adhesivity and elasticity, and is capable of applying to the fields of anti-corrosion of inner wall of desulfuration chimney and adhesive bonding and coating of various light glass bricks.

Owner:武汉双键新材料股份有限公司

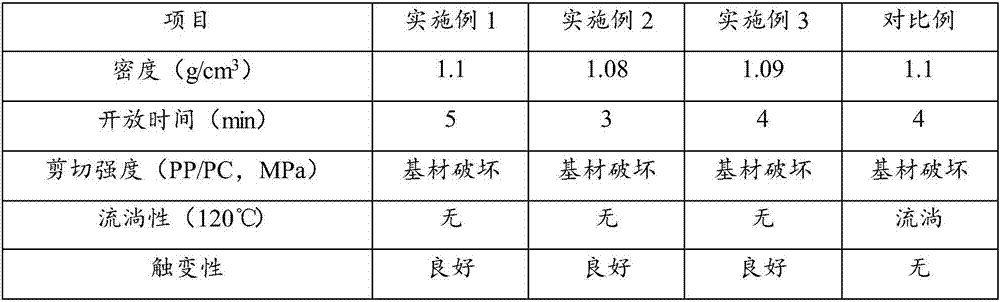

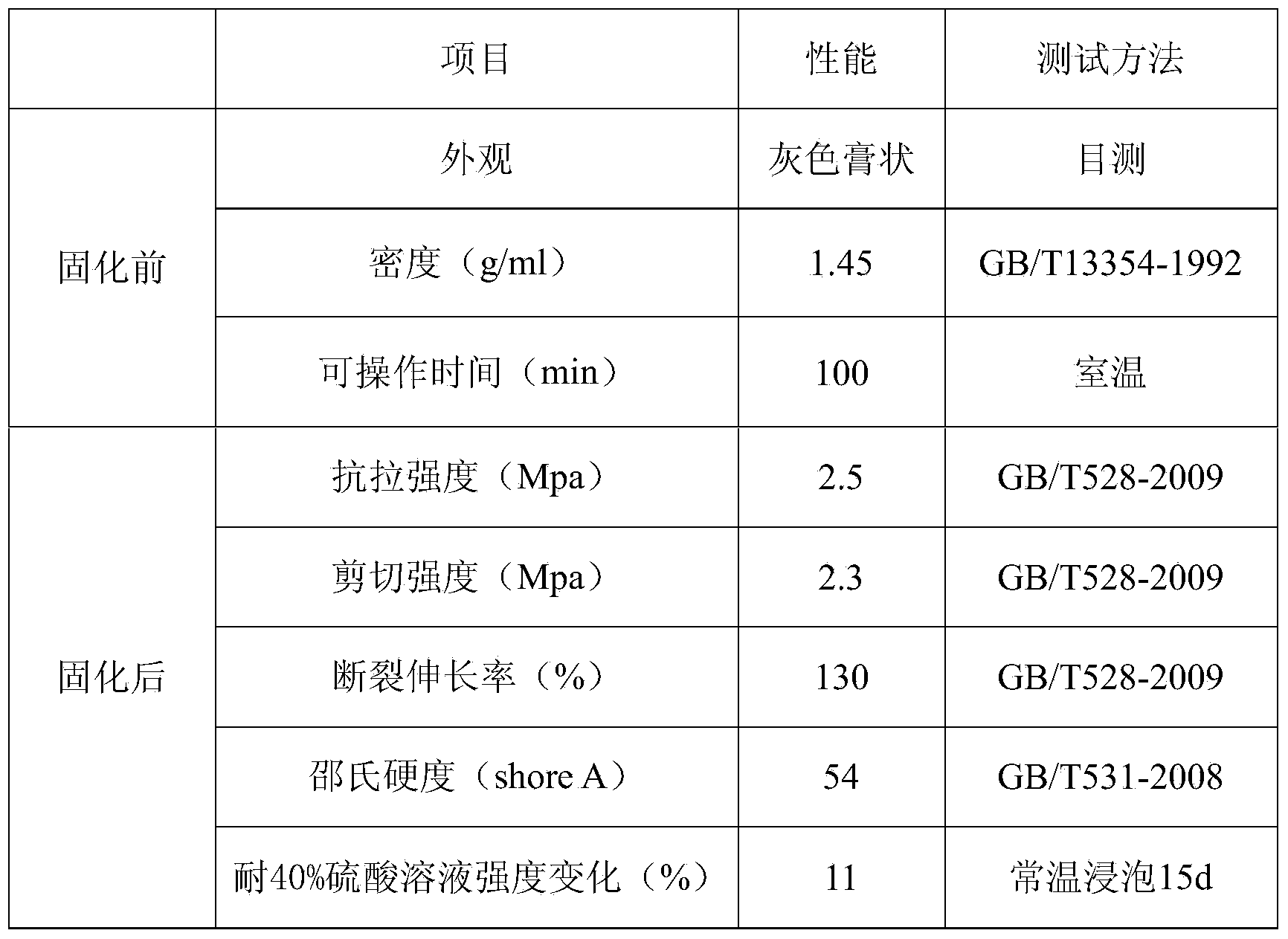

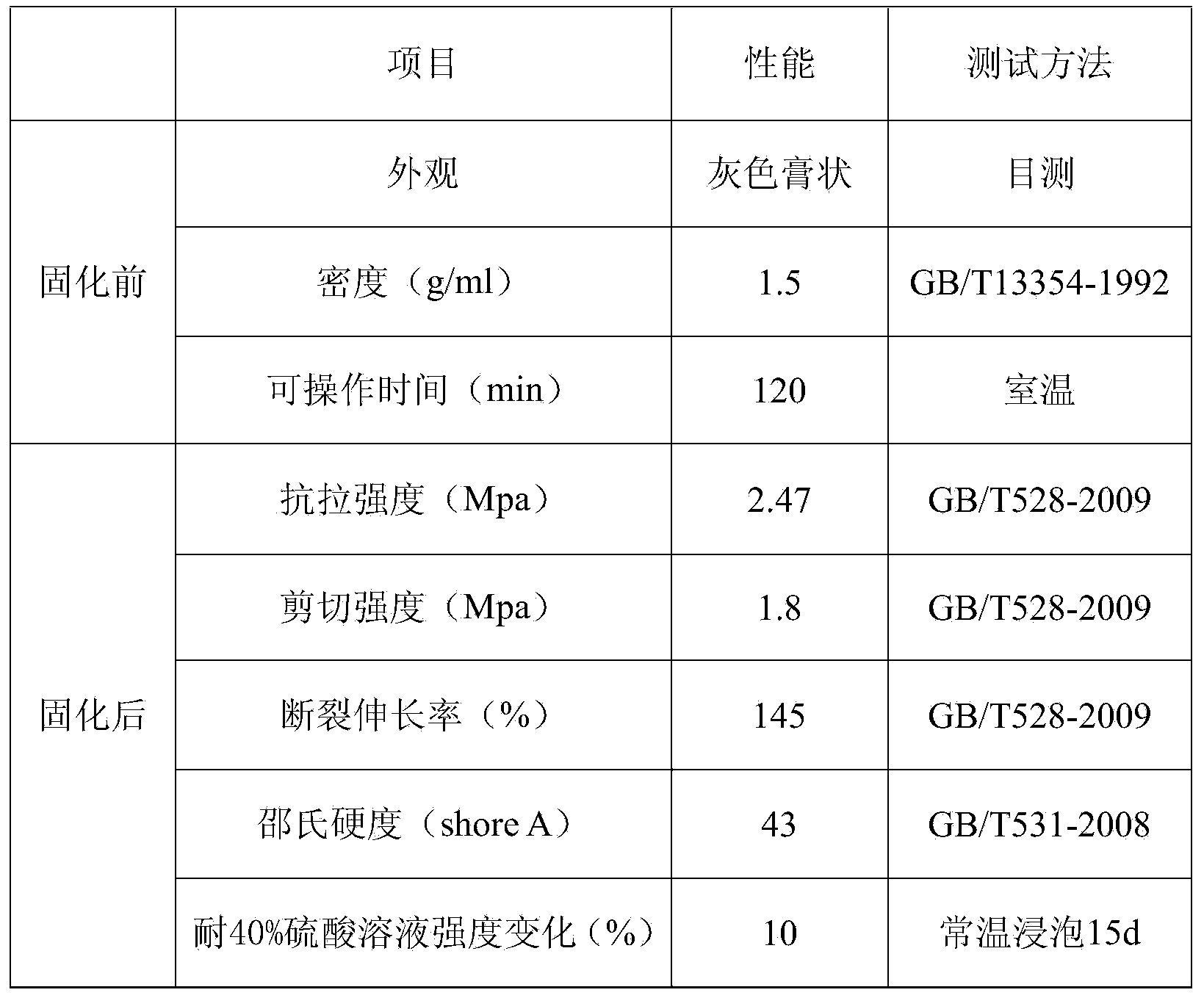

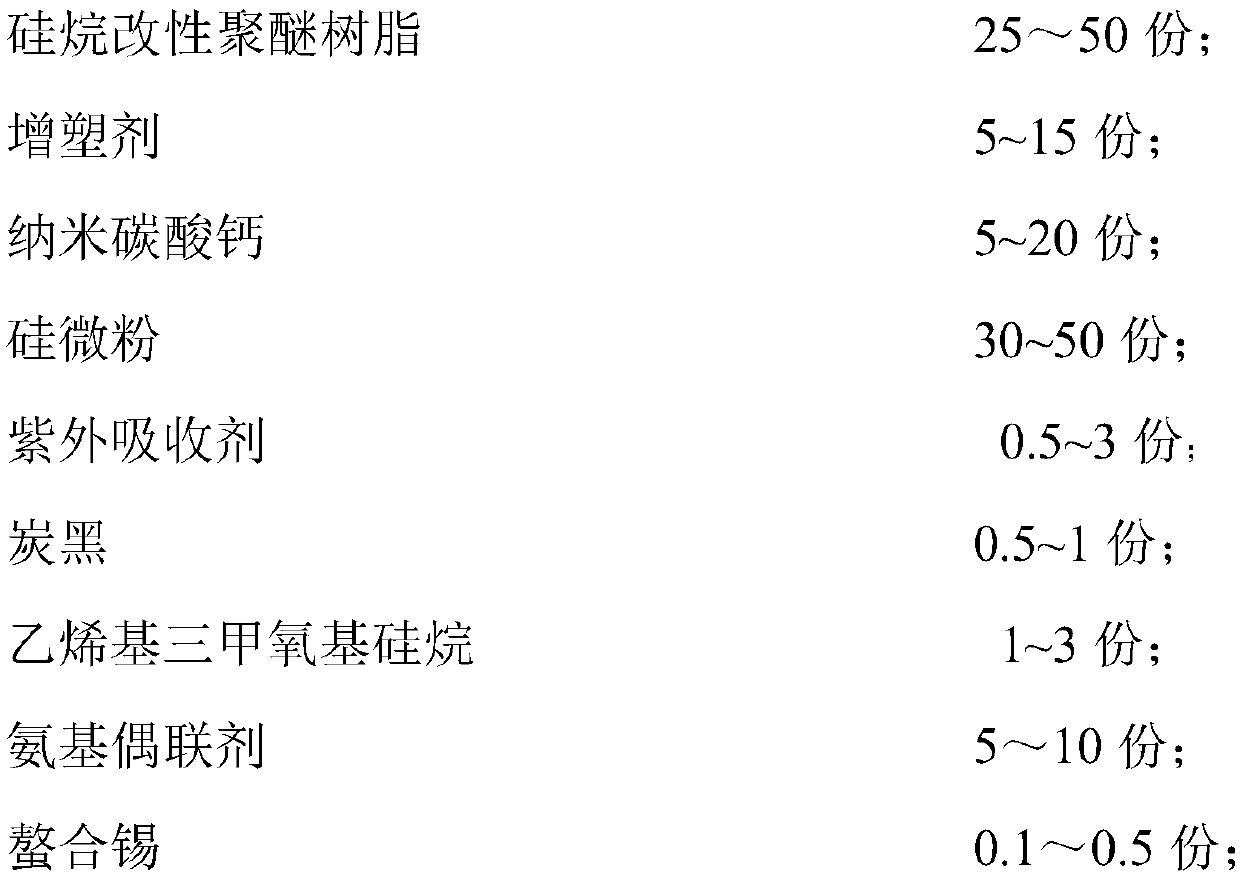

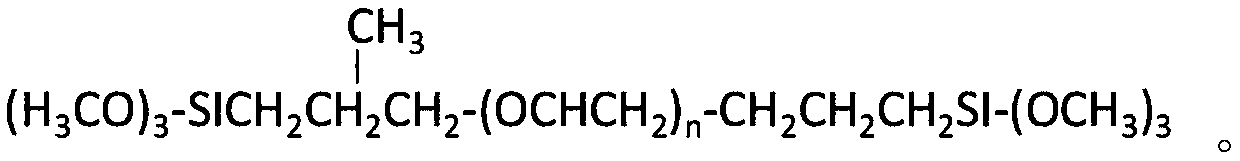

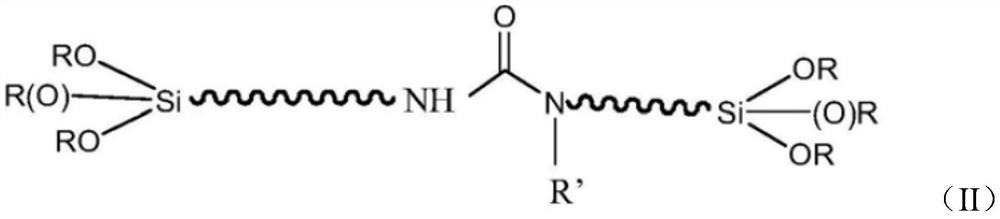

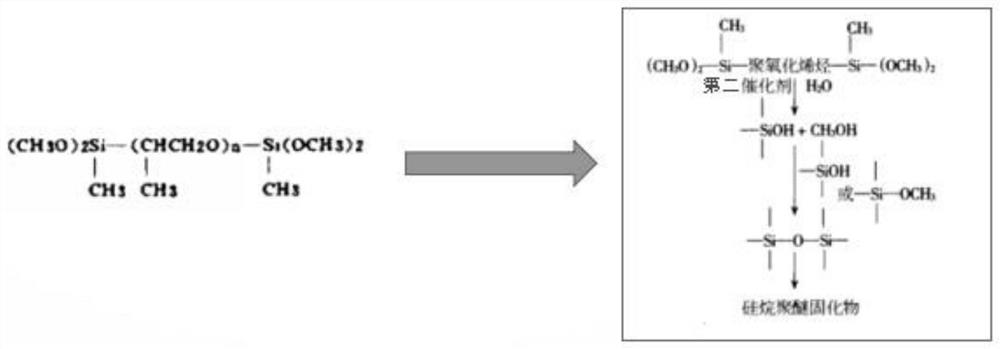

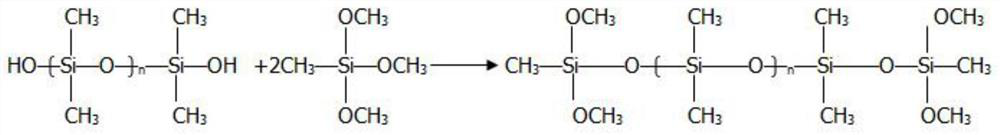

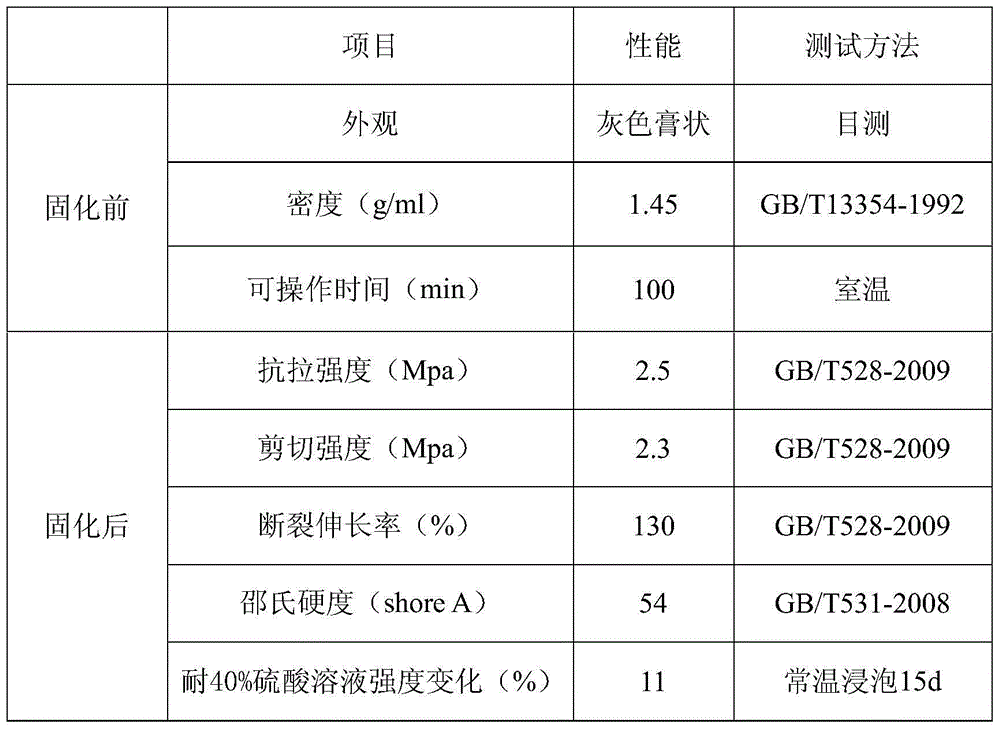

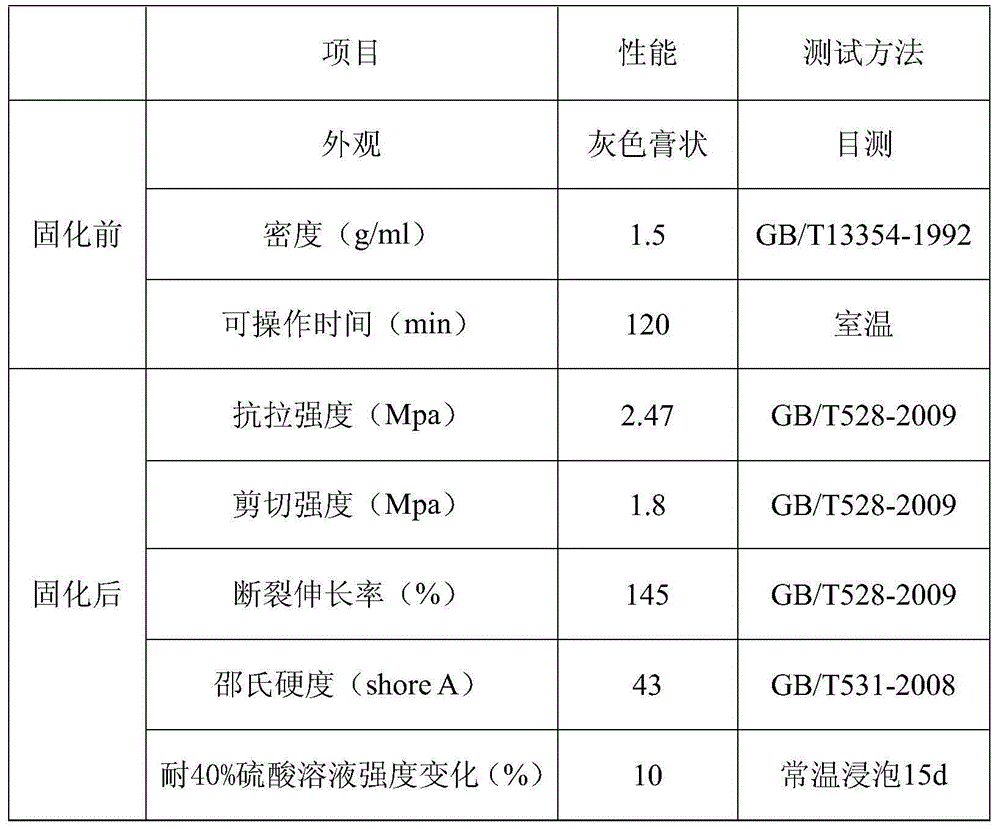

Double-component silane modified polyether sealant with controllable curing speed

InactiveCN109628046ADeep curing fastHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxySealant

The invention discloses a double-component silane modified polyether sealant with a controllable curing speed, which comprises a component A and a component B, wherein the mass ratio of the componentA to the component B is 1-100:1, and the component A comprises 25-50 parts of silane modified polyether resin, 5-15 parts of a plasticizer, 5-20 parts of nano calcium carbonate, 30-50 parts of siliconmicropowder, 0.5-3 parts of a ultraviolet absorbent, 0.5-1 part of carbon black, 1-3 parts of vinyl trimethoxy silane, 5-10 parts of an amino coupling agent and 0.1-0.5 part of chelated tin; the component B comprises, by mass, 20-30 parts of epoxy resin, 20-30 parts of a plasticizer, 10-20 parts of silicon micropowder and 5-20 parts of an accelerator. According to the invention, rapid deep curingof the component A can be achieved through the promotion effect of the component B, and the strength is increased, so that the shear strength can reach 1.5MPa within 4h, and the shear strength can reach 2.3MPa within 24h.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Prepreg rapidly cured at room temperature and preparation method

The invention relates to a prepreg rapidly cured at room temperature. The prepreg comprises a resin composition and a fiber-reinforced fabric, wherein the resin composition is prepared through uniformly mixing the following raw materials at room temperature in a shaded manner: resin, a photoinitiator, a thermal initiator, a reactive diluent and additives, and is viscous liquid; a flaky prepreg isprepared through dipping the fiber-reinforced fabric with the resin composition and sticking a black barrier film on the fiber-reinforced fabric; and when a composite product is prepared through subjecting the prepreg to tailoring, sticking and curing, the curing process conditions are as follows: the time of irradiation by an ultraviolet light source at room temperature is 10 to 30 seconds, and the time of curing placement is 0.1 to 5 minutes. According to the prepreg, room-temperature rapid curing can be carried out by using autologous reaction heat by only irradiation under the ultravioletlight source without supplying energy to a reaction system, heating and adding of other chemicals are not required during molding, a postcuring procedure is also not required, and thus, the aim of room-temperature rapid curing is achieved.

Owner:HEFEI UNIV OF TECH

Preparation method of cationic ultraviolet light and heat dual deep curing adhesive

InactiveCN106928893ARapid responseDeep curing fastNon-macromolecular adhesive additivesEpoxy resin adhesivesPhotosensitizerAdhesive

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Organosilicon sealant and preparation method thereof

ActiveCN111004604ADeep curing fastImprove flexibilityNon-macromolecular adhesive additivesOrganosiliconSiloxane

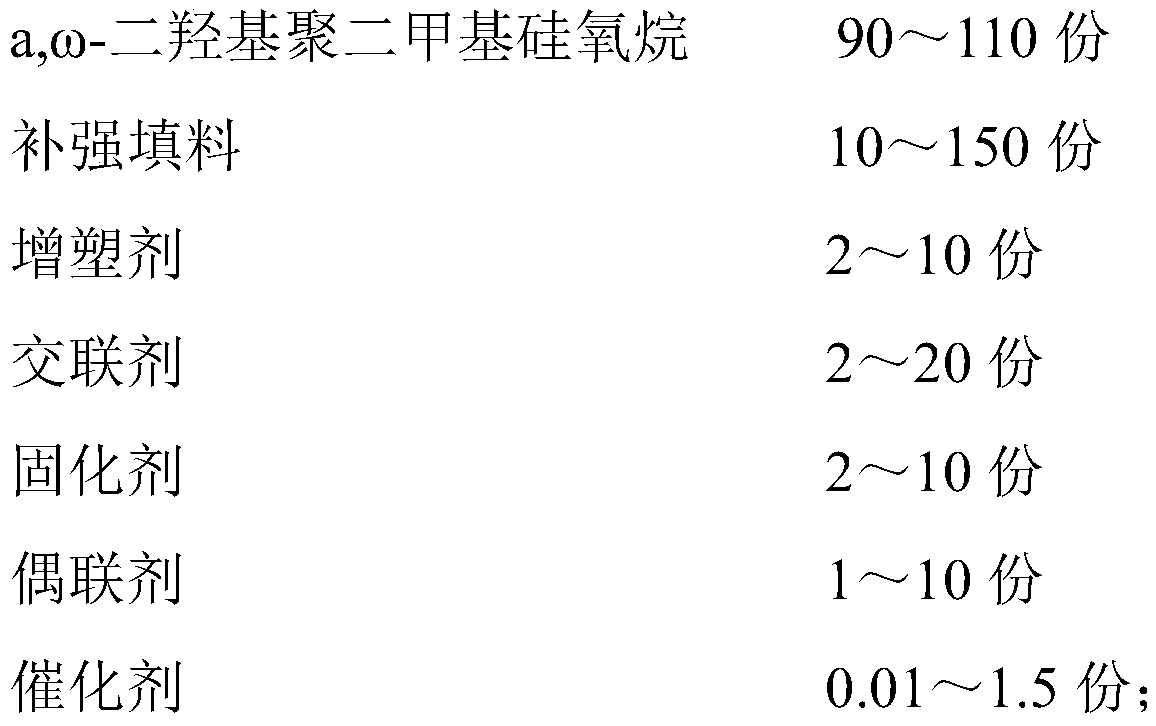

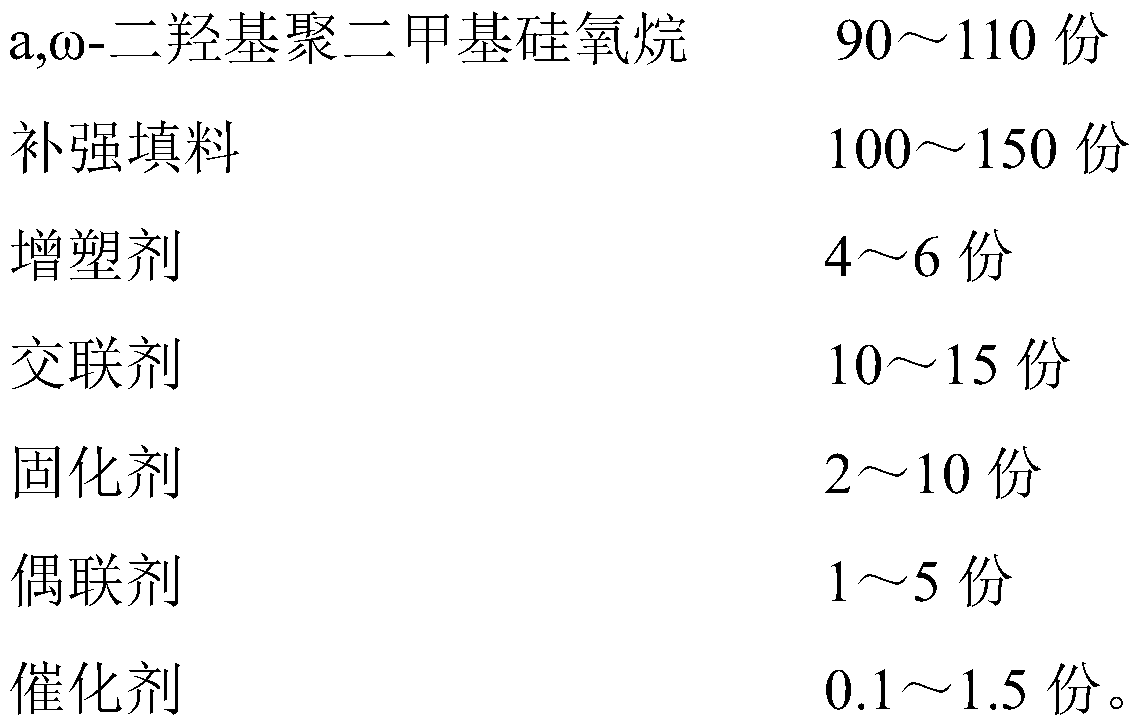

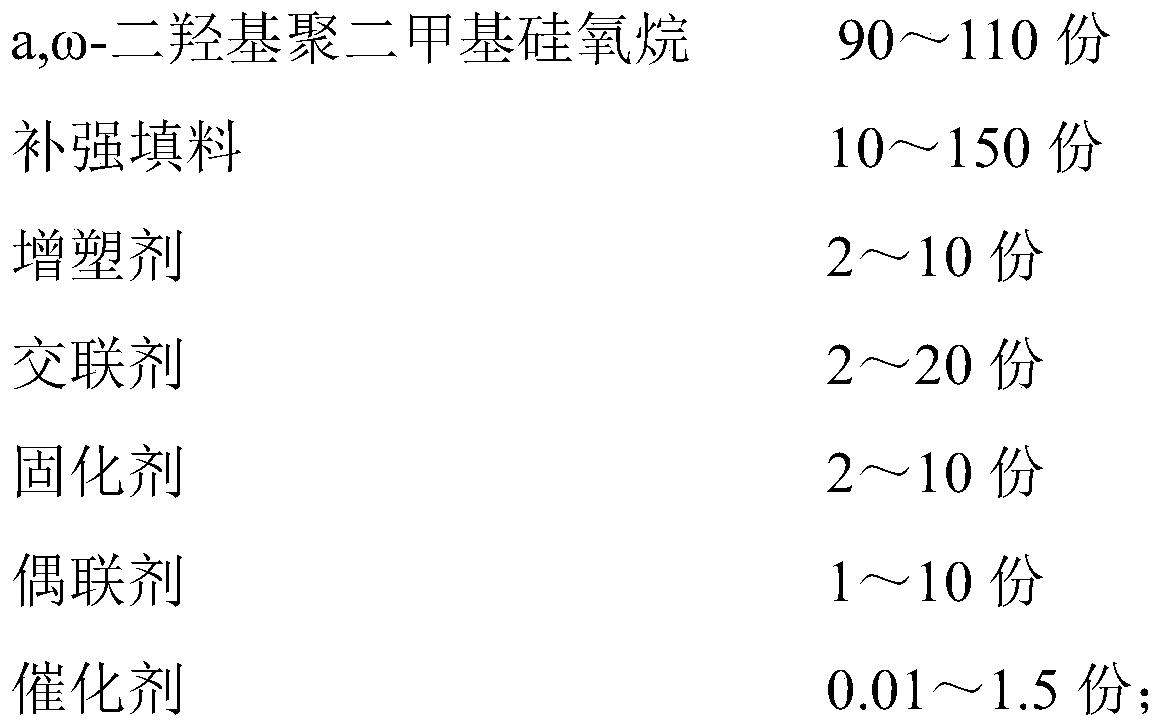

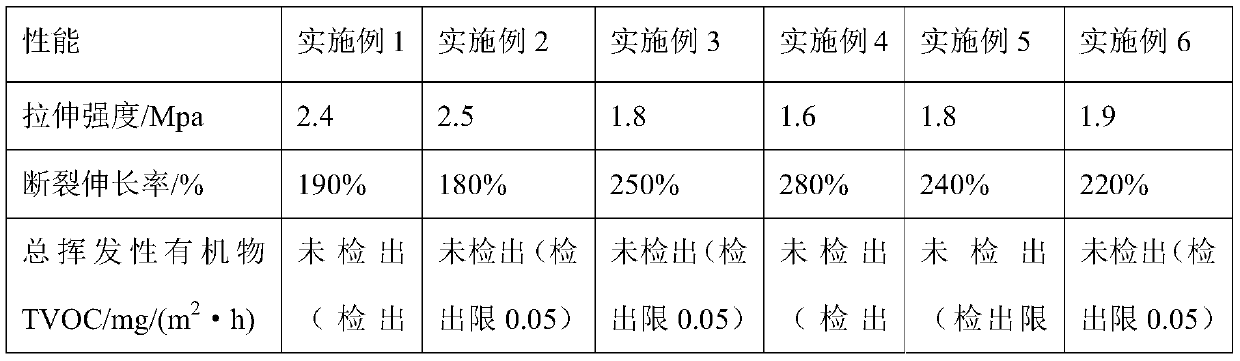

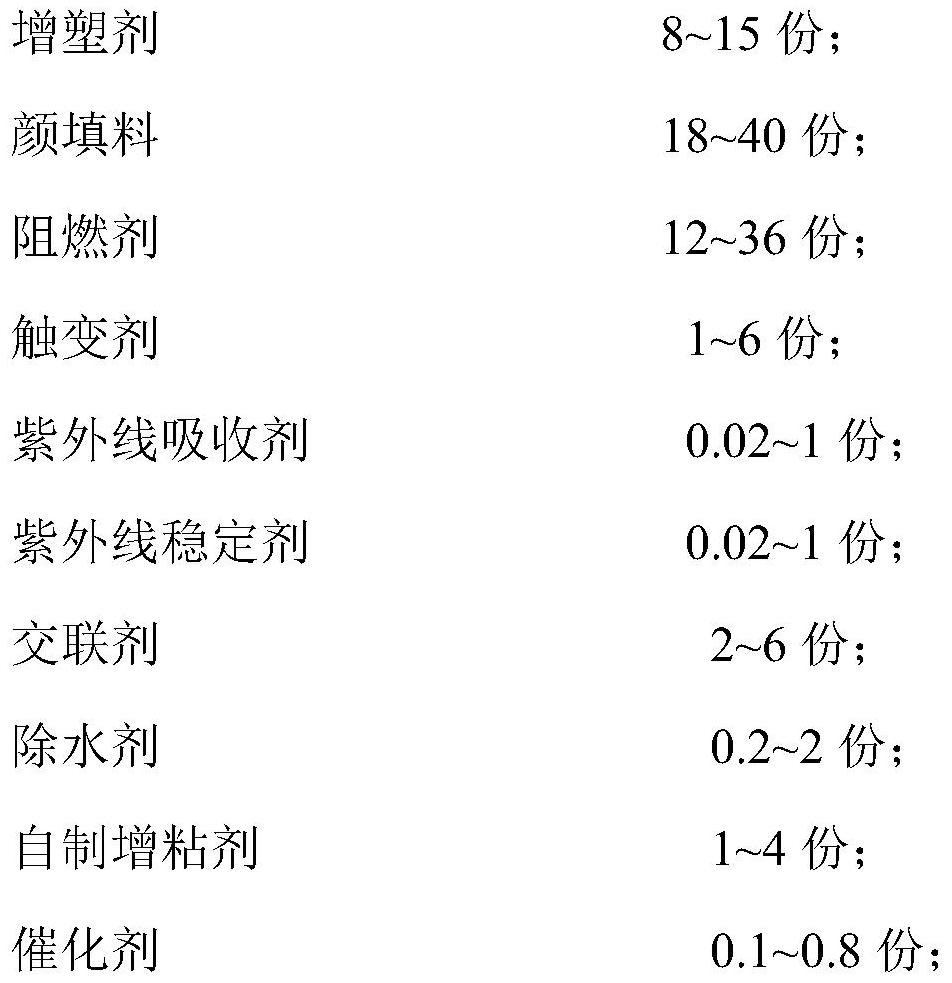

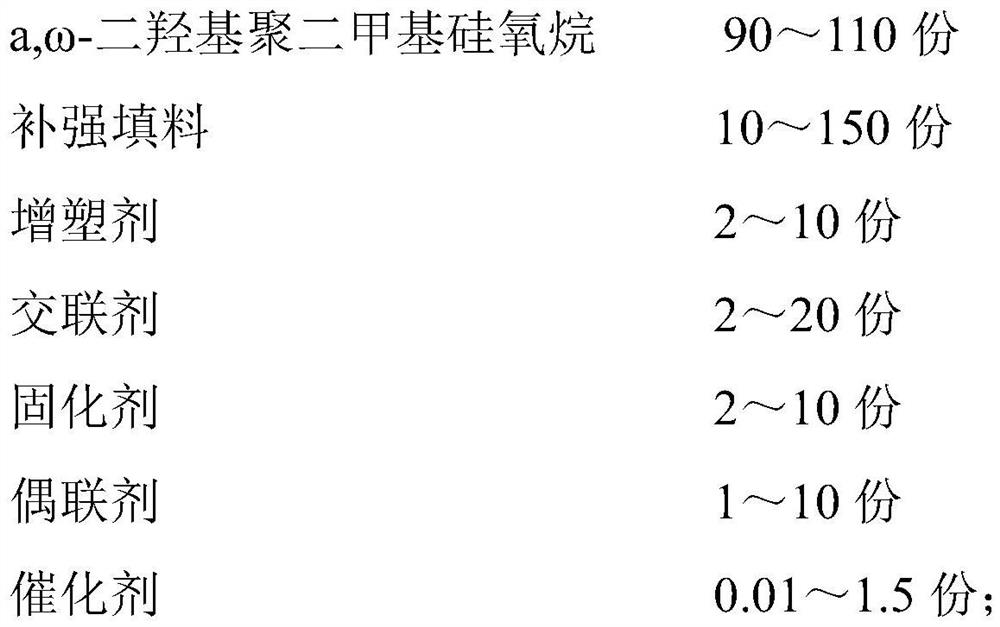

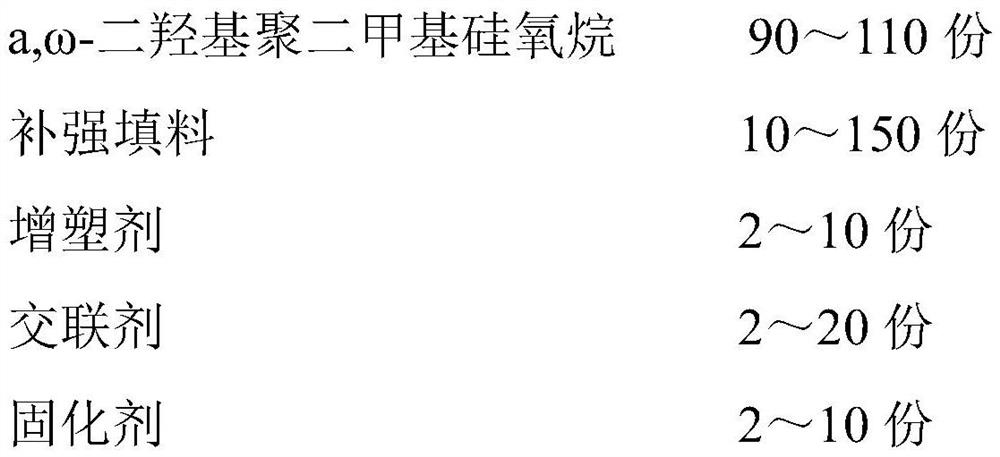

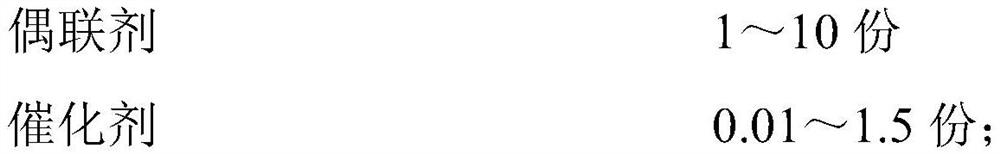

The invention relates to an organosilicon sealant and a preparation method thereof, wherein the organic silicon sealant is prepared from the following raw materials in parts by weight: 90 to 110 partsof alpha,omega-dihydroxy polydimethylsiloxane, 10 to 150 parts of a reinforcing filler, 2-10 parts of a plasticizer, 2-20 parts of a cross-linking agent, 2-10 parts of a curing agent, 1-10 parts of acoupling agent, and 0.01-1.5 parts of a catalyst. The organosilicon sealant provided by the invention can realize rapid deep curing, and has good hardness and good mechanical properties.

Owner:GUANGZHOU BAIYUN CHEM IND

Organic silicon pouring sealant for LEDs and preparation method for organic silicon pouring sealant

InactiveCN105086923ASimple to useAutomatic defoamingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkVacuum pumping

The invention relates to an organic silicon pouring sealant for LEDs. The organic silicon pouring sealant for LEDs is characterized by comprising the following components (in parts by weight): 90-100 parts of low-viscosity 107 glue, 1-5 parts of hydroxyl end-capping silicone oil, 2-5 parts of methyl silicone oil, 1-5 parts of methyl fluorosilicone oil , 5-10 parts of a cross-linking agent, 1-5 parts of a cross-linking agent and 1-5 parts of a catalyst. The preparation method comprises: adding the low-viscosity 107 glue, the hydroxyl end-capping silicone oil, the methyl silicone oil and the methyl fluorosilicone oil into a stirrer in formula to be stirred for 30 minutes at a high speed, and carrying out vacuum pumping to remove air bubbles to obtain a mixture II; taking the mixture I as base glue; adding the cross-linking agent, the coupling agent and the catalyst according to the formula to be uniformly mixed to obtain a mixture II, and taking the mixture II as an auxiliary gent; and uniformly mixing the base glue with the auxiliary agent in a ratio of the base glue to the auxiliary agent being 10:1, thereby obtaining the organic silicon pouring sealant for LEDs. The organic silicon pouring sealant disclosed by the invention is excellent in bonding force, high in transparency, good in bubble discharge, quick in deep-layer curing and free of yellowing. The organic silicon pouring sealant can be used for protecting the LEDs from invasion of the external environment for a long time.

Owner:SUZHOU DATONG ADVANCED MATERIAL

Method for preparing fiber-reinforced resin-based composite material through cationic photocuring and resin composition used therein

InactiveCN106987092AWith post-cureSolve the problem of light curing thicknessPhotosensitizerResin matrix

The invention relates to a method for preparing a fiber-reinforced resin-based composite material by cationic photocuring and a resin composition thereof, belonging to the technical fields of photocuring technology and resin-based composite material. In the formula of the cationic photocurable resin composition, the ingredients and parts by weight of each raw material are as follows: 90-110 parts of epoxy resin, 0.1-10 parts of cationic photoinitiator, 0-10 parts of photosensitizer, and 0-35 parts of reactive diluent. parts, 0-30 parts of additives. The ultraviolet curable resin composition of the present invention is prepared by a method of photoinitiating and dispersing active centers to obtain a fiber-reinforced resin-based composite material, which has the advantages of low curing energy consumption, fast curing speed, and large curing thickness, and can realize one-time rapid deep-layer curing. The fiber-reinforced resin-based composite material prepared by the composition and method has good tensile strength, and can solve the problem of light-cured thickness of an opaque system or a thick-size system.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

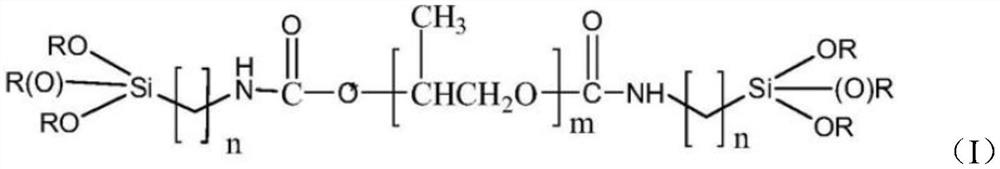

Bubble-free fast and deep curing one-component modified PU court material and preparation method thereof

The invention provides a bubble-free fast and deep curing one-component modified PU court material. The material comprises the following components in percentage by weight: 10-30% of a polyether polyol, 2-7% of an isocyanate, 15-50% of a filler, 15-40% of an environment-friendly diluent, 1.5-4.5% of a composite stabilizer, 2-10% of a latent curing agent, and 3.42-20% of an auxiliary agent, whereinthe latent curing agent is a mixture of one or more of aldimines, ketimines, and oxazolidines. Compared with the silicon PU court of the prior art, the bubble-free fast and deep curing one-componentmodified PU court material uses the latent curing agent to replace a blocked silane coupling agent, has small use amount and low price, and has the advantages of low TVOC content, convenient and simple construction, fast curing speed, no bubbles when curing, excellent physical properties, and the like.

Owner:广东盛天体育股份有限公司

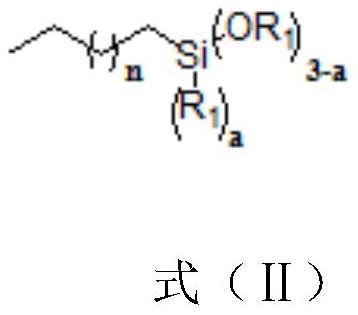

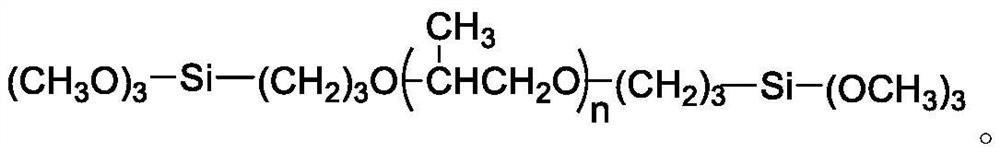

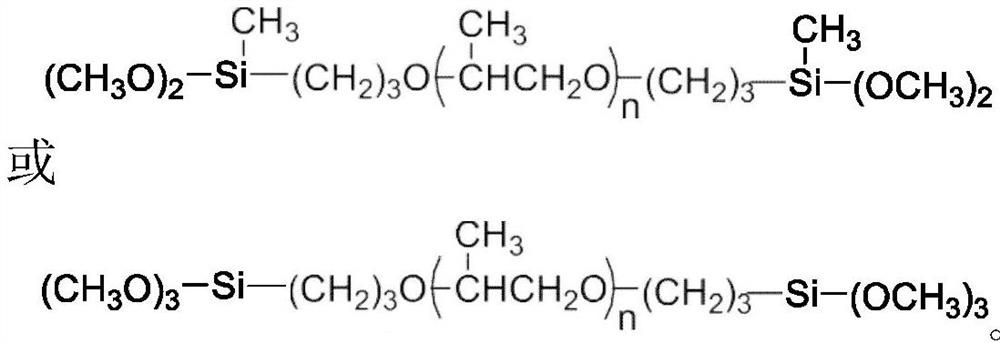

1,2-ditrialkoxy silane crosslinking agent and preparation method and application thereof

InactiveCN105585734AGood compatibilityImprove the lack of slow curing in deep layersGroup 4/14 element organic compoundsSilanesSealant

The invention provides a 1,2-ditrialkoxy silane crosslinking agent and a preparation method and application thereof. The 1,2-ditrialkoxy silane crosslinking agent has the structure as follows: (R1O)3SiCH2CH2(CH2)nSi(R2O)3, wherein the R1 and the R2 are independently any one of -CH3, -CH2CH3 or -CH2CH2CH3, and the n is an integer of 0-3. The 1,2-ditrialkoxy silane crosslinking agent prepared by means of the preparation method can strengthen the compatibility of a crosslinking agent and siloxane and has wide application prospect, deep curing is fast, the curing depth within 24 hours can reach 3-7 mm, and the shortcoming that a domestic dealcoholization type sealant is slow in deep curing can be overcome.

Owner:兆舜科技(广东)有限公司

Composition of double-component organosilicon photovoltaic component sealant, and preparation method thereof

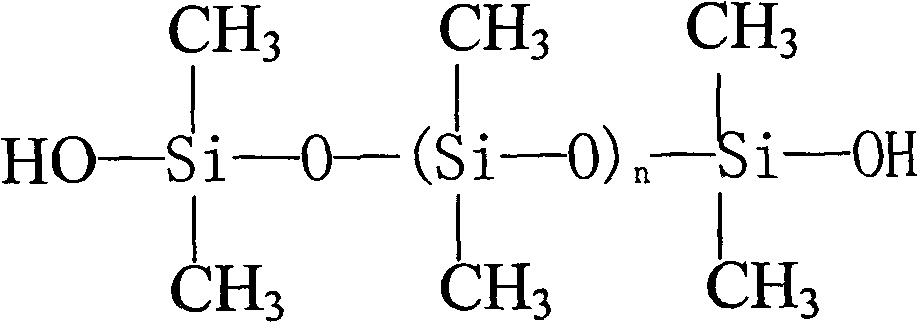

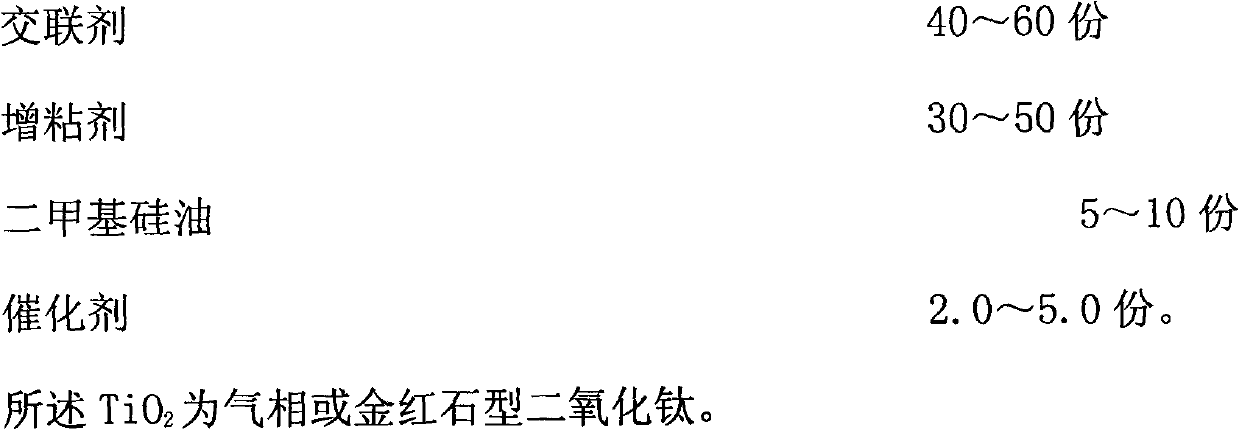

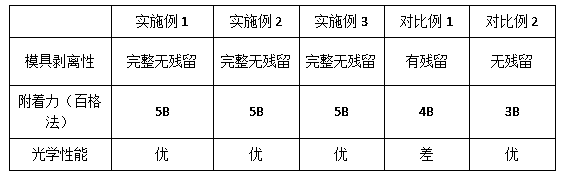

ActiveCN102304345BHigh bonding strengthHigh outdoor service lifeNon-macromolecular adhesive additivesDrying timeSealant

The invention relates to the polymer material, specifically to a double-component organosilicon photovoltaic component sealant. The sealant comprises a component A and a component B. The component A comprises the following materials, by weight, 30-70 parts of a first 107 silicon rubber, 30-70 parts of a second 107 silicon rubber, 1-2 parts of TiO2, 50-100 parts of hydroxyl silicone oil and 50-150parts of a filler. The component B comprises the following materials, by weight, 40-60 parts of a cross-linking agent, 30-50 parts of a tackifier, 5-10 parts of dimethyl silicon oil and 2.0-5.0 partsof a catalyst. According to the present invention, the sealant provided by the present invention has a long storage time under a room temperature condition; the surface drying time after constructionis moderate; the sealant can be rapid deep cured at the room temperature; the sealant has characteristics of high adhesive strength, good weathering resistance, long outdoor service life, aging resistance, yellowing resistance, environmental protection and the like, and is mainly applicable for the solar photovoltaic component sealing adhesion and the field with high adhesion performance requirements.

Owner:深圳市希顺有机硅科技有限公司

UV (ultraviolet) optical adhesive

InactiveCN109735290AHigh speedReduce foulingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOligomerAdhesive

The invention discloses UV (ultraviolet) optical adhesive, made from, by weight, 30-60 parts of an acrylate oligomer, 30-50 parts of an acrylate monomer, 1-4 parts of a photopolymerization initiator,and 3-5 parts of an adhesion promotion aid. The UV optical adhesive has the advantages that the finished adhesive has reliable indexes, the yield is increased, fewer defects are shown to customers, mobility and curing speed of the adhesive are increased, and coating speed is increased so that production efficiency is improved.

Owner:苏州宝瑞德纳米光学材料有限公司

Low-temperature, low-humidity and rapid-curing polyurethane composition and preparation method thereof

The invention relates to a low-temperature, low-humidity and rapid-curing polyurethane composition and a preparation method thereof. The polyurethane composition comprises a polyurethane prepolymer P1, a polyurethane prepolymer P2, a polyurethane prepolymer P3, a modified filler, carbon black, a plasticizer, a catalyst and an adhesion promoter. The polyurethane composition provided by the invention can be quickly cured under low-temperature and low-humidity conditions through the matching of the polyurethane prepolymer P1, the modified filler and other components, and has the advantages of wide application and convenience in construction.

Owner:广东盛业化学科技有限公司

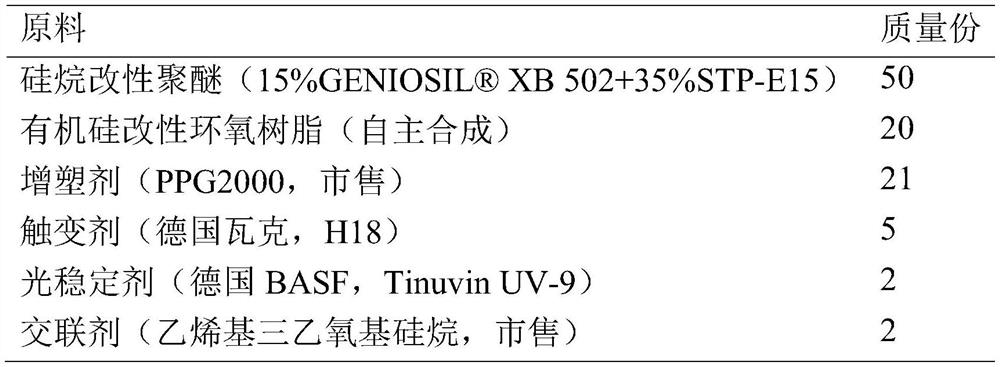

Transparent two-component silane-modified polyether sealant and preparation method thereof

ActiveCN110157376BRetain flexibilityHigh mechanical strengthEpoxy resin adhesivesEpoxyPolymer science

The invention relates to a transparent two-component silane-modified polyether sealant and a preparation method thereof. The transparent two-component silane-modified polyether sealant includes: component A, in weight percent, made of raw materials including the following components: 30-60% of silane-modified polyether, silicone-modified epoxy Resin 10-50%, plasticizer 0-40%, thixotropic agent 5-10%, light stabilizer 1-5%, cross-linking agent 1-5%; B component, by weight percentage, consists of the following The components are made of raw materials: plasticizer 50-80%, amine catalyst 20-50%. The silane-modified polyether sealant has the characteristics of high transparency, high strength and good bonding performance at the same time, and does not need to use an organic tin catalyst, the inner and outer layers are cured simultaneously, and the construction property is good.

Owner:GUANGZHOU BAIYUN CHEM IND

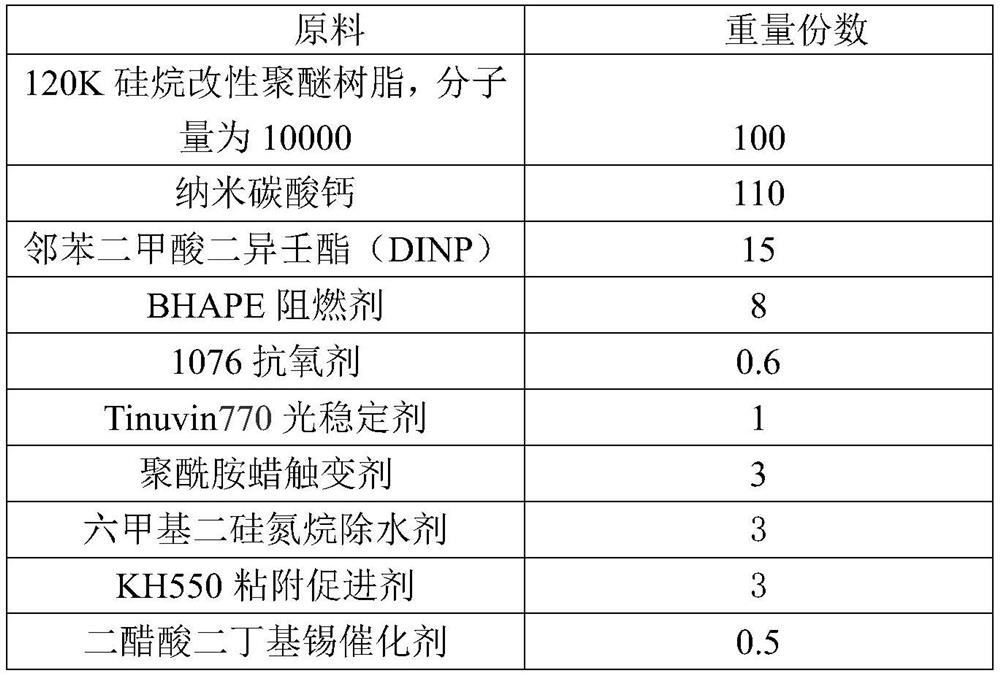

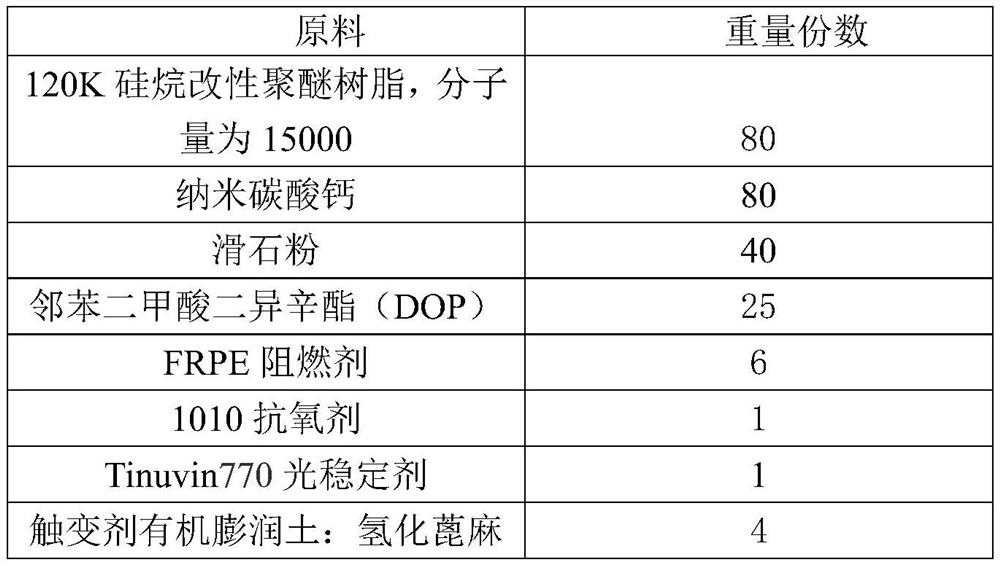

A kind of flame-retardant silane-modified polyether sealant and preparation method thereof

ActiveCN108893087BImprove flame retardant performanceImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a flame-retardant silane-modified polyether sealant and a preparation method thereof. The sealant is prepared by mixing the following raw materials in parts by weight: 50-100 parts of silane-modified polyether resin, reinforcing filler 80-150 parts, 10-35 parts of plasticizer, 5-10 parts of flame retardant, 0.1-1 part of antioxidant, 1-2 parts of light stabilizer, 2-8 parts of thixotropic agent, 1-4 parts of water remover 2-6 parts of adhesion promoter and 0.1-1 part of catalyst. Described flame retardant is one or more in flame-retardant glycol (BHAPE), P-N type ricinoleic acid-based polyether polyol (FRPE) and P-containing ricinoleic acid-based polyether polyol (COFPL) kind of combination. The sealant prepared by the invention has the advantages of excellent flame retardant performance, good bonding performance, good mechanical properties, fast curing and other weather resistance, and is suitable for bonding materials that require high flame retardant performance, such as indoor fireproof doors and windows, public fireproof facilities, etc. and seal.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Silicone sealant for rail transit and preparation method thereof

InactiveCN111793462AImprove drummingDeep curing fastNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

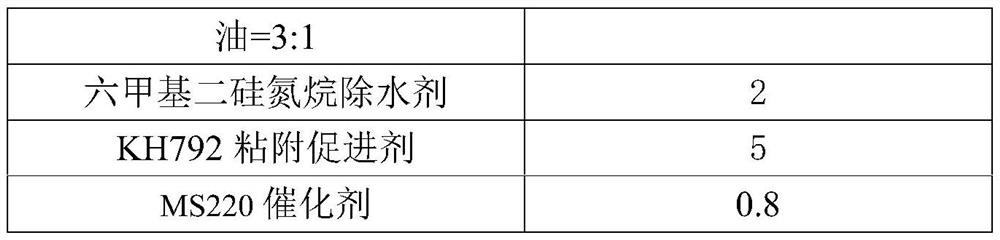

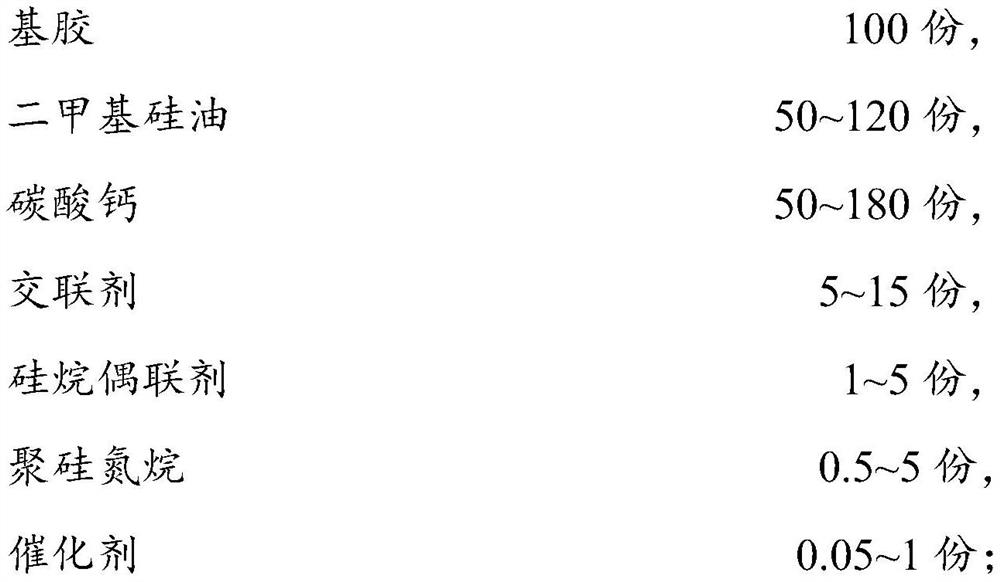

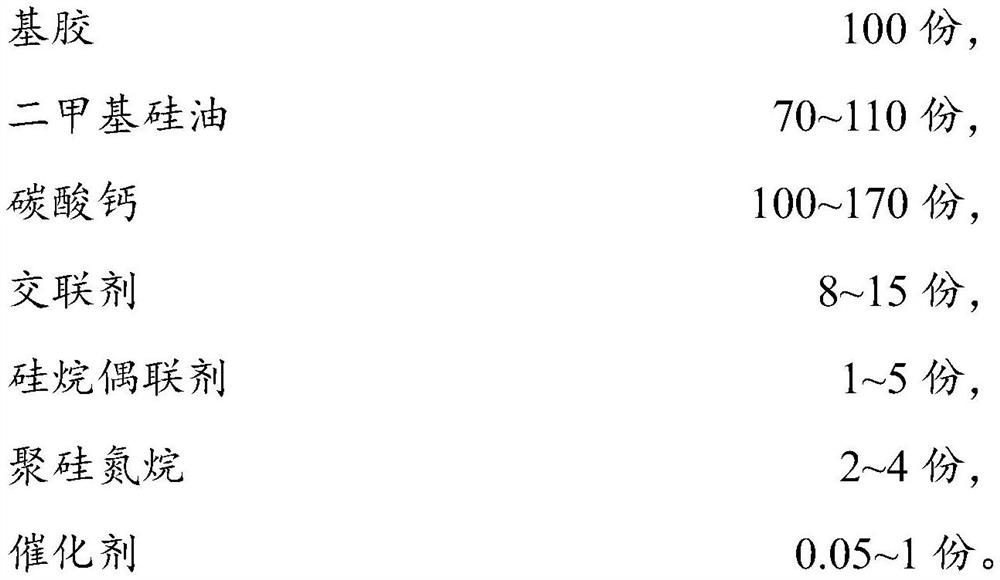

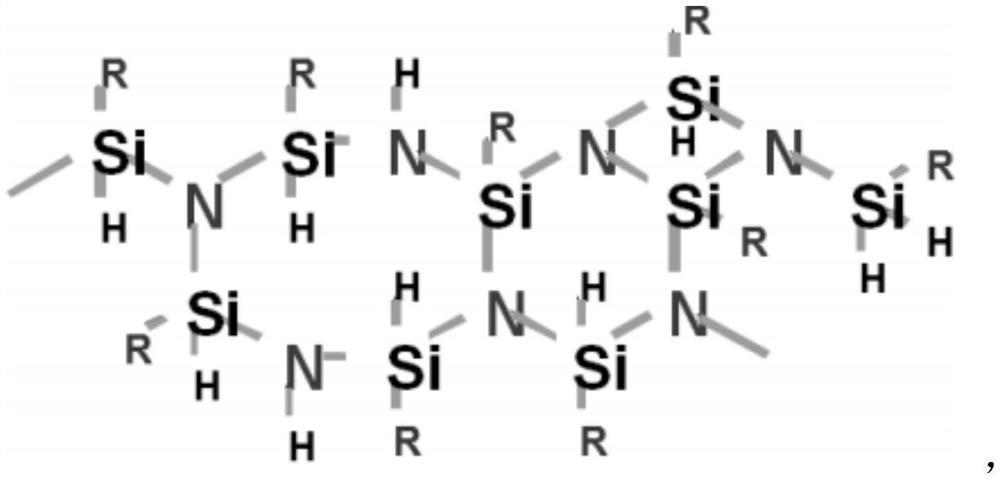

The invention relates to a silicone sealant for rail transit and a preparation method thereof. The silicone sealant is prepared from the following raw materials in parts by weight: 100 parts of base rubber, 50-120 parts of dimethyl silicone oil, 50-180 parts of calcium carbonate, 5-15 parts of a cross-linking agent, 1-5 parts of a silane coupling agent, 0.5-5 parts of polysilazane and 0.05-1 partof a catalyst, wherein the base rubber is alpha,omega-dihydroxy polydimethylsiloxane. According to the silicone sealant, the bulging phenomenon under the condition of large day and night temperature difference is improved, deep curing is accelerated, mechanical properties are obviously improved, and a storage period is greatly prolonged.

Owner:GUANGZHOU BAIYUN CHEM IND

A kind of two-component room temperature curing silicone rubber and preparation method thereof

The invention is a two-component room temperature curing silicone rubber and a preparation method thereof, comprising two components A and B, and component A includes A1α, ω-100 parts of dihydroxy polydimethylsiloxane in parts by weight, A2 methyl silicone oil 0-20 parts, A3 filler 50-150 parts; component B includes: B1 methyl silicone oil 100 parts, B2 crosslinking agent 10-25 parts, B3. deep curing agent 10-25 parts, B4. silane 5-25 parts of coupling agent, 0.2-2 parts of B5 catalyst; the preparation method of component A is to add components A2 and A3 to component A1 in sequence, and stir under the condition of vacuum greater than 0.095MPa after each addition 10‑20min, and finally component A can be obtained; the preparation method of component B is to add B2, B3, B4 and B5 components to B1 successively under N2 protection, and stir 20‑20‑ 30min, and finally component B can be prepared. The silicone rubber provided by the invention not only cures quickly in the deep layer, but also produces alcohol after curing, which is environmentally friendly, and has excellent moisture-heat aging resistance.

Owner:TONSAN ADHESIVES INC

Water-soaking-resistant flame-retardant single-component silane modified polyether sealant and preparation method thereof

PendingCN113512393AImprove water resistanceGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

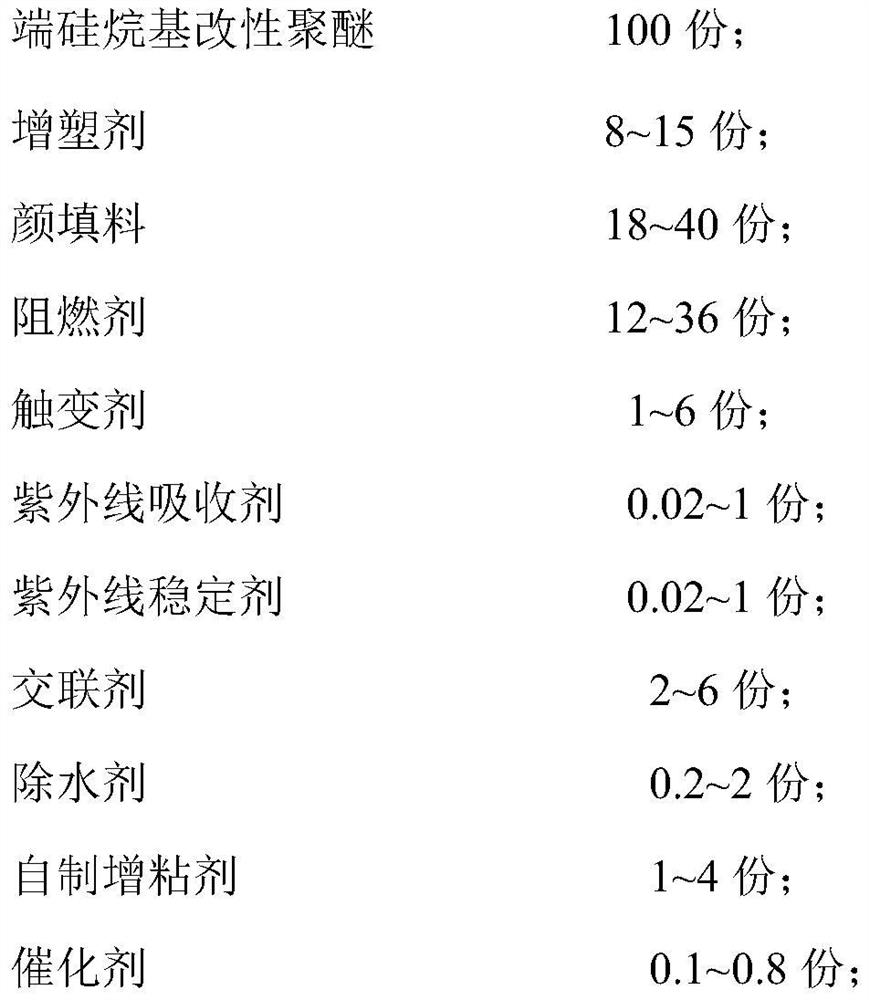

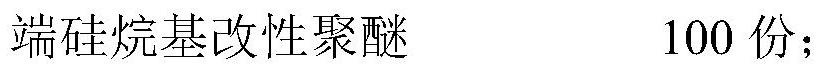

The invention discloses a water-soaking-resistant flame-retardant single-component silane modified polyether sealant which comprises the following components in parts by weight: 100 parts of silane-terminated modified polyether, 8-15 parts of a plasticizer, 18-40 parts of a pigment and filler, 12-36 parts of a flame retardant, 1-6 parts of a thixotropic agent, 0.02-1 part of an ultraviolet light absorber, 0.02-1 part of an ultraviolet stabilizer, 2-6 parts of a cross-linking agent, 0.2-2 parts of a dewatering agent, 1-4 parts of a self-made tackifier, and 0.1-0.8 part of a catalyst. The self-made tackifier is organic silicon modified epoxy resin synthesized by reacting an organic silicon oligomer with at least two hydrolysable alkoxy silane at one end with epoxy resin, wherein alkoxy is methoxy, ethyoxyl or propyl. The invention also discloses a preparation method of the sealant. According to the invention, the water soaking resistance, flame retardance and adhesive property of the single-component modified silane polyether sealant are improved, so that the double requirements of buildings on water resistance and flame retardance of the sealant are met at the same time.

Owner:FOSHAN KESHUN BUILDING MATERIAL CO LTD

Silicone sealant and preparation method thereof

ActiveCN111004604BDeep curing fastImprove flexibilityNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention relates to a silicone sealant and a preparation method thereof. The silicone sealant is prepared from raw materials including the following components in parts by weight: 90-110 parts of a,ω-dihydroxy polydimethylsiloxane; 10-150 parts of reinforcing filler; 2-10 parts of plasticizer 2-20 parts of cross-linking agent; 2-10 parts of curing agent; 1-10 parts of coupling agent; 0.01-1.5 parts of catalyst. The organic silicon sealant of the invention can realize fast deep curing, and has good hardness and mechanical properties.

Owner:GUANGZHOU BAIYUN CHEM IND

Condensation type two-component silicone sealant and preparation method

ActiveCN106590519BHigh strength retentionHigh retention rateNon-macromolecular adhesive additivesMacromolecular adhesive additivesOmegaDimethyl siloxane

The invention relates to a condensed dual-component silicone sealant and a preparation method thereof. The silicone sealant is prepared from a component A and a component B, wherein the component A comprises, by weight, 100 parts of alpha, omega-dihydroxypolydimethylsiloxane, 1-50 parts of dimethicone, 5-25 parts of silicone resin, 1-10 parts of an additive and 90-110 parts of an inorganic filler; and the component B comprises, by weight, 100 parts of dimethicone, 0.5-25 parts of carbon black, 0-25 parts of an inorganic filler, 5-35 parts of a composite cross-linking agent, 3-20 parts of a composite coupling agent and 0.05-0.5 parts of a catalyst; a mass ratio of the component A to the component B is (8-20):1; the silicone resin is at least one selected from methyl silicone resin, methylphenyl silicone resin, methyl MQ silicone resin and vinyl MQ silicone resin; and the additive is at least one selected from zinc oxide, ferric oxide, cerium oxide and nickel oxide. The strength retention of the silicone sealant in high temperature environment is high.

Owner:GUANGZHOU BAIYUN CHEM IND

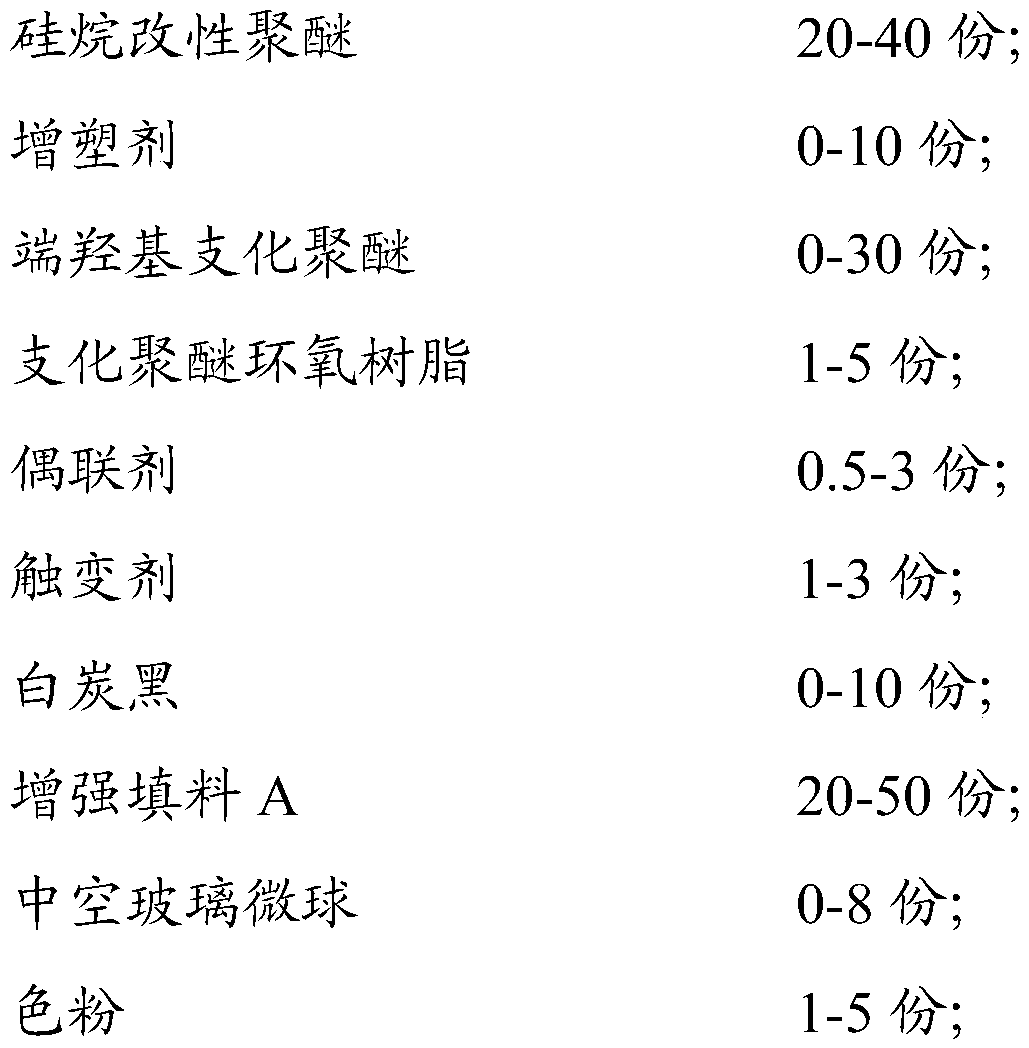

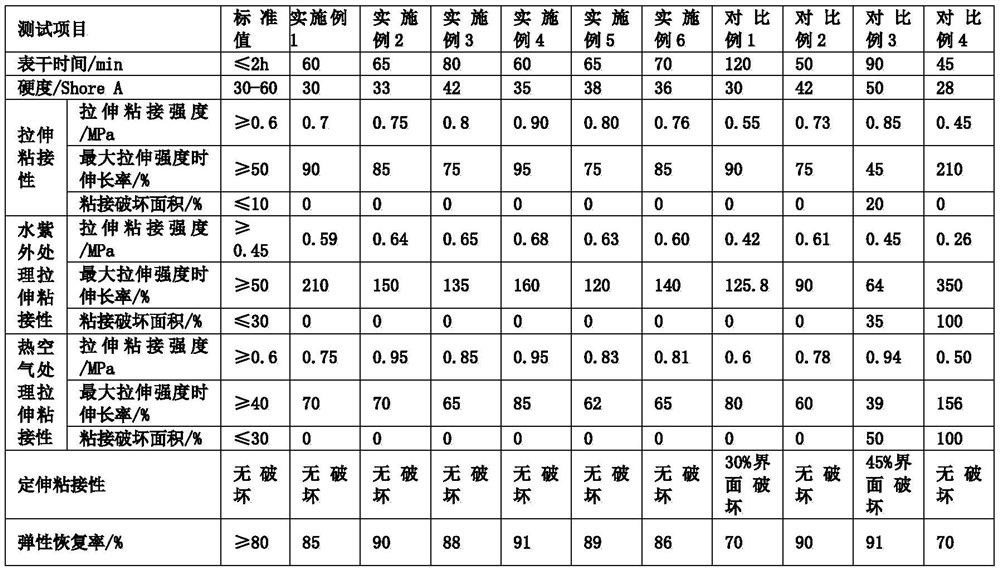

Silane-modified polyether adhesive for low-modulus and high-adhesion assembly building and preparation method thereof

ActiveCN108179000BOvercome the defect of slow curingGood compatibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWater leakage

The invention provides a low-modulus high-adhesion assembling type silane modified polyether adhesive used for a building. The low-modulus high-adhesion assembling type silane modified polyether adhesive is divided into a component A and a component B, wherein the component A comprises silane modified polyether, a plasticizer, hydroxyl-terminated branched polyether, branched polyether epoxy resin,a coupling reagent, a thixotropic agent, white carbon black, enhanced filler A, hollow glass microsphere and toner; the component B comprises the plasticizer, the hydroxyl-terminated branched polyether, a light stabilizer, enhanced filler B, an organic tin catalyst and an amine curing agent. In addition, various ingredients in the silane modified polyether adhesive are optimized to obtain a sealant formula with an optimal binding effect. The double-component polyether adhesive system has good compatibility, in addition, the adhesion of the double-component polyether adhesive is greatly improved, the double-component polyether adhesive system is applied to the prefabricated construction member material abutted seam connection used by the assembling type building, a good binding and waterproof effect can also be achieved without being cooperated with a first coat, and meanwhile, a water leakage risk brought by an existing first coat construction misoperation can be avoided.

Owner:GUANGZHOU BAIYUN CHEM IND

A two-component silane-modified polyether sealant for insulating glass and its preparation method

ActiveCN109880570BFor long-term storageRealize simultaneous curingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a two-component silane-modified polyether sealant for insulating glass, relates to the technical field of sealant, and comprises: A component: 100 parts of MS polymer, 50-150 parts of plasticizer 150-350 parts of the first reinforcing filler, 10-50 parts of the second reinforcing filler, 0.5-1.0 parts of light stabilizer, 0.5-1.0 parts of ultraviolet absorber; component B: 100 parts of the third reinforcing filler, 200-300 parts of plasticizer, 100-200 parts of silane coupling agent, 5-10 parts of catalyst. The two-component silane-modified polyether sealant for insulating glass has fast solidification speed in the deep layer as a whole, good storage stability and good aging resistance, and can meet the performance requirements of insulating glass bonding and sealing. The invention also discloses a preparation method of a two-component silane-modified polyether sealant for insulating glass.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

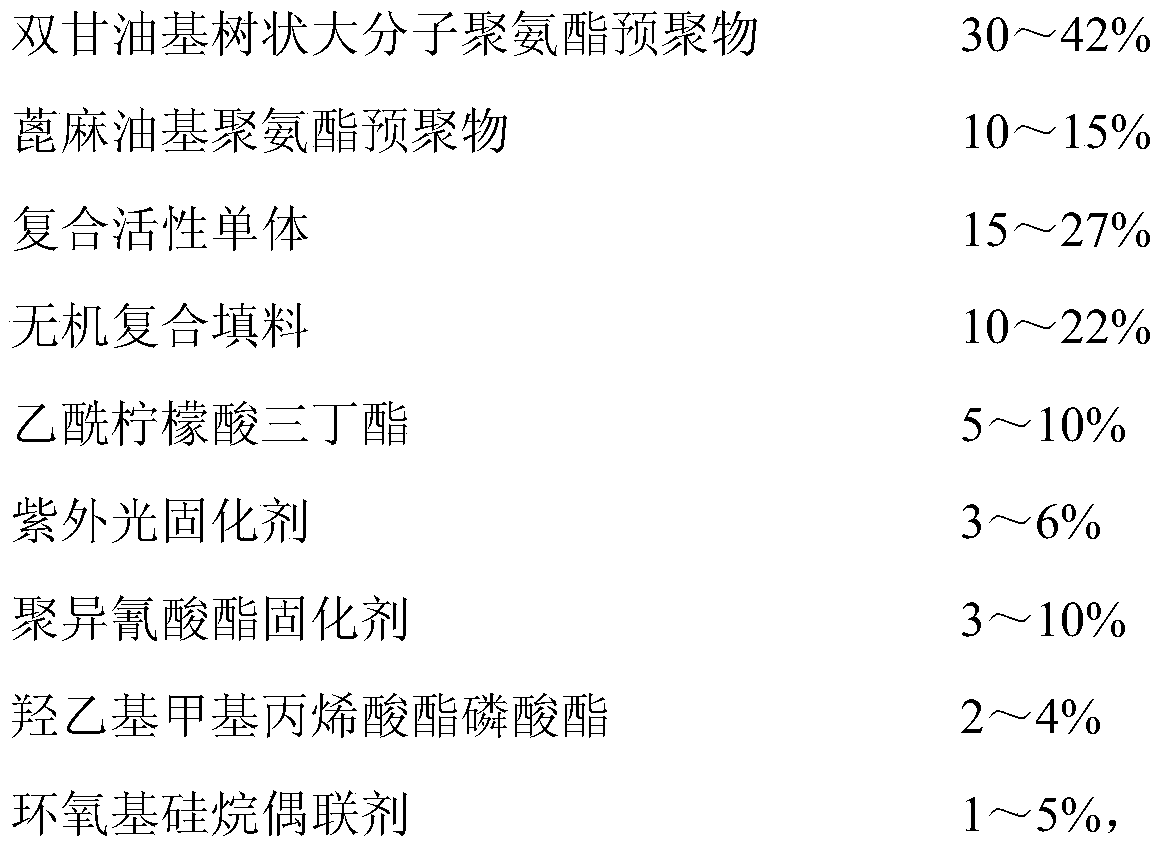

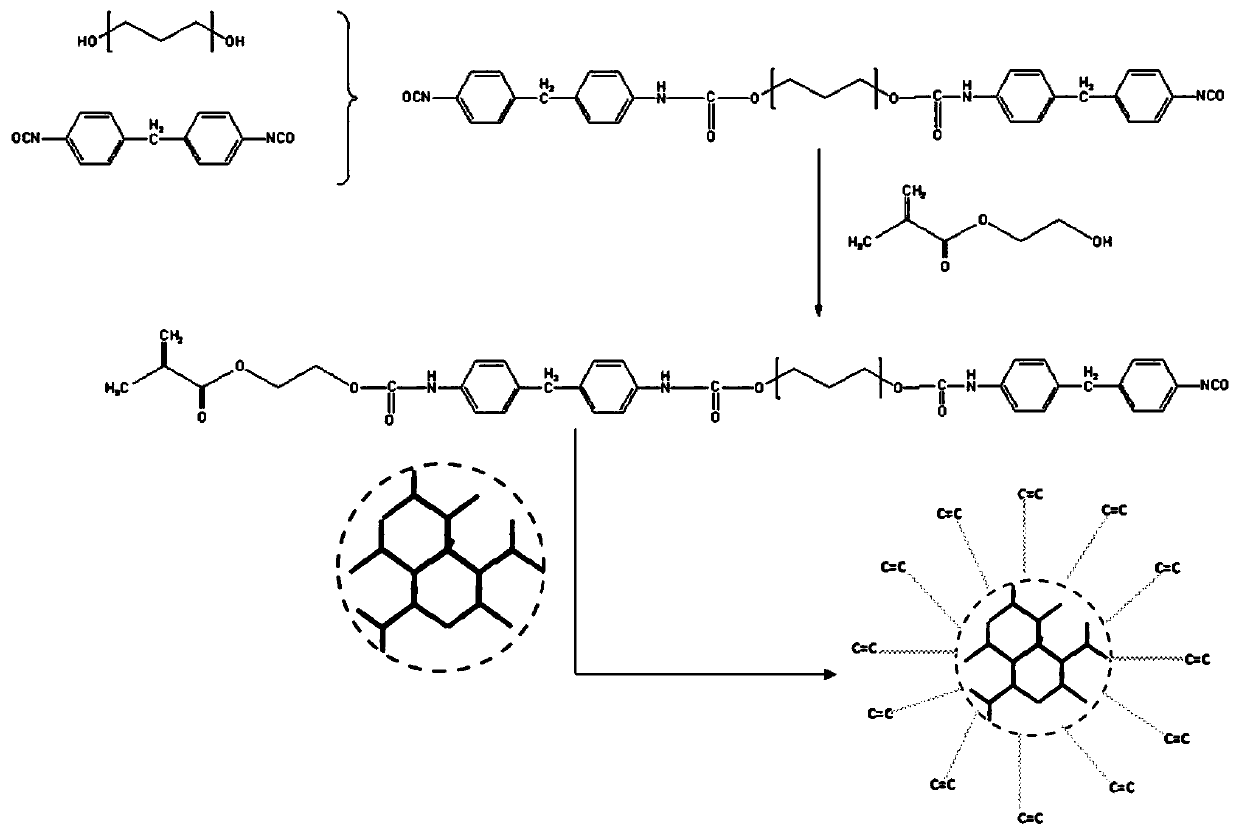

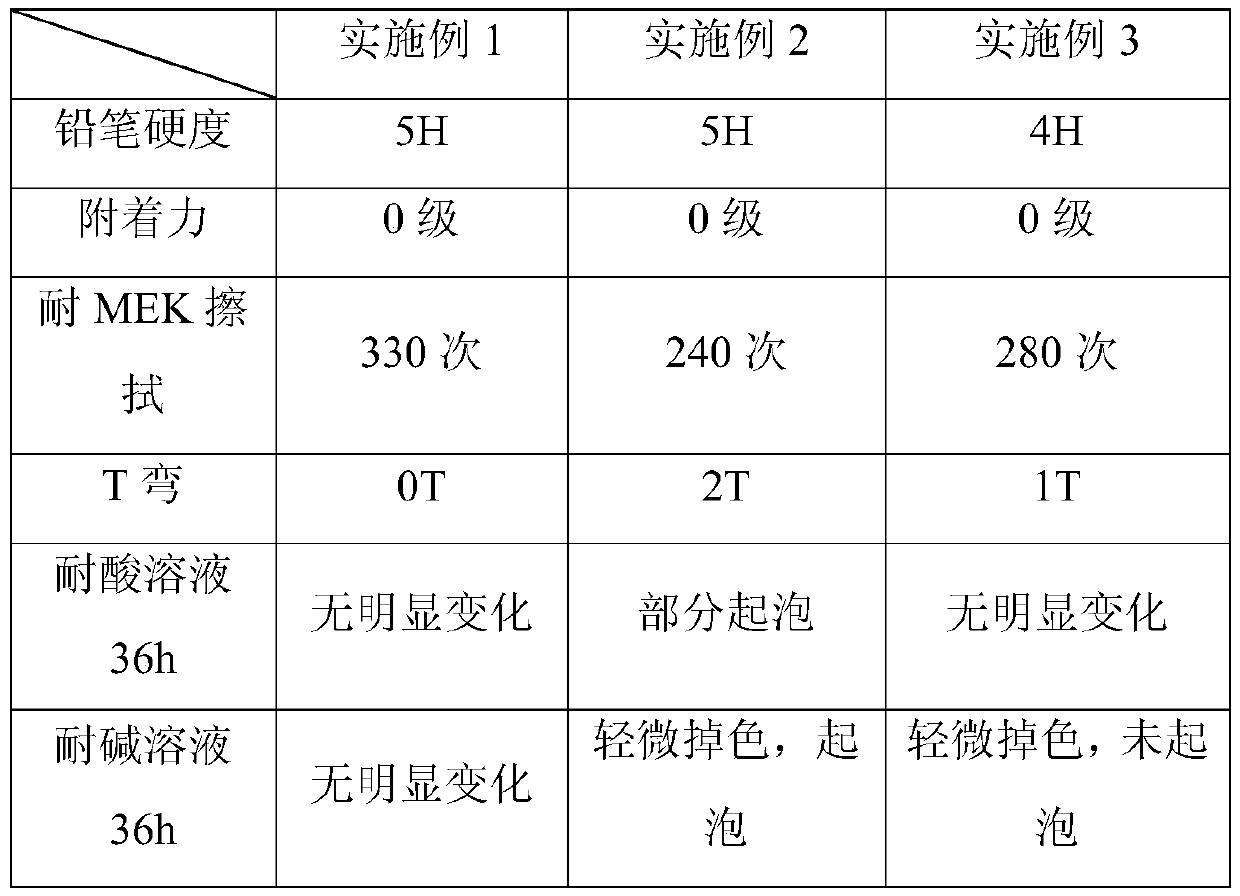

A kind of dual curing solvent-free polyurethane coil coating and preparation method thereof

ActiveCN107556914BLow costImprove performancePolyurea/polyurethane coatings(Hydroxyethyl)methacrylatePhosphate

The invention belongs to the technical field of environment-friendly coil coatings and particularly relates to a dual-cured and solvent-free type polyurethane coil coating and a preparation method thereof. The coating product is prepared from components in percentage by mass as follows: 30%-42% of diglycerol based dendritic macromolecular polyurethane prepolymers, 10%-15% of castor oil based polyurethane prepolymers, 15%-27% of composite active monomers, 10%-22% of inorganic composite filler, 5%-10% of acetyl tributyl citrate, 3%-6% of an ultraviolet curing agent, 3%-10% of an aliphatic polyisocyanate curing agent, 2%-4% of hydroxyethyl methacrylate phosphate and 1%-5% of an epoxy silane coupling agent. The coating product is a solvent-free type environment-friendly coating, has good adhesive force, MEK (methyl ethyl ketone) scrubbing resistance and high-and-low-temperature resistance, and can be applied to coating and protection of various coiled materials.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Two-component hybrid adhesive and preparation method thereof

PendingCN112680160ADeep curing fastGood adhesionNon-macromolecular adhesive additivesPolyether adhesivesPolymer scienceAdhesive

The invention discloses a preparation method of a two-component hybrid adhesive. The preparation method comprises the following steps: 1) preparing a component A according to a formula ratio under a first dehydration condition; 2) preparing a component B according to the formula ratio under a second dehydration condition; and 3) uniformly mixing the component A and the component B according to a volume ratio of 1: (1-4) to obtain the double-component hybrid adhesive. The invention also discloses the two-component hybrid adhesive. According to the invention, the volume ratio of the component A to the component B can be adjusted according to the actual use condition of the double-component hybrid adhesive, such as the requirements on the operable time, the curing speed, the strength, the hardness and the like, so as to adapt to different performance requirements; and the component A and the component B can be hybridized, cured and crosslinked with each other to form a more complex spatial interpenetrating network structure, have more excellent stability and mechanical strength than a single cured network structure, can make up for the respective defects of an adhesive system adopting a single component, and can reinforce the respective advantages of the component A and the component B.

Owner:东莞市瑞朗电子有限公司

Anti-corrosion organic silica gel adhesive for inner wall of desulfurization chimney and preparation method thereof

ActiveCN103396759BLong storage periodImprove performanceNon-macromolecular adhesive additivesCross-linkBrick

The invention discloses an anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney and a preparation method thereof. The preparation method comprises following steps: preparing a component A, mixing 107 silicone rubber, fumed silica, silicon powder, silicone oil, kaolin, and a deep curing addictive together to prepare the component A; preparing a component B, mixing a cross-linking agent, tackifier, catalyst, silicone oil, fumed silica and carbon black to prepare the component B, and mixing the component A and the component B according to a certain ratio to prepare an anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney. The anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney has the advantages of high tensile strength, excellent elongation at break, high shear strength, long operation time, convenience for on-site construction, fast deep curing, and good adhesivity and elasticity, and is capable of applying to the fields of anti-corrosion of inner wall of desulfuration chimney and adhesive bonding and coating of various light glass bricks.

Owner:武汉双键新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com