Silane-modified polyether adhesive for low-modulus and high-adhesion assembly building and preparation method thereof

A silane-modified polyether, high-adhesion technology, applied in polyether adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. problems such as adhesion and complicated operation, and achieve the effects of low production cost, improved adhesion, and easy-to-operate steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a branched polyether epoxy resin and a preparation method thereof, comprising the following steps:

[0058] (1) Weigh 768g of pentapentyl polyether tetraol PP150, heat to 120°C for vacuum dehydration for 20min, then cool to room temperature through dry nitrogen, add 5.62g of boron trifluoride-diethyl ether complex as catalyst, use Stir evenly with a magnetic stirrer;

[0059] (2) Heat up to 60±2°C, stir evenly, slowly add 356g of epichlorohydrin dropwise within 2h with a constant pressure funnel, then keep warm for 6h, and then vacuum remove unreacted epichlorohydrin;

[0060] (3) After cooling down to 45±2°C and adding an appropriate amount of toluene for dilution, add an excess of 112.4g of solid sodium hydroxide several times within 2 hours, and keep warm for 6 hours;

[0061] (4) The product is suction filtered, and the filtrate is collected with a separatory funnel to extract the organic phase with toluene, washed with distilled wat...

Embodiment 2

[0067] The present embodiment provides a branched polyether epoxy resin and a preparation method thereof, comprising the following steps:

[0068] (1) Weigh 1450g of polyether trihydric alcohol N330, heat to 120°C for 30 minutes in vacuum dehydration, then cool to room temperature with dry nitrogen, add 7.96g of boron trifluoride-diethyl ether complex as catalyst, and stir with magnetic force stir evenly;

[0069] (2) Warm up to 60±0.5°C, stir evenly, slowly add 142g of epichlorohydrin dropwise within 2 hours with a constant pressure funnel, then keep warm for 8 hours, and then remove unreacted epichlorohydrin in vacuum;

[0070] (3) After cooling down to 45±0.5°C and adding an appropriate amount of toluene for dilution, add 159.2g of solid sodium hydroxide several times within 2 hours, and keep warm for 4 hours;

[0071] (4) The product is suction filtered, and the filtrate is collected with a separatory funnel to extract the organic phase with toluene, washed with distilled...

Embodiment 3

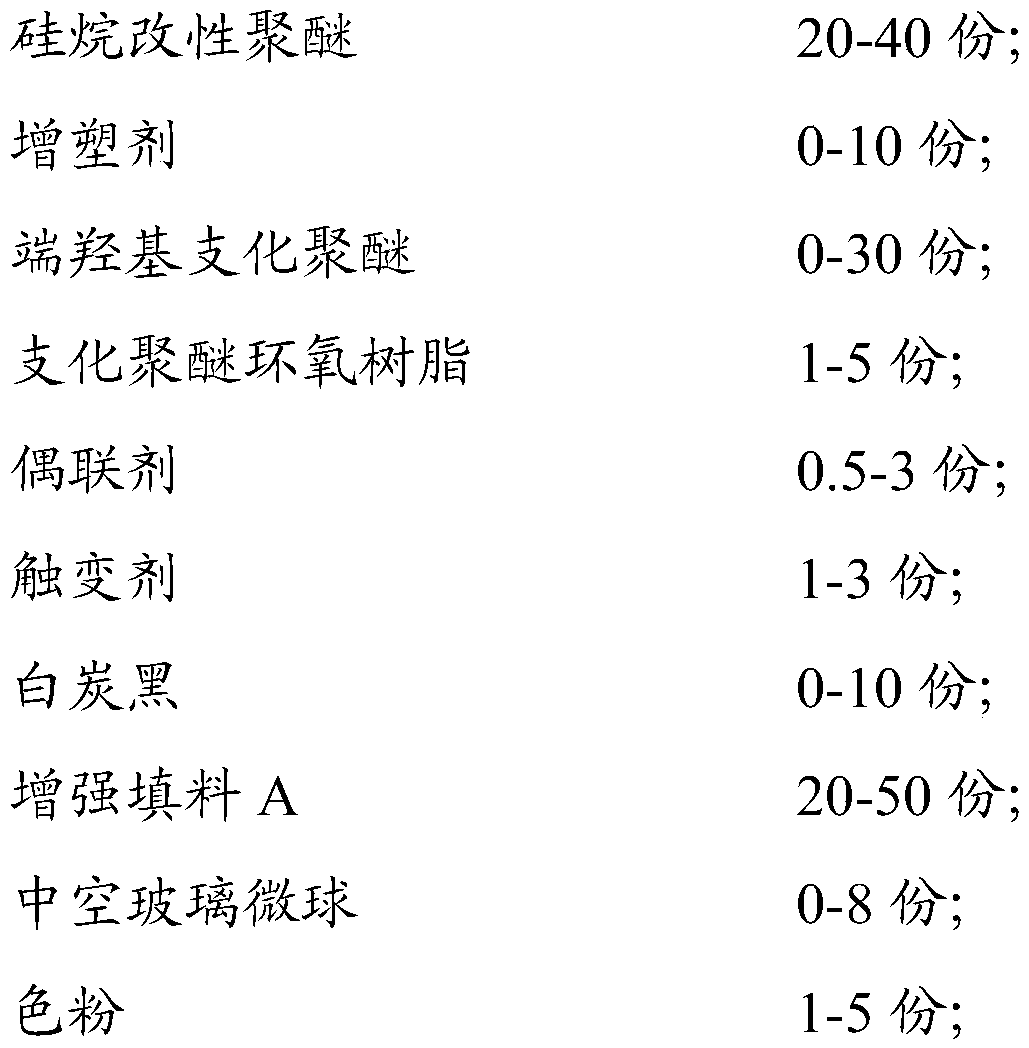

[0077] Silane-modified polyether glue for low-modulus high-adhesion prefabricated buildings described in this embodiment, in parts by weight, includes:

[0078] A component:

[0079]

[0080]

[0081] B component:

[0082]

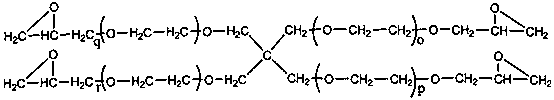

[0083] Wherein, the viscosity of the above-mentioned silane-modified polyether is 40Pa.s, and has the following structural characteristics:

[0084]

[0085] The preparation method of silane-modified polyether glue for low-modulus high-adhesion prefabricated buildings described in this embodiment comprises the following steps:

[0086] 1. Prepare component A:

[0087] (1) Add the above-mentioned silane-modified polyether, pentapentyl polyether tetraol PP150, the branched polyether epoxy resin FBEPO prepared in Example 1, polyamide wax, white carbon black, and titanium dioxide to the planetary machine material In the tank, stir for 8 minutes;

[0088] (2) Add nano-active calcium carbonate therein, disperse and stir for 50min under the condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com