Anti-corrosion organic silicon adhesive for inner wall of desulfurization chimney and preparation method thereof

A silicone adhesive and organic technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of high hardness of silicone resin, which cannot meet the construction environment and curing conditions of the inner wall of the chimney, and achieve adhesive performance Good, easy to adjust the glue environment and use, good for the effect of acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

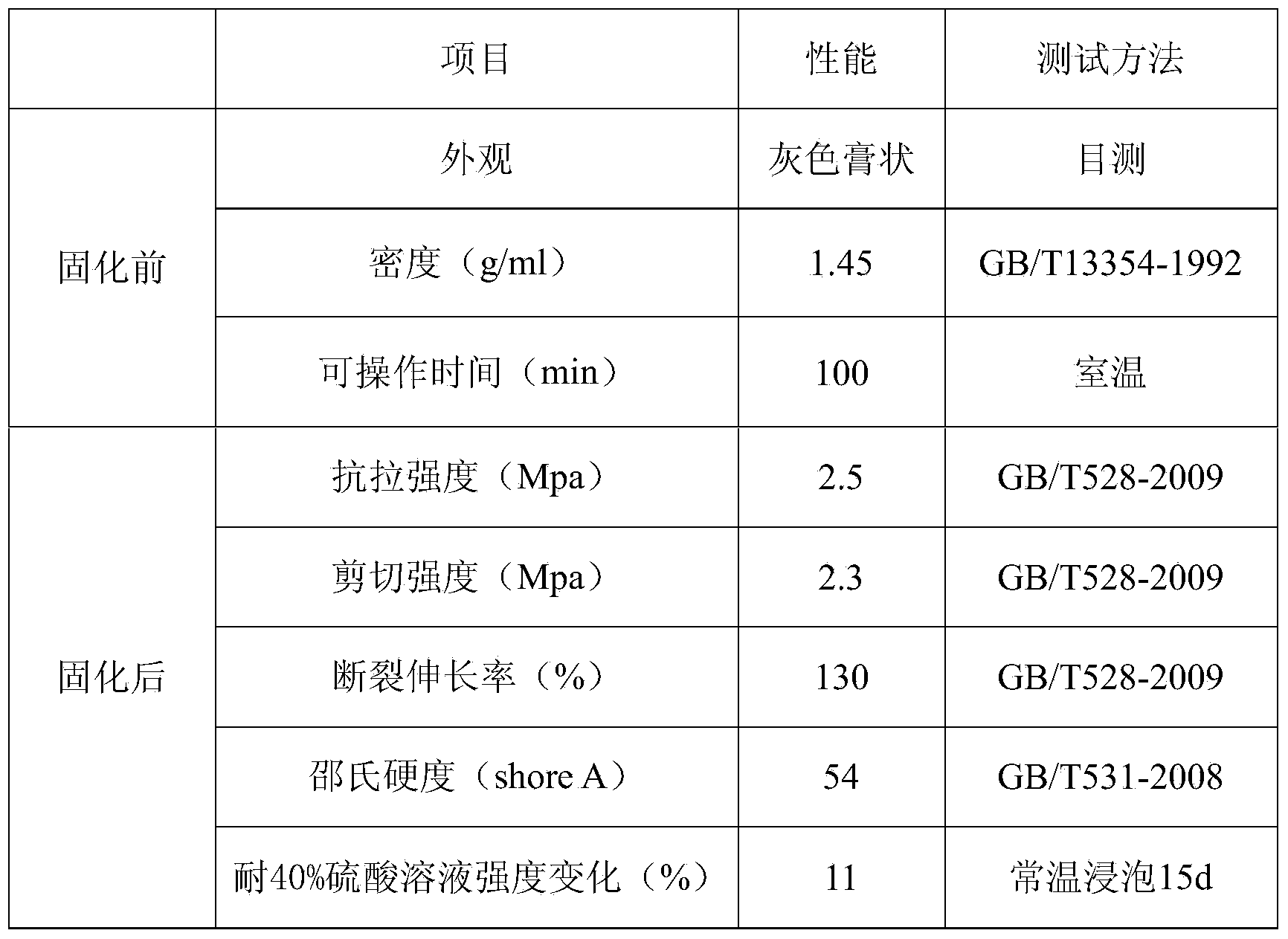

Embodiment 1

[0026] Add 100 parts of α.ω-hydroxyl-terminated polydimethylsiloxane with a viscosity of 20,000 centiwaves, 8 parts of simethicone oil with a viscosity of 100 centiwaves, and 2 parts of methanol into the first power mixer, mix and stir 10 minutes; then add 70 parts of microsilica powder with a particle size of 2500 mesh, 30 parts of washed kaolin with a mesh number of 1500, and a specific surface area of 200m 2 5 parts per gram of fumed white carbon black, and stirred in vacuum for 60 minutes (vacuum degree is 0.08Mpa), so as to prepare A composition, and set aside.

[0027] Add 100 parts of simethicone, 60 parts of ethyl orthosilicate, 10 parts of γ-aminopropyltrimethoxysilane, 5 parts of γ-(ethylenediamino)propyltrimethoxysilane into the second power mixer 1 part and 1 part of dibutyltin acetate were mixed and stirred for 10 minutes; then 2 parts of carbon black with a particle size of 50nm and a specific surface area of 200m were added 2 4 parts of fumed white carbon b...

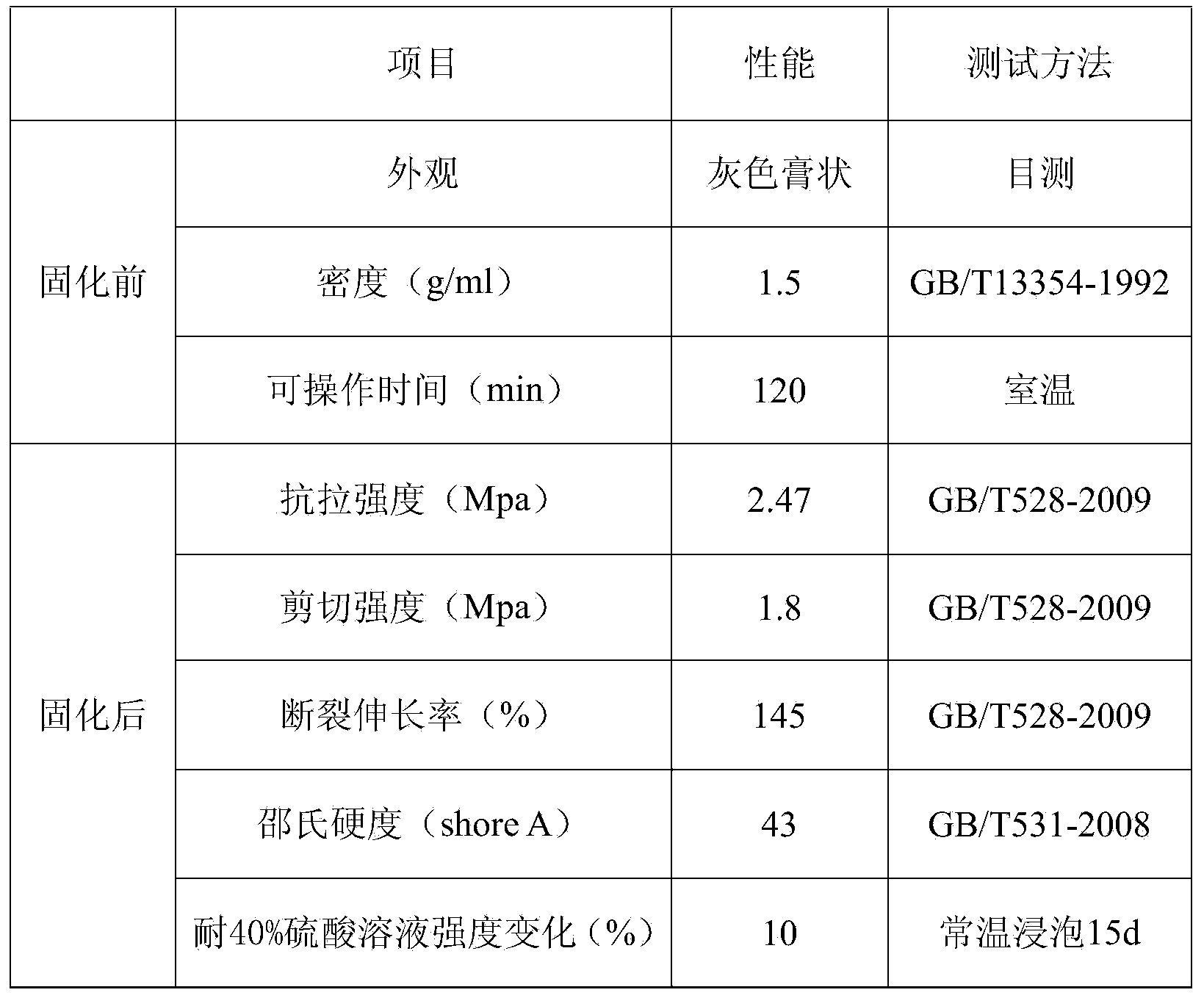

Embodiment 2

[0032] Add 100 parts of α.ω-hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000 centiwaves, 5 parts of simethicone oil with a viscosity of 100 centiwaves, and 3 parts of ethanol in the first power mixer and mix and stir for 10 minutes; then add 100 parts of microsilica powder with a particle size of 2000 mesh, 10 parts of washed kaolin with a mesh number of 3000, and a specific surface area of 150m 2 1 part of fumed white carbon black per gram, and stirred in vacuum for 60 minutes (vacuum degree is 0.08Mpa), so as to prepare A composition and set aside;

[0033] Add 100 parts of simethicone, 30 parts of ethyl orthosilicate, 20 parts of propyl orthosilicate, 10 parts of γ-aminopropyltrimethoxysilane, γ-(ethylenediamine ) 5 parts of propyltrimethoxysilane and 1 part of dibutyl tin acetate were mixed and stirred for 10 minutes; then 2 parts of carbon black with a particle size of 60nm and a specific surface area of 150m were added 2 6 parts of fumed white carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com