Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

A technology of surface treatment and manufacturing method, which is applied to the manufacture of surface-treated silver-containing powders and the field of silver pastes using surface-treated silver-containing powders, can solve the problem of inability to develop, decrease in filling degree of silver or silver compounds, and electrical conductivity. The circuit resistance is easy to change and other problems, so as to achieve the effect of improved dispersion and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

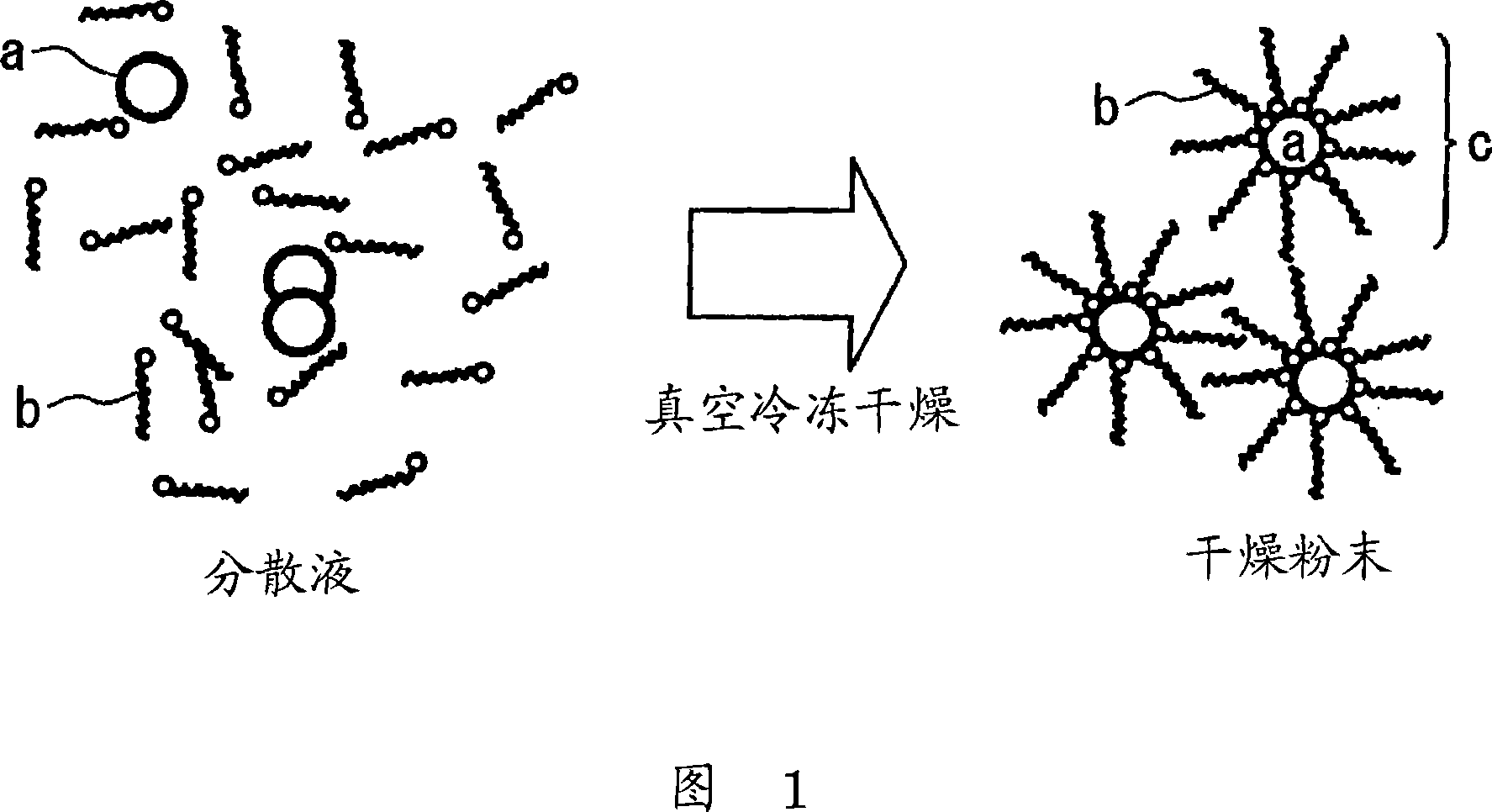

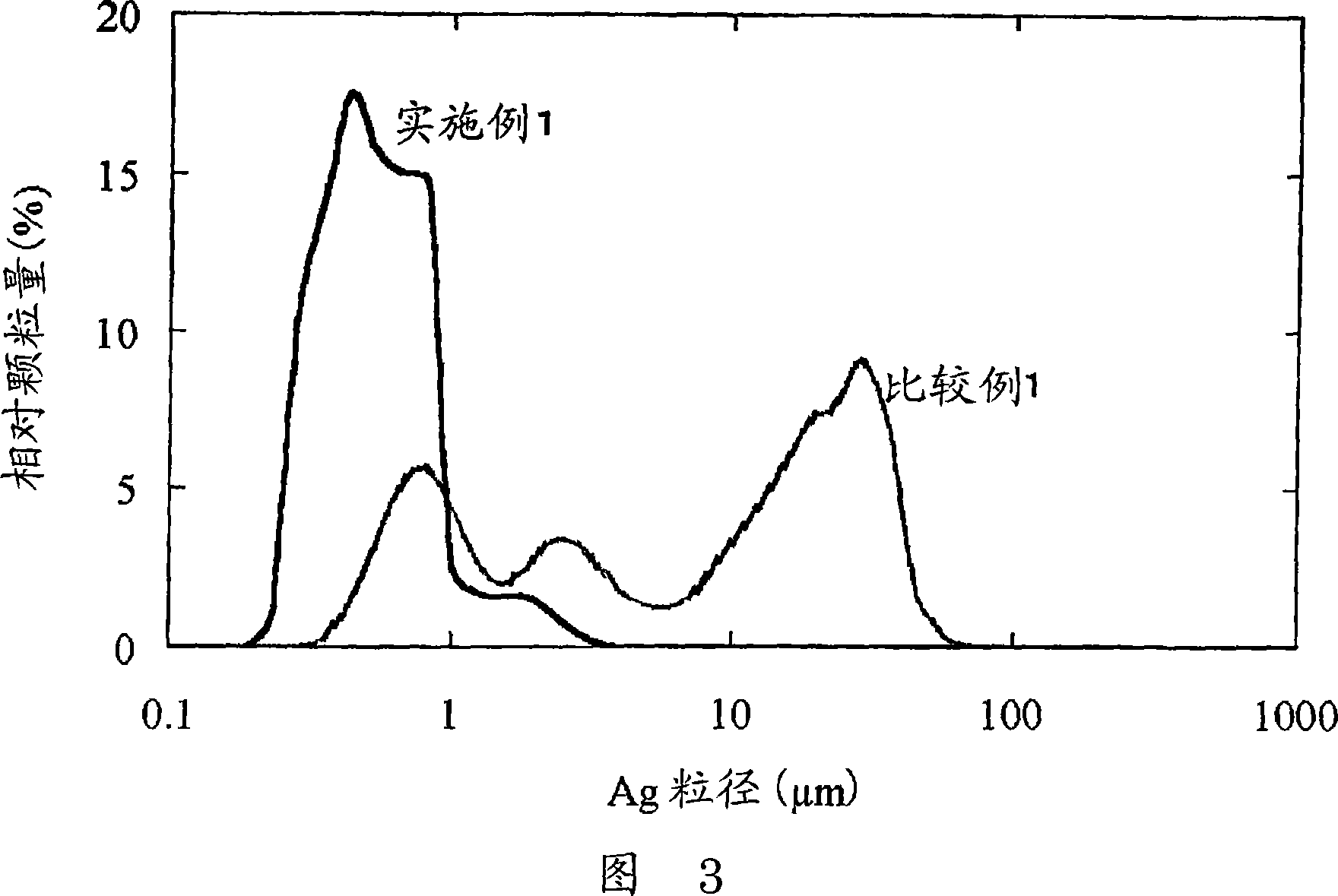

[0143] 50 g of silver powder FHD (crystallite diameter < 10 nm) manufactured by Mitsui Kinzoku Co., Ltd. with a central particle diameter of 0.3 μm, 2.5 g of a 10% by mass aqueous solution of surfactant A as a surfactant, 50 g of water as a solvent, and 400 g of zirconia beads with a diameter of 2 mm were mixed in a 250 cc plastic bottle, and kneaded for 4 hours using a rotary machine (ball mill) to obtain a silver powder dispersion (a1).

[0144] 100 g of the dispersion (a1) of the silver powder was put into a flat plate having a size of 200 mmL×150 mmW on the bottom surface, and after pre-freeze-drying, freeze-drying was carried out. As the freeze vacuum dryer, "DFM-05AS" manufactured by Nippon Vacuum Co., Ltd. was used. Place the pre-frozen silver powder dispersion (a1) on a shelf pre-cooled to about -40°C, freeze and vacuum-dry it at a vacuum degree of 7-10 Pa for 20 hours, and obtain a loose spongy dried product. The surface treatment of silver powder Object (b1) 50g. T...

Embodiment 2

[0147] Except having replaced the surfactant in Example 1 with surfactant B, 105 g of dispersion liquid (a2) of silver powder and 50 g of surface-treated matter (b2) of silver powder were obtained by the method similar to Example 1. The average volume particle size of this surface-treated product was 0.6 μm, showing the same particle size distribution as in Example 1.

[0148] Next, 58.3 g of silver paste B-2 was obtained similarly to Example 1. This silver paste is stable without causing a rise in viscosity or aggregation over time. Screen printing was performed using a mask in which a printed pattern of a 50 μm line width conductive circuit was formed, and a printed coating film was obtained in the same manner as in Example 1. Carry out full-pattern printing with a film thickness of 50 μm in the same manner as in Example 1, and measure the volume resistance after drying and putting it in a furnace at 160° C. and 250° C. for 60 minutes. The results are shown as 1.7E-02 Ω cm ...

Embodiment 3

[0150] Except that the silver powder FHD in Example 2 was replaced by the silver powder Ag C-G manufactured by Fukuda Metal Foil Powder Co., Ltd., 105 g of the dispersion liquid (a3) of the silver powder and the surface-treated product of the silver powder were obtained by the same method as in Example 2. (b3) 50g. The volume average particle diameter of the silver particles at this time was 0.2 μm, showing a particle size distribution with a narrow distribution width.

[0151] Next, 58.3 g of silver paste B-3 was obtained by the method similar to Example 1. This silver paste is stable without causing a rise in viscosity or aggregation over time. Using the mask in which the printing pattern was formed similarly to Example 1, screen printing was performed, and the printing coating film was obtained. Carry out full-pattern printing with a film thickness of 50 μm in the same manner as in Example 1, and measure the volume resistance after being dried and placed in a furnace at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com