Composition of double-component organosilicon photovoltaic component sealant, and preparation method thereof

A photovoltaic module, silicone technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of inapplicable bonding, aging-resistant solar photovoltaic modules, and inapplicable bonding requirements. High bond strength, long outdoor service life and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

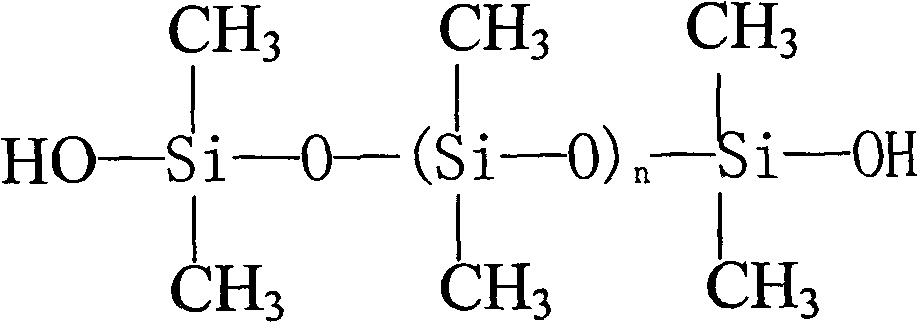

[0029] In parts by weight, mix 70 parts of 107 liquid silicone rubber (polymerization degree 800) with a viscosity of 40000mpa.s and 30 parts of 107 liquid silicone rubber (polymerization degree 90) with a viscosity of 1000mpa. 2 , 10 parts gas phase SiO 2 (specific surface area 200g / m 2 ), 10 parts of precipitated SiO 2 (specific surface area 150g / m 2 ), 50 parts of aluminum oxide, 50 parts of aluminum hydroxide, and 6 parts of hexamethylsilazane were sequentially added to the kneader at room temperature, stirred and mixed evenly, and then heated to 100 ° C for 2 hours, and finally the temperature of the material was raised to Vacuumize at 160°C for 2 hours, and keep the vacuum at -0.08Mpa to remove water, reaction by-products, and volatile low molecules in the filler. After cooling, add 80 parts of 500mpa.s hydroxyl-terminated dimethylsiloxane (polymerization degree 100) to the rubber compound for dilution, and grind it finely three times to obtain component A rubber comp...

Embodiment 2

[0032] In parts by weight, mix 30 parts of 107 liquid silicone rubber (polymerization degree 900) with a viscosity of 60000mpa.s and 70 parts of 107 liquid silicone rubber (polymerization degree 100) with a viscosity of 1500mpa.s, and add 1.2 parts of rutile TiO 2 , 20 parts gas phase SiO 2 (specific surface area 300g / m 2 ), 80 parts of aluminum hydroxide, 20 parts of silicon micropowder, and 10 parts of hexamethylsilazane were sequentially added to the kneader at room temperature, stirred and mixed evenly, then heated to 120°C for 2 hours, and finally the temperature of the material was raised to 180°C Vacuumize for 2 hours and keep the vacuum at -0.09Mpa to remove water, reaction by-products and volatile low molecules in the filler. After cooling, add 100 parts of 500mpa.s hydroxyl-terminated polydimethylsiloxane (polymerization degree 100), dilute the rubber material, and then finely grind it on a three-roll mill three times to obtain the A-component rubber material; Tri...

Embodiment 3

[0035] In terms of parts by weight, 50 parts of 107 liquid silicone rubber (polymerization degree 700) with a viscosity of 50000mpa.s and 50 parts of 107 liquid silicone rubber (polymerization degree 80) with a viscosity of 2000mpa. 2 , 15 parts gas phase SiO 2 (specific surface area 150g / m 2 ), 5 parts of precipitated SiO 2 (specific surface area 150g / m 2), 20 parts of nano-calcium carbonate, 20 parts of aluminum oxide, 20 parts of aluminum hydroxide, 50 parts of quartz powder, and 10 parts of silazane were added to the kneader at room temperature, stirred and mixed evenly, and then heated to 120 ° C for 2 hours , and then raise the temperature of the material to 170 ° C for 2 hours and keep the vacuum at -0.09Mpa to remove the moisture, reaction by-products and volatile low molecules in the filler. After cooling, add 100 parts of 450mpa.s hydroxyl-terminated polydimethylsiloxane (polymerization degree 95) to dilute the material, grind it three times on a three-roll mill t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com