Sealing material composition and sealing material

A technology of sealing materials and compositions, applied in adhesive types, electrical components, semiconductor devices, etc., can solve problems such as contamination operability, foreign matter attachment, etc., and achieve excellent shape setting and excellent uneven followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0037]

[0038] The present invention will be described in more detail based on the embodiments. The sealing material composition of the present invention is pasted and pressure-bonded on an electronic substrate on which electronic components are arranged, covers the electronic components and closely adheres thereto, and then irradiates light to cure to form a sealing material, thereby improving the bonding property to the electronic components , can protect electronic components from the intrusion of moisture or foreign matter, etc.

[0039] The sealing material composition contains a cured epoxy resin having a soft skeleton, a monofunctional (meth)acrylate monomer, a photoradical polymerization initiator, and a styrene-based elastomer as essential components. Hereinafter, these essential components of the sealing material composition will be described.

[0040] Cured Epoxy Resin

[0041] In the sealing material composition, the epoxy resin exists as a cured product obtai...

no. 2 Embodiment approach

[0092]

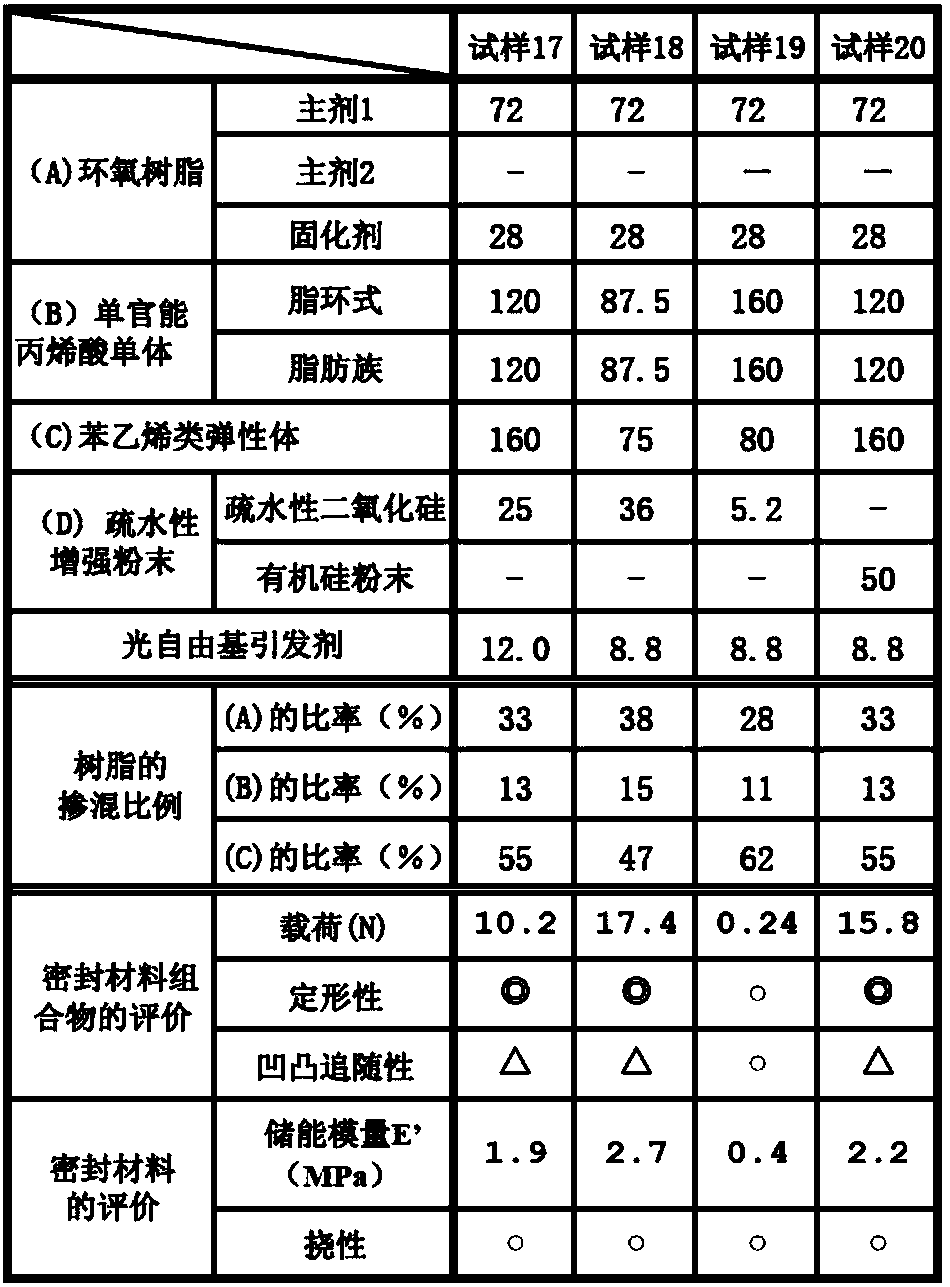

[0093] The sealing material composition of the second embodiment further includes hydrophobicity enhancing powder in the sealing material composition described in the first embodiment. Components other than the hydrophobicity-enhancing powder are the same as those described in the first embodiment, and thus description thereof will be omitted.

[0094] Hydrophobic Enhanced Powder

[0095] The hydrophobicity enhancing powder is a component added to improve the handleability of the sealing material composition. It is preferable to add 5 to 50 parts by mass of the hydrophobicity enhancing powder with respect to 100 parts by mass of the epoxy resin, since the handleability of the sealing material composition can be greatly improved. When it is less than 5 parts by mass, the handleability improvement effect is small. On the other hand, when it is added in excess of 50 parts by mass, the permeability to ultraviolet rays is impaired, and the sealing material composition b...

Embodiment

[0109] Hereinafter, the present invention will be described in more detail based on experimental examples.

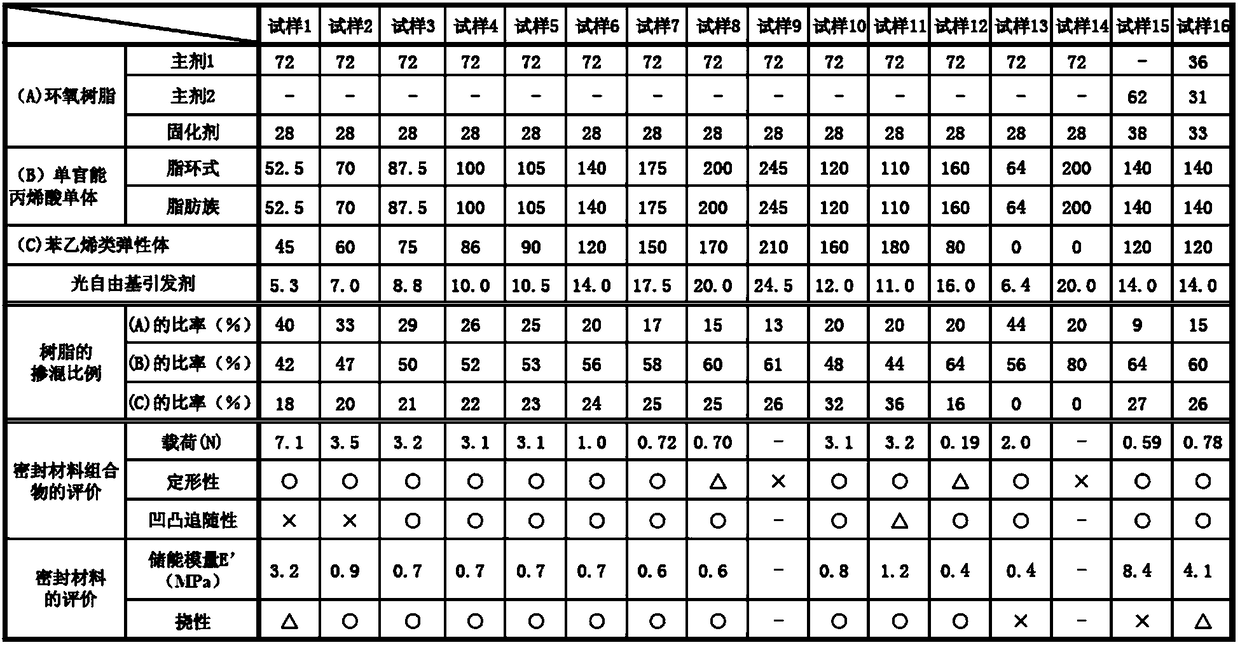

[0110] The following sealing material compositions and sealing materials of Samples 1 to 16 were produced.

[0111]

[0112] Sample 1

[0113] The main ingredient of the mixed epoxy resin is a bifunctional epoxy resin compound having a soft skeleton, two epoxy groups in the molecule, and polyalkylene oxide as a soft skeleton added to bisphenol A (manufactured by ADEKA Co., Ltd. EP-4000S", hereinafter referred to as "main ingredient 1") 72 parts by mass, polyamine as a curing agent for epoxy resin ("EH-4357S" manufactured by ADEKA Co., Ltd.) 28 parts by mass, 52.5 parts by mass of lauryl acrylate monomer, 52.5 parts by mass of isobornyl acrylate as monofunctional alicyclic (meth)acrylate monomer, 45 parts by mass of styrene-based elastomer, A uniform liquid composition was obtained with 5.3 parts by mass of 2-hydroxy-2-methyl-1-phenylpropan-1-one as a photoradical po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com