High-sulfur-loading-capacity lithium-sulfur battery positive plate and production method thereof

A lithium-sulfur battery and positive electrode technology, which is applied in the field of high-sulfur lithium-sulfur battery positive electrode and its preparation, can solve the problems of easy cracking of the electrode coating layer, long drying time, and positive electrode problems, so as to benefit engineering application, ensure coating processability, and realize the effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

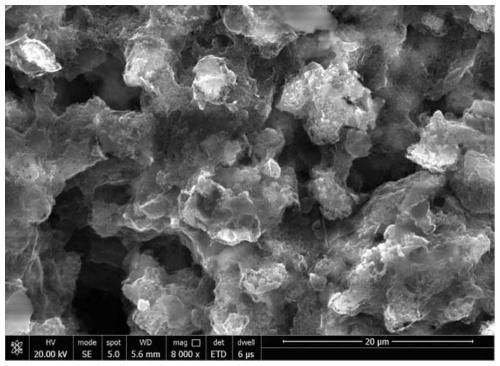

Image

Examples

Embodiment 1

[0027] 6mg / cm 2 (Single-sided sulfur loading) The preparation of the sulfur-loading pole piece, in the material that constitutes the positive pole piece, the mass ratio of elemental sulfur, Ketjen carbon (ECP-600JD), carbon nanotubes, graphene, and binder PVDF is : 8.5:1:0.5:0.5:2; adopt the steps of the inventive method as follows:

[0028] Step 1: Use a vibrating sieve to sieve the sulfur-carbon composite material to remove foreign matter.

[0029] Step 2. Add PVDF glue and graphene conductive paste to the planetary mixer, stir and disperse, the dispersion speed is 3000rpm, and the dispersion time is 30min;

[0030] Step 3: Add sulfur-carbon composite material, stir to disperse, wet and mix to prepare premixed slurry. Dispersion speed 3000rpm, dispersion time 2h;

[0031] Step 4. Transfer the above-mentioned premixed positive electrode slurry to a ball mill tank, cover and seal it, place it in an oven at 150°C for a long enough time, and then quickly transfer it to a ball...

Embodiment 2

[0035] 7mg / cm 2 (Single-sided sulfur loading) The preparation of the sulfur-loading pole piece, in the material that constitutes the positive pole piece, the mass ratio of elemental sulfur, Ketjen carbon (ECP-600JD), carbon nanotubes, graphene, and binder PVDF is : 8.5:0.7:0.8:0.3:1.5; adopt the steps of the inventive method as follows:

[0036] Step 1: Use a vibrating sieve to sieve the sulfur-carbon composite material to remove foreign matter.

[0037] Step 2: Add PVDF glue and graphene conductive paste to the planetary mixer, stir and disperse, the dispersion speed is 3000rpm, and the dispersion time is 30min.

[0038] Step 3: Add sulfur-carbon composite material, stir to disperse, wet and mix to prepare premixed slurry. Dispersion speed 3000rpm, dispersion time 2h;

[0039] Step 4. Transfer the above-mentioned premixed positive electrode slurry to a ball mill tank, cover and seal it, place it in an oven at 150°C for a long enough time, and then quickly transfer it to a ...

Embodiment 3

[0043] 8mg / cm 2 (Single-sided sulfur loading) The preparation of the sulfur-loading pole piece, in the material that constitutes the positive pole piece, the mass ratio of elemental sulfur, Ketjen carbon (ECP-600JD), carbon nanotubes, graphene, and binder PVDF is : 8.5:0.6:0.4:0.2:0.8; adopt the steps of the inventive method as follows:

[0044] Step 1: Use a vibrating sieve to sieve the sulfur-carbon composite material to remove foreign matter.

[0045] Step 2: Add PVDF glue and graphene conductive paste to the planetary mixer, stir and disperse, the dispersion speed is 3000rpm, and the dispersion time is 30min.

[0046]Step 3: Add sulfur-carbon composite material, stir to disperse, wet and mix to prepare premixed slurry. Dispersion speed 3000rpm, dispersion time 2h;

[0047] Step 4. Transfer the above-mentioned premixed positive electrode slurry to a ball mill tank, cover and seal it, place it in an oven at 150°C for a long enough time, and then quickly transfer it to a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com